Does this sound like heat creep?

I've been having problems with filament jams on my MK3S the last few days and I was wondering if it sounds to experts like heat creep of the sort described here: https://help.prusa3d.com/en/article/extrusion-stopped-mid-print_1948. I'd like to have an idea of whether it seems likely before I start disassembling the extruder to clean it.

The symptoms: about an hour in to the print, I start to get occasional extruder clicks, which then become more and more frequent until I no longer get any flow out of the nozzle. When I remove the filament I can see that the extruder gear has been grinding on it. The nozzle and filament pathway are NOT blocked or clogged, as if I reload the filament, it extrudes fine; if I start a new print it will again go for about an hour. I've done the obvious things like checking the Bondtech gears are clean and well attached and that the idler tension is right. The slicer settings and temperature are ones that I have used with no problems for a long time, the bed is flat and clean, and the Z offset is set correctly. I've seen it happen on two different varieties of PLA (one regular, one silk), printing at 210/60.

The printer is about 2 years old and has at a guess 2000-3000 hours of printing on it. I've done routine maintenance (cleaning, lubricating) a few times and there are no modifications apart from a light to illuminate the print surface, and a silicone sock on the heat block. I use a 0.4mm nozzle.

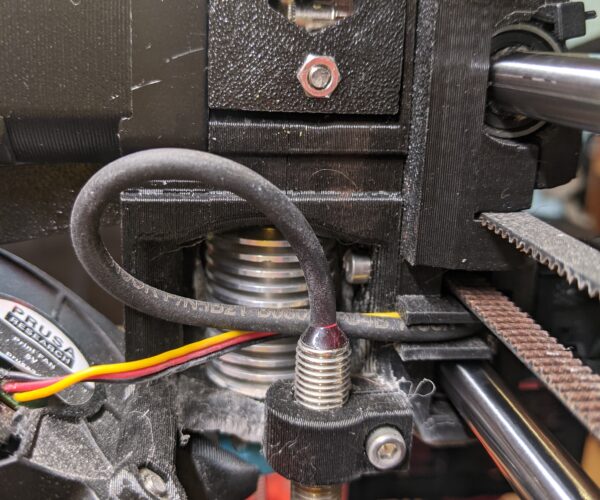

Looking at the extruder I can see it has quite a lot of white dust on it. Could this be enough to cause heat creep? I don't know how well it will show up on photos, but here are a couple (the first taken in a mirror lying on the bed):

Any thoughts welcome! I have some compressed air on the way, so will try cleaning it when it arrives, but if you have any ideas in the mean time, please let me know.

Are you printing in an enclosure or area with ambient temps > 40C/104F?

We see a lot of heat creep posts as things warm up in many parts of the world. The E3D V6 hotend is an air-cooled design rated to work at up to 40C ambient temps. If ambient temps exceed that, the air cooling is less efficient, and more heat can build up (creep) into undesired areas. This will show up quickly with low-temp filament like PLA. The first thing I'd try is improving air flow.

I've compiled notes on every "extruder clicking" and "heat creep" discussion and resolution I've been part of over the last 3 years. Give that a scan and see if any of the problems sound like what you're experiencing.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Probably not ambient temperature.

Thanks for the pointers. I will take a look. I don't think the problem is ambient temperature. I am in southern California, near the ocean, and it doesn't usually get that hot. I also had no problems during some recent heat waves when the temperature was higher. The printer is not enclosed and has plenty of space around it.

Heat creep

For me, heat creep is more common if I am in an enclosure. I don’t think I have seen it without one.

--------------------

Chuck H

3D Printer Review Blog

Airflow

Thanks for the pointers. I will take a look. I don't think the problem is ambient temperature. I am in southern California, near the ocean, and it doesn't usually get that hot. I also had no problems during some recent heat waves when the temperature was higher. The printer is not enclosed and has plenty of space around it.

Check the fans and airflow. There were a few cases where people put decorative fan covers on that caused problems. Simple things like poor cable connections can reduce cooling. Other than that, I put everything I suggest checking on the notes pages. Good luck with it.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

No recurrence

An update, in case anyone reads this topic in future. I have not had any recurrence of the problems I reported. I don't think that the ambient temperature was the issue, as it has been similar in the last few days to the day when I reported this problem. My belief is that one specific model was causing the issues. It was a gear which had a lot of retractions, and it's possible (as discussed in https://projects.ttlexceeded.com/3dprinting_mk3_extruder.html) that this was the issue. I have printed many gears which require a lot of extractions before, and not had any issues other than some spider's web, but this model had more than most. Printing a different version of the same model which sliced slightly differently worked, and all other prints I've done since have been fine. I could go back and try the original model again, but as it took an hour before it failed each time, I'm inclined not to. My settings (with respect to the page I just mentioned) are the defaults or similar: 0.8mm retraction at 35 mm/s with 1mm minimum move. The max volumetric speed at 15mm^3/s, and this may be too high.