Re: Does someone want to know how fast they can print/extrude? look here

Rigid Ink PETG with a plated copper volcano with a 0.4mm nozzle at 220°C/230°C, 30%-50%fan from layer 3, 90°C bed, 0.75mm line width 0.3mm layer height and 20mm/s initial speed. This is the temperature profile I use for this filament.

It started under extruding at 350% - 15.75mm³/s and the extruder started clicking at 500% - 22.50mm³/s. Full gloss at 20mm/s gloss faded at 40mm/s. This corresponds to Rigid Ink's recommended max print speed of 30-40mm/s at the base temperature. The V6 plated block started showing extrusion problems at 175%.

So the 300% - 13.50mm³/s maximum volumetric print speed on the plated copper volcano is twice the 150% - 6.75³mm/s of the plated copper V6 for Rigid Ink PETG.

So in practical tems with both PLA+ and PETG the plated copper volcano has twice the volumetric rate of the plated copper V6 for the same temperature. Nice but not quite the 2.65 times that Devilhunter reckoned but close enough. That two times rule gives me a starting point for volcano filament profiles.

V6 theoretical is 15mm3, but practical is 11,3mm3/s

Volcano is theoretical 35mm3, but practical is 30mm3/s

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

While I'm not after the raw linear speed you guys are pursuing, I'm learning a lot from your work.

A few annoying questions. I hope you don't mind:

[...] It started under extruding at 350% - 15.75mm³/s and the extruder started clicking at 500% - 22.50mm³/s. Full gloss at 20mm/s gloss faded at 40mm/s. This corresponds to Rigid Ink's recommended max print speed of 30-40mm/s at the base temperature. The V6 plated block started showing extrusion problems at 175%.

I see a lot of posts here with people having problems with extruders, and I wonder if Prusa's aggressive speed settings are partially to blame. It seems 170-200mm/s is overly optimistic for the E3D V6 with a lot of common filaments.

I'm understanding the big benefit to the Volcano would be pushing out more filament at a set linear speed, which is really going to come into play when using larger nozzle sizes. I may not be able to print faster than the 30-45mm/s specified by the filament manufacturer, but I might be able to lay down a thick perimeter in a single pass this way. Is that correct?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: Does someone want to know how fast they can print/extrude? look here

Martin,

Are you verifying your actual true extruded width with an accurate micrometer? If not, that can certainly make a big difference. I just this week got a Mitutoyo, and wow, it makes doing that measurement so much easier and faster. You can even print a stand for it from thingiverse, which also helps a lot.

Re: Does someone want to know how fast they can print/extrude? look here

I'm understanding the big benefit to the Volcano would be pushing out more filament at a set linear speed, which is really going to come into play when using larger nozzle sizes. I may not be able to print faster than the 30-45mm/s specified by the filament manufacturer, but I might be able to lay down a thick perimeter in a single pass this way. Is that correct?

Maybe not. A big thick extrusion also cools slower, so you may have trouble, even at some of the lower speeds, on tight corners. I think finding ways to cool more effectively as you extrude is going to be important for getting the most out of the volcano, and we have barely scratched the surface on that.

Of course, I'm sure you *can* print wide if you're willing to slow to a crawl, but that is self-defeating.

Re: Does someone want to know how fast they can print/extrude? look here

Yup. The wall thicknesses are coming up as 0.75±0.01mm so they are pretty much spot on according to my micrometer. Same with my calibration cubes coming to 20.00±0.01mm.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Just for fun I printed these "print in place" tank treads using my "200mm/sec" print speed settings. Though they printed fine (and actually work!), I was surprised to get sporadic extruder clicking during the print. So, as general purpose print settings, 200mm/sec may be the limit, at least for me. I guess for special cases, like DevilHunter's test print, I could crank it higher, but I'm aiming to find general purpose settings I can just set and let 'er rip on arbitrary prints.

https://www.thingiverse.com/thing:2319872

Re: Does someone want to know how fast they can print/extrude? look here

I have read some of the posts here, based on the info i read i come write my values.

I'm waiting for my volcano block to install on mk3, but i already have one on my Ender3, bowden setup, so the things i learn from it:

Nozzle: 0.8mm

Extrusion width: 0.9mm

- volcano bowden setup have massive stringing, tested from 4 to 10mm retraction and still string like hell! I may upgrade for a direct drive.

- Initially i thought volcano has a limit of 40mm^3/s, well thats not true, my tests start clicking/skip way far from that value, with a 0.4mm layer height my infill can't go over 80mm/s, that's 25.2mm^3, with 70mm/s it won't skip but it underextrude, not a perfect infill, so i start to lower and i come with the conclusion a safe value is 20mm^3/s or a bit lower for a perfect infill layer, thats not 3x the v6 but only 2x which is a bit disappointing.

- I run dual 5015 dual bearing fan, they have a good airflow, at 100% they blast alot of air, still for small details or high speed is not enough to make a perfect extrusion, so this is another limiter factor

- Plastic need to cooldown in a proper way, and not by forcing a huge amount of air or a very cold air, this also create problems with extrusion, so there is a optimal time/cooldown temperature line, forcing more wind or cooling on a small amount of time will not benefit the print. This means volcano has no benefits over stock v6 on small parts

My setup:

Re: Does someone want to know how fast they can print/extrude? look here

- I run dual 5015 dual bearing fan, they have a good airflow, at 100% they blast alot of air, still for small details or high speed is not enough to make a perfect extrusion, so this is another limiter factor

- Plastic need to cooldown in a proper way, and not by forcing a huge amount of air or a very cold air, this also create problems with extrusion, so there is a optimal time/cooldown temperature line, forcing more wind or cooling on a small amount of time will not benefit the print. This means volcano has no benefits over stock v6 on small parts

I had this problem as well with my 0.8mm nozzle prints. Then I switched to a 0.4mm nozzle, and I was a lot happier. I suggest you try a 0.4mm nozzle. Maybe with the change to a 0.4mm nozzle and, say, a ~0.45-0.48mm extrusion width, your double blowers will make a difference. At least I hope so! I would agree this is all rather disappointing if there are no benefits at all on small parts. However, as in my post directly above, I don't think I could be printing tank treads (which are printed on their side, and thus behave like small parts) at the speed I am without a volcano, as even with a volcano I'm already encountering extruder clicking.

Re: Does someone want to know how fast they can print/extrude? look here

I had this problem as well with my 0.8mm nozzle prints. Then I switched to a 0.4mm nozzle, and I was a lot happier. I suggest you try a 0.4mm nozzle. Maybe with the change to a 0.4mm nozzle and, say, a ~0.45-0.48mm extrusion width, your double blowers will make a difference. At least I hope so! I would agree this is all rather disappointing if there are no benefits at all on small parts. However, as in my post directly above, I don't think I could be printing tank treads (which are printed on their side, and thus behave like small parts) at the speed I am without a volcano, as even with a volcano I'm already encountering extruder clicking.

I know that 0.4mm nozzle fix lot of the problems, including the stringing, bad perimeters look due bubbles and others, still my objective is reduce print time and print at same speeds (for perimeters), 0.8mm still benefit my objective for my large parts, the only dissapointing aspect to me is the infill speed, as i don't care about infill look, traped inside the part i expect to bump that to max but i end to print a infill at same speed as perimeters at 0.6mm layers height (40mm/s), i can run 120mm/s on 0.2mm layer heigth but that layer height is not my objective.

Currently i run 0.6mm on the MK3 and i think is the best quality/speed nozzle, you should try it, when i upgrade to volcano on mk3 i will use a 0.6mm there, keep my speeds and max out infill

My current 0.6 nozzle speeds for 0.45mm layers (No volcano)

That preset is doing great, and detail is also great with 0.6mm nozzle, but i wan't to speed up a little with volcano, but in the end i see that not worth as much as i thought. Maybe only 40% benefit

Re: Does someone want to know how fast they can print/extrude? look here

One problem I ran into with the 0.8mm nozzle is that support material is just too strong! With a 0.4mm nozzle, support material is nice and wispy, and easily knocked away. Not sure how support material behaves with a 0.6mm nozzle, but I fear it may be stronger than what I'd like. Since you're using a 0.6mm nozzle already, though, maybe you can say?

Also, I want one nozzle that I can use for everything, as I don't want to be changing nozzles. But that's me. Maybe others don't mind.

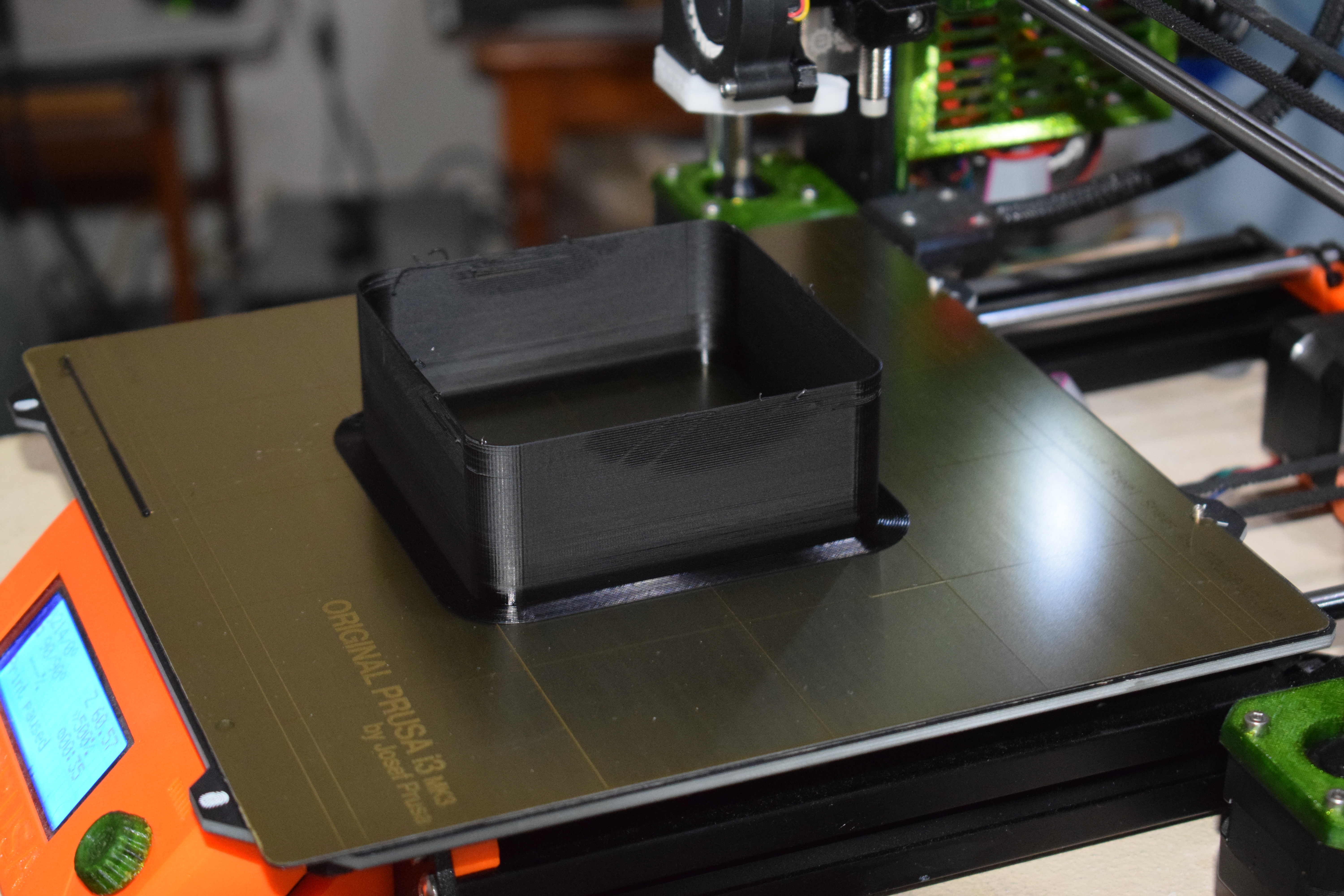

Here's a photo of the print-in-place tank treads I posted about above:

Re: Does someone want to know how fast they can print/extrude? look here

One problem I ran into with the 0.8mm nozzle is that support material is just too strong! With a 0.4mm nozzle, support material is nice and wispy, and easily knocked away. Not sure how support material behaves with a 0.6mm nozzle, but I fear it may be stronger than what I'd like. Since you're using a 0.6mm nozzle already, though, maybe you can say?

Also, I want one nozzle that I can use for everything, as I don't want to be changing nozzles. But that's me. Maybe others don't mind.

I had print a part today with full supports, PETG. They are just a bit harder to remove compared with the 0.4mm but i find it easy.

Bed only supports are always easy to remove since they dont make contact with the part most of the time. But for supports on part i use a Blade to trim de supports.

Also i underextrude supports so i removed the PETG supports with my fingers, no tools.

Since i use 0.6mm nozzle i never feel the need to go back to 0.4mm and i can use from .1 to .45 layer heights so you stiil have the quality of lower heights.

I cant notice a quality difference from 0.3mm to 0.45 layers, but i win a good print time, so for me 0.6mm is the best general nozzle this days.

If i upgrade my ender3 to direct drive i may go with the 1.2mm nozzle, so i can print 1 perimeter and 1 bottom/top. Otherwise i have to try the 0.6mm or 0.4mm nozzle just to get rid of the stringing

Re: Does someone want to know how fast they can print/extrude? look here

Nozzle: 0.8mm

Extrusion width: 0.9mm

As I learned here just recently, you can do an extrusion width of 0.9mm with a 0.4mm nozzle. If doing that, I'm not sure if that also means (?) you can do a layer height of 0.4mm with a 0.4mm nozzle. Anyone know? If so, then one could match your preferred extrusion width and height using just a 0.4mm nozzle.

On the other hand, if your happy with the resolution of a 0.6mm nozzle, the counter-argument to that would be: why bother? My answer to that would be: insurance against the day when you feel you really do need the resolution of a 0.4mm nozzle, but you don't want to do a nozzle change.

I prefer not to do nozzle changes, not because I can't, but because it's just another opportunity for something to go wrong. And when something goes wrong on this machine, it can mean lost time (sometimes a lot of lost time) spent getting things working again. I mean, I'd rather not even change the filament unless I absolutely have to. Why? Again, not because I can't, but because it's just another opportunity for something to go wrong.... you get the idea.

Re: Does someone want to know how fast they can print/extrude? look here

As I learned here just recently, you can do an extrusion width of 0.9mm with a 0.4mm nozzle. If doing that, I'm not sure if that also means (?) you can do a layer height of 0.4mm with a 0.4mm nozzle. Anyone know? If so, then one could match your preferred extrusion width and height using just a 0.4mm nozzle.

0.4mm hole can't extrude more than 0.4mm at instant, that means the 0.45 width is push more material by spending a more tiny time.

Eg: 4mm width is 1:1 (Material to Time), to have 0.45 width it should be 1.05:1.

So teorical you can do the width larger by pushing more material. Grab a liquid glue, place it vertical agaist a flat surface and squish, the hole can be 1mm, but if you squish against a surface it will spread made dispense more than 1mm wide of glue, you can also try do that moving the glue, if you perfect your force and movement you can do "consistence" extrusions of glue that outsize the hole width.

So extrude more than nozzle hole is normal, but now you must think what are the downsides of it, and why the recommended is 120% of the size.

By set 0.9mm width you are puting alot of stress under the nozzle and you have to print slower to mantain that width, also you will have a problem of extrusion start to lift on sides. If you test with the glue at some point the sides will get up as they are pushed from the center and the height is not longer consistance over the width.

Using 100% of the size is best for nozzle and machine so you are extruding 1 hole size for 1 instant of time, 120% are used to compensate and avoid other problems. There are people using 0.4mm and other slicers most use 100% rather 120%.

But if you use 100% you will able to print even faster. The more you increase the extrusion the slower you need to print, slowdown is not linear due the thing i have explained.

On the other hand, if your happy with the resolution of a 0.6mm nozzle, the counter-argument to that would be: why bother? My answer to that would be: insurance against the day when you feel you really do need the resolution of a 0.4mm nozzle, but you don't want to do a nozzle change.

I prefer not to do nozzle changes, not because I can't, but because it's just another opportunity for something to go wrong. And when something goes wrong on this machine, it can mean lost time (sometimes a lot of lost time) spent getting things working again. I mean, I'd rather not even change the filament unless I absolutely have to. Why? Again, not because I can't, but because it's just another opportunity for something to go wrong.... you get the idea.

I 100% agree with this, i think the same.

But from the first time i changed the nozzle i find it easy, just need to release the block from heatbreak and then you can freely work on nozzle without worry.

Still i do not plan to go back or change, and i still think dual extruder or toolhead would be a awesome addon, so you can have multiple nozzles sizes.

Re: Does someone want to know how fast they can print/extrude? look here

tiago,

I'm glad you're taking the opposing viewpoint, because maybe then we can arrive at the truth of all this. Unfortunately, it's hard for me to evaluate: I don't yet have much experience at printing at wider than 120%, though I have tried printing at 0.75mm just to see if I could, and that seemed to go OK. Maybe Martin can comment? Both Martin and Metacollin seem fine with printing at wider than 120% nozzle diameter. Metacollin says that he's fine printing all the way up to 1mm in width using a 0.4mm nozzle. I don't have any grasp yet on what all the downsides of that might be.

Right now, if I had to guess, I would guess that the 120% figure for width was picked as a conservative number that allows some fudge factor against both under-extruding and over-extruding without getting too far from the nominal nozzle diameter. However, if one does an accurate calibration of the true extrusion width, maybe one can be a bit less conservative? That's what I'm guessing, but it's just my wild guess without anything to back it up. I do get the impression that a lot of people who 3D print rarely, if ever, do an extruded width calibration, and so, given that, they need a rule of thumb to help keep their prints from failing.

Re: Does someone want to know how fast they can print/extrude? look here

If layer height >= nozzle bore, you're putting out a round or bulging filament profile. There's no "squish", so you'll get very poor 1st layer bed and layer-to-layer adhesion. The general guidance seems to be max layer height <= 0.8 * nozzle size. With a 0.40mm nozzle, this equates to 0.32mm layer height. With a 0.6mm nozzle, it's up to 0.48mm. These layer heights are pushing things. With the right temperatures and material, you'll gain adhesion due to needing fewer layers, but layer-to-layer may not be as strong (less squish), so I try to stay below 0.8 * nozzle size for part strength. OTOH, if you're doing vase mode prints and after transparency, nothing says you can't push past these boundaries for decorative pieces.

[...] I'm not sure if that also means (?) you can do a layer height of 0.4mm with a 0.4mm nozzle. Anyone know? If so, then one could match your preferred extrusion width and height using just a 0.4mm nozzle.

I haven't found anything definitive on minimum layer height, and apparently a lot of people are doing fine layers with larger nozzles. If you're after vertical resolution, a larger nozzle isn't a problem. I haven't tried 0.05mm with a larger nozzle... takes way too much time for my patience.

On the other hand, if your happy with the resolution of a 0.6mm nozzle, the counter-argument to that would be: why bother? My answer to that would be: insurance against the day when you feel you really do need the resolution of a 0.4mm nozzle, but you don't want to do a nozzle change.

I started out thinking the same, mostly because I was new and anxious about changing nozzles and possibly damaging something in the process. Hell, starting out, I was nervous about filament changes. After two nasty clogs and having to tear the extruder and hotend down, I no longer fear it. Changing a nozzle takes 2 minutes. I like the analogy the Prusa guy used: Using a 3D printer without changing nozzles is like using a DSLR camera without changing lenses. It works fine, but you're missing out on a lot of what it can do.

The big plus to a larger nozzle size is speed gains from not having to lay down as many perimeters. With a 0.6mm nozzle, it's really satisfying watching two big thick perimeters go down. Almost looks like toothpaste coming out of the tube. Infills go very quickly. Everything is really strong, and I can go with thicker layers. The downside is you're not going to be able to print detail smaller than your bore size. If you only print larger or functional parts, this may not be an issue at all.

That said, if you're doing miniatures or jewelry, you'll miss out on detail unless you go to something smaller. I did a comparison print with the same miniature model using identical settings (0.10mm layer height, etc.) but with 0.25 and 0.40mm nozzles:

You can see a big difference around the wheels and tracks. Some details are simply not there at 0.4mm. Even more detail would be missing at 0.6mm. You'll lose out on horizontal detail (thin lines and perimeters on surfaces) with a larger nozzle size.

You can see a big difference around the wheels and tracks. Some details are simply not there at 0.4mm. Even more detail would be missing at 0.6mm. You'll lose out on horizontal detail (thin lines and perimeters on surfaces) with a larger nozzle size.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: Does someone want to know how fast they can print/extrude? look here

Say, speaking of which, do volcano nozzles even exist in 0.25mm? I don think I've ever seen one for sale. I guess maybe because it's a non-sequitur of sorts.

Nice photo! It would be fun to see one with a 0.6mm nozzle tank side-by-side with the other two that you already have.

Re: Does someone want to know how fast they can print/extrude? look here

Hadn't even thought about that. I took a look at MatterHackers and the E3D site, and it looks like 0.40-1.20mm are available for the Volcano.

Say, speaking of which, do volcano nozzles even exist in 0.25mm? I don think I've ever seen one for sale. I guess maybe because it's a non-sequitur of sorts.

Nice photo! It would be fun to see one with a 0.6mm nozzle tank side-by-side with the other two that you already have.

I was going to give this a shot, and immediately ran into the minimum resolution issue:

Some spokes are missing on the smaller wheels. You can see gaps in between the treads. These occur where the resolution is too fine for the 0.6mm nozzle to print. Also notice that the bolts in the large idler and toothed gears at the front and back are missing. You start to lose a lot of fine horizontal detail.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: Does someone want to know how fast they can print/extrude? look here

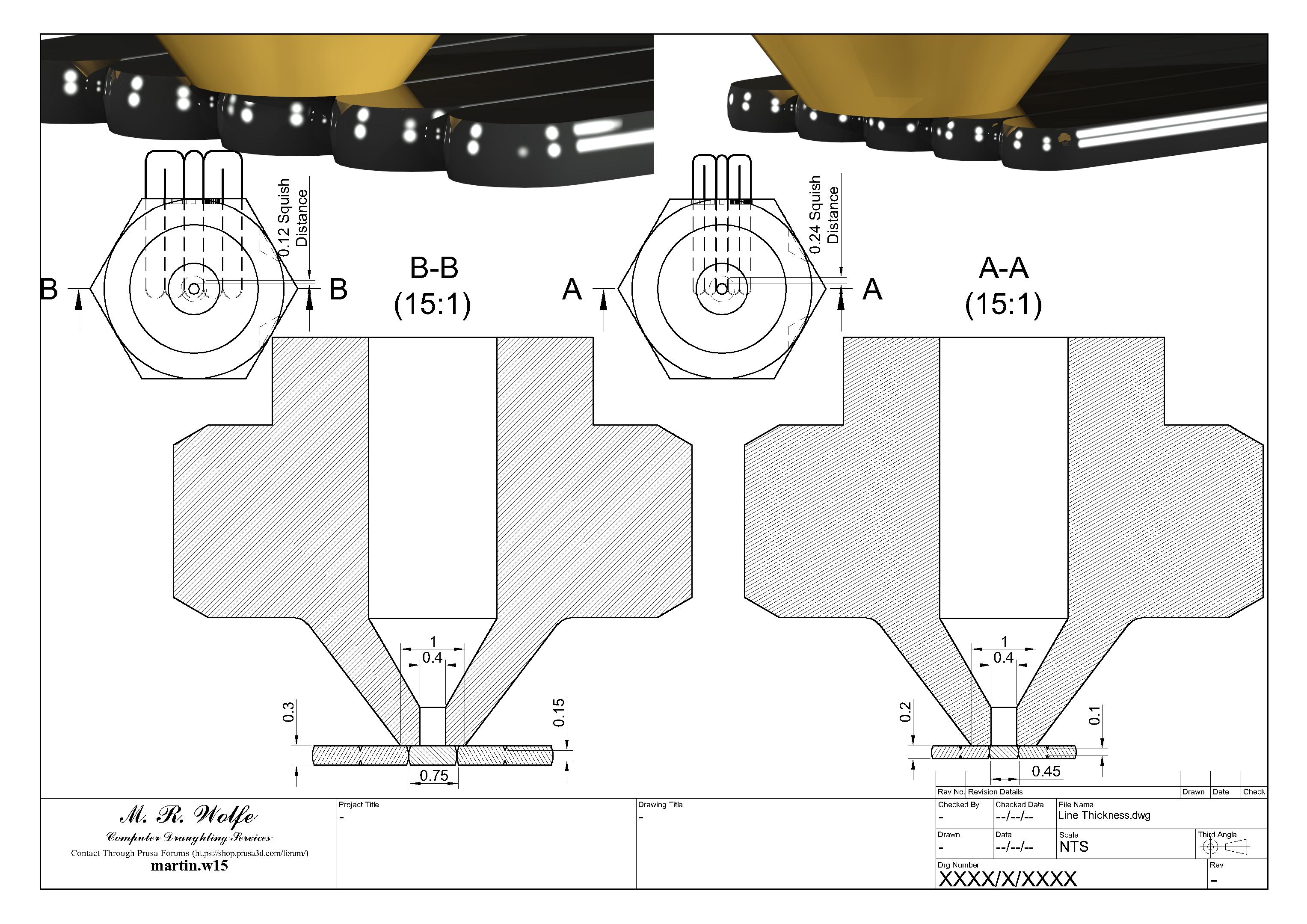

It is a matter of looking at the nozzle geometry. Not only the nozzle size but the diameter of the tip. Larger nozzles also have a larger tip diameter. This gives more distance over which the filament can be squished. While using a 0.4mm nozzle with a wide line width was acceptable for the volumetric and speed tests. It would not necessarily give a good surface finish when used on an actual print as it would only have a very short time to properly squish the extruded filament to the correct shape before it is no longer in a position to do so meaning the shell of the filament is likely to spring back to a rounder shape before it sets.

Notice that the 0.45 line width has a squish distance of 0.24mm whereas the 0.75mm line width has a squish distance of 0.12mm. These means that even though the nozzle can handle the volumetric flow to guaranty the surface finish the linear speed will have to be 50%.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

It would be nice if E3 would extend the nozzle size range to smaller nozzles in the volcano. However when I spoke to them regarding the volcano block and plated copper the feeling I got was they regard changing between heater blocks as easy as changing nozzles. Probably why they have the thermistor connections close to the heater block.

The only solution to a quick swap is to have two complete E-axis assemblies with a plug/socket arrangement on the X-Carriage for a quick change over without having to go through the full hassle of removing the thermistor and heater cartridges to and from the Volcano to the V6 and back again.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Can anyone tell me what Accelaration Control does? The description is very poor...

It seens the infill print alot faster (More motion) at 40mm/s than a perimeter at 40mm/s, is the Accelaration Control responsible for that?