Re: Does someone want to know how fast they can print/extrude? look here

At a minimum, it should look at least as fast as this:

I'd still would like to get the very high accelerations (4000+) that were shown in the video I linked to earlier. Regardless of how the printing comes out, I'm curious as to whether the Prusa can even do it.

Re: Does someone want to know how fast they can print/extrude? look here

The bigger question, for me at least, is "and for how long?" I'm all for going faster, but if it's going to mechanically destroy the printer in a short time, I'd rather stick to the design defaults. Somebody (not me!) needs to do some run-to-destruction tests.

I'd still would like to get the very high accelerations (4000+) that were shown in the video I linked to earlier. Regardless of how the printing comes out, I'm curious as to whether the Prusa can even do it.

I do wonder what material they're printing in the video. I find limits of the filament to be as limiting as the printer's mechanical capabilities in many cases.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Does someone want to know how fast they can print/extrude? look here

This morning, among other things, I upgraded to the copper hot-end and re-ran the K=20 test:

This time it printed all the way through 325mm/sec before the last layer set of 350mm/sec, whereupon the "clunking" began and the undeniable print failure happened.

So, I would agree that the "clunking" probably isn't good for the printer. The question is: what's causing it? Is it the faster acceleration rates that kick in on that layer set? If so, then maybe just maintain the accelerations that were active at the 325mm/sec layer set, but move to the higher speed anyway.

Re: Does someone want to know how fast they can print/extrude? look here

...if it's going to mechanically destroy the printer in a short time, I'd rather stick to the design defaults.

Prior to the clunking phase at 350mm/sec, I haven't seen any evidence that it's destroying the printer. Nothing seems to get tremendously hot. It's just running faster. It's like saying that riding your bicycle at 20mph instead of 5mph is going to destroy it.

If parts of it were getting overheated, then I might worry. But like I say, I haven't seen it happen.

Re: Does someone want to know how fast they can print/extrude? look here

[...] It's like saying that riding your bicycle at 20mph instead of 5mph is going to destroy it.

If parts of it were getting overheated, then I might worry. But like I say, I haven't seen it happen.

More like driving your sedan at 120MPH on city streets when you hit certain levels. It'll work. For a while. Wear & tear are cumulative. Friction and heat are one issue, but vibration and frame stress are another. A lot of fast, rapid movements are going to shake it, possibly well past the levels the frame is meant for. Looking through these forums, it sounds like people are having issues with wear on belts and wire connections at regular speeds.

I'm not saying it will necessarily happen, but I do wonder about stress on the various parts with rapid movements, not just long straightaways. Like I said, I'm happy to watch somebody else do the test-to-destruction bit. I wonder at what point making it all more rigid along the lines of the Bear enhancements becomes necessary for long-term printer health.

[Aside: My sis nearly killed herself riding her bike beyond limits on a steep San Francisco downhill, so it's a good analogy. Her brake pads melted off at speed.]

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Does someone want to know how fast they can print/extrude? look here

I wonder at what point making it all more rigid along the lines of the Bear enhancements becomes necessary for long-term printer health.

What are Bear enhancements? First I've heard of it.

[Edit: nevermind: found it: https://github.com/gregsaun/prusa_i3_bear_upgrade ]

Re: Does someone want to know how fast they can print/extrude? look here

Not trying to be a downer. It's just my Mk3 shakes quite a bit doing tight turns already. By the time you dampen acceleration enough to safely hit those speeds, I wonder if you're gains are really going to be limited to very long, straight pieces.

That said, the volumetric throughput levels you guys are hitting are interesting. Rather than focusing on speed, I'd be curious to see what you could get done with a 0.8 or 1.0mm nozzle using moderate layer heights. Straightaway speeds might not be so impressive, but man print times would be fast. I'd be curious to see the relative print times of say a large-ish cube or cylinder with various combinations of hardware.

Edit: In other words, rather than "how fast can it go", look for "how quickly can it build a shape of X, Y, Z dimensions". It sounds like you'd be able to lay down nice thick walls in a single pass, tremendously speeding up everyday prints, not just sprints. Not a quarter-miler dragster, a truck that can get more work done!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Does someone want to know how fast they can print/extrude? look here

I will be retrying my PLA+ test with the 0.8 width and 0.3mm layer height on the 0.4mm nozzle making sure I start at the correct feed rates this time.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

I will be retrying my PLA+ test with the 0.8 width and 0.3mm layer height on the 0.4mm nozzle making sure I start at the correct feed rates this time.

I've read that the max. width you can reliably get is 1.2 X nozzle width for a single pass. That's where the max. 0.48mm line width comes from that you find in some slicers. I did some tinkering with a $10 nozzle sampler and am now addicted to 0.6mm (0.72mm lines! -- I stick with 0.68mm) as my default. Even without extensive tuning, prints of a given thickness are a lot faster due to reducing the need for so many perimeters. Actual linear speed is slower, but print completion is faster if I can eliminate printing an extra perimeter.

I've been looking at the plated copper nozzles & heater block. Sounds like they might be worthwhile for the increase in volume.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Does someone want to know how fast they can print/extrude? look here

That said, the volumetric throughput levels you guys are hitting are interesting. Rather than focusing on speed, I'd be curious to see what you could get done with a 0.8 or 1.0mm nozzle using moderate layer heights. Straightaway speeds might not be so impressive, but man print times would be fast. I'd be curious to see the relative print times of say a large-ish cube or cylinder with various combinations of hardware.

You'd think so. However, I started this thread with a 0.8mm nozzle, and the prints failed at surprisingly low speeds for the reasons discussed there. Mainly, it appears that the extrusion doesn't have enough time to cool before getting yanked to the side at corners.

However, I agree that there's more that can be investigated regarding nozzle diameter. Maybe 0.6mm will turn out to be the sweet spot. If only more people would participate in this thread, then the answers would likely come faster. At least for now, though, I feel like I've done my share, and I'm sticking with 0.4mm, because it "just works."

Re: Does someone want to know how fast they can print/extrude? look here

[...] It's like saying that riding your bicycle at 20mph instead of 5mph is going to destroy it.

If parts of it were getting overheated, then I might worry. But like I say, I haven't seen it happen.

More like driving your sedan at 120MPH on city streets when you hit certain levels. It'll work. For a while. Wear & tear are cumulative. Friction and heat are one issue, but vibration and frame stress are another. A lot of fast, rapid movements are going to shake it, possibly well past the levels the frame is meant for. Looking through these forums, it sounds like people are having issues with wear on belts and wire connections at regular speeds.

I'm not saying it will necessarily happen, but I do wonder about stress on the various parts with rapid movements, not just long straightaways. Like I said, I'm happy to watch somebody else do the test-to-destruction bit. I wonder at what point making it all more rigid along the lines of the Bear enhancements becomes necessary for long-term printer health.

[Aside: My sis nearly killed herself riding her bike beyond limits on a steep San Francisco downhill, so it's a good analogy. Her brake pads melted off at speed.]

By the way, have you done the Bear enhancements, or know anyone who has? I just wonder whether they make any actual, meaningful difference.

Re: Does someone want to know how fast they can print/extrude? look here

[...] By the way, have you done the Bear enhancements, or know anyone who has? I just wonder whether they make any actual, meaningful difference.

I have not. I encountered them whilst reading up on the effects of vibration on print quality. I know they were a bigger deal with the older Prusa printers, but the Mk3 is an improvement itself, so perhaps it's not as significant. I have been trying to reduce weight and increase stability, starting with moving the filament spool off the frame and getting the bed as stable as possible. Vibration is my enemy. Bracing the fame strikes me as an economic place to start.

I was on a bit of my own "quest for speed" when the quality impacts became apparent, so I started looking into frame reinforcement (e.g. Haribo, Bear), and then into the overall impact of volumetric throughput on actual print times. My emphasis lately has been on getting as much through the extruder as possible, although I haven't been able to spend a lot of time on it. I do want to order the plated copper heater block and nozzle, but not go so far as completely changing the Mk3 with a Volcano since it's my only printer... for now. I want to push any increases into layer thickness or line width gains rather than linear speed. From what I've read, the stock E3D V6 can push 11.5 mm^3/s. I'd like to see what difference the plated copper components make. Then again, a lot of materials won't push that fast, but at least PLA could print quick(er).

I've been following your discussion. I just didn't want to derail anything since my focus is on other factors. The vibrations you were hitting at top speed did remind me of problems I've read up on elsewhere.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Does someone want to know how fast they can print/extrude? look here

I will be retrying my PLA+ test with the 0.8 width and 0.3mm layer height on the 0.4mm nozzle making sure I start at the correct feed rates this time.

Regards,

Martin

Thanks for the updated test. I was able to print that and get an increase in speed for each layer all the way to 999%! This is with a volcano 0.4 nozzle on skelestruder. The only change I made was to up the nozzle temp to 230C.

One thing I noticed is that the Y cannot keep up with the X, I assume due to the extra mass of the bed. I tried to manually time the x side with a stopwatch and was getting ~0.25 sec at 900%. So I don't think it is going quite as fast as claimed, but still pretty good. By the final layers I was probably closing in on 450 mm/s and still printing.

Re: Does someone want to know how fast they can print/extrude? look here

Last night I played around with a 1.2mm nozzle, and I think I may have this figured out. Basically, the fastest acceptable prints from the 1.2mm nozzle have the same volumetric extrusion rate as the fastest acceptable prints from a 0.4mm nozzle. In other words, the volumetric extrusion rate dominates everything. Or, to put it differently, you can't get a higher volumetric extrusion rate by going to a bigger nozzle without impairing the relative print quality. The same for layer height.

Anyhow, do your own testing and see if you don't agree.

So, if using a 1.2mm nozzle, I may as well just print everything at a 0.1mm layer height and get a very smooth finish. The volumetric extrusion rate, for the same overall print quality, is the same as when I use a 0.2mm layer height, even though the total print time is the same (i.e. the speed is twice as fast if doing a 0.1mm layer height).

One notable advantage of the 1.2mm nozzle is that the prints are very strong. I'm not sure whether or not you could get comparable strength by doing an equivalent width of perimeter with a 0.4mm nozzle using multiple loops.

[Edit: Also, for some reason, the "rated" volumetric extrusion rate is higher than the volumetric extrusion rate at which I can make prints at acceptable print quality. Not sure why (?) that would be, but I have experienced enough datapoints now that I'm calling it. It does seem to improve a bit by using a copper nozzle and copper hot-end.

I upgraded to a 40 watt heater cartridge, and it's great! Much faster heatup times, and it appears I don't specifically *need* to have the sock on anymore like I did with the 30w cartridge.]

Re: Does someone want to know how fast they can print/extrude? look here

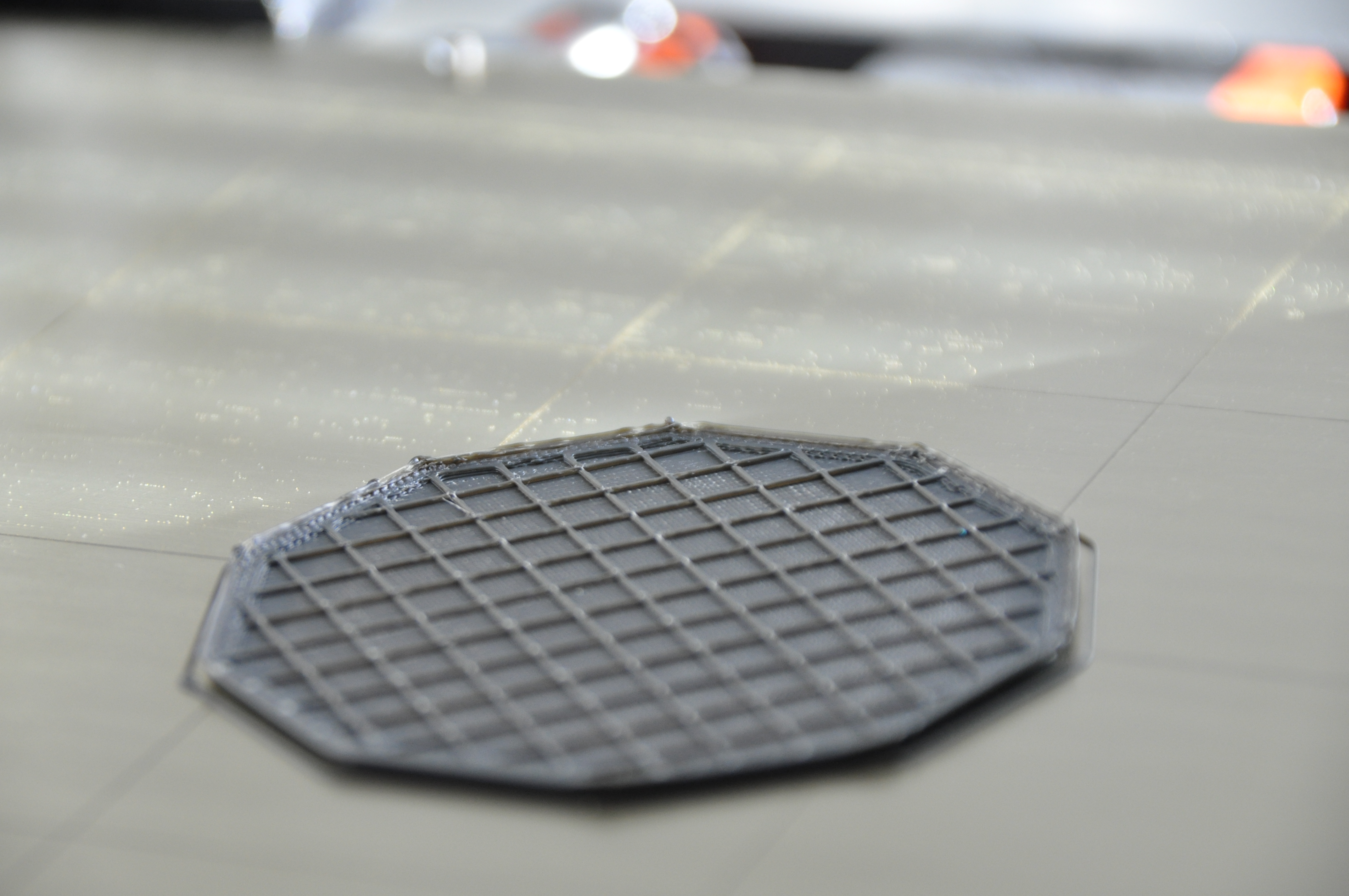

I have done a new PLA test.

The setup:-

Sunlu PLA+ (An old spool near the end)

0.4mm nozzle

0.75mm line width

0.3mm layer height

20mm/s initial speed

800mm/s² initial acceleration

X-Y jerk values 1 to get those corners working

4000mm/s² max acceleration

Volumetric flow increasing by 50% every 16 layers (4.8mm height)

Acceleration increasing by 90mm/s² every 16 layers (4.8mm height)

205/195 nozzle temperature

60 bed temperature

100% fan throughout.

The initial speed was chosen so that the volumetric flow in each band would be the same as Devil Hunter's test

The spiral vase on the fourth side where the extruder had lifted by a fair bit almost to the next layer did not stick to the brim but as at was correcting itself I let it run and by layer 16 it was correct and running straight.

The extruder started to misfeed at 400% (18.00mm³/s) so the last successful band was 350% (15.75mm³/s). It was only clicking once per level so it may have been possible to push to 16mm³/s. However 15.75mm³/s is very close to the volumetric limit Prusa have put on PLA in Slic3r.

Now for print quality. Apart from a slight change in colour the 150% band was identical to the 100% band tying in with the slicer external perimeter default speed of 35mm/s. At 200% and above ringing became apparent getting worse on higher bands as the acceleration increased. However appart from that surface finish was good all the way up till the extruder started to miss feed at 400%

With regards to my previous PLA test with the 0.45 line width and 0.2mm layer height I think that the already extruded and set filament was helping to pull the fresh filament through relieving the pressure on the extruder making the crazy speed I got possible.

In conclusion I just confirmed for PLA that the Slic3r values are optimal of a 0.4mm nozzle with a V6 block (weather plated copper or aluminium/brass).

Test Files

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

[...] In conclusion I just confirmed for PLA that the Slic3r values are optimal of a 0.4mm nozzle with a V6 block (weather plated copper or aluminium/brass).

Sorry to be dense, but are you saying the default Slic3rPE values are optimal for a stock setup, or a tuned set?

I've got Print Settings->Speed->Max. volumetric speed set to 11.5mm^3/s, corresponding to the best available info I could find from E3D for the V6. Unfortunately, the tooltip only offers up "default 0", so I'm not sure what Prusa uses.

Thanks for sharing all your results. You guys put a lot into this.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Does someone want to know how fast they can print/extrude? look here

I am saying for a MK3 with a V6 block and 0.4mm nozzle (weather it is aluminium/brass or plated copper) that the default PLA volumetric and speed values are already optimally tuned and that no speed increase can be found. Prusa's default value for PLA is 15mm³/s

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Ah, got it. I'm surprised there's no gain from the plated copper components. I was considering ordering a titanium heatbreak+plated cooper heatblock + plated copper nozzle, but it doesn't sound like there's much point. It does sound like a Volcano setup is the logical next step for any need for speed.

I know Prusa set 15mm^3/s for PLA, but I'm wondering if the E3D V6 is up for that throughput. Most of my "clicking extruder" issues seem to go away when I lower that setting closer to the 11.5 value.

That's another question though, and you're probably tired of all this. 😀 Thanks again for all your hard work.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Does someone want to know how fast they can print/extrude? look here

Well there may be a small gain to 2 or 3% but it is not worth the effort of narrowing it down. Plated copper is more for high temperature filaments than anything else. The actual rate heat energy transfer from the nozzle to the filament is purely determined by the surface area contact and the temperature difference between the nozzle and the filament. That is is why the volcano is the choice if you want a large volumetric flow.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Marti,

Nice write-up! Thanks for posting.

0.75mm line width

Small typo. I presume you meant 0.45mm.

With such professionalism, I very much look forward to your Volcano write-up.

Do these results mean you'll be using an aluminum Volcano or instead installing a copper Volcano anyway?