RE: Does someone want to know how fast they can print/extrude? look here

[...] Anyhow, if anyone reading this has any other suggestions on high speed 3D printers worth considering, please do post. I'm sure there must be more out there. Given enough time I think an obvious winner in the corexy high-speed category will eventually emerge, just as Ender 3 did for the low-end and Prusa I3 MK3/s/+ did for the medium-end.

I think we're nearing the end of big gains in FFF printing. There may be incremental gains in print speeds, but you still need filaments that can handle being printed at such speeds, and the results may not attractive. If the results are attractive, you're limited to functional prints. And FFF printing does not yield the best strength for many functional prints.

In my mind, we're at about the same stage where computer printers were in the early-mid 1980s. We were plugging along with dot matrix printers that printed one line at a time. Some could produce better results (more DPI, better fonts). Some were faster. Some were larger. All were limited to one line at a time. Laser printers showed up a few years later and changed the game completely. I don't think resin is the laser printer of 3D printing yet, but if they can get rid of the nasty chemicals and fumes, some sort of "full page" technology is going to make FFF obsolete.

In other words: I'm not spending too much time and effort on it myself. If I need a new printer, I'll look to see what's available. If the XL is out by then, I expect it will be the obvious choice.

Fair enough. I'm not yet convinced that a corexy is the way to go anyway. The argument put forth in favor of a corexy is a more rigid frame and that for some movements you can get the added torque of two stepper motors pulling together instead of just one. Well, the frame part may be true, but is the extra rigidity really needed? Maybe it would help with ringing, but otherwise it doesn't seem needed at current speeds. Maybe the extra rigidity only becomes important at higher speeds? That's what I don't yet know. Also, if it's more torque that's desirable, one could fairly easily upgrade an i3's xyz steppers to to higher torque steppers, so I don't see higher torque as enough justification by itself to switch to corexy.

Now that I think of it, I'd probably be better off making adapters that would allow my cheap chinese CNC (which I'm currently in the middle of upgrading) to be a 3D printer when needed than I would be buying some cat-in-a-bag 3D printer that's unknown to me. When finished my CNC will have higher torque 60mm Nema 17's, closed loop positioning with 0.195 micron resolution, and TMC5130 drivers that can be powered up to 42v if need be for faster acceleration. As a platform, although still lacking ballscrews and linear rails (maybe some future upgrade), to me that seems like a better starting point than what I see in most prosumer 3D printers currently on the market.

RE: Does someone want to know how fast they can print/extrude? look here

Anyway, getting back to the original topic of this thread, I'd like to find some way of monitoring what the speeds and accelerations are that actually happen, not just what the gcode instructs should happen. If the two were perfectly the same, then there would be no difference between the slicer's estimated total print-time and actual total elapsed print-time that occurs on the machine--yet typically they aren't the same. Part of the difference might be attributed to arbitrary limits imposed by the firmware, but if those limits are removed, would the two exactly match or would there still be some difference? I don't know the answer to that.

RE: Does someone want to know how fast they can print/extrude? look here

Anyway, getting back to the original topic of this thread, I'd like to find some way of monitoring what the speeds and accelerations are that actually happen, not just what the gcode instructs should happen. If the two were perfectly the same, then there would be no difference between the slicer's estimated total print-time and actual total elapsed print-time that occurs on the machine--yet typically they aren't the same. Part of the difference might be attributed to arbitrary limits imposed by the firmware, but if those limits are removed, would the two exactly match or would there still be some difference? I don't know the answer to that.

If the two exactly matched, then I could use the color coded speed view and volumetric flow rates (as shown in the screenshots I posted above) to know the actual speed and volumetric extrusion rate of the printhead at all times, and there would be no need to dig any further than that to get the information. Those answers could directly inform exactly where and how the print job could be improved so as to reduce the overall print time. So, in case you're wondering, that's why I'd like to know.

RE: Does someone want to know how fast they can print/extrude? look here

Anyway, getting back to the original topic of this thread, I'd like to find some way of monitoring what the speeds and accelerations are that actually happen, not just what the gcode instructs should happen.

In this case get you accelerometer and measure it. Computations are always just an approximation of the real world scenario. But beware that you're measurements will apply to the one printer you're measuring. If you have multiple, you will need to do it for every one separately.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: Does someone want to know how fast they can print/extrude? look here

Anyway, getting back to the original topic of this thread, I'd like to find some way of monitoring what the speeds and accelerations are that actually happen, not just what the gcode instructs should happen.

In this case get you accelerometer and measure it. Computations are always just an approximation of the real world scenario. But beware that you're measurements will apply to the one printer you're measuring. If you have multiple, you will need to do it for every one separately.

That's an interesting idea. I have no prior experience with accelerometers, and there are a lot to choose from. That said, there are probably github arduino libraries for many of them. Which accelerometer do you most recommend for the purpose?

RE: Does someone want to know how fast they can print/extrude? look here

Meh, I'd wager it would be easier to do with inexpensive 14-bit magnetic encoders on the x and y axis steppers (for measuring velocities and accelerations) plus one on the extruder stepper also (for measuring the volumetric flow rate).

RE: Does someone want to know how fast they can print/extrude? look here

Looking into it a bit more, evidently another reason corexy printers are popular at the larger build volumes is that the mass of the bed on an i3 printer becomes, obviously, larger and perhaps a barrier to speed because of the inertial mass. Well, that's the argument. I can't say whether or not it's a solid argument or just a sales pitch with holes in it.

Interestingly, on the Railcore corexy printer, they use 3 z-axis motors to very accurately physically level the bed relative to the print nozzle rather than just map the differences and adjust for them during the print. I'm not aware of any other 3D printer which does that. The claimed benefit is that this allows for faster print speed, though it's not clear to me why that would be, since you'd expect z compensations to be small relative to x and y motions.

Anyhow, since corexy speed benefits (or not) isn't drawing any comments here, I'll leave it at that.

RE: Does someone want to know how fast they can print/extrude? look here

Looking into it a bit more, evidently another reason corexy printers are popular at the larger build volumes is that the mass of the bed on an i3 printer becomes, obviously, larger and perhaps a barrier to speed because of the inertial mass. Well, that's the argument. I can't say whether or not it's a solid argument or just a sales pitch with holes in it.

There's at least some solid theory behind it. "Bedslinger" cartesians do have to deal with more weight as the bed size increases, and I can see visible ringing on the Y-axis on my 300x300 Sidewinder. I've adjusted the Y acceleration and jerk settings to reduce this, but that increases print times. I'd like to add a removable PEI print surface, but the weight of the magnetic and spring steel sheets just adds to that weight. I'm sure that's a big reason behind Prusa's change for the upcoming XL printer.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Does someone want to know how fast they can print/extrude? look here

Looking into it a bit more, evidently another reason corexy printers are popular at the larger build volumes is that the mass of the bed on an i3 printer becomes, obviously, larger and perhaps a barrier to speed because of the inertial mass. Well, that's the argument. I can't say whether or not it's a solid argument or just a sales pitch with holes in it.

There's at least some solid theory behind it. "Bedslinger" cartesians do have to deal with more weight as the bed size increases, and I can see visible ringing on the Y-axis on my 300x300 Sidewinder. I've adjusted the Y acceleration and jerk settings to reduce this, but that increases print times. I'd like to add a removable PEI print surface, but the weight of the magnetic and spring steel sheets just adds to that weight. I'm sure that's a big reason behind Prusa's change for the upcoming XL printer.

Yes, that makes sense: the demo prints I've seen for delta printers (which have fixed beds) don't show ringing.

RE: Does someone want to know how fast they can print/extrude? look here

Allegedly a super volcano can supply up to 11 times the volumetric throughput of a standard E3D-V6 hotend:

I do have some projects which involve printing a mountain of parts (not just a dozen or more large custom weights for a home gym weight stack but also hundreds of custom drawer organizer modules for a variant of: ), where print asthetics matter less than strength and far less than simply quickly printing the hundreds of printed parts that would otherwise take an eternity at normal E3D-V6 print times.

Matchless Nozzle queries

Hey! Based on what I read here I went and bought a matchless nozzle myself. Would it be possible to see what it looks like mounted on your hot end? In setting mine up I've discovered the threads seem to go all the way to the nozzle itself, so there isn't a space like there is on the nozzle that came with the printer. I tried leaving a small space, but that caused a leak. Do you end up having to have it flush against the hot end?

I still show a gap

Hey! Based on what I read here I went and bought a matchless nozzle myself. Would it be possible to see what it looks like mounted on your hot end? In setting mine up I've discovered the threads seem to go all the way to the nozzle itself, so there isn't a space like there is on the nozzle that came with the printer. I tried leaving a small space, but that caused a leak. Do you end up having to have it flush against the hot end?

Mine shows a small gap with all 3 sizes of Matchless that I own. Not as noticeable as with some other nozzles, but still visible. My heartbreak may just be screwed I to the heater block a little further. Do make sure you got the actual Prusa style!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Matchless, continued

Okay, cool, that's very reassuring! I did not have mine flush, but the gap is small, and I was worried about it. I double checked, I did get the right ones. I may have not screwed it in quite as tightly as I should have, because I was worried about the lack of gap.

Thank you! Did you find you needed to change your slicer settings significantly?

RE: Clarification on tightening procedure & MVS

Okay, cool, that's very reassuring! I did not have mine flush, but the gap is small, and I was worried about it. I double checked, I did get the right ones. I may have not screwed it in quite as tightly as I should have, because I was worried about the lack of gap.

Just to be clear: If you have your hotend assembled correctly, it will be impossible to tighten the nozzle snugly up against the heater block. It will push up against the heatbreak inside the block, with the block acting as a coupler holding the nozzle and heatbreak together. If you are able to tighten your nozzle flush, you will have a leak.

Thank you! Did you find you needed to change your slicer settings significantly?

Other than a minor temperature adjustment, it was mostly a question of increasing the Maximum volumetric rate settings to take advantage of the increased capacity. I've got some notes on how I identified the "red line" rates that a extruder+hotend+nozzle combination can handle with a specific filament here.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Does someone want to know how fast they can print/extrude? look here

For anyone who is still interested in the topic of how to drive your MK3 as fast as possible while still getting high quality prints, reportedly you can get 300mm/sec by driving your bog standard MK3 using just Klipper and and a CHT nozzle and using the Bambulab slicer (a Prusa slicer derivative). i.e. reportedly it makes the MK3 print just as fast as the Bambulab X1C.

RE: Does someone want to know how fast they can print/extrude? look here

Hi all, just finished a bear upgrade, and have a few questions about speed.

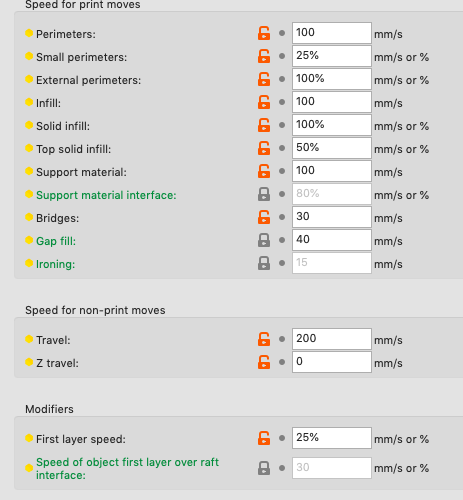

What is the feed rate/flow rate setting in prusaslicer? Is it the external perimeters value?

Also, how is the percentage on the LCD calculated?

I was able to print a successful benchy using these settings, should I increase or decrease any?

RE: Does someone want to know how fast they can print/extrude? look here

I've had more of a play with the teching tech tool, and did some quick math. I'm using a Revo 6, with a max flow rate of 17, which limits my speed at 238 (0.2 layer height, and 0.4 width), is this correct?

I can hear my prusa stop at 200mm/s, I've tried using a M203 command through the terminal, and also putting a M203 command into the gcode, I can't seem to break that 200mm/s barrier.

RE:

IIRC, you may have to change some limits in the firmware and then recompile. Those firmware limits may override the G-code limits.