Re: Does someone want to know how fast they can print/extrude? look here

I can see the allure of the thicker walls though. Maybe with Martin's better cooling fan I'll try the 1.2mm nozzle again for project enclosures.

My part fan nozzle may have an impact is it will not cool the block and nozzle only the extruded filament once it is fusing to the printed part. So with a bit of luck a speed increase will be possible. It all depends on the actual tuned range it has at the moment I am still closing out the under cooling. Once that is done I will have to make a few more iterations to find out where over cooling starts so I can find the median value for best overall results. I expect this to be a very narrow range of air path restrictions.

The W10 Benchy working up from the bed has 6mm of perfect cooling, 11mm of under cooling then perfect cooling the rest of the way up. The W9 was 5mm of perfect cooling, 15mm of under cooling then perfect cooling the rest of the way up. for comparison on the default Prusa V6 aluminium block brass nozzle setup with sock 9mm of perfect cooling, 2mm of slight over cooling (slightly reduced glossiness at the level where the Prusa silver grey one has a slight artefact on the bow) and perfect the rest of the way up. So it looks like as well as it's mono directional quality it also suffered slightly in uneven cooling on a benchy, I wonder how many variations Prusa went through refining their design. I get the feeling they just tuned it via fan speed.

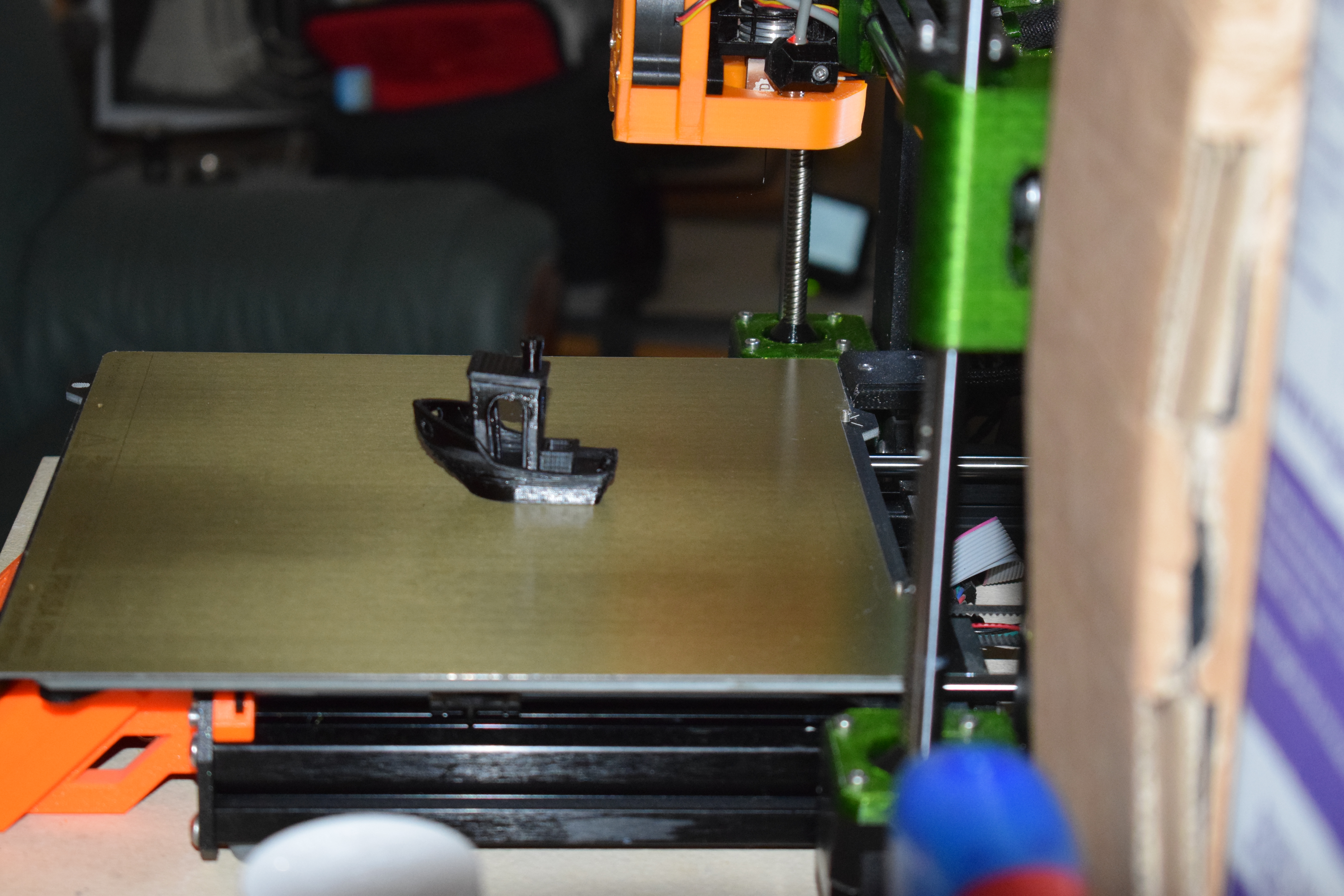

W10 Benchy

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

OK, I tried PETG with a 0.6mm nozzle. I get a good print quality at 0.45mm layer height, 1.2mm extrusion width, and 17mm/sec speed, but print quality starts to visibly degrade at 25mm/sec.

So, I really just don't know how you're getting that kind of speed. Maybe a copper nozzle would be better, but I doubt that much better.

I can see the allure of the thicker walls though. Maybe with Martin's better cooling fan I'll try the 1.2mm nozzle again for project enclosures.

With volcano right? You can go faster, maybe you are printing small object, renember the layer must cooldown before apply the new one. No matter if ABS, PLA or PETG, small objects need to cooldown first so the solutins are use a fan or lower print speeds or both.

I haven't try PETG with this setup, but tested with PLA and ABS and i can mantain the 52mm/s speed without any problem, and im about to test the ABS limit now, because that 52mm/s is for PLA, as ABS have lower density i guess i can go a bit more fast.

martin how many benchies do you have by now? 🙂

The last one looks awesome

Re: Does someone want to know how fast they can print/extrude? look here

It only looks awesome at a distance. I have not kept all my benchies. What I have is two from my universal nozzle (Still needs a lot of work on that,) the original from V6 default with sock from when I first dialled in Rigid Ink black PETG (the test filament I am using,) the default Prusa nozzle with plated copper volcano and the W7 through W10 ones.

One thing print bed temperature limits for using my print fan nozzle are 100°C if it is printed in HIPS and 110°C if it is printed in ABS. I am thinking of printing my final nozzle for use in PMMA (it has the same glass transition temperature as ABS) so that the light from my endoscopic camera will properly illuminate the printed part and I will not have to think my about the bed and nozzle temperatures of whatever I am printing.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

I have finish my ABS test, as i expected i can run a bit faster, up to 30mm/s^3 which is 55mm/s to be safe. Only +3mm/s compared to PLA.

Note i'm not boosting my temperatures to get that speed, i run stock temperatures for PLA, and 240ºc for ABS (recommended temp from instructions)

I have brass nozzle and normal volcano block (Not copper) + sock. With all copper and a bit more temp i guess limit can be increased to 35mm/s^3, but not worth the extra care/money.

Re: Does someone want to know how fast they can print/extrude? look here

It only looks awesome at a distance. I have not kept all my benchies. What I have is two from my universal nozzle (Still needs a lot of work on that,) the original from V6 default with sock from when I first dialled in Rigid Ink black PETG (the test filament I am using,) the default Prusa nozzle with plated copper volcano and the W7 through W10 ones.

One thing print bed temperature limits for using my print fan nozzle are 100°C if it is printed in HIPS and 110°C if it is printed in ABS. I am thinking of printing my final nozzle for use in PMMA (it has the same glass transition temperature as ABS) so that the light from my endoscopic camera will properly illuminate the printed part and I will not have to think my about the bed and nozzle temperatures of whatever I am printing.

Regards,

Martin

I currently print ABS at 115ºc bed, and shroud does not deform. It was printed with ABS from FilaFarm at 250ºc

They have a filament that looks the ideal for that kind of situation: https://www.filafarm.de/collections/filament/products/greentec-pro

Up to 160ºc

Advantages

temperature resistant up to 160°C (VICAT) / 130°C (HDT)

low printing temperatures 190-250°C

less warping (0,4%)

high mechanical resistance

food safe

less odor

high layer bondage and excellent optical and technical features

biodegradable

Co2 neutral and ecologically harmless.

Print paramteres

print bed: 0-60°C

bed adhesion: FilaPrint®, CarboPrint, blue tape, kapton, glass

print speed: up to 120mm/s

weight: 800g/spool

Re: Does someone want to know how fast they can print/extrude? look here

Looks good on the temperature qualities. Unfortunately it is opaque. Still with those temperature qualities it is pretty much ideal for a print fan nozzle even better than ABS. I have half a real of Extrudr orange PETG (used for the R2 parts) so I know that they make excellent filaments. As the thermal properties are far more important than the optical I will go with this.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Looks good on the temperature qualities. Unfortunately it is opaque. Still with those temperature qualities it is pretty much ideal for a print fan nozzle even better than ABS. I have half a real of Extrudr orange PETG (used for the R2 parts) so I know that they make excellent filaments. As the thermal properties are far more important than the optical I will go with this.

Regards,

Martin

Extrudr sells greentec pro 2,5 kg, but price is a bit high.

Where do you see the greentec pro is opaque?

I think greentec pro is excelent due no abrasive and lower print temps than other hard materials, even if opaque i thick wall will block any transparency.

It's also a good replacement for PETG, this is food safe

Re: Does someone want to know how fast they can print/extrude? look here

I ended up ordering through 3D Jake. Only ordered 800g it should be more than enough for my needs.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Martin,

So, just to confirm, your blower design will be able to deliver a lot more cooling (e.g. for quickly cooling big extrusions from a 1.2mm nozzle) and not, because of the extra baffling, only flawless benchies from a 0.4mm nozzle?

Re: Does someone want to know how fast they can print/extrude? look here

I wasn't getting results as good as tiago's with the 0.6mm nozzle, so I went on to try a copper 1.2mm nozzle, and, curiously enough, I'm getting a higher rate of volumetric extrusion from it. I can print 2.4mm extrusion width by 0.6mm layer height by 1000mm/mmin, which is much better than I was getting from the brass 0.6mm nozzle. Not sure as to why, but there it is.

I will say, though, that a 2.4mm wide wall feels nice and robust as well as very solid and strong. 🙂

Re: Does someone want to know how fast they can print/extrude? look here

I ended up ordering through 3D Jake. Only ordered 800g it should be more than enough for my needs.

Regards,

Martin

Please write a review of the filament with your thoughts when you test it.

I wasn't getting results as good as tiago's with the 0.6mm nozzle, so I went on to try a copper 1.2mm nozzle, and, curiously enough, I'm getting a higher rate of volumetric extrusion from it. I can print 2.4mm extrusion width by 0.6mm layer height by 1000mm/mmin, which is much better than I was getting from the brass 0.6mm nozzle. Not sure as to why, but there it is.

I will say, though, that a 2.4mm wide wall feels nice and robust as well as very solid and strong. 🙂

If you are using original volcano + originals nozzles theres no reason to get a much lower result than me. Check if you have tight the nozzle correctly.

I'm using normal volcano block + 0.6mm nozzle, all the rest is MK3 original, i used same heater, same thermistor. Accel values and feedrate are the defaults, on firmware side i only change max z. Max extrusion volume is defined by volcano+nozzle, but all nozzles are the same thread and height, so all nozzles have the same max volume.

You still are extruding less plastic than me (24mm/s^3), my values are: PLA = 28 | ABS = 30. If you are using PETG then your value is OK.

The more wide the extrusion is the more robust is.

With that nozzle you can try even more awesomeness, try 2.7mm extrusion width, 1mm layer height at 10mm/s. and show that beauty lines to us 😀

I think a dynamic nozzle would be perfect, where you can ajust the hole diameter 😀 Better if you can do that on fly by gcode 😀

They does not exist, but not impossible 😎

Re: Does someone want to know how fast they can print/extrude? look here

Please write a review of the filament with your thoughts when you test it.

Will do. Probably run a whole series of heat tests on it with one layer prints and raising bed temperatures just to find out how hot I can have the bed with the nozzle printed with it being used. (I'll have to print two nozzles one for destructive testing and one for use.)

You still are extruding less plastic than me (24mm/s^3), my values are: PLA = 28 | ABS = 30. If you are using PETG then your value is OK.

For comparison I am using the following volumetric limits at the moment PLA = 30mm³/s, PETG = 15mm³/s, HIPS = 22mm³/s. HIPS I have not yet run any speed tests with so it is at double the Prusa default and PETG I need to run a finer graduated test to do a finer dial in as each step in the speed test is 0.75mm x 0.3mm x 20mm/s x 50% = 2.25mm³/s

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Per Tiago's request, I tried doing a 2.7mm wide extrusion, but the surface didn't print well. Hard to describe really, but the layer lines looked more like rope than nice smooth lines. I think 2.4mm may be close to the maximum.

Martin's number for PETG volumetric limit is much closer to what I typically get than what Tiago is getting. That's partly why I was surprised I seemed to be able to extrude so much more and still get a good print with the 1.2mm nozzle, as I wasn't expecting that. It would seem like a nice bonus for using the 1.2mm nozzle. If you guys ever try it, I'd be curious if you get a similar increase.

Re: Does someone want to know how fast they can print/extrude? look here

Per Tiago's request, I tried doing a 2.7mm wide extrusion, but the surface didn't print well. Hard to describe really, but the layer lines looked more like rope than nice smooth lines. I think 2.4mm may be close to the maximum.

Martin's number for PETG volumetric limit is much closer to what I typically get than what Tiago is getting. That's partly why I was surprised I seemed to be able to extrude so much more and still get a good print with the 1.2mm nozzle, as I wasn't expecting that. It would seem like a nice bonus for using the 1.2mm nozzle. If you guys ever try it, I'd be curious if you get a similar increase.

With that kind of extrusion try to print only at 5mm/s. Your rope effect should be solved.

I not have tried max. PETG volume with my current config, but i can do a test latter and report the values, i guess it will hit same values as you.

For me 1.0-1.2mm nozzle not worth here, only with a super volcano and huge volumes. Because you have to print very slow, so if you use 0.6mm nozzle maxed or 0.8mm nozzle you can print same volume rate at a good print speed for the printer (40-60mm/s), which mean same completion time as bigger nozzles. They only worth if you really want the layer heights or with super volcano to print at 90mm/s^3

So 0.6mm seens ideal for multi purpose, or 0.8mm if you don't care about precision

Also be carefull, i test Slic3r filament volumetric speed limit and that don't work well, if you set it for 30 the real extrusion will be higher and stepper will skip, aways use manual speed values at print speed tab. The volumetric limit at print speed don't work well too, i guess they are calculating that based on filament density and other stuff. I don't know. So don't bump your speeds to 120mm/s for example and relly on limits and autospeeds

Re: Does someone want to know how fast they can print/extrude? look here

They only worth if you really want the layer heights or with super volcano to print at 90mm/s^3

That sounds totally worth it. Are the super volcano's already for sale? I don't care if I have to trade-off a few centimeters of build height to get it either.

Re: Does someone want to know how fast they can print/extrude? look here

They only worth if you really want the layer heights or with super volcano to print at 90mm/s^3

That sounds totally worth it. Are the super volcano's already for sale? I don't care if I have to trade-off a few centimeters of build height to get it either.

Not yet. Not a few centimeters... You will end up with +/-150mm Z based on what i see, i can't tell for sure how much.

That will worth for tall delta's, and huge printers like CR10S5 or big CORE XY. For a MK3 you have a big trade off

Re: Does someone want to know how fast they can print/extrude? look here

I could live with that.

Re: Does someone want to know how fast they can print/extrude? look here

I could live with that.

I see, you want mass production at home 😀

Re: Does someone want to know how fast they can print/extrude? look here

Absolutely. My son is a young teenager, and I can tell you: the longer he has to wait, the less interested he is in 3D printing. The same is true for me. Well, almost. I'm more willing to let it run in the background. 🙄