Re: Does someone want to know how fast they can print/extrude? look here

If you're not already, maybe putting a volcano sock on the hot end would help? Maybe it would be an easier problem to solve.

Re: Does someone want to know how fast they can print/extrude? look here

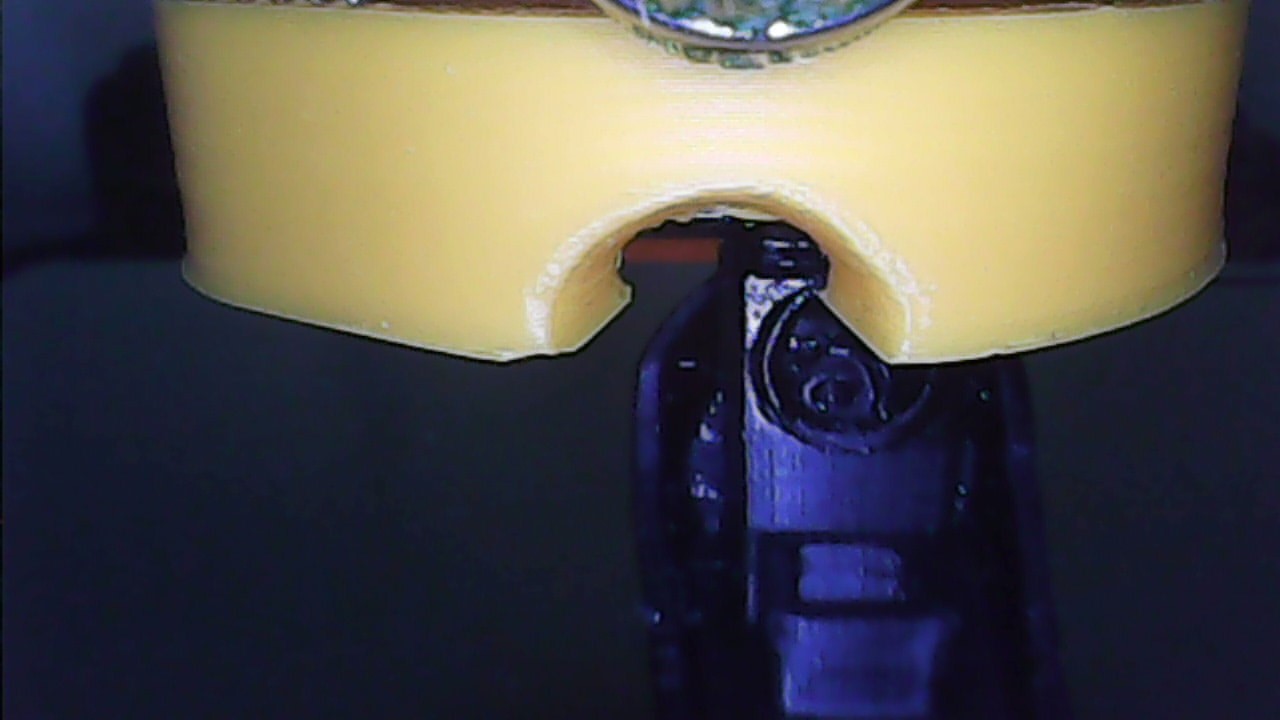

This is without a sock its the plated copper Volcano block and nozzle. The whole point of this design is even air flow all round with none hitting the block and nozzle. That is part of what makes it so hard to get correct but when properly dialled in should give superior results and it wont mater which way the part is facing (eg the Benchy needs to be placed with the bow pointing to the front of the heated bed with the default nozzle.)

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

As you are touching the noctua fan, can a grill/protector be also added? to protect and prevent air go down, as bonus it will offer more secure if you decide to use screws 😀

Maybe designs with and without cover for people who want raw

Re: Does someone want to know how fast they can print/extrude? look here

No nothing can be added to the noctua fan as it would restrict the X-axis.

With regards to the W7 iteration. Using slicer generated support material actually made it worse. I will have to use manual supports that will need cutting away or just rotate those curved fins.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Martin,

I guess you have reasons for encircling the hot-end rather than pushing the air from just one side, like the existing Prusa design. If it's giving you trouble, though, I wonder if the Prusa design, but just aimed more precisely, as you are already doing to avoid hitting the hot-end, might also accomplish what you want to do (improve the cooling efficiency)?

Re: Does someone want to know how fast they can print/extrude? look here

The encircling is to blow on the part from all directions so the orientation of the print wont matter. The existing Prusa design as no vertical aiming at al and not enough distance for the fins to aim properly in the horizontal plane. To get that aiming without doing a lot of fluid dynamics calculations in laminar flow I went with the plenum design so that no matter where it is along the fan side of the nozzle the air pressure is the same to give an even flow along the entier length. That is the reason my design is so bulky. I am very close to getting it correct. Probably would have been better to reduce the bypass rather than remove it. Still I have the design files for all my previous iterations so I can always do that but I like the elegance of my resistive path damper design.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Sounds great! I hadn't realized you were killing two birds with one stone. Thanks for all your efforts. 😀

On a different topic, the Mosquito hot-end engineers claim that there's "drop in resolution" going from the standard v6 to a volcano: https://shop.prusa3d.com/forum/user-mods-octoprint-enclosures-nozzles--f65/mosquito-hotend-extruder-for-mk3-t22886.html#p97642

Not quite sure what they are referring to, but maybe their white paper will say if/when they write it.

Re: Does someone want to know how fast they can print/extrude? look here

The 1.2mm extrusion width with 0.6mm nozzle looks awesome and trouble free 😀

Can go up 52mm/s (0.45mm layer height) with PLA which gives a good look and fell without sacrifice the part quality, print time reduce alot, since i print perimeters slower than infill and now i can use only 1 perimeter for my parts. From 9h print (Stock nozzle at 0.3mm layers) i go down to 1.30h (0.6mm nozzle/0.45mm layers/1.2mm extrusion width/volcano/28mm/s^3) that's a big win 😀

Re: Does someone want to know how fast they can print/extrude? look here

The W8 iteration is very close only small signs of under cooling.

As the fan is only hitting 2000 RPM approx at 100% the air resistance is still a little high. With no resistance the fan hits 4200 RPM so ideally I should be hitting 4000 RPM at 100%. The air resistance should be just high enough to barely impact fan speed at 100% to give precise control of the fan.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

The 1.2mm extrusion width with 0.6mm nozzle looks awesome and trouble free 😀

Can go up 52mm/s (0.45mm layer height) with PLA which gives a good look and fell without sacrifice the part quality, print time reduce alot, since i print perimeters slower than infill and now i can use only 1 perimeter for my parts. From 9h print (Stock nozzle at 0.3mm layers) i go down to 1.30h (0.6mm nozzle/0.45mm layers/1.2mm extrusion width/volcano/28mm/s^3) that's a big win 😀

A 6x reduction in print time? You've aroused my curiosity! What math and assumptions explains such a large of a reduction in print time?

Re: Does someone want to know how fast they can print/extrude? look here

The general recommendation I'm seeing is extrusion width <= 1.2*nozzle bore. Good on ya if it's working, but do some serious testing for strength & quality.

The 1.2mm extrusion width with 0.6mm nozzle looks awesome and trouble free 😀

I just got my settings to pass a 0.15mm clearance test, so I'm chasing other challenges. Good luck with it!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: Does someone want to know how fast they can print/extrude? look here

A 6x reduction in print time? You've aroused my curiosity! What math and assumptions explains such a large of a reduction in print time?

That's because i was comparing with stock settings, stock nozzle.

Now i'm using all that i said, beside i boost all speeds to max extrusion rates, inc. perimeters. And only 1 perimeter against 3 from stock. Much less infill.

That is of course for a simple enclosure, nothing serious, complex objects i would not print that big nor fast

The general recommendation I'm seeing is extrusion width <= 1.2*nozzle bore. Good on ya if it's working, but do some serious testing for strength & quality.

I just got my settings to pass a 0.15mm clearance test, so I'm chasing other challenges. Good luck with it!

I just finished my two ABS parts of the enclosure with the settings i said, and i can say the extrusion width is beautiful, first layer included, is all so perfect that i will keep using this for simple objects and to print fast.

About strength i can say is much more robust, delamination is way more hard.

About clearance it seens to respect the same widths i have defined, my enclosure have a 0.2mm tolerance to fit the walls inside a hole, they still fit the same like 0.4mm nozzle prints i have done before

I have took some pictures

The upper walls doesn't come good because lack of cooling and layer not cooldown when the new was applied as i print with ABS, but thats not a problem since that part fit in another and keep hidden from the view

My Maxed settings for 0.6mm nozzle at 0.45 layer height

So this nozzle is the best quality/speed for me. Is like run a 1mm nozzle, I can have the benefit of 1.2mm and maybe 1.3mm extrusion width up to a 0.45 layer height, which give us +/- 53mm/s max print speed, which is a good value for decent visual quality. This mean no need to go 1mm or 1.2mm nozzle as print completion time will be the same because you need to print a lot slower with larger nozzles. Also you can get detail with it, by set extrusion at 0.6mm or 0.7mm.

The 0.4mm nozzle can only go up 0.8-0.9mm extrusion and up 0.3mm height, that is 110mm/s max. So for me print x times more plastic at slower speed will always benefit, you will get more strength from layers, a better part quality because you print slower and the printer will thank you for not put much stress and wear fast due crazy speeds.

Also i found that i was running 0.35mm with for supports, because of copy and forget, i do some prints that require supports, and they are easy to remove by hand. So i was severe underextruding supports, i find that by mistake but i'm glad that work well and overaall supports don't look like missing extrusion, they look like a continuous line, i'm surprised

Re: Does someone want to know how fast they can print/extrude? look here

By the way, we were talking earlier about how E3D doesn't make a volcano nozzle at less than 0.4mm. Looking at Aliexpress, though, I notice there are quite a number of vendors that are selling 0.2mm, 0.25mm. and 0.3mm "volcano" nozzles. e.g.: https://www.aliexpress.com/item/10Pcs-3D-Printer-Volcano-Nozzle-0-2-1mm-For-1-75mm-3mm-High-Flow-Big-Caliber/32830847447.html?spm=2114.search0104.3.2.1d3f44bcV0D8LL&ws_ab_test=searchweb0_0,searchweb201602_2_10152_10151_10065_10344_10130_10068_10324_10547_10342_10325_10546_10343_10340_10548_10341_10545_10696_10084_10083_10618_10307_10846_10059_100031_10103_10624_10623_10622_10621_10620,searchweb201603_16,ppcSwitch_7&algo_expid=61f57a9a-5b41-4a23-ad39-db4528d2008c-0&algo_pvid=61f57a9a-5b41-4a23-ad39-db4528d2008c&priceBeautifyAB=0

The price is just incredibly low compared to E3D. It really has me wondering what the quality is like. Anyone here tried one?

Re: Does someone want to know how fast they can print/extrude? look here

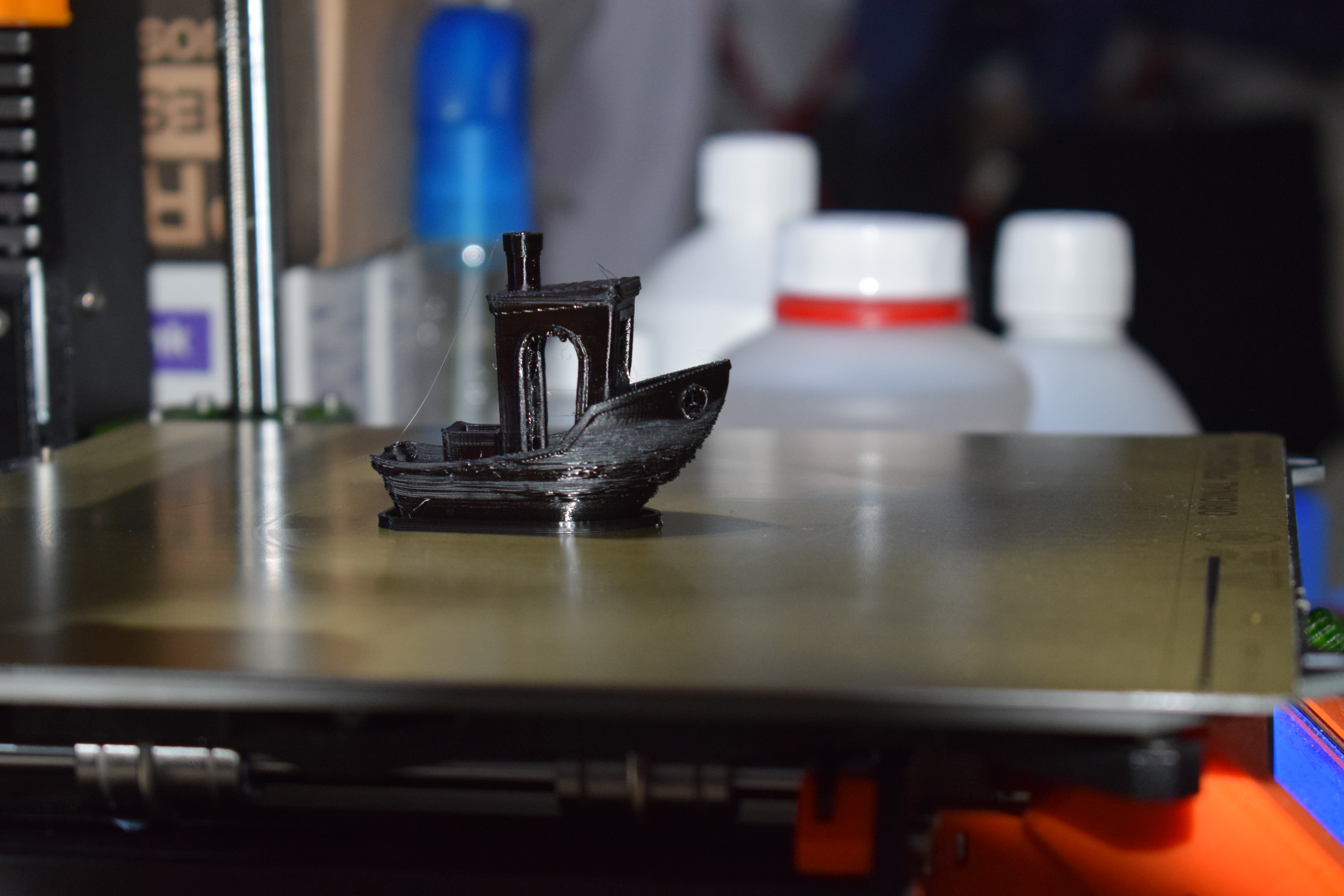

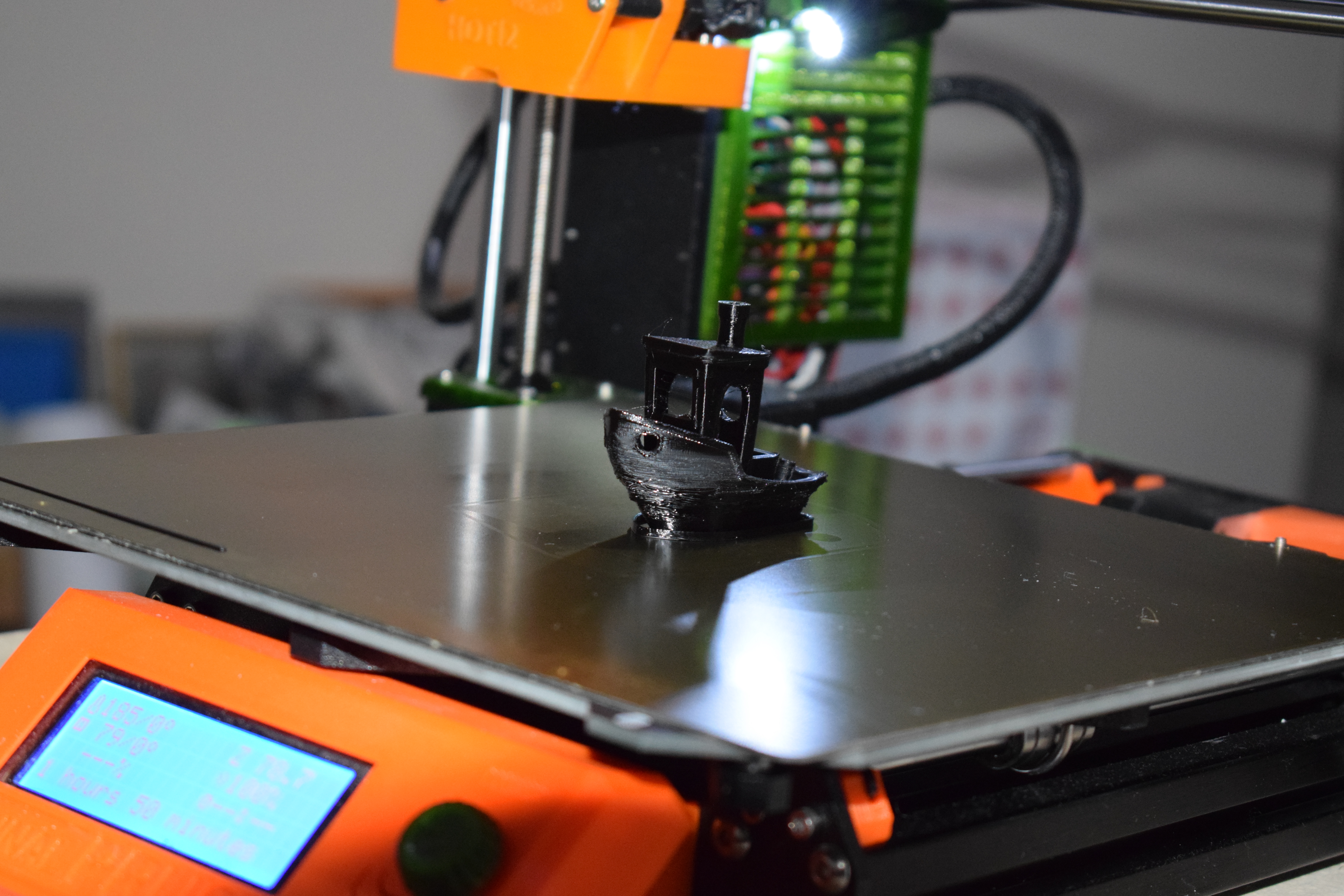

Thought I would do something slightly different to show the W9 iteration.

Here is the test Benchy mid print. It is still showing signs of slight under cooling but is very close to the target quality.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

By the way, we were talking earlier about how E3D doesn't make a volcano nozzle at less than 0.4mm. Looking at Aliexpress, though, I notice there are quite a number of vendors that are selling 0.2mm, 0.25mm. and 0.3mm "volcano" nozzles. e.g.: https://www.aliexpress.com/item/10Pcs-3D-Printer-Volcano-Nozzle-0-2-1mm-For-1-75mm-3mm-High-Flow-Big-Caliber/32830847447.html?spm=2114.search0104.3.2.1d3f44bcV0D8LL&ws_ab_test=searchweb0_0,searchweb201602_2_10152_10151_10065_10344_10130_10068_10324_10547_10342_10325_10546_10343_10340_10548_10341_10545_10696_10084_10083_10618_10307_10846_10059_100031_10103_10624_10623_10622_10621_10620,searchweb201603_16,ppcSwitch_7&algo_expid=61f57a9a-5b41-4a23-ad39-db4528d2008c-0&algo_pvid=61f57a9a-5b41-4a23-ad39-db4528d2008c&priceBeautifyAB=0

The price is just incredibly low compared to E3D. It really has me wondering what the quality is like. Anyone here tried one?

You can try them, without so you will never know... The nozzle looks a bit different from original, i guess they will not perform the same. For them fabricate brass nozzles are very cheap but the details make the difference.

https://www.aliexpress.com/item/trianglelab-Top-quality-V6-volcano-Nozzle-for-3D-printers-hotend-5pcs-lot-volcano-upgrade-kit-for/32839344108.html

That seller sells high quality nozzles and looks like the originals, but don't have the size you are asking

Re: Does someone want to know how fast they can print/extrude? look here

The 1.2mm extrusion width with 0.6mm nozzle looks awesome and trouble free 😀

Can go up 52mm/s (0.45mm layer height) with PLA which gives a good look and fell without sacrifice the part quality, print time reduce alot, since i print perimeters slower than infill and now i can use only 1 perimeter for my parts. From 9h print (Stock nozzle at 0.3mm layers) i go down to 1.30h (0.6mm nozzle/0.45mm layers/1.2mm extrusion width/volcano/28mm/s^3) that's a big win 😀

I'm still not so sure. I'd love to be convinced, but I think you end up with the same volume of extruded plastic in the same amount of time, and the only difference is what shape it's in. You may be right that for your particular application, a 0.6mm nozzle is optimal (at least no plastic is wasted by a 0.4mm nozzle with double walls wider than what you want), but in the general case.... I can't quite wrap my head around why it would be better. Is it obvious to everyone but me? The flip side is that 0.4mm offers better resolution that a 0.6mm can't match, whenever you happen to need it. That's why, on balance, I still lean toward 0.4mm nozzle as the most general purpose. Am I wrong?

Re: Does someone want to know how fast they can print/extrude? look here

I'm still not so sure. I'd love to be convinced, but I think you end up with the same volume of extruded plastic in the same amount of time, and the only difference is what shape it's in. You may be right that for your particular application, a 0.6mm nozzle is optimal (at least no plastic is wasted by a 0.4mm nozzle with double walls wider than what you want), but in the general case.... I can't quite wrap my head around why it would be better. Is it obvious to everyone but me? The flip side is that 0.4mm offers better resolution that a 0.6mm can't match, whenever you happen to need it. That's why, on balance, I still lean toward 0.4mm nozzle as the most general purpose. Am I wrong?

I'm not here tring to convince people to change to 0.6mm, i'm just sharing my experience.

Nothing better than try yourself to see if worth or not to you. For me it worth, i never feel the need of the precision from a 0.4mm nozzle and i like print higher layer heights, my point is print slower but with thicker extrusion. the max volume is the same as anyother volcano v6 nozzle, the point is i can print a bit slower which ends to: Save your 3d printer from fast wear, better part quality due lower speeds, stronger layer, fast results.

Example:

Let's say you are with 0.4mm nozzle, 0.3mm layer height, 0.5 extrusion width, to hit the max. extrusion rate you have to run it at 200mm/s. I don't know about you, but i don't like to print that fast, that speed will wear your printer so fast if you run it all day, also i don't like to print the perimeters so fast, i like to keep recommended speeds or up to 60 max. for a good quality and precision.

Even if you boost your extrusion to 0.8mm you need to run at 125mm/s to hit the max volume, that's still a high speed

Now imagine your run 0.6mm nozzle, 0.45 layer height, 0.7 extrusion width, with that you can print at 95mm/s, half the 0.4mm nozzle but with same extrusion rate (30mm/s^3). And that is my point, extrude the max plastic i can but with lower speeds so i can run the max speed everywhere (infill, perimeters, top layers)

Still 95mm/s seens high to me for perimeters, so again i increased the extrusion width to 1.2mm, so i can run at 52mm/s everywhere with the same quality no matter if infill or perimeters. As bonus 1 perimeter at 1.2mm is the same as 2 perimeters with 0.4mm nozzle, so you only need to print one which is a huge time saver for large prints or perimeters everywhere parts. Note that one perimeter is much more stronger than two bonded perimeters at same width

It also give you the freedoom to put like: first layer 0.65m, top layer 0.6mm, infill: 0.7mm, solid infill: 1.2mm, you you will get optimal bottom and top layers and solid infill go thick width for time spare, eyes only see first and top layers so... And infill set to 0.6 or 0.7mm to spare plastic.

PS: The precision you lost with a 0.6mm nozzle compared to 0.4mm nozzle is only 0.2mm horizontal. Vertical precision can be the same (Layer Height) and up to 0.45mm

That's my point 🙂

You can simulate all this on slic3r, no need to change nozzle, see advanced details and compare with two instances of slic3r.

My enclosure: https://www.thingiverse.com/thing:2847365

Stand: https://www.thingiverse.com/thing:2881417

Re: Does someone want to know how fast they can print/extrude? look here

From the bit of reading I've done, some of the clone nozzles work just fine with PLA, but may encounter problems either printing at higher temperatures, or switching between temperature ranges. I saw one example where the nozzle sheared off in the heat block after printing at high temps. I use the cheap brass nozzles to experiment with, then buy an E3D version for "serious" prints.

[...] You can try them, without so you will never know... The nozzle looks a bit different from original, i guess they will not perform the same. For them fabricate brass nozzles are very cheap but the details make the difference.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: Does someone want to know how fast they can print/extrude? look here

I think this is one of those things that don't matter until it matters. If you're never printing fine detail, 0.60mm works very well. If you can get by with fewer perimeters, 0.60mm even at lower linear speeds may finish printing faster. If you're doing vase mode, there won't be a difference in speed, although 0.60mm will be thicker. If you want fine detail, even a 0.40mm may be too coarse.

[...] PS: The precision you lost with a 0.6mm nozzle compared to 0.4mm nozzle is only 0.2mm horizontal. Vertical precision can be the same (Layer Height) and up to 0.45mm

I've tried a range, and really like printing with a 0.60mm nozzle. Lines look very sexy going down, and speeds can be markedly faster, depending on print specifics. At the same layer heights, the prints look the same as those printed with smaller nozzles. For large things like support arms & stands, it's great. I ordered a hardened steel version for carbon fiber prints that I really like. I've also ordered a 0.25mm from E3D for fine detail prints. I'm normally not patient enough for that sort of work, but it's nice knowing I can.

I'm still experimenting, and have yet to spend time with 0.30 and 0.50mm nozzles. They may be a more satisfying middle ground. Part of me wonders what the conspiracy is against 0.70mm nozzles. What are they hiding?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: Does someone want to know how fast they can print/extrude? look here

Still 95mm/s seens high to me for perimeters, so again i increased the extrusion width to 1.2mm, so i can run at 52mm/s everywhere with the same quality

OK, I tried PETG with a 0.6mm nozzle. I get a good print quality at 0.45mm layer height, 1.2mm extrusion width, and 17mm/sec speed, but print quality starts to visibly degrade at 25mm/sec.

So, I really just don't know how you're getting that kind of speed. Maybe a copper nozzle would be better, but I doubt that much better.

I can see the allure of the thicker walls though. Maybe with Martin's better cooling fan I'll try the 1.2mm nozzle again for project enclosures.