Re: Does someone want to know how fast they can print/extrude? look here

Interesting. Not even that expensive.

[...] Hmm.... Here's one that claims it can print at up to 400mm/sec: https://www.imakr.com/us/en/all-filaments/779-fiber-force-high-speed-pla-filament.html

if only it were on amazon. Shipping is $15, making it $50 for one roll. I think I'll stick with PETG, which I like better anyway. Is there even any reason to print in PLA, aside from it being generally cheaper? PETG has practically no smell, isn't brittle, won't biodegrade on you or dissolve in water, isn't as temperature sensitive, and, at least for me, it seems to print a whole lot faster than regular PLA.

I mean, PLA is stronger, but how often is that really a deciding issue?

Re: Does someone want to know how fast they can print/extrude? look here

Interesting. Not even that expensive.

[...] Hmm.... Here's one that claims it can print at up to 400mm/sec: https://www.imakr.com/us/en/all-filaments/779-fiber-force-high-speed-pla-filament.html

if only it were on amazon. Shipping is $15, making it $50 for one roll. I think I'll stick with PETG, which I like better anyway. Is there even any reason to print in PLA, aside from it being generally cheaper?

Re: Does someone want to know how fast they can print/extrude? look here

From my experience so far, things like bridging and overhangs are tougher to master with PETG. You don't want too much cooling to promote good layer adhesion, but it tends to sag if not supported. Supports can also be a bit trickier to keep them easy to remove. PETG doesn't lend itself to post-processing such as sanding or painting. If those things aren't critical, it seems like the better material. I'm looking at PETG or perhaps NGEN as my "real" filament for anything but test or ornamental prints. For the ornamental stuff, I tend to use filled PLAs, so speeds aren't a critical factor.

[...] Is there even any reason to print in PLA, aside from it being generally cheaper? PETG has practically no smell, isn't brittle, won't biodegrade on you or dissolve in water, isn't as temperature sensitive, and, at least for me, it seems to print a whole lot faster than regular PLA.

I mean, PLA is stronger, but how often is that really a deciding issue?

Even "stronger" is a tough term to define. PLA is brittle where PETG will bend. PLA is miserable in anything warmer than summer sun, whereas PETG tends to be OK (still testing a car parked in sunlight). Unless you're after looks, PETG is probably a better choice.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Does someone want to know how fast they can print/extrude? look here

PLA is easy to print, cheap, good look and fell. Great for decoration or toys that don't need extra care.

Today PETG is become cheap, at almost the price of PLA, for who have good machines like MK3 theres not a excuse and PLA can be replaced by PETG, still some users will enconter problems and switch to PLA.

When i need something stronger i print in ABS, ABS is cheap so i most use only ABS -> PLA -> PETG

Re: Does someone want to know how fast they can print/extrude? look here

How do NGEN and ABS compare to PETG in terms of print speed? I haven't tried either one.

Re: Does someone want to know how fast they can print/extrude? look here

How do NGEN and ABS compare to PETG in terms of print speed? I haven't tried either one.

ABS you can print very fast but you need to be sure last layer is solified before apply a new one. A big square have no problem but small parts you cant print very fast. It need auto colling for dynamic parts. Print ABS without rules will end in a big mess.

For example if you print a triangle 100x100, you can go crazy fast at base, but as height get higher you need to slow down or else you will end with a round mess top detail instead of sharp angles. And it will also triger lot of crash detection because ABS will warp and get off from safe zone, will hit the nozzle. (This is valid for PLA and PETG, but ABS is more critical)

NGEN worth if you can get the 2KG from Prusa, very cheap for what is, still i have not tested with NGEN.

I think the speeds we are hiting are already good for a slow mechanical printer, we can go even faster but for what and what at cost? Even simple objects will not look so good when we go crazy fast, for me the high speeds are only good for hidden volume like infill.

Better than go crazy fast, wear print at high speed and get bad looking parts is print multiple objects at same time, this is of course for production, so two printers will always be better than one printer at high speed.

EDIT: There are single printers with two independent hotends, can print copies at once

Re: Does someone want to know how fast they can print/extrude? look here

Say, that 2KG Prusa orange NGEN does look like a good deal, even if I do have to spend $25 getting it delivered by DHL.

https://shop.prusa3d.com/en/filament/284-ngen-prusa-orange-2kg.html

Thanks for the tip! Prusa's 2kg version is somehow cheaper than the 750g version from everywhere else.

Hmm... That motivated me enough that I went ahead and ordered some clear colorfab NGEN from amazon. I'll test it for speed after it arrives later today. Maybe I'll use PETG as my cheaper workhorse and NGEN for the difficult cases.

Re: Does someone want to know how fast they can print/extrude? look here

Say, that 2KG Prusa orange NGEN does look like a good deal, even if I do have to spend $25 getting it delivered by DHL.

https://shop.prusa3d.com/en/filament/284-ngen-prusa-orange-2kg.html

Thanks for the tip! Prusa's 2kg version is somehow cheaper than the 750g version from everywhere else.

Hmm... That motivated me enough that I went ahead and ordered some clear colorfab NGEN from amazon. I'll test it for speed after it arrives later today. Maybe I'll use PETG as my cheaper workhorse and NGEN for the difficult cases.

To me Shipping is like 8 EUR, so it worth alot.

Note that NGEN on amazon will be much more expensive, don't know how prusa got that price to public

Re: Does someone want to know how fast they can print/extrude? look here

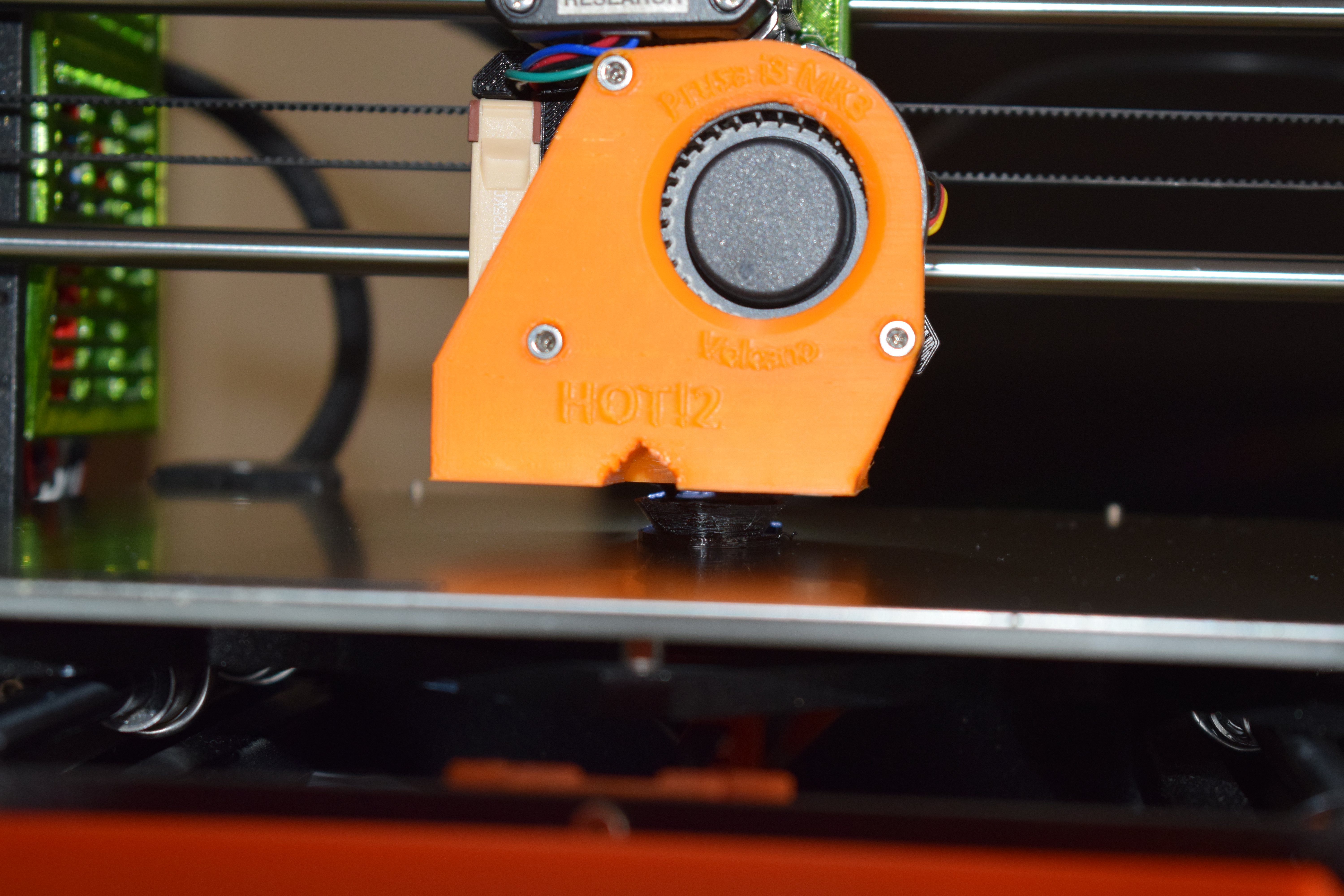

I have been using HIPS as a substitute for ABS for the print fan nozzle. This is to match ABS thermal properties more than anything else while avoiding the smell and toxicity problems. However I have noted a major difference between the two reals HIPS I have.

One the natural Rigid Ink HIPS has a decent strength to it.

The second a reel of orange 3DP Filament HIPS seems to have breakaway properties and poor surface finish. This is not good as I brought the orange specifically to print final parts. Why add colour to something that is only good as a soluble support material?

I have just referred to the Rigid Ink print settings and it says no fan. I wonder if 3DP print quality will improve if I use no fan on that rather than the Prusa 20% fan default.

I am going to re-print that nozzle in natural colour Rigid Ink HIPS once I have finished my PETG Benchy cooling tests.

One thing I have made up some HIPS juice using Limonene and the colourless Rigid Ink HIPS. No problems with bed adhesion or warping without an enclosure at 26°C ambient. I think the HIPS juice would also work for ABS and the advantage being any staining of the bottom of the print from the HIPS can be removed with a wipe over of Limonene.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

FWIW, more than other filaments, there does seem to be some concern over styrene: https://pubs.acs.org/doi/pdf/10.1021/acs.est.5b04983

You can save time by short-cutting to the conclusions towards the end.

I suppose in a perfect world, we'd be printing in enclosures that either exhaust to the outdoors or have some kind of gas/particulate filtering built in. I don't know about the rest of you, but I'm not there yet.

Even PETG is clearly giving off something, or else it wouldn't have been triggering my smoke alarm.

Aside from that, HIPS does sound pretty interesting.

Re: Does someone want to know how fast they can print/extrude? look here

Definite concern about HIPS although they only tested it on one printer emits around 50% of the styrene that ABS does on the same printer but when including the other particles is at around 70% of ABS so it is safer but not safe. Pretty much what I expected. Just tells me I will have to put a filter and fan on my enclosure when I have the basic thing finished to take care of it.

Well it is summer and a bit on the hot side here at the moment so I have my windows wide open so plenty of ventilation

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

That is a good price. Too bad I recently ordered 3DXTech's Prusa orange PETG. I don't need that much bright orange stuff!

[...] Note that NGEN on amazon will be much more expensive, don't know how prusa got that price to public

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Does someone want to know how fast they can print/extrude? look here

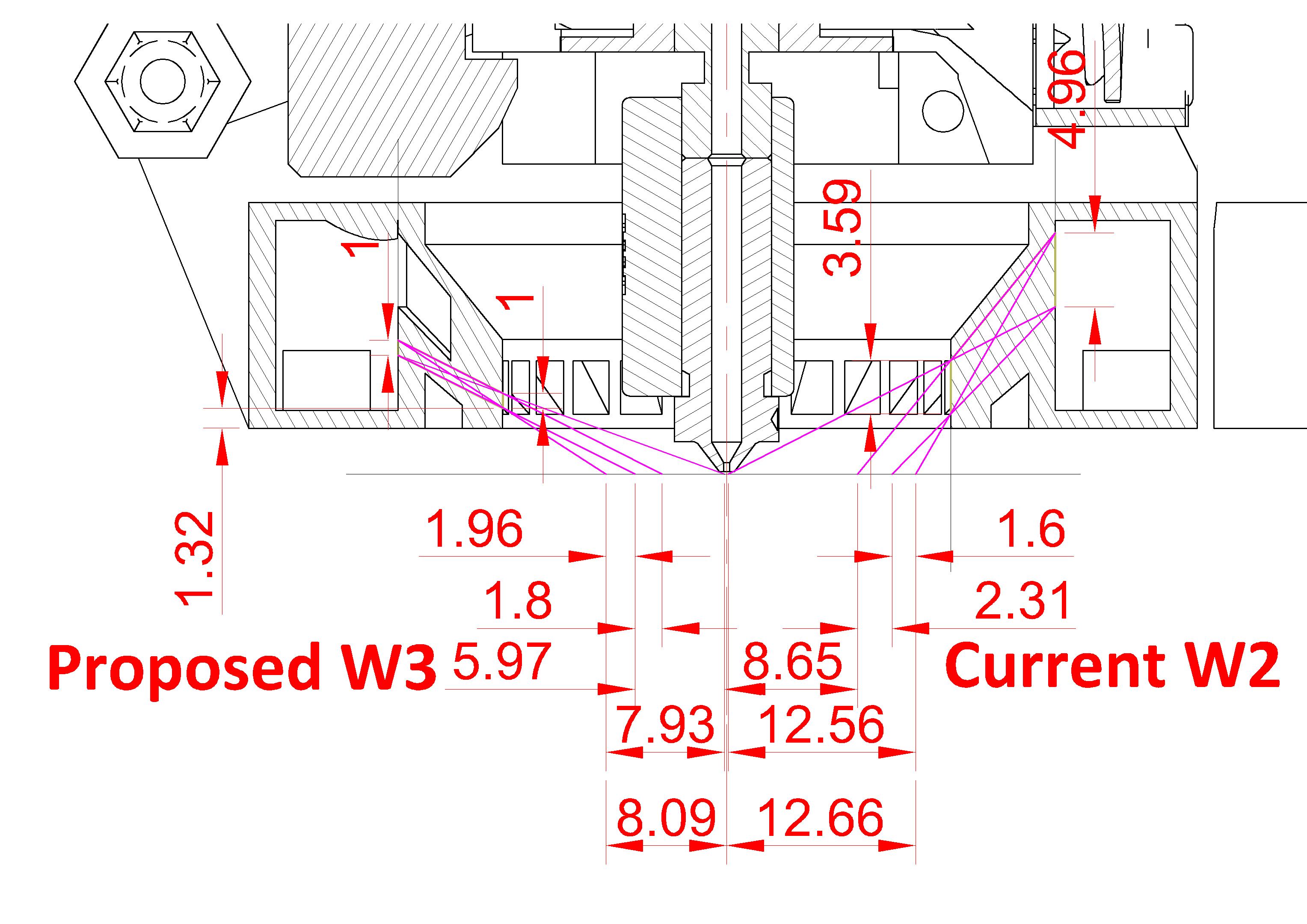

Well my dampers have made it a lot more controllable. Now I can see what I need to work on to refine the nozzle shape. Basically it seams that the W2 version of my nozzle spreads the cooling air over too larger area of the print. Still that is an easy fix now I can see what is going wrong. So perhaps one or two more iterations to perfect it. 🙂

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

😀

Re: Does someone want to know how fast they can print/extrude? look here

I received the NGEN and gave it the small cube test at speed=12000mm/min (=200mm/sec). I would say it printed about one notch lower in quality than the PETG I tested at that speed, but it was far superior to PLA at that speed.

In all fairness, ColorFab's recommended print speed for NGEN is 40-60mm/sec, and I'm quite clearly running faster than that: https://learn.colorfabb.com/how-to-print-with-ngen/

Also, like PLA, it's more brittle than PETG.

So, at least for now, PETG remains my all around "best" filament for high speed printing.

Re: Does someone want to know how fast they can print/extrude? look here

Someone (Chris Warcocki) recommended HTPLA for higher speeds. He mentioned more high-speed filaments are coming.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Does someone want to know how fast they can print/extrude? look here

I found a blog about printing at 300mm/sec: https://dyzedesign.com/2017/03/printing-at-300-mm-s-part-3-firmware-tests/

It has some interesting commentary regarding firmware settings and also offers up some speed tests.

Re: Does someone want to know how fast they can print/extrude? look here

Just an update on my Volcano print fan nozzle. In the end I decided to adjust the dampers rather than the nozzle shape when I moved to the W3 iteration. I decided that my proposal in my previous post would introduce to sharp a temperature gradient in the printed part however I will put it in my universal nozzle where the nozzle height has a greater constraint (8.5mm less height to work with.)

W3 Iteration

Now I am close to the final result I can see that I need to make the clearance for the heater block near the heater cartridge slightly larger as radiated heat is a problem. That damage was done during two prints. The first print was a PETG Benchy 220C/230C nozzle, 100C bed and 30% - 50% fan layer three onwards. The second print was the W4 iteration of the nozzle in HIPS, 220C/240C nozzle, 100C bed and 50% fan bridges only. The benchy came out with slight under cooling.

W4 Iteration

For this iteration I increased the rear heater block clearance, added a rear view channel (for camera use) and reduced the damping slightly. Also I made a couple of tweaks for better printing that have no effect on air flow and removed a few cubic cm of material from the print fan spacer that was not needed for strength.

All in all the W4 is looking good. The cooling is only slightly off. I will take a closer look when the Benchy has finished printing. Also I will look to see if the melting problem has been fixed. The camera view chanel is not quite good enough for the camera to see the nozzle so I will tweak that in W5 but it is good enough for a look at the nozzle while printing.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

That's a good article series. They touched on the effect on materials:

I found a blog about printing at 300mm/sec: https://dyzedesign.com/2017/03/printing-at-300-mm-s-part-3-firmware-tests/

It has some interesting commentary regarding firmware settings and also offers up some speed tests.

We are now able to print at 300 mm/s, which is quite impressive. However, the result shows a complete different texture from traditional 3D printing results.

This part really underscored my main concerns about focusing on high linear speeds:

15mm is quite long for a single edge. Remember that this distance is for accelerating only. The worst case, like a square edge, will require decelerating too, so the same length will be required. In short, we need to print a 30mm square if we want to reach 300 mm/s during a fraction of a second. In this case, the average speed will be about half of the max speed, so 150mm/s .

There are some interesting notes in part 2 about the need to fling about the print bed at higher speeds, so impact on print quality with all that physical movement is a concern.

Unfortunately, the promised Part 4 covering tests & analysis doesn't seem to have been written.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…