Does someone want to know how fast they can print/extrude? look here

Does somebody want to know how fast they can move/extrude with their current setup?

I have put together a gcode for testing the speed you can get on your MK3 with the possible extrusion rate of your hotend.

It requires:

- Prusa MK3 or MK3 clone

- 0.4mm nozzle

- PLA filament

It goes like this:

- 0.4mm nozzle

- 0.2mm layer height

- 1 perimeter, no top/bottom,infil

- 2mm brim for adhesion

- seam on back

- 50mm perimeter speed

- 230 degrees for PLA (with max fan setting)

- Layer change script for every 5mm in height.

- Linear Advance: OFF

Print object:

100x100x100 rounded test cube

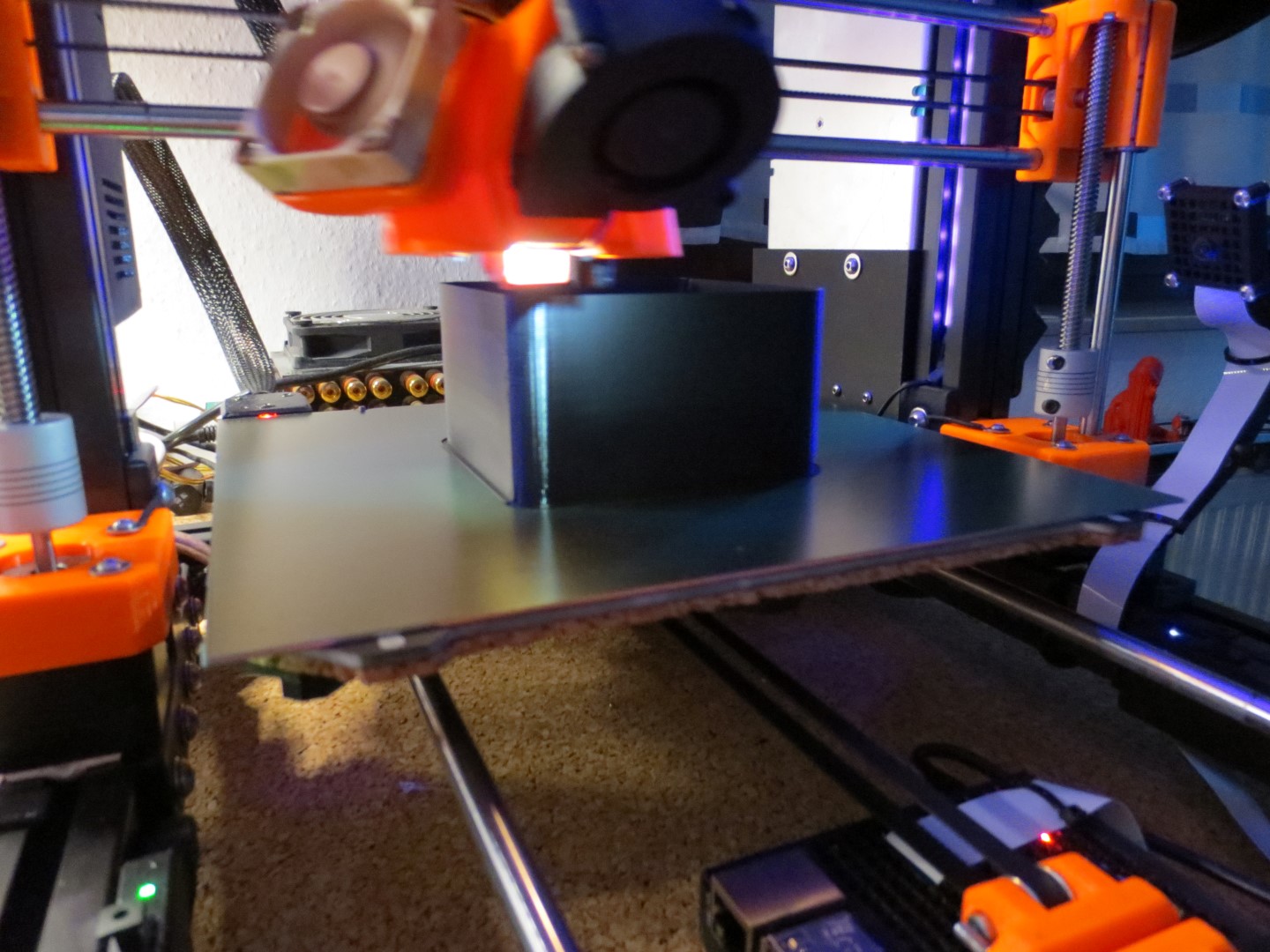

looks like this

; gotta go fast

{if layer_z > 5 and layer_z < 6}M220 S150{endif}

{if layer_z > 10 and layer_z < 11}M220 S200{endif}

{if layer_z > 15 and layer_z < 16}M220 S250{endif}

...

and so on

What this does:

It changes the feed rate from 100% (50mm/sec) to 150% (75mm/sec) to 200% (100mm/sec) and so on for the print, meaning it will increase speed by 25mm/sec for every 5mm in printed layers

You should notice the following things:

- the motor speeds should sound different for every 5mm in layer height; the faster you go, the higher the whining of the motors.

If the motors don't sound different at the next 5mm in height, you are acceleration and feedrate locked by your firmware. (currently 1000 and 100 in the firmware) This speed script will go up 10-fold if possible. Changing the acceleration and feedrate in the firmware will let you print faster - provided your hotend is up to it.

- the extrusion rate of your hotend and the nozzle size will limit how fast you can print. If the layer lines will start to have holes in them, cancel the print immediately, you are done here. You cannot print any faster than that.

I have holes at a feed rate of 600%, meaning 6 times x 50mm/sec, so 6x50 = 300mm/second possible print speed, but more like 250mm/s reliable print speed. (mainly because the temperature gets too cold to extrude, from the base 230 degrees, the faster it goes the less time the filament will get heated. layer lines look very cold at the top, will try to raise the temp on the next test.) Edit: nope, 250 degrees on PLA will not make it flow better.

My current setup for reference:

- E3D Volcano

- E3D 0.4mm Volcano Nozzle

- Prusa 40Watt heater @ 230 degrees

- custom built MK3s + custom firmware

- DasFilament black PLA

This gcode works on normal MK3's too.

Your Results will be:

100% speed OK = 50mm/s

150% speed OK = 75mm/s

200% speed OK = 100mm/s

250% speed OK = 125mm/s

300% speed OK = 150mm/s

350% speed OK = 175mm/s

400% speed OK = 200mm/s

450% speed OK = 225mm/s

500% speed OK = 250mm/s

550% speed OK = 275mm/s

600% speed OK = 300mm/s

650% speed OK = 325mm/s

700% speed OK = 350mm/s

750% speed OK = 375mm/s

800% speed OK = 400mm/s

850% speed OK = 425mm/s

900% speed OK = 450mm/s

950% speed OK = 475mm/s

999% speed OK = 499.9mm/s

Attachments:

speed test_cube_0.4mm.gcode <- Print this

speed_test_cube.stl <- don't print this, just how it will look like

Note:

- i can do this for a 0.6mm or a 0.8mm nozzle, too, if you post screenshots of your usual print settings

(Screenshots of: Layers & Perimeters, Speed, Advanced)

- i take no responsibility if your Printer explodes 😉 (j/k, stock MK3's are locked down speed wise in the firmware)

Again, the only way to check if you are actually going faster is to listen to the sound of the X/Y motors.

If it's not sounding different, you are locked speed wise in the firmware (I think stock MK3s are locked down to 200mm/s acceleration)

change in configuration_prusa.h

#define DEFAULT_MAX_ACCELERATION {4000, 4000, 200, 5000} // (mm/sec^2) max acceleration (M201)

#define DEFAULT_MAX_FEEDRATE {500, 500, 12, 120} // (mm/sec) max feedrate (M203)

Re: Does someone want to know how fast they can print/extrude? look here

adding a 0.8mm nozzle speed test gcode, as per the settings of david

Settings:

- 0.4mm layer height

- speed: reduced to 25mm/second (because of the much bigger nozzle)

- 0.96mm extrusion width.

- 0.8mm nozzle setting in Extruder 1

Speed Results for the 0.8mm Nozzle will be:

100% speed OK = 25mm/s

150% speed OK = 37.5mm/s

200% speed OK = 50mm/s

250% speed OK = 62.5mm/s

300% speed OK = 75mm/s

350% speed OK = 87.5mm/s

400% speed OK = 100mm/s

450% speed OK = 112.5mm/s

500% speed OK = 125mm/s

550% speed OK = 137.5mm/s

600% speed OK = 150mm/s

650% speed OK = 167.5mm/s

700% speed OK = 175mm/s

750% speed OK = 187.5mm/s

800% speed OK = 200mm/s

850% speed OK = 212.5mm/s

900% speed OK = 225mm/s

950% speed OK = 237.5mm/s

999% speed OK = 249.9mm/s

Be careful when testing this, i haven't tested it myself. (missing a 0.8mm nozzle for the volcano)

Re: Does someone want to know how fast they can print/extrude? look here

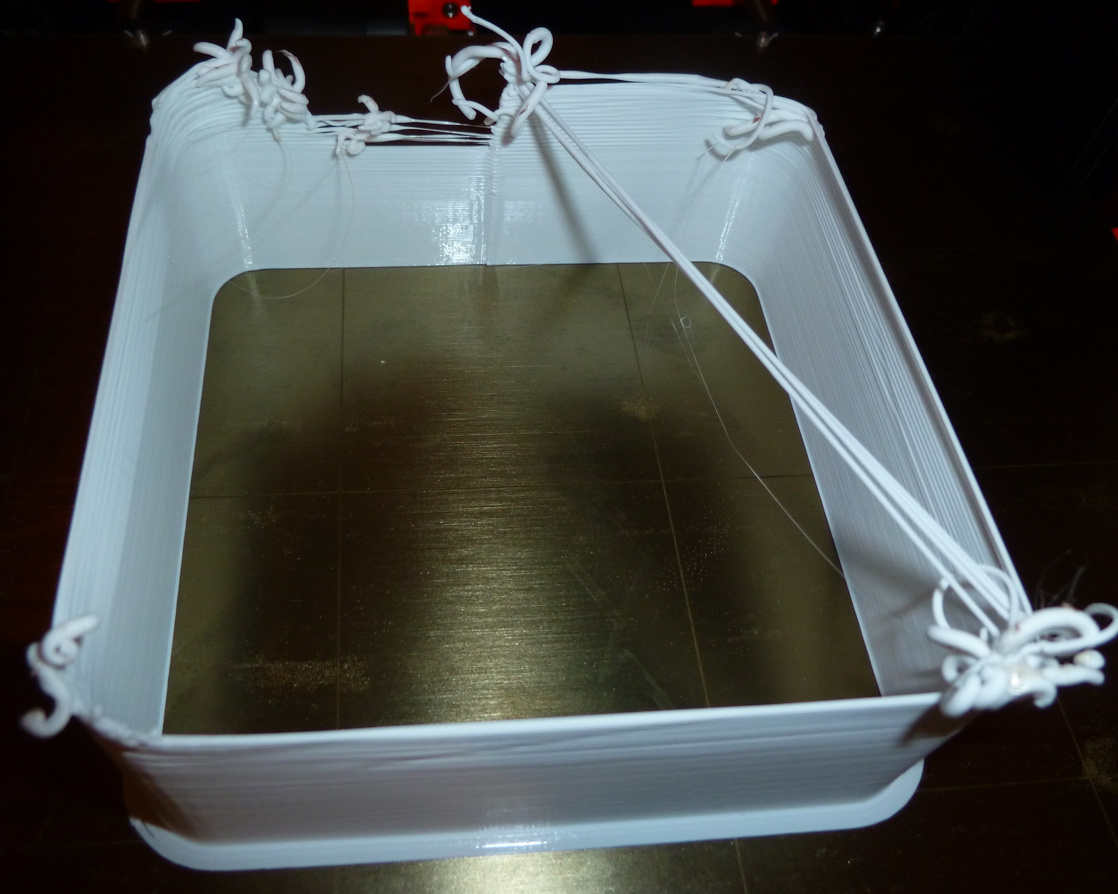

It needs a much wider brim and maybe a bedtemp of 90C too. It got only this far before it started to print on air, because, as you can see, it lifted from the print bed on two of the corners:

Part of the reason is that I only clean with windex now, because I want an easy release. I don't want to use IPA, not even once, on this new PEI surface. If it requires bigger brims, well, that's a trade-off that I'm willing to make, because I don't want to have to change the PEI sheet again anytime soon (and preferably never).

Re: Does someone want to know how fast they can print/extrude? look here

OK, I tried again, this time with a bed temperature of 90C. I think it may have stuck to the bed, though I'm not 100% sure . Anyhow, this time the first point of failure was the seam in the back where it bumps up the z-axis at the completion of each circumambulation.

Therefore, I recommend you switch to vase mode so as to avoid that untidy transition and, perhaps, stretch out the test a bit further.

That's as far as I can take it. I can't add more brims on my own, and I can't switch your code to vase mode either. The ball is in your court, DevilHunter. 😉

Re: Does someone want to know how fast they can print/extrude? look here

This is a nice test but don't you need to increase the temperature of the hotend when you increase speed? I'm thinking that you are really measuring the temperature limits of the speed you are trying to print at. That's why you are getting delamination at higher speeds.

Re: Does someone want to know how fast they can print/extrude? look here

This is a nice test but don't you need to increase the temperature of the hotend when you increase speed? I'm thinking that you are really measuring the temperature limits of the speed you are trying to print at. That's why you are getting delamination at higher speeds.

Well, in theory the PID would increase the amount of watts it supplies to the hotend in an attempt to maintain the same temperature. Whether it does a good job at that is a different question, but isn't that the objective? i.e. why prefer raising the temperature over just raising the watts?

But maybe you're right. There's less time in the hotend as speed increases. Maybe the hotend should get hotter at higher speeds so that the desired amount of joules gets into the filament?

Re: Does someone want to know how fast they can print/extrude? look here

I've written this into the opening post, that increasing the temperature of the hotend does absolutely nothing. Did a few tests on this, above 230 - 235 degrees for PLA nothing gives an improvement while printing faster. Even with the Volcano.

And currently no slicer increases the temperature when it has areas that print faster, PID will suffice for minor drops. Temp for printing fast at the start is up to the user.

Re: Does someone want to know how fast they can print/extrude? look here

If vase mode is too complicated, you might try putting the z-axis incrementation at one of the corners. Maybe it's less likely to break there than when going full speed in the middle of a wall and hitting the bump.

Re: Does someone want to know how fast they can print/extrude? look here

The residence time of the filament in the heat block will certainly make a difference in the temperature of the filament coming out the end of the nozzle as well as the ability of the extruder to push the filament through. The delamination of the top layers make this obvious. It may be that, given all the variables, that you can't achieve the required temperature to prevent delamination of PLA but it is obviously a temperature and adhesion issue.

Re: Does someone want to know how fast they can print/extrude? look here

OK, I tried again, this time with a bed temperature of 90C. I think it may have stuck to the bed, though I'm not 100% sure . Anyhow, this time the first point of failure was the seam in the back where it bumps up the z-axis at the completion of each circumambulation.

speedTest2.jpg

Therefore, I recommend you switch to vase mode so as to avoid that untidy transition and, perhaps, stretch out the test a bit further.

That's as far as I can take it. I can't add more brims on my own, and I can't switch your code to vase mode either. The ball is in your court, DevilHunter. 😉

So you are wiping with windex for PLA too...

That explains why you are cooking PLA on your bed.

Anyway, here you go

90 degree bed

30mm brim

optional vase mode

Re: Does someone want to know how fast they can print/extrude? look here

The residence time of the filament in the heat block will certainly make a difference in the temperature of the filament coming out the end of the nozzle as well as the ability of the extruder to push the filament through. The delamination of the top layers make this obvious. It may be that, given all the variables, that you can't achieve the required temperature to prevent delamination of PLA but it is obviously a temperature and adhesion issue.

How about you run an experiment and report back to us with the numbers? If you're correct, you should be able to prove it with just a regular hot-end, right? i.e. you wouldn't need a volcano per se to see a difference. Of course, if you have a volcano, then even better!

I'm remembering now that last week I did some cursory testing of my own, but (disappointingly) I didn't see improvement from raising the temperature, so I shifted my focus to other things. However, it was just very informal seat-of-the-pants testing, not anything rigorous. Nonetheless, with that as my only empirical reference, I suspect DevilHunter is right.

Re: Does someone want to know how fast they can print/extrude? look here

...Anyway, here you go

90 degree bed

30mm brim

optional vase mode

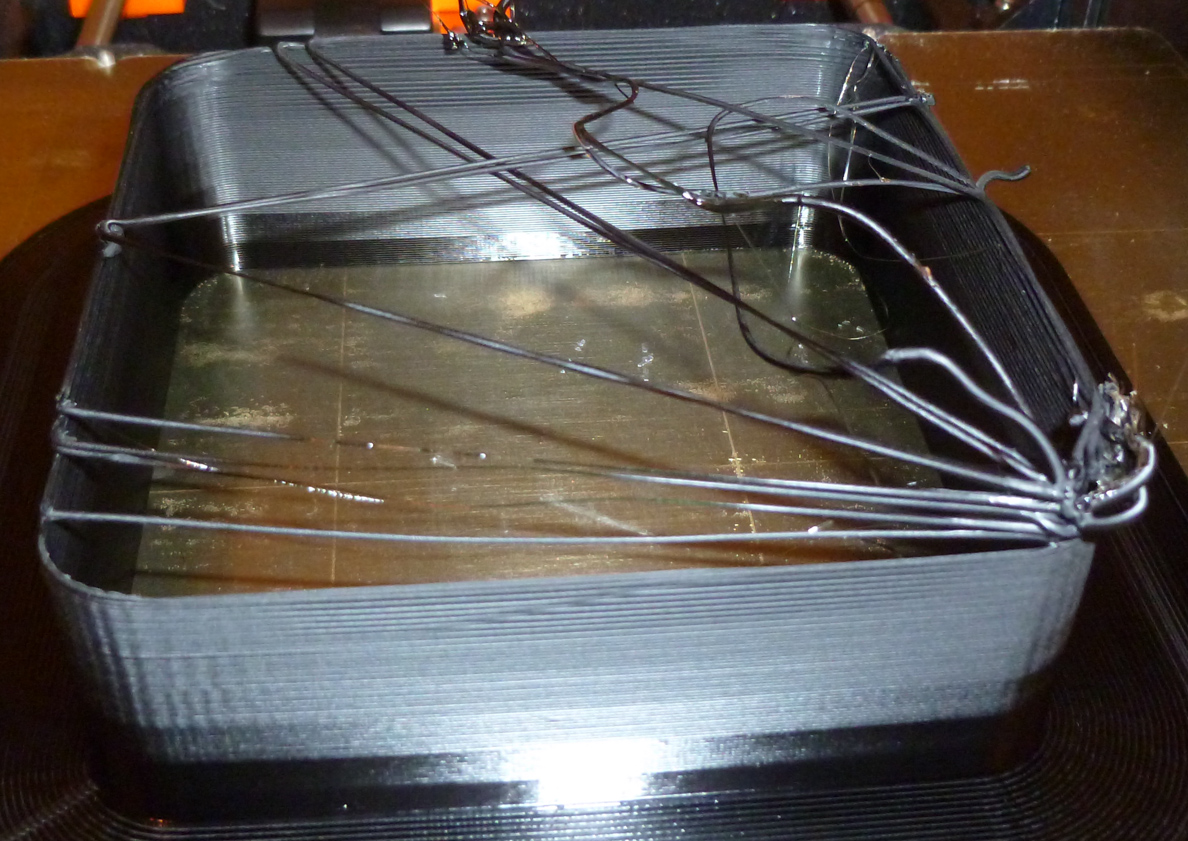

Thanks! Here is a wideshot of the result:

and here's a closeup:

It looks to me that the cause of failure was not a failure to extrude fast enough, but rather a failure of the the fresh extrusion layer to stick to the layer beneath it. That kinda makes sense. i.e. the layer beneath had already cooled enough that at the higher speed it doesn't re-melt enough to properly fuse with the fresh layer being laid down.

More than anything, this may be a reflection of the filament material being used. In this case, here's the filament that I'm using:

https://www.amazon.com/gp/product/B074DTRL53/ref=oh_aui_detailpage_o01_s00?ie=UTF8&psc=1

i.e. perhaps a different filament would handle the faster speeds better.

Aha, looking back at the OP, I see the glaringly obvious requirement that it requires PLA, not the PETG that I currently have loaded. And this most recent result explains why. Therefore, I presume DevilHunter used PLA in his test, and that is probably at least partly why DevilHunter was able to build to a higher height.

When I get a chance, I'll load PLA and have another go at it with that.

Re: Does someone want to know how fast they can print/extrude? look here

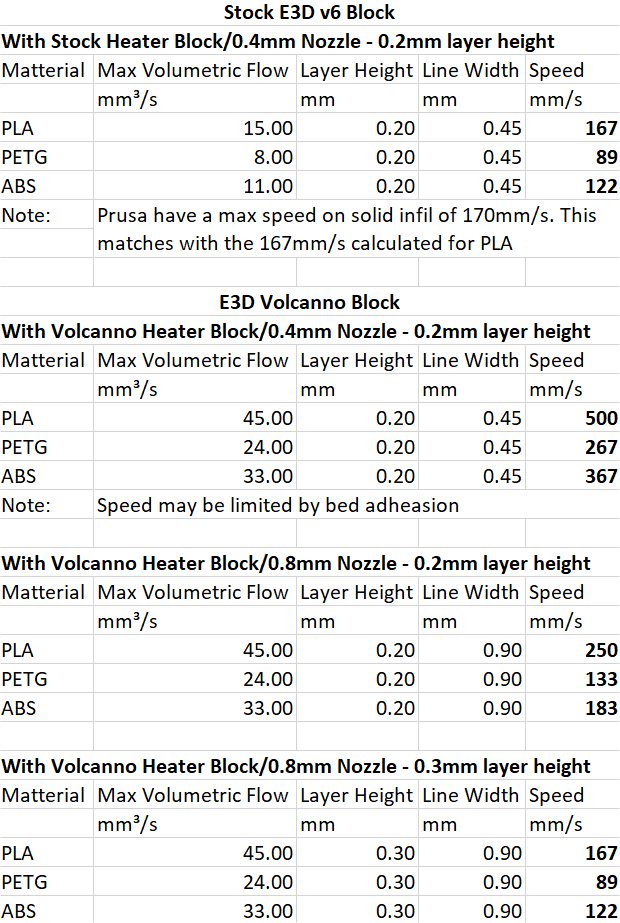

Just using calculation basing it on the max volumetric speeds Slic3r for the stock E3D v6 block and a 0.4mm nozzle assuming no delamination and bed adhesion problems the max prints speeds you can expect are:-

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Just using calculation basing it on the max volumetric speeds Slic3r for the stock E3D v6 block and a 0.4mm nozzle assuming no delamination and bed adhesion problems the max prints speeds you can expect are:-

Printing Speed Limits.jpg

Regards,

Martin

That ain't quite right.

V6 theoretical is 15mm3, but practical is 11,3mm3/s

Volcano is theoretical 35mm3, but practical is 30mm3/s

V6 with a 0.4mm Nozzle and 0.2mm layer height can handle up to 140mm/s reliable output, and the Volcano with the same nozzle and layer height can print 250mm/s

No further, even if you raise the temps. Granted, i'm using a pancake stepper with 13Nm of force, but the E3D Titan will up this to around 35Nm.

Normal stepper with 40Nm and 3:1 gearing will result over 100Nm of force, but a cold filament extrusion and no layer bonding.

Re: Does someone want to know how fast they can print/extrude? look here

The 15mm³/s and 170mm/s came straight from the default profiles in Sic3r 1.39.2 Prusa edition. I have had no problems running my preferred PLA+ at that speed. Admittedly I print it at 205/195 so that 15 degrees drop from the Prusa PLA temps may have had an impact.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

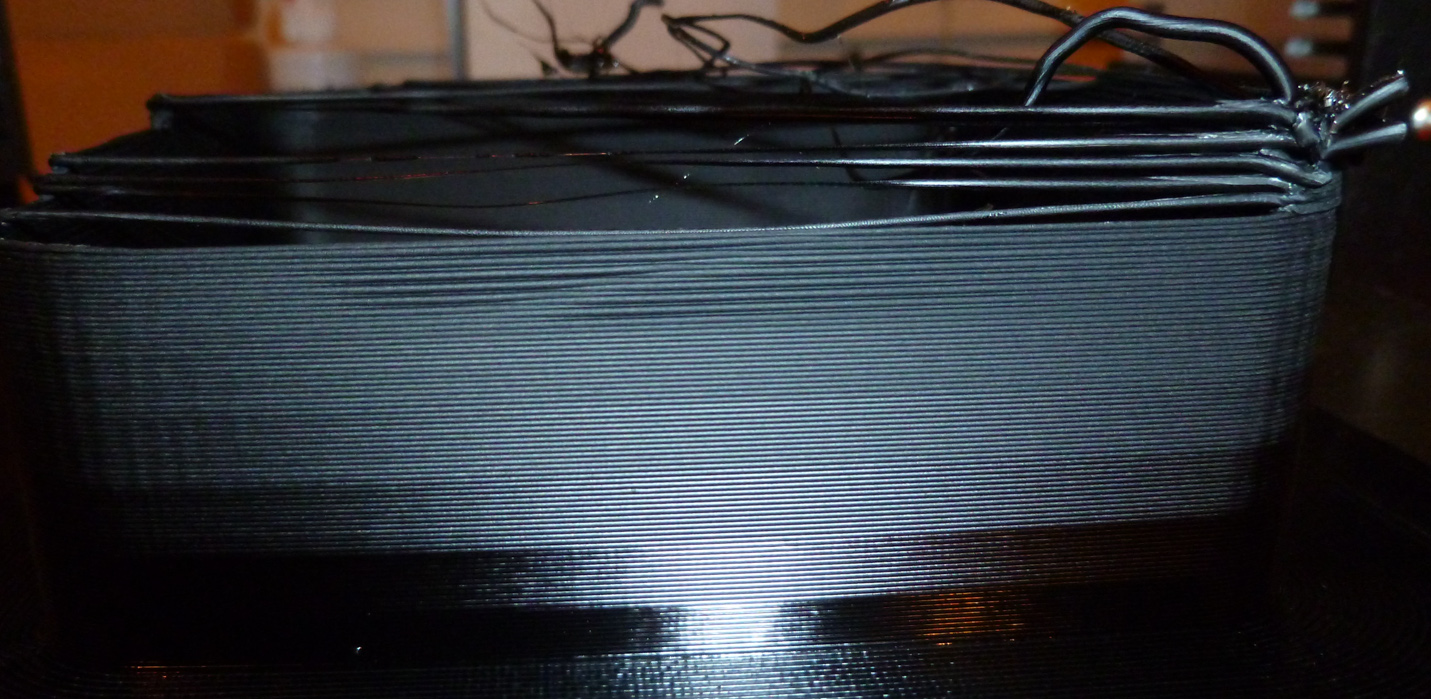

I just now redid the test using the Prusa PLA that came with the kit. I set bed temperature to 60C and hot-end temperature to 215C. Here is a wideshot of the result:

and here is a close-up:

Surprisingly, it failed even before the PETG did.

At least to my untrained eye, though, the cause of failure is the same: failure of new layers to adequately fuse with the layer beneath.

Anyone want me to run any further tests before I de-mount the Prusa PLA?

I'm tempted to conclude: to maximize volumetric extrusion, I should use an even bigger diameter nozzle, because so far it appears that travel speed is the enemy. i.e. print wider extrusions. Am I wrong?

Re: Does someone want to know how fast they can print/extrude? look here

I just now redid the test using the Prusa PLA that came with the kit. I set bed temperature to 60C and hot-end temperature to 215C. Here is a wideshot of the result:

pla1.jpg

and here is a close-up:

pla2.jpg

Surprisingly, it failed even before the PETG did.

At least to my untrained eye, though, the cause of failure is the same: failure of new layers to adequately fuse with the layer beneath.

Anyone want me to run any further tests before I de-mount the Prusa PLA?

I'm tempted to conclude: to maximize volumetric extrusion, I should use an even bigger diameter nozzle, because so far it appears that travel speed is the enemy. i.e. print wider extrusions. Am I wrong?

Your cooling is your enemy No. 1

Blast a desk fan onto the print, this should improve things.

Also looks like you can print about 125-150mm/sec with the 0,8mm nozzle at 0,4mm layer height. Getting close to what the Volcano block can handle

Re: Does someone want to know how fast they can print/extrude? look here

It certainly looks like the speed is not allowing the layers to bond so a wider nozzle would work. The reason why PETG would work at that speed is it is stickier and probably solidifying faster due to is higher print temperature.

You could just try lowering the acceleration while keeping the top speeds for PLA that way the ends/direction changes should bond before the print head has moved to far but still allowing full speed on long runs.

When I was tuning for PETG I found on the first layer that acceleration had more of an impact on bed adhesion than speed. This may be an indicator on the limits for a speed test on any material. So if the found acceleration is lower than the default value it should be applied to any MK3 no matter what heater block/nozzle is fitted and speed used.

Regards,

Martin

Martin Wolfe