Degreasing linear bearings

I picked up some Misumi bearings a while ago, but that aren't perfectly smooth and I wanted to degrease and regrease them. I know I have read you can use acetone, or iso to degrease, but I haven't been able to find if you have to worry about the rubber seals or how long to let them sit. This is specifically for acetone.

So, using acetone, assuming you put the whole linear bearing in it, how long should it stay before you pull it out (with a little stirring during the process). Then I'm assuming you have to leave them to dry for a while so the acetone doesn't clean out the new grease you just put on?

RE: Degreasing linear bearings

When I packed my Prusa supplied bearings (at my first PM teardown while applying the MK3S mod) I used 91% IPA. I let that sit for hours with the occasional stirring to try to flush the IPA through the internals of the bearings. I didn't see any degradation of any of the polymer parts (neither the internal carrier, nor the seals). I did try to let them sit out of the IPA to air dry before repacking.

I didn't use acetone so I can't answer that part of your question.

See my (limited) designs on:

Printables - https://www.printables.com/@Sembazuru

Thingiverse - https://www.thingiverse.com/Sembazuru/designs

RE: Degreasing linear bearings

Don't use acetone, it can damage some plastics, you are best off using IPA or even automotive degreaser such as GUNK followed by flushing with IPA. Grease sparingly but make sure the grease has worked round all the balls in recirculation, you do not want to pack the bearing so that the balls cannot move easily.

Some people say use superlube grease, some say use something thinner, some say use oil. Oil requires frequent application but results in the most free movement (possible ringing artifacts at high speeds though), greases will exhibit some drag, the thicker the grease, the more drag and the more chance of over packing the bearings resulting in the balls not being able to recirculate.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Degreasing linear bearings

If you go the Superlube route (I did), Thingiverse has a nice bearing grease injector and cap. It screws right on the Superlube tube.

RE: Degreasing linear bearings

Triple NO on the ACETONE for the bearing cleaning: it will destroy the rubber seals. Pretty sure I read Misumi's shipping oil is compatible with most greases, including lithium soap and synthetic, and doesn't need to be removed before packing.

RE: Degreasing linear bearings

Whichever grease you use, be sure to get something with decently low viscosity. Lots of the bearing greases are too viscous and not well suited for the low temp, low speed, low load use profile we have on those bearings. I have used SKF low temperature spindle grease - future will tell if it was a suitable choice...

RE: Degreasing linear bearings

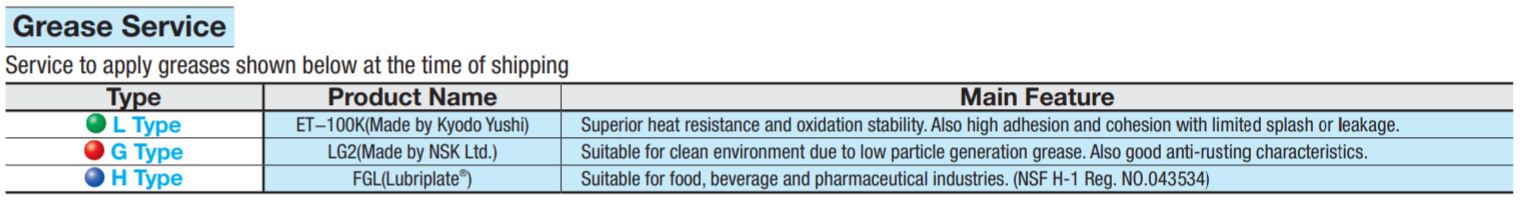

Grade #2 Lithium or Synthetic is what you use. It is what Misumi recommends for their linear bearings in this application.

RE: Degreasing linear bearings

Grade 2 includes a broad range of greases for very different applications (at least here in europe) and is a broad recommendation ranging from LHGB2 (high viscosity, high temperature -quite unusable for our loadcase) to LGMT2 general purpose automotive grease to LGLT2 (extreme low temperature low viscosity) products. All would qualify misumis recommendation and not all are well suited for the application.

“use grade 2 lithium based or synthetic“ is like advising someone to buy a car with four wheels...

That is not criticism on you tim - it is rather criticism that misumi did not really give useful recommendation.

RE: Degreasing linear bearings

https://www.machinerylubrication.com/Read/798/grease-selection

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Degreasing linear bearings

Sort of funny: the machinery article starts by saying NLGI #2 is way too generic; yet later in the article is says as long as the thickener or base oil adds up to the proper NLGI rating, it doesn't matter which formula is used.