Clogs in the hotend

Good day to all,

I've two Prusa MK3, one with a 0.4 nozzle and a 0.2 nozzle.

From some days the 0.2 is starting to act up strangely, the printer seem to clog randomly in the hotend, it load and unload filament but at a random point during the print the filament gets stuck. If I pause the print and unload and reload, it starts printing again.

At first I thought it was a nozzle problem, even if it's quite new, but then I found no clog in it, instead I found a bunch of PLA stuck before the nozzle (at the end of the cooling grid)

To be sure it wasn't a nozzle problem I switched nozzles on the printers and the other Prusa works flawlessy with the 0.2 nozzle

On the other hand the problematic Prusa seem to clog randomly with the 0.4 nozzle as well.

I even removed the hotend and unmounted it pieces by pieces but the only visible clog was the PLA at the beginning of the heating block, strangely enough that block didn't melt even at 290°, I had to pull it off with the smallest Allen key.

What could cause this clog? Even if I remove it, it comes back a few prints later

Re: Clogs in the hotend

Is the PTFE tube of the extruder seated all the way down into the extruder?

If not, there might be a gap encouraging formation of a plug

Re: Clogs in the hotend

as Guy says make sure the bottom of the PTFE tube is shaped as in this Prusa document

https://manual.prusa3d.com/Guide/How+to+trim+PTFE+tube+-+Original+Prusa+i3+printers/500?lang=en

If you print this it makes it much easier to shape them

https://www.thingiverse.com/thing:3121653

you may find this one does a better job on that bottom shape I use them both

https://www.thingiverse.com/thing:3070952/comments

and

https://www.thingiverse.com/thing:2212260

to Keep it in contact when it is properly shaped and in position

Re: Clogs in the hotend

Thanks for the reply and I'm really sorry for the really late answer but I really had caught up in a lot of personal and work things.

I opened the hotend and checked the PTFE tube but it looks still new (it has only a few months of life and is original) and in the right place

I made sure it was seated in the right place and mounted all back.

I made a 4 hours long print and it didn't clogged but the extrusion is uneven, especially on long lines.

It looks like that it heavily underextrude at random times, then he goes back to normal extrusion.

Really can't figure out the problem...

Re: Clogs in the hotend

if you could provide photos showing the problem perhaps someone else can take a crack at it. When I had clog problems early in my Mk3 externs they were linked to movement in the ptfe tube, hence my attempt to help, sorry it did not work out in your case.

Re: Clogs in the hotend

Here is the pic of two layers for the base of a statue

It looks like something slows down the flow as the printer has problems when it's extruding a long line at "high speed" (Original Prusa files for Simplify 3D that work perfectly with the other printer, same PLA)

As I said above I've compensate a little this problem by going 115% flow and slowing down the print, but it doesn't remove entirely the problem.

Once again, the other printer with the exact same speed and flow doesn't suffer any extrusion problem 😕

EDIT: All the basic check have been made, like the bed leveling, this problem continues at every layer, even the top layers

Re: Clogs in the hotend

Other than a restricted flow in the hot end (Try another hotend in it?) perhaps an intermittent problem with the heater cartridge... but the temperature excursions would be seen by control board and shut things down... or the the idler bond tech gear missing one of its caged roller bearings or its axel not evenly supported in both tabs on the idler door; and given two identical MK3 printers set up in exactly the same way running the same code file; my guess would be something in the electronics of the controller board.

what do the 24/7 support folks at Prusa's online chat system say?

Re: Clogs in the hotend

I would suggest to rebuild the complete hotend and make sure everything is clean. Because of your description " instead I found a bunch of PLA stuck before the nozzle (at the end of the cooling grid)" I assume your coupler is full of plastic.

In general following components could be an issue and need to be checked:

1. Filament can be easily feed in

2. Extruder motor is working as expected.

3. Bondtech gear is placed correctly and tied

4. Bondtech gears are under correct pressure and are able to feed the filament

5. PTFE tube position is correct

6. Coupler is clean and screwed tied

7. Nozzle is clean and screwed tied

Items 1-4 you can check before disassemble everything. For the last items I would recommend to rebuild it, because it's easier to cleanup things and reduces the risk of damaging the thermistor/heater wires.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Clogs in the hotend

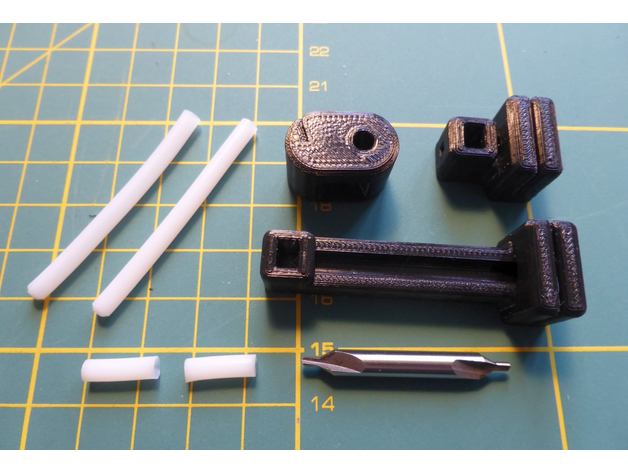

I had the time to disassemble the hotend.

I checked the extruder gear and it's firmly attacked to the extruder motor.

The heat sink is free (doesn't show well in the pic but it's perfectly clean) as well as the PTFE tube

The only PLA I found was in the coupler on the heatblock side, like last time the "blob" wouldn't come out until heated and pushed

Put I don't know if it's normal to find PLA there.

I don't have a pic of the nozzle but it isn't clogged.

Here are some additional photoes of the bad printing.

I'm mailing the support and I'll let you know the answer

Re: Clogs in the hotend

In general following components could be an issue and need to be checked:

1. Filament can be easily feed in - No troubles going in

2. Extruder motor is working as expected. - Tried a couple of spins and it does what is told

3. Bondtech gear is placed correctly and tied - Yup

4. Bondtech gears are under correct pressure and are able to feed the filament - Again ok!

5. PTFE tube position is correct - Looks so

6. Coupler is clean and screwed tied - Not clean!

7. Nozzle is clean and screwed tied - Yup

Re: Clogs in the hotend

Found out in the end that I had the same problem of this topic https://shop.prusa3d.com/forum/hardware-firmware-and-software-help-f64/prusa-needs-to-fix-the-bondtech-idler-shaft-t27979.html

Removed completely the extruder idler and found out it was bend