Clicking and "tension" on the filament and underxtrusion

Hi,

I'm getting some strange clicking and bad prints on my MK3.

It happens the most when the print head is moving fast in flat spaces so, to rule out a slicer problme, I printed the batman gcode file from the drivers package (2.1.4) that can be donwloaded from prusa's page.

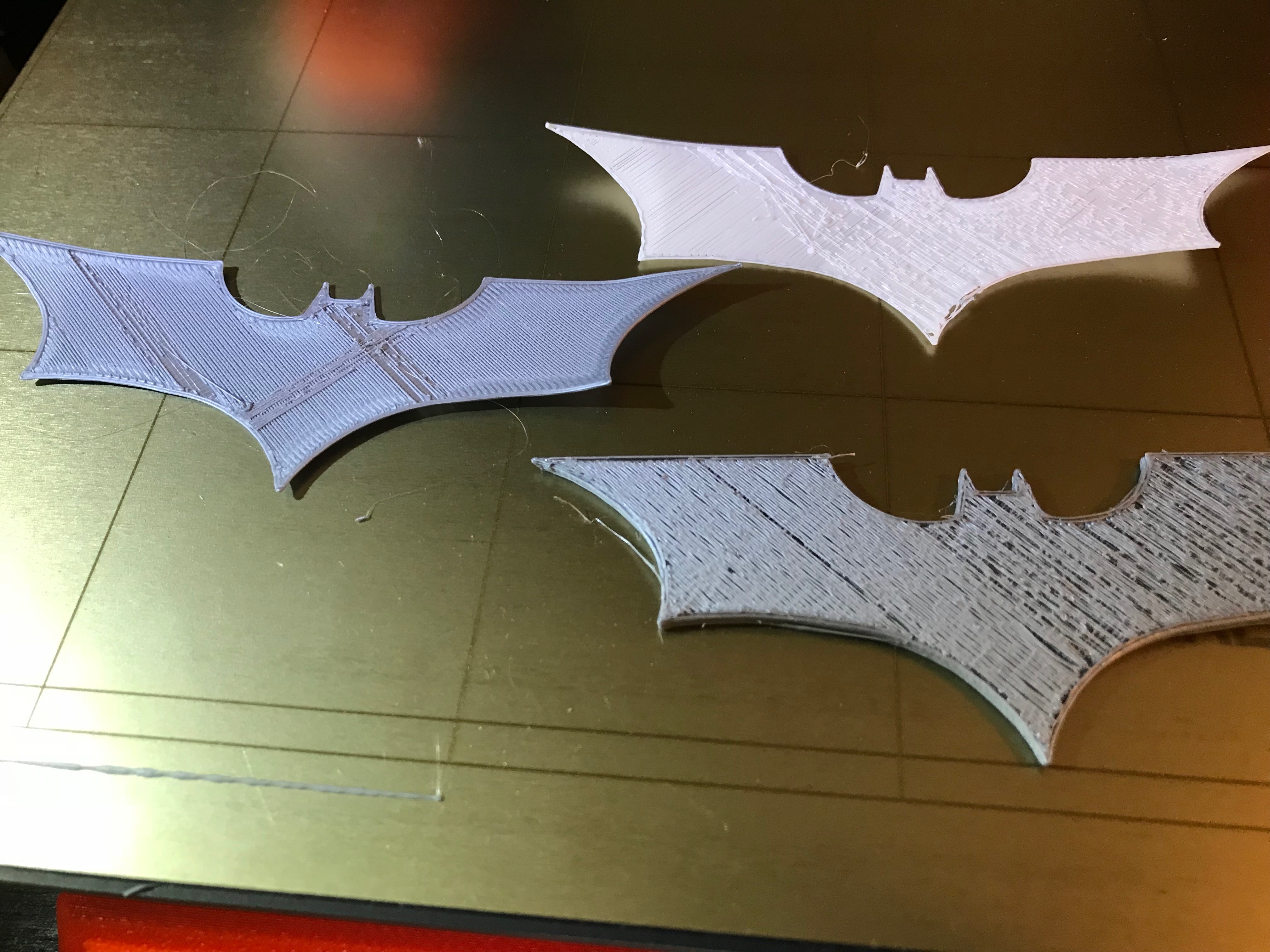

I stoped the print after 3 layers and it's noticeable that the first layer is ok (the head was moving slowly, no clicking) the second layer is very underextruded and the infill is not going to end up well.

The sounds are in sync with the head movement and if I gently place a finger on the filament that comes to the gears I can feel the clicking. Whatever it's causing the vibration is, at least, propagating through the filament.

The filament can unspool freely and I tried the same with a newly opened filament with the same results.

I don't know how to explain it better, maybe listening to the video is the best option:

I have a stock MK3 and I did have to disassemble and reassemble the heat block/extruder for a clog. Not sure if that affected. I can reassemble that and check but I'd like to know if someone has encountered this sort of clicking before.

Please notice that the little windmill is not skipping steps so it's not the same as this clicking:

https://shop.prusa3d.com/forum/others-archive--f66/clicking-printhead-filament-stuck--t14916.html

Re: Clicking and "tension" on the filament and underxtrusion

I am having the very same problem on a freshly-assembled kit. The first layer prints just fine, then clicking and underextrusion starts happening. I let the included batman print run to completion, but it's flimsy and missing a lot of plastic. Problem happens with both the included silver PLA and some Nova white PLA I already had around.

EDIT:

Miquel, are you also getting a temperature drop when the PLA cooling fan kicks in? I just noticed that on the second layer the batman file calls for a lower extruder temperature, going from 215 degrees to 210. However, the actual temperature of the nozzle drops to 200-203, which is also when the clicking and underextrusions begin. I'm gonna try a PID calibration and see if it helps.

Re: Clicking and "tension" on the filament and underxtrusion

Hi @clyde.s,

At least I'm not alone in this ^_^

At the moment I have the prusa disassembled because I did want to try to assemble the hot end carefully following these instructions:

https://e3d-online.dozuki.com/Guide/V6+Assembly/6?lang=en

I don't see how that would cause the problem we are having (maybe it doesn't) but I did buy an assembled printer and the only thing I "touched" is this assembly so I want to go back my steps.

Anyway, that means that I can not test the temperature issue right now… and I do remember a drop in temperature but I guess it was much lower.

I'll let you know as soon as I have the printer running again

Re: Clicking and "tension" on the filament and underxtrusion

Have you tried to increase the tension of the gears?

Those two screws adjust how strong the gears will grab the filament

http://manual.prusa3d.com/Guide/5.+E-axis+assembly/510?lang=en#s8193

Don't overtighten them 🙂

Re: Clicking and "tension" on the filament and underxtrusion

I did, I also did untighten them. I even asked support what the correct tension should be. They answered that "it depends" and said that a a good guide would be that the screws just "exit" the other side (if I recall correctly).

In general I felt lacking some way to test this. Like tighten them a bit and if A happens your are set if B tighten more if C tighten less.

Thanks for your answer!

Re: Clicking and "tension" on the filament and underxtrusion

Hi,

Since firmware update to 3.2.0-RC1 I had the same issue with infill on large parts, I print with HD Glass Formfutura PETG which is intended to be printed between 195° and 225°.

First I raise the temp to 240° but it's doesnt change anything, so I decide to explore my Prusa Control generated gcode with slic3rPE.

My gcode infill print speed was set to 3500mm/s, I reduce the infill speed to 1500mm/s like default setting in slic3rPE.

It solved my infill issue, and I was able to achieve my print without any other problem.

MK4/MMU3 - VORON 2.4 350 Stealthburner

Re: Clicking and "tension" on the filament and underxtrusion

After several weeks printing on my first 3D printer "MK3" I started getting the same clicking noises from the extruder. From what I've read before I started isolating the noise and when I realized where it was coming from I lightly pinched the filament and could feel the vibration.

It started after I began a new print, a narrow 3x3mm heart shape that I made for my wife to use on her dream catchers. You can see in the first few layers where there were gaps.

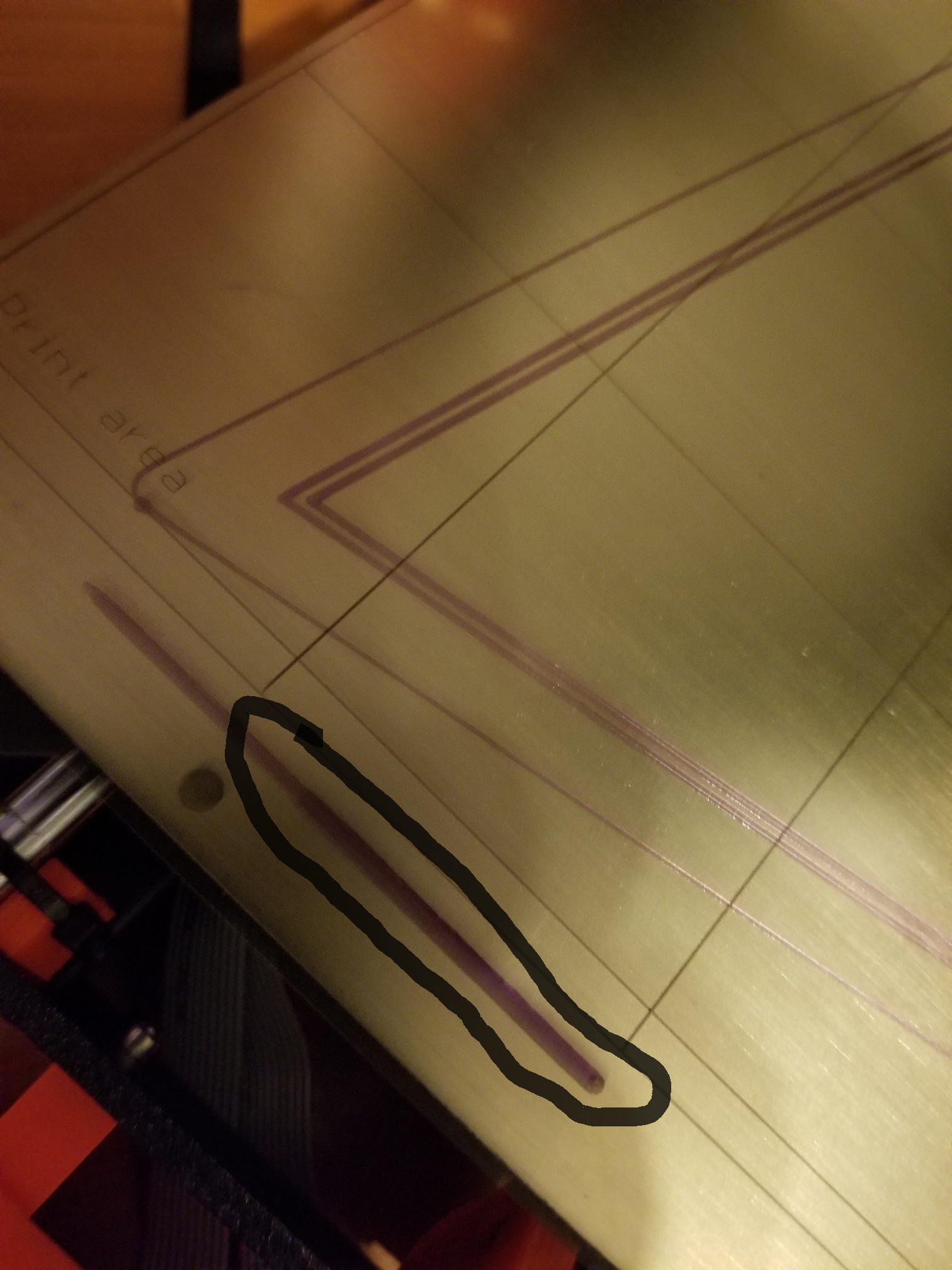

I stopped the print, cleared the bed and was going to start over. During the restart it didn't lay down the test extrusion on the bottom right of the bed like this one after I cleared the problem.

When I tried to unload the filament it got stuck in the top of the extruder chamber where the feeding gear chamber is.

I fixed this by removing the top portion with the two screws that holds the cap to where the PTFE tubing sits. I rocked the filament back and forth until it dislodged and was free.

At this point I'm figuring a nozzle jam so I broke out the "Cleaning Filament" I purchased. I've read stories about how to use it, but with what I thought was a full jam I selected the highest temperatures for pre-heating ABS "255".

I still had the gear door open so I was hand feeding it. The filament started coming out of the extruder until I saw the clear color of the cleaning filament. I then selected pre-heating for PLA "220" and pushed some more through.

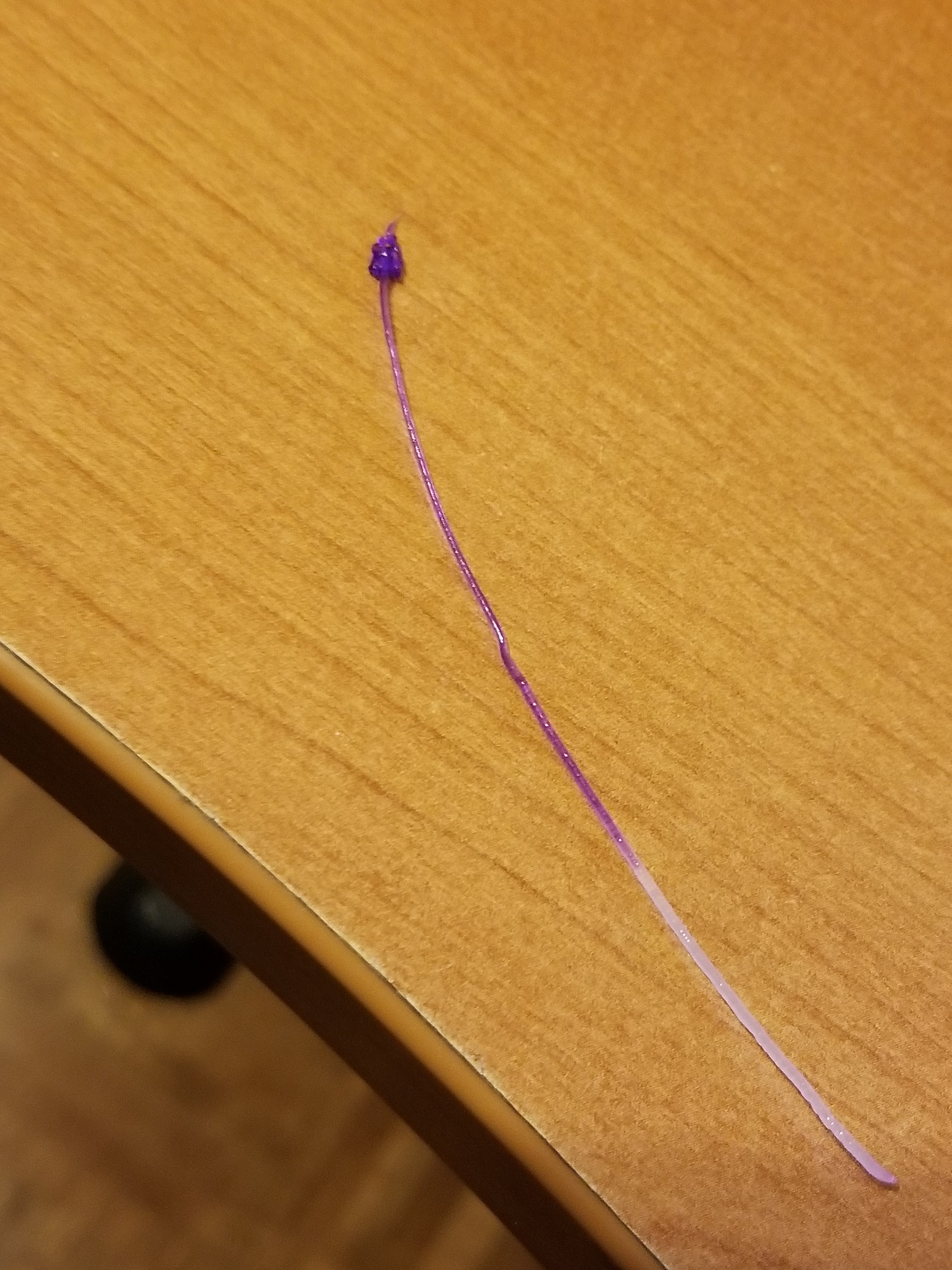

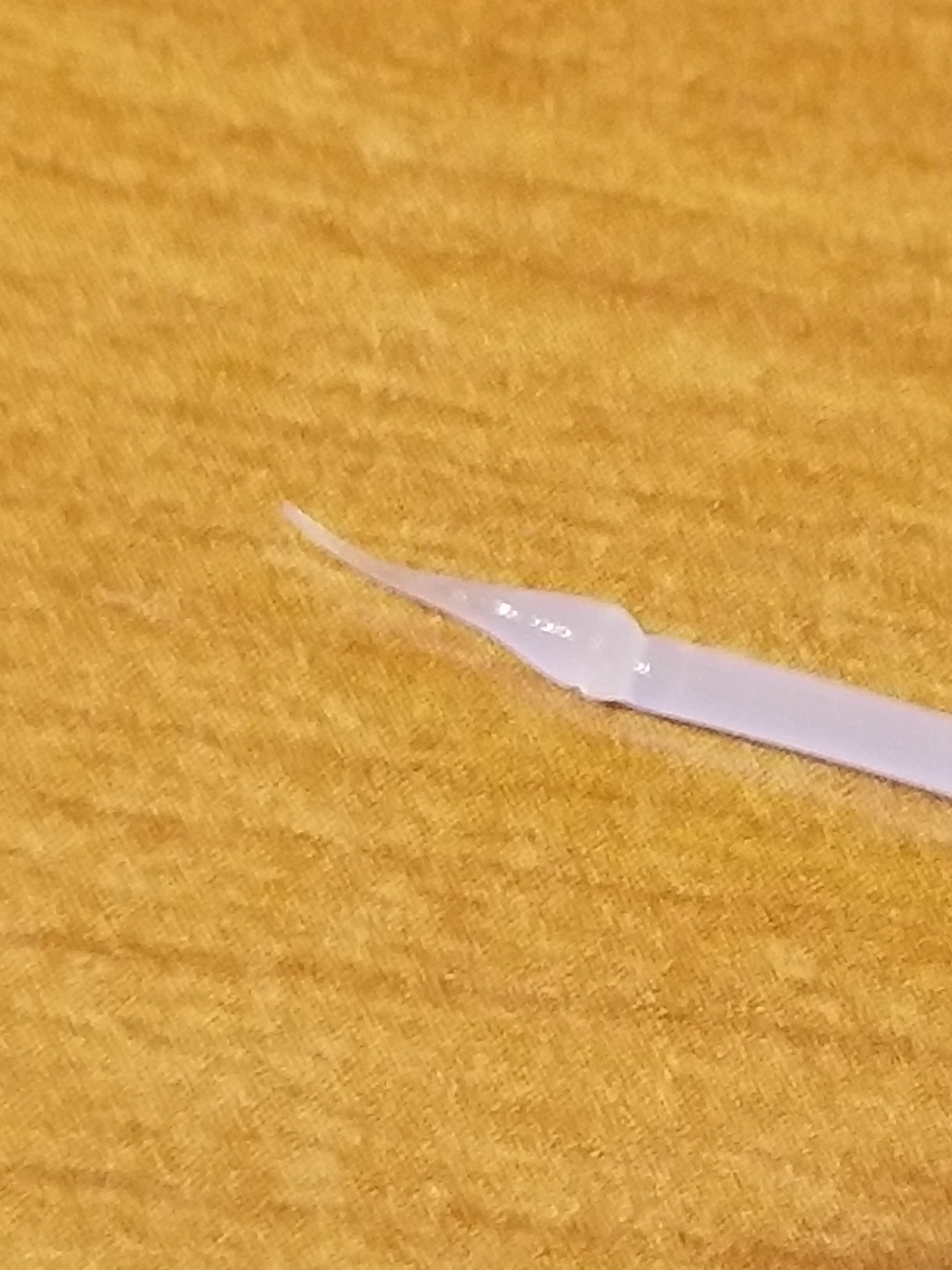

Once I thought it was cleared I closed the gear door, put it back together again and loaded the filament. Here's the clog I pushed out of the nozzle.

In the second picture you see the clean lines of the bottom tip of the heart. I had no clicking or other problems after this and completed my heart rings for my wife's dream catchers.

Re: Clicking and "tension" on the filament and underxtrusion

I've seen this before and I think this is what causes filament jams in different parts of the extruder besides the nozzle. A bulb forms and jams the filament.

I've been lucky in that after my first jam I put tension on the filament as I unload it. This second jam occurred up near the PTFE tube ia. We need to figure out something about these bulbs and how to stop them from forming.

Re: Clicking and "tension" on the filament and underxtrusion

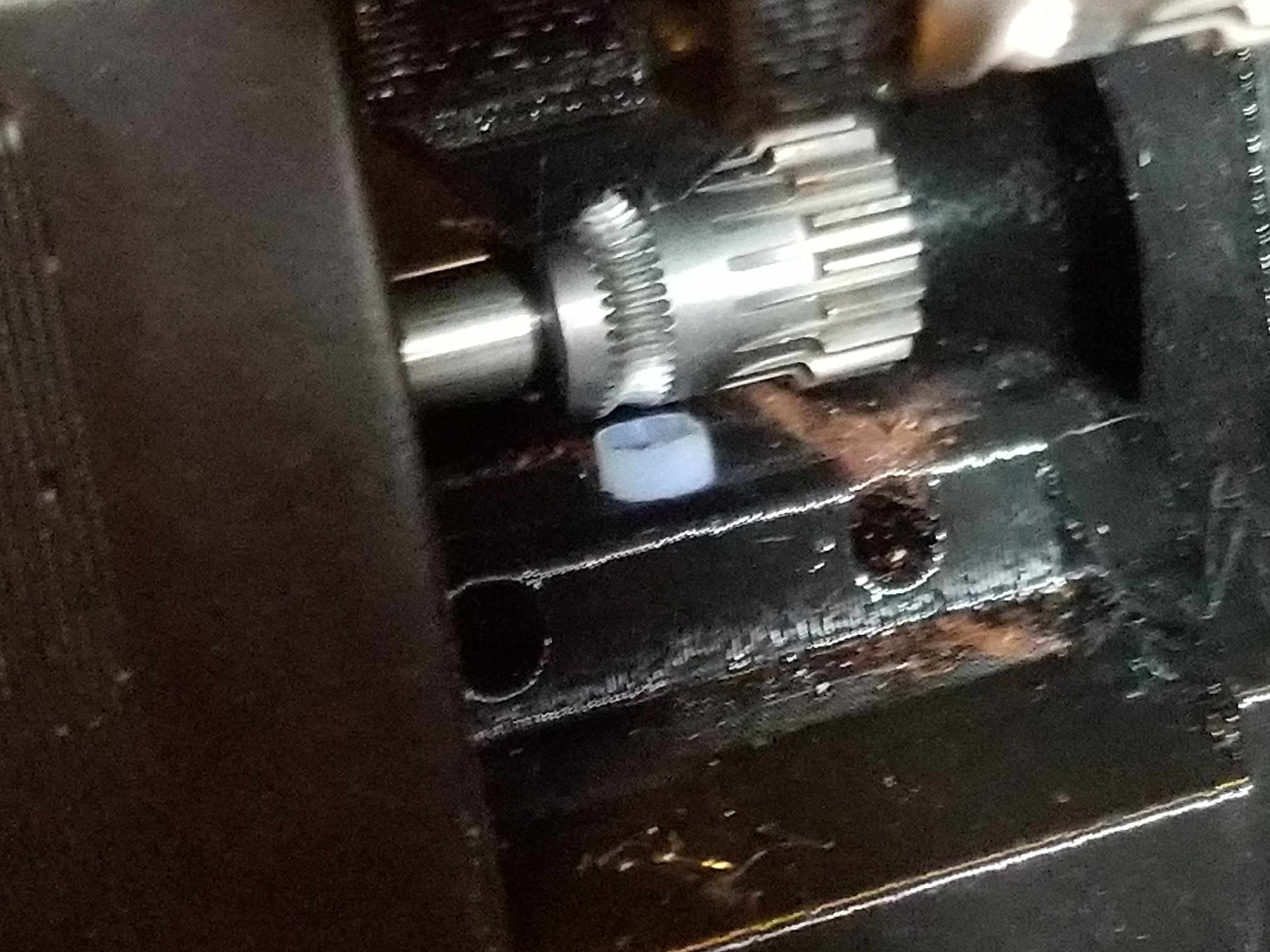

Forgot to mention, when I opened the chamber where the gears are I had this brown dust or grit in there. All of the gears seemed to spin freely and I haven't used anything near this color.

This is rust. I'm also having that and I'm not happy at all with it but Prusa says "it's ok"

I did grease my gears but that did not change my issues.

I'm on the phone now and I'll try to post a full update later after I test a few things more (not that I think I solved anything) but meanwhile you can try to tighten the idler a bit.

I have to kinds of clicking the one described on this thread and this other one:

https://shop.prusa3d.com/forum/others-archive--f66/clicking-printhead-filament-stuck--t14916.html

I think that a tight idler makes the gears skip and "clack" and a loose one skips and "click"

Re: Clicking and "tension" on the filament and underxtrusion

I'm gonna throw this out there, and hope I help someone.

First of all.

Your money, your decision. Don't blame me, or prusa if my idea don't work. I will explain what I did for myself.

First: Backstory on why I propose this is a problem for... almost everyone in here.

I had my printer for ~2 months, when I started getting "clicking" and "stopped extrusion".

I was consistently getting jams in prints, and from the point I noticed my printer had a problem, 2 weeks later, I couldn't print ANYTHING.

I don't recall the exact measurement,but the next time your printer "jams". Simply stop the print, and let the nozzle cool down. (keep the fans on)

After about 15 minutes do an "atomic cold pull".

Chances are you won't see a nozzle imprint at all. You will see a "collar" like blob at the end of the filament. This is BAD. "measure" the teethmarks the bondtech left in the filament. See how far down the filament goes. If your piece of filament ends at the TOP of the "neck" of the heatbreak. You have the *EXACT* same symptom I had.

Hate to say it, your heatbreak is LIKELY broken/flawed/bent/santa-dropped-it.

I replaced my MMU E3D heatbreak, with a MicroSwiss one.

THIS ONE

I would advise against getting a MMU/MK3 heatbreak. If you wanna order one from Prusa, get the Mk2 (non-MMU) heatbreak.

If this helps any of you guys, shoot me a message and tell me, I'll document the exact WHY with a little more detail.

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.

Re: Clicking and "tension" on the filament and underxtrusion

Sean, interesting info. Will wait for the WHY post. 🙂

Re: Clicking and "tension" on the filament and underxtrusion

I ended up "merging" this issue with another one I had because I assumed that having a different clicking sound meant I had a different problem.

I explain the difference in clickings here

And I solved my issue by removing the heatbreak entirely (see assembly instructions and execute them in reverse order):

http://manual.prusa3d.com/Guide/5.+E-axis+assembly/510

Once you have the heatbreak removed you can push the ptfe tube down through the tube and clean it (I just pushed the clog with a little allen).

Then reasemble.

To reasemble have the E3D-V6 assembly instructions in mind:

https://wiki.e3d-online.com/E3D-v6_Assembly

I have to do it twice because I did not screw tight the things in order so read those carefully.

I don't know exactly what caused the issue and I'm not sure it will not come back but I've been printing for a couple of days without issues.

See the test batman:

RE: Clicking and "tension" on the filament and underxtrusion

This same clicking and under extrusion issue got me for the several hours of troubleshooting until I solved it. The printer was working perfectly the day before too. I had this happen before but the cause was different. I will explain both causes and fixes, as well as other causes.

The two main symptoms you encounter are the extruder clicking and under extrusion on the print bed. The clicking is the easy symptom to understand. It will always be accompanied by under extruded printed. Under extrusion comes in many forms of varying severity and can be hard to identify if it is slight, because it could be due to filament quality, temperature, or print speed, and might not be accompanied by clicking, but when accompanied by clicking I have found two main causes.

Problem 1 - The bondtech gears are not aligned well

Cause 1 - Easy to fix! There is debris in the extruder gear area and this is preventing the gears from meshing well

How to fix - use a air can to blow out the debris, then use a brass brush to clean the bondtech gears.

Cause 2 - (This happened to me a year ago and this fixed it) The grub screw came loose and the bond tech gear on the extruder motor rod can move horizontally or is just loose enough so it slightly wiggels vertically.

How to diagnose - Open the side extruder door and with your finger try to jiggle or move the bond tech gear attached to the extruder motor rod. If it moves this is your problem.

How to fix - Use the menu to go to the extruder motor and move it so the flat side of the extruded rod is facing you, adjust the bondtech gear so the filament channel lines up and use the smallest wrench tool to tighten the bondtech gear. You only need to tighten it so it doesn't move. Do not overtighten or think it needs to be tighter than this.

Cause 3 - The bondtech gear on the extruded door has a loose bearing rod

How to diagnose - The Gears appear aligned but when you press on the one on the extruded door, one side moves a little. When you look in the end holes you see the rod is not equally inserted in both sides.

How to fix - insert a small tool into the hole on the door cover and move the rod so it is in each side. If it moves too freely, you will need to print this part again or order it (if you only have one printer) and then disassemble the extruder to get to the door cover, and move your bondtech door gear, rod and two bearings to the new part with the tighter rod hole.

Problem 2 - Although the gears are clean, mesh well, and work fine, they can push the filament through and you under extrusion, like the picture

Cause 1 - (I just encountered this and this fixed it) You might read you need to tighten the extruder door bolt with the spring to on it, but you don't. This just need to engage a little and the gears should work fine. You only need to really tighten this with flexible filament. The real problem is that the gears cant push the filament well because something very small is partially blocking the PTFE tube somewhere along the filament path. This could be some dirt, a piece of your metal cleaning brush, or something else. All that matters is that it wont come out the hot end section but is messing up the flow of filament, like a small pebble might in a garden hose.

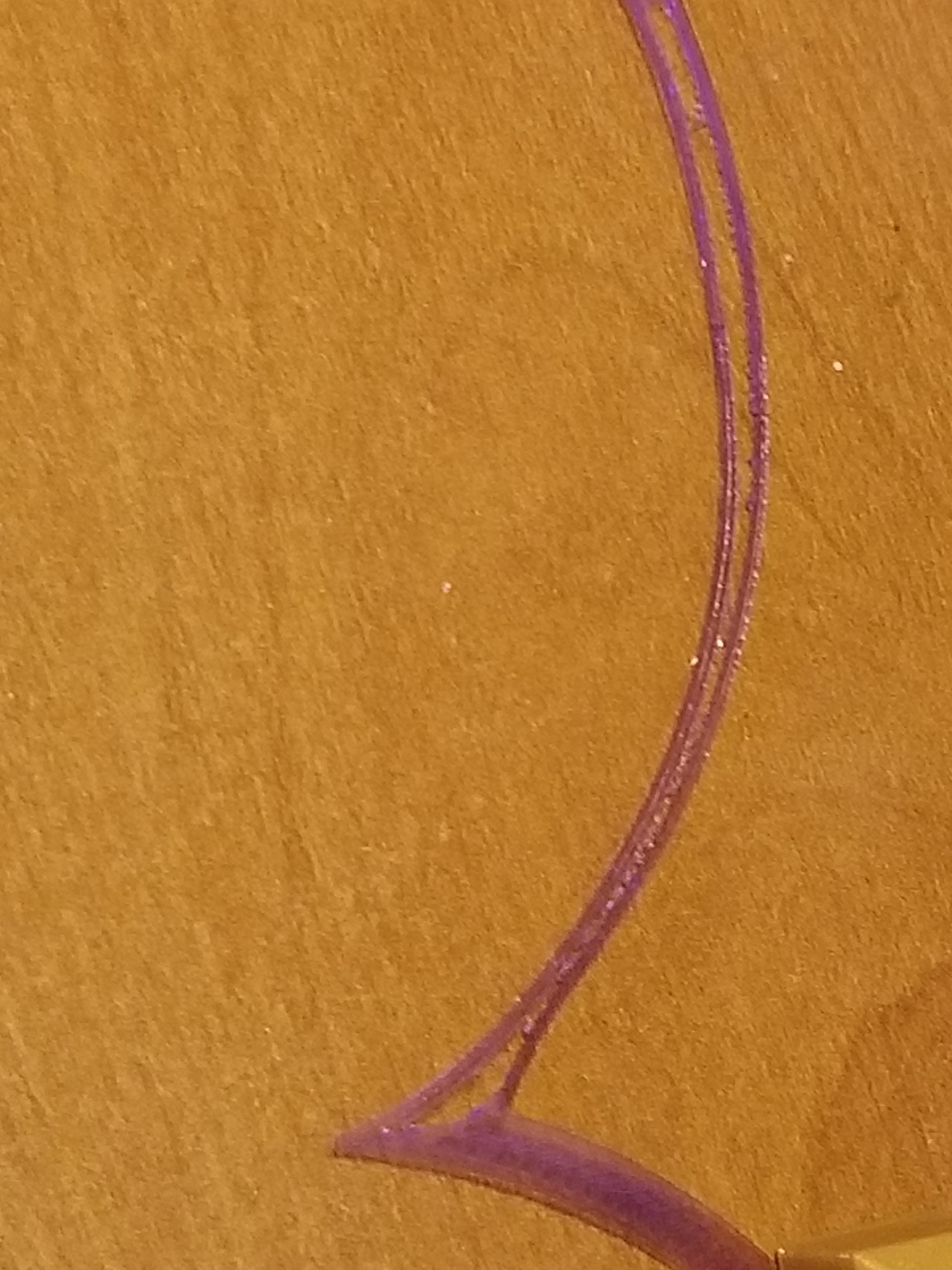

How to diagnose - You cant really diagnose this issue easily, but you might see the filament when you initially load it come out with some big blobs, then really thin, then a big blob again. When you print you will see under extrusion and might hear clicking if bad enough.

How to fix - Do a cold pull to remove the debris partially blocking the flow in the extruder. The way you do this is to load filament, then go to your settings and choose temperate type like PLA, PETG etc. scroll all the way to the bottom and choose cooldown. Open the extruder side door. When the temp hits 100 firmly pull the filament up and out of the extruder top, ie backwards towards the spool. Repeat this process two or three times, or until you notice no discoloration on the filament you pulled out. Use white filament for this so you can notice it. See the screenshot above and you will see a small green dot next to where i placed the sandpaper. That must be the dirt spec. After this cold pull the extrusion was perfectly fixed.