Check My Work/Thought Process: Working to Fix a Blobbing Issue

Context: Since I began my 3d printing adventures about 3 weeks ago I have put over 17 days on my printer. My husband mathed this out to about 16h of uptime every day. Printing went great with no issues. Then on Saturday I started having some black blobby odditites on my prints. The nature of what I was printing (and the fact that I was using glossy jet black filament) hid the issue. I had just swapped my nozzle back to 0.4 so I suspected there was an issue with the extruder or some setting. (I since have learned I was wrong about that). Then after a few short prints I swapped back to my grey filament. When a few black blobs appeared on these... I knew something was up.

So I read a lot of the posts here. The good news is that I think I caught the issue before any major damage occurred. When I had replaced the nozzle it had felt loose, but there isn't anything in the beginner info that states 'under no circumstance should your heat block feel loose!'. So, user error on not figuring that out. In any case, the only solution seemed to disassemble and reassemble. So I disassembled my hot end.

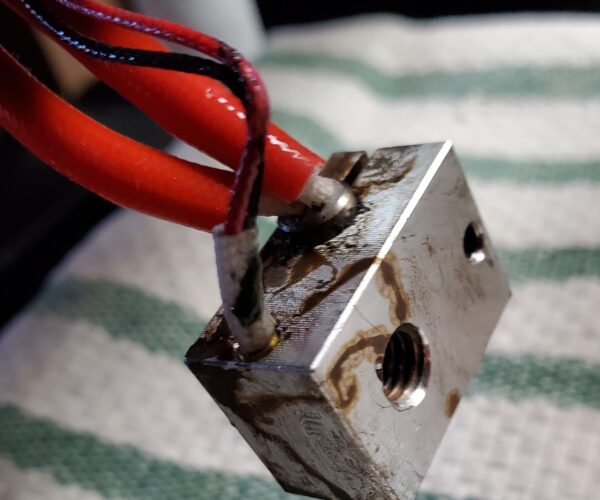

All in all there was probably less than a 1/2 tsp of oozing filament on top of the heat block. I had removed the nozzle prior to removing the hot end as if I was doing a nozzle change. I was following along with the Prusa instructions ( https://help.prusa3d.com/en/guide/how-to-replace-a-heatbreak-heatsink-heaterblock-mk3s-mk3s-mk2-5s-mmu2s_16104#17040) as best an I could. The heatsink could be removed with some effort. However, the heatbreak was well fused to the heatblock. Since the instructions don't indicate to heat up the heatblock for this step, we did as best we could.

Check my thought process: In hindsight I should have turned on the printer and had it heat the block to help with removal of the heatbreak? It makes sense that they would be fused they were basically hot glued together. Since I did not heat up the heatblock, we ended up damaging some of the delicate threads of the heatbreak.

Check my thought process: We started cleaning off the heatblock and realized doing it cold would not work. So we turned the printer on, told it to heat it up, and were able to clean off the heatblock with some cotton swabs sticks (q-tips) and a paper towel. I think this was the right way to do this. The block came out clean. I tested the threads by screwing the heatbreak back in and a nozzle back in. There was some resistance but I think there is still a bit of gunk on the threads that I can clean with another pass. I didn't see anywhere that suggested using this kind of method. Was this a terrible idea? And if so, why?

Regardless, I was able to order a new heatbreak. I think all in all everything should go well. Here are some pictures of my cleaned parts and damaged heatbreak for context.

Look ma! No wires broken!

Prevention for the future?: In hindsight, I suspect that when I changed the nozzle the first time I didn't have it hot enough (user error/new user excitement). It ran well enough for a long time, but that doesn't mean it didn't start the issue. I think after two more nozzle changes (even though they were at the right temperature) something got a bit more loose each time. I also question if turning the block prior to changing the nozzle is necessary or a good idea. If I am bracing the heatblock it follows that just changing the nozzle without the slight turn should be fine? (Good idea?/Bad idea?)

Any other advice for what to check for or pointing out errors in my thought process would be much appreciated. I have learned a lot from this forum.

RE: Check My Work/Thought Process: Working to Fix a Blobbing Issue

Meant to add a few other questions:

- Would a coke (the soda) bath clean up the nozzle? (Like you do with other screws that get corroded)

- Would filing down to correct the threads on the heatbreak be a bad idea? I used to do this with other machine parts for grinders and such, but a heatbreak seems a bit too sophisticated to take this approach.

- Any recommendations for parts that I should keep on hand?

RE: Check My Work/Thought Process: Working to Fix a Blobbing Issue

Meant to add a few other questions:

- Would a coke (the soda) bath clean up the nozzle? (Like you do with other screws that get corroded)

- Would filing down to correct the threads on the heatbreak be a bad idea? I used to do this with other machine parts for grinders and such, but a heatbreak seems a bit too sophisticated to take this approach.

- Any recommendations for parts that I should keep on hand?

Congratulations, you've certainly have had an adventure, you will now be more powerful.

You ask about how to clean out the heat break threads, I'd put the heat break in a vice (protect the threads) heat it with a torch and take a brass brush to the threads and clean out plastic.

The heater block could be cleaned with the right tap, since the plastic is softer than the aluminum it'll attack the plastic first.

Don't use Coke for cleaning anything on a 3d printer. The reason Coke works on rust is the phosphoric acid in the Coke attacks the bonds in the rust and dissolves them so it can be wiped away. Coke won't do this for plastic. Depending upon the plastic you're using there may be other solvents you can use, Acetone works well on ABS, but not on PLA. I'm not aware of any solvent that works with PLA that is safe and easily available.

Parts to keep on hand; I have a replacement for everything in my hot end. I can build a completely new hot end from what I have in my parts box, heat sink, heat break, heater block, PTFE fittings, heater cartridge, PTFE tubing, thermistor and of course nozzles.

Take care when you buy nozzles, while many nozzles can successfully thread into the heat block not all are long enough to contact the heat break, make sure you buy real E3dV6 nozzles or after market nozzles that meet the same specs as the factory nozzles.

Cheers

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE: Check My Work/Thought Process: Working to Fix a Blobbing Issue

Thanks Bob. I appreciate the encouragement and advice.

If anyone else has any pointers or 'wish I had knowns' feel free to let me know. 🙂