Bunk rods still an issue?

I'm curious if there has been another batch of bunk rods... Anyone else experienced the same?

I recently had a Y rod replaced because it was binding and scored. Rebuilt my extruder as a quasi-Mk3S today, and was surprised to see quite severe scoring on one of the X rods too. They are magnetic, so they are hardened, and the kit is from early Jan, so definitely not old stock. Or perhaps just really bad bearings doing damage?

I lubricated all my bearings per the numerous guides out there during assembly. Using SuperLube because that is what I already had from another project, rather than also buying an oil.

I'll have to hit up support to get a replacement, but I was just curious whether others have noticed this too. I've run maybe 2 spools worth of filament through; definitely not just age related wear. Perhaps once I have a replacement I'll tear down the bearings and see if I can see why.

Re: Bunk rods still an issue?

I had the same problem on both of my MK3's, rods had bad scoring in them and had black junk building up on the end of the rods where the bearing stop (the black gunk was metal from the scoring and oil). The Prusa bearings are cheap bearing, Prusa charges like $13 for a pack of 10, brand names are like $5-6 each. Replaced my rods and bearing with brand name and have not seen any scoring on my rods or black gunk building up at end of the rods for 2 months now.

Re: Bunk rods still an issue?

I had the same problem on both of my MK3's, rods had bad scoring in them and had black junk building up on the end of the rods where the bearing stop (the black gunk was metal from the scoring and oil). The Prusa bearings are cheap bearing, Prusa charges like $13 for a pack of 10, brand names are like $5-6 each. Replaced my rods and bearing with brand name and have not seen any scoring on my rods or black gunk building up at end of the rods for 2 months now.

Where'd you get your shafts? Misumi ones are at least $10+ making that whole affair well over $100. And one could argue that is not an investment I should have to make after a $750 printer.

Re: Bunk rods still an issue?

Yes I went with Misumi rods and bearings on one of my MK3's. the other still has the bad bearing and scored rods. Do not see any difference in print quality.

Re: Bunk rods still an issue?

Hmm... then I wonder if it's not so much bad bearings as just a tolerance issue...

Re: Bunk rods still an issue?

I had a linear bearing failure occur on my 3rd print on a new MK3S

(I followed all of the bearing location/u-bolt tightening directions carefully during assembly. There was no problem until the failure).

It resulted in a y-axis crash... I moved it around and it freed up. I tried the print again and it essentially seized. When I slid the rod out of the bearing, it gifted me 3 of its balls. I did not have a spare bearing so I put it back together and it seems to work ok for now.

I sent PRUSA a message a few days ago about it, but they have not replied.

I bought a cheap set of bearings from Amazon for back up, but ...

Where can I source quality bearings (in the US)?

Re: Bunk rods still an issue?

Misumi USA has LM8Us which are drop-in replacements. They are ~$5 each but I am concerned about bad bearings having damaged rods, which in turn requires a paired rod replacement lest the scored rods cause damage to any new bearings I were to buy myself. And the correct rods are $12 each, bringing a total replacement for all three axes to $120. I've been too busy to reach out to Prusa yet, but live chat will get you a faster response than email.

I'm hoping they are willing to send a complete set of rods and bearings to stave off future problems (probably cheaper than having to ship me yet another replacement in the future) and maybe I'll get the misumi bearings instead. I'm contemplating giving printed PLA bearings a try first though; at least that won't damage the rods if something goes wrong.

Re: Bunk rods still an issue?

Email support can be very slow use the 24/7 live chat feature; log in to the Prusa store page and in the lower right corner click on the CHAT button and enter your kit invoice number in the space provided.

and for more than you want to know about Rods and bearings

https://www.facebook.com/groups/prusacommunity/permalink/949953875345345/

Re: Bunk rods still an issue?

Quality ---> Misumi (10 of 12 bearings I received were perfect. 2 a little notchy) Fantasticly tight tolerance when matched with their rods.

Don't care about quality ---> Amazon cheapo chinese bag of 10 bearings. 2 of 10 were barely usable, albeit with a LOT of play. The rest went straight into the waste bin.

I'd order from Misumi. They are good quality units.

Re: Bunk rods still an issue?

Email support can be very slow use the 24/7 live chat feature; log in to the Prusa store page and in the lower right corner click on the CHAT button and enter your kit invoice number in the space provided.

and for more than you want to know about Rods and bearings

https://www.facebook.com/groups/prusacommunity/permalink/949953875345345/

Sorry, I don't do facebook as I do not agree to their terms of service and policies. I'm saddened that group has chosen that as their platform as I'm sure there is a wealth of knowledge.

Is that info equivalent to the quasi-infamous "Set your bearing straight" article? I know Chris W considers the igus bearings to be either a sidegrade or downgrade; PLA seems to be hit or miss depending on the effort you put in to get it right. At worst I'm out a little of my time and some material if I try.

Re: Bunk rods still an issue?

Email support can be very slow use the 24/7 live chat feature; log in to the Prusa store page and in the lower right corner click on the CHAT button and enter your kit invoice number in the space provided.

and for more than you want to know about Rods and bearings

https://www.facebook.com/groups/prusacommunity/permalink/949953875345345/

Sorry, I don't do facebook as I do not agree to their terms of service and policies. I'm saddened that group has chosen that as their platform as I'm sure there is a wealth of knowledge.

Is that info equivalent to the quasi-infamous "Set your bearing straight" article? I know Chris W considers the igus bearings to be either a sidegrade or downgrade; PLA seems to be hit or miss depending on the effort you put in to get it right. At worst I'm out a little of my time and some material if I try.

I feel the same way about them and access via an assumed name via a vpn I also do not take part in any of their features like friend or like.

this is not like the article you mentioned it is quite a rigorous cross testing of the the 3 main types of bearing wintin the limits of no specalized test equipment

Stock Prusa Hardened rods

Misumi PSFJ rods

Misumi PSFU rods

Stock Prusa LM8UU bearings

Misumi LMU8 bearings

THK LM8UU bearings

oh the heck with it there is more value in being able to read the whole thread but here is his main post

Let's talk bearings and rods. I've had a chance to play with some new combos and also do some unscientific tests to see which combination(s) fit best.

Here is what I have to work with:

Stock Prusa Hardened rods

Misumi PSFJ rods

Misumi PSFU rods

Stock Prusa LM8UU bearings

Misumi LMU8 bearings

THK LM8UU bearings

Rod differences:

Prusa - standard hardened steel rods HRC64 unkown clearance or tolerance values but I was told G6 but feel they are closer to F8.

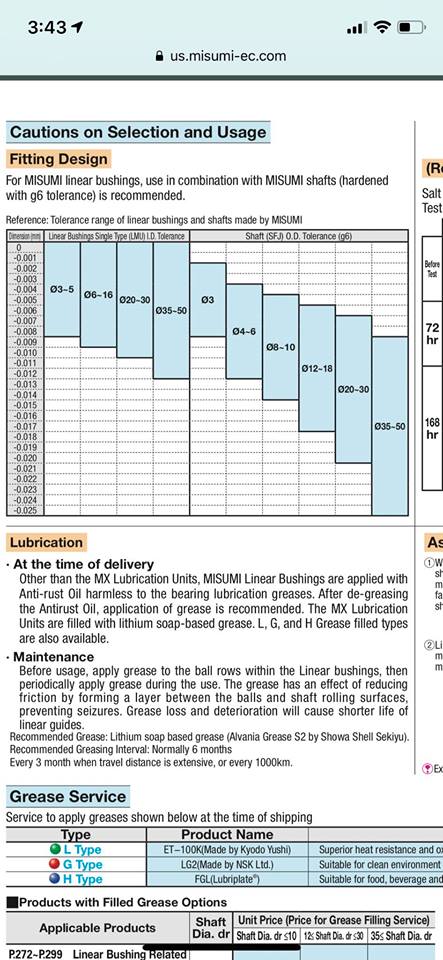

Misumi U/J - bearing steel hardened rods HRC58 with J being lower tolerance and U being higher. This equates to larger or smaller clearance when pairing bearings and rods.

J = -0.005 to -0.014mm aka g6

U = 0 to -0.006 aka h5

G = -0.013 to -0.035mm aka f8

Bearing differences:

Prusa- double sealed (UU) and steel balls with HRC58

Misumi - single sealed (U) and bearing steel balls at HRC58 0 to -0.009mm tolerance

THK - double sealed like prusa and steel HRC58 balls. 0 to -0.006mm tolerance

Bearing tolernace vs rod tolerance.

Rods are measured as expected. They subtract from how close to 8mm they are. So a G6 rod is between 7.995mm and 7.986mm.

Bearings use there own tolernace which is marked. So the misumi bearings are between 8mm and 7.991mm.

You can then find your max clearence. You don't want a bearing to be 8mm on the dot and the rod to be 8mm on the dot. You also don't want the bearing to be it's largest ID and your rod to be it's smaller diameter.

Initial feedback on LMU8 vs LM8UU. The later is better. Sealed bearings keep grease in and particles out of the system and are quieter. If you have the choice LM8UU is the better option and is more common. Just make sure the outer diameter is 15mm and the length is 24mm.

What does misumi recommend on paper?? Their own data sheet says their bearings should be matched with g6 aka PSFJ rods. When speaking to misumi because the load we use is so light it may be best to H5 aka PSFU rods since it'll keep all the bearing rollers in use on lighter loads. Ever notice that placing pressure on the bed makes the bed not rattle anymore???

Initial tests of combos that work and don't work.

Prusa Bearings == Prusa Rods

Prusa Bearings != PSFJ rods can be too tight

Prusa Bearings != PSFU rods too tight

Misumi Bearings != Prusa rods far too loose

Misumi Bearings != PSFJ rods a little loose

Misumi Bearings == PSFU rods

THK bearings == Prusa rods minimal play

THK bearings == PSFJ rods

THK bearings != PSFU rods little tight

I tested multiple rod and multiple bearing combos. 6 rods of each type and 6 bearings of each brand using the following basic methods.

The wiggle test. If the bearing wiggles a lot most likely the bearing tracks won't actually be activated during movement unless pressure is applied. This can make the system noisy and you'll get that classic bed wobble many complain about.

Rolling test. Without any grease roll the bearings and feel/listen for the rollers to be activated during movement. Too tight or loose and it'll slide without activating the bearings causing issues.

The rotator. A proper bearing to rod shouldn't be able to rotate on itself smoothly. If it does that means it's too loose.

Issues and why they are so:

Too loose: you can experience increased noise, increased wear, increased binding and overall poor print quality.

Too tight: you can experience increased wear, stuttering on low speed moves, and overall diminished print quality.

These aren't super scientific tests as I have no access to dedicated bearing testers so sound data was taken from all manufacturers and applied to that was basic fitting tests that would be done.

What's the damage???

Cheapest option is to remove the Prusa bearings for THK bearings at USD $6.19 each and replace only the X and Y axes while retaining the Prusa rods which I find to be perfectly fine.

Your next option is to upgrade the X and Y axes rods and bearings to Misumi LMU8 bearings and Misumi PSFU rods. 6 bearings and 4 rods is going to be a bit of dollars.

The other option would be to snag THK rods and bearings but I haven't priced this option yet but should be similar to the Misumi option. THK recommends g5 aka -0.005 to -0.011mm rods for precision while for accuracy the g6 aka PSFJ -0.005 to -0.015m with their LM bearings. The PSFJ rods would work in this instance and sums up that I'm seeing a negligible wiggle with that combo.

All brands recommend a degreasing of the anti rust oil and a fresh packing on new grease.

That's all I got. Hope that helps anyone trying to figure out the bearing and rod craze.

I'm going to order some LDO bearings soon and perhaps a couple others and see what matches what but I don't think we are going to find too many options here more fitting than mentioned at a reasonable price. Bearings jump from $5-6 to $20 really fast and we don't need the benefits the $20 option gives us.

Re: Bunk rods still an issue?

Email support can be very slow use the 24/7 live chat feature; log in to the Prusa store page and in the lower right corner click on the CHAT button and enter your kit invoice number in the space provided.

and for more than you want to know about Rods and bearings

https://www.facebook.com/groups/prusacommunity/permalink/949953875345345/

Sorry, I don't do facebook as I do not agree to their terms of service and policies. I'm saddened that group has chosen that as their platform as I'm sure there is a wealth of knowledge.

Is that info equivalent to the quasi-infamous "Set your bearing straight" article? I know Chris W considers the igus bearings to be either a sidegrade or downgrade; PLA seems to be hit or miss depending on the effort you put in to get it right. At worst I'm out a little of my time and some material if I try.

Chris Warkocki

Admin · February 25 at 11:24 PM

For the Igus fans I've started my testing and found no rods that fit without a decent amount of wiggle.

Now remember that the Igus RJ4JP-01-08 should be encased specifically to 40 lbs of pressure in order to to get to its final correct size.

1. This would make the bearings not fit in a standard prusa design as the bearing is already 15mm x 24mm without the casing.

2. A self printed housing can give uneven pressure. I did a quick test and used my fingers to pinch the bearing and to my amazement I can cause it flex enough to bind.

3. Proper mounting on the X axis using stock extruder designs is impossible.

This moves be back to point 2. You need equal pressure to get the Igus bearings to be at size. Using the U bolt would mean pressure is only at the center causing binding at the dead center of the bearing. If you use these please use a printed housing with what looks to distribute pressure evenly.

This moves us to the RJZM-01-08 Igus bearing.

This is housed in the proper aluminum housing which makes it a better candidate for our application due to key points 1,2, and 3 from above.

I do not have these yet but will begrudgingly order 6 to test side by side. The issue is they are usually $15ea so a bit investment and I know I'll have to be very picky as how I'm supposed to mount these.

I haven't done a ton of research on Igus besides using them on a stock MK2s and wearing them oval within 3 months and fighting odd printing issues. Most likely from binding.

What I need to know is does anyone have a recommendation for a holder for the standard uncased RJ4JP bearings and another they'd suggest for the RJZM bearings???

I haven't tested how tightening the X and Y axes down will fully affect fit but since I have all the rods here I can at least find which work better or worse with each setup.

With regular ball style bearings I'm not afraid of tightening down a printed part on them but these Igus bearings even in the aluminum housing seems suspect.

Also if you have a different Igus bearing more suited to test let me know.

Gracias fellow humans

Re: Bunk rods still an issue?

Fantastic info, thanks!

Re: Bunk rods still an issue?

Spoke to support yesterday; Not sure how I feel now.

They were helpful and while I have a reasonable plan going forward (swap the affected bearings with a spare I have, follow up if I continue to have problems) so feel things will be taken care of regardless. I just metaphorically raised an eyebrow they didn't seem overly concerned about the scoring on the rod itself. The explanation was that a scored rod isn't really likely to damage a bearing (??!?)... aren't bearings usually what is meant to wear out as a consumable and not the part it slides on?

I'm by no means a mechanical expert but my gut always says these sorts of things should be replaced together to avoid a perpetuating problem. Doesn't make sense to me to replace a bad bearing when there is evidence of rod damage lest you damage the new one, nor does it to replace a damaged rod and not the bearing if there is reason to suspect it also caused damage to the bearing.

Also interesting was a comment that "we are changing the way we ship small replacement parts for kits" and whether I could source a replacement locally. First times around with my Y rod issues, they shipped bearings and then a rod separately without hesitation. I don't know what that phrase means, but I got the impression replacement parts might only be shipped if they are either large enough/costly enough to be viable, or along with a new order from the store. If that's the case PR needs to get their shipping sorted and offer a cheaper (by regular post?) option. Because having to spend more money in the store plus another $20 shipping fee to get a replacement small part won't sit well with folks having issues with their printers already. At least in the former case it seems penny-wise and pound foolish; saving cents on parts only to have to spend more on shipping down the road. I'm sure a full set of rods costs PR less than it costs to ship them somewhere so rather than sending them individually if they send a set for any rod warranty claims, only do you potentially save money, customers will also be happier since they already have spares should more issues arise.

Curious to hear others' takes on this.

Re: Bunk rods still an issue?

I think that it might make sense for Prusa as far a north america is concerned to make sure a reliable outlet like Printedsolid.com has a stock of the most needed spares and send the customer to BUY the needed replacement part and then credit the user for that cost with prusa store credit or arrange for printedsolid.com to bill prusa directly... I Think this might work for small stuff like rods and bearings, heaters and sensors PINDA etc. large items like the ensie heat bed frame parts might then stay with Prusa... I am the first to admit I have not thought this through for problems like potential user abuse and then compensation for what outfit they might use on this side of the pond and this is no help for folks outside of north america (europe is well served directly from Prague

Re: Bunk rods still an issue?

I tore down my X axis today only to find out... it's definitely the rod. I had the exact same thing on my Y rod that was previously replaced.

If I take the same bearing and run it on the other X rod or the Z rods, it's smooth as butter, and they will also turn smoothly in the radial direction. but if I run it on the rod in question or my affected Y rod, I can feel it vibrating and stuttering, and it binds if you try to rotate it. So some of the rods I got are slightly oversize, not perfectly round, or just not consistent in diameter.

My cheap $15 calipers confirmed it; the good rod comes in at about 7.95-7.98, whereas the problematic one varies from 7.97 to 8.05.

In retrospect all of the bearings I've had feel surprisingly good on a "good" rod. so I have to wonder whether the at least some of the problem and hate for the PR bearings perhaps comes from poor rod supplier tolerances instead.

I guess I'll have to hit up chat support again with my findings. In the interim I did print up some PLA bearings to try out since my X axis is apart anyway, and I'll have to take it apart again to replace the rod when I get it; perfect opportunity to see what they do for me. Post-processing to get them right is quite a workout...but a rod that is a smidgen oversize definitely helps 😀

Re: Bunk rods still an issue?

turn smoothly in the radial direction

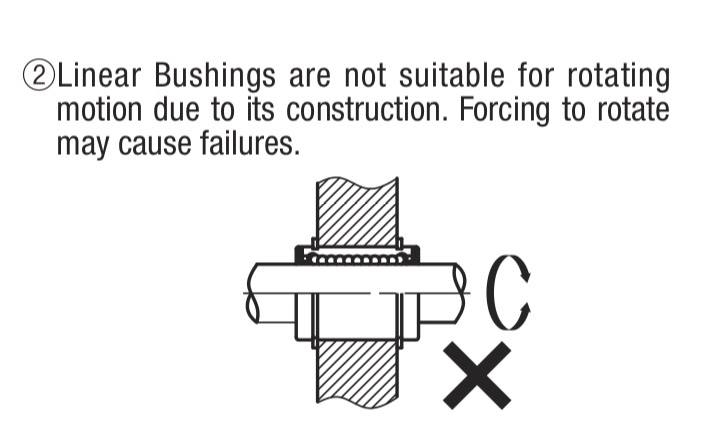

If you get better quality bearings, Never TURN them around the rod. You can damage tighter tolerance bearings in short order doing that. The ball guides are not designed to withstand direct rotation like that. You can convert a smooth running bearing into a notchy one.

If you need to realign the rotation, do so only incrementally while moving them back and forth linearly. Best is to load them onto the rods already in proper rotation.

BTW, a helpful trick is to mark the ball row postions on the outside of the bearing casing. That lets you verify alignment without pulling the bearing back off the rod.

Re: Bunk rods still an issue?

turn smoothly in the radial direction

If you get better quality bearings, Never TURN them around the rod. You can damage tighter tolerance bearings in short order doing that. The ball guides are not designed to withstand direct rotation like that. You can convert a smooth running bearing into a notchy one.

If you need to realign the rotation, do so only incrementally while moving them back and forth linearly. Best is to load them onto the rods already in proper rotation.

BTW, a helpful trick is to mark the ball row postions on the outside of the bearing casing. That lets you verify alignment without pulling the bearing back off the rod.

Obligatory "If I /had/ better bearings we wouldn't be having this discussion!" joke 😉

Kidding aside, what is the mechanical explanation for that? I get they are linear and not meant for radial *loads* like that, but there is virtually zero force and load involved in such an action. It sounds like one of those internet lore items that just gets repeated and taken as canon because someone misinterpreted the specs, which is why I'm curious as to the reason behind it.

Re: Bunk rods still an issue?

It's on the Misumi spec sheet for linear bearings. They warn against rotational motion. The ball guides let the bearings ROLL only along their linear raceway direction. Rotation means the balls may slide rather than roll - that is what causes damage to the bearing. They do make special bearings that don't use raceways, but rather circular holes to hold the balls. Those CAN be rotated without damage.

From the Misumi spec sheet...

Re: Bunk rods still an issue?

That's exactly what I meant by misinterpreting the specifications.

The image you posted would appear to be in the context of an under-load application in which the bearing rotates. It does not explain how a no-load minimal-force turn while assembling or testing fit actually causes any damage, if at all. Hence my skepticism.