Broken Filament in Extruder – Please Advise

While changing filament on my MK3, the old (Gold-colored) filament felt like it broke as I pulled it out. Sure enough, the new (Black-colored) filament would not load (“Click, click, click, …”).

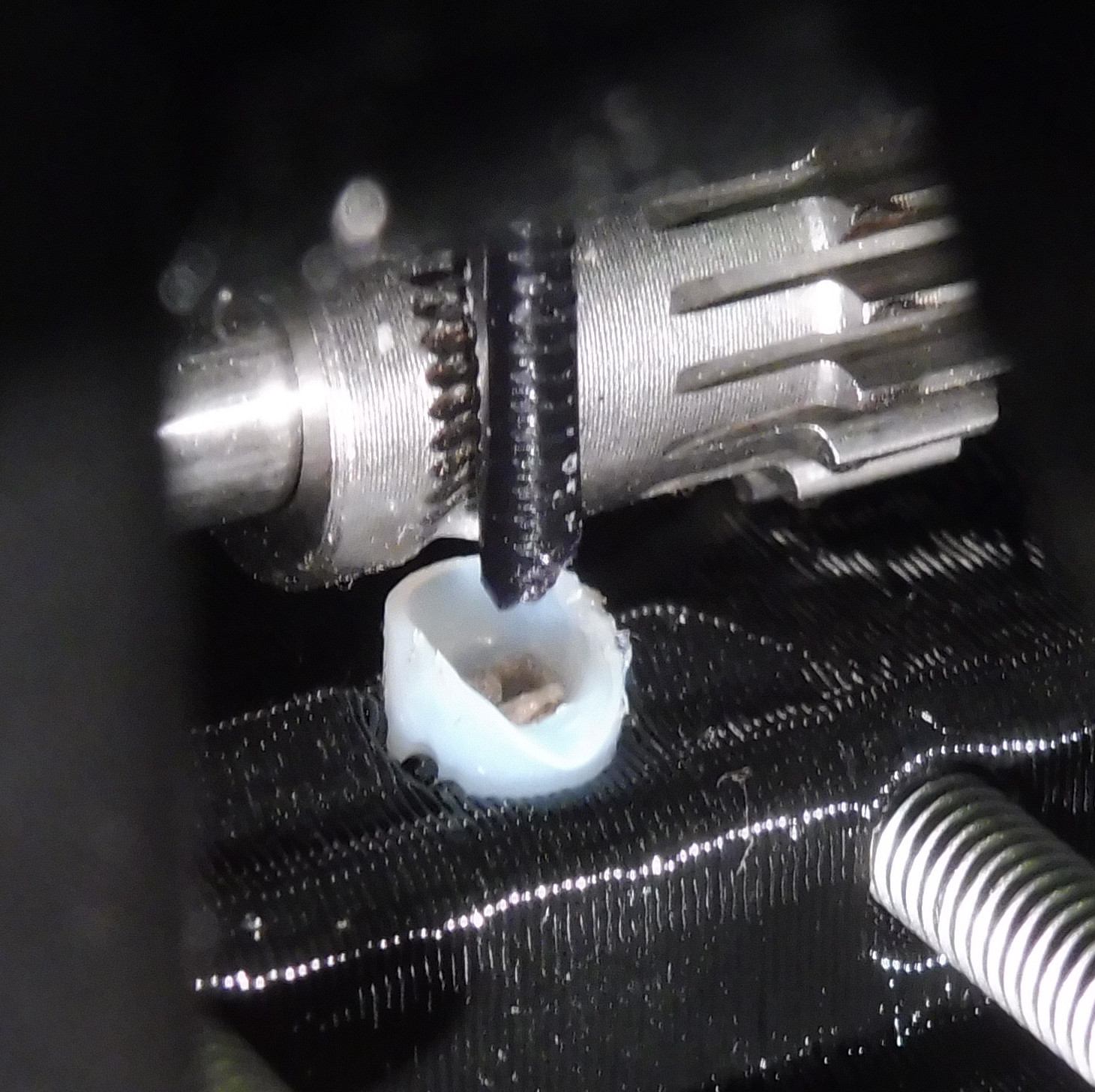

I opened the Extruder idler door and took this picture below. New, black filament is poised above. Old, gold filament appears to be just below the lip of the PFTE tube.

The lip of the PFTE tube also seems to be damaged. There also appears to be other issues in this area – deformed black PETG to the left of the PFTE tube, and maybe caked something on the metal gear itself (clear PFTE??).

I did not build this from a kit, so my skills are limited. Please advise the best course to take …

-- Clint Goss

Re: Broken Filament in Extruder – Please Advise

The filament in the PTFE looks deformed, so it probably won't push out downwards, easily.

you could consider heating the hot end, removing the nozzle and trying to push the filament up into the Bondtech chamber, with a stiff piece of wire. but this is likely to damage the PTFE, if that's not already damaged...

have a look at the last post in this thread https://shop.prusa3d.com/forum/assembly-and-first-prints-troubleshooting-f62/-extruder-jammed-can-t-unload-filament-click-sound-t19161.html#p91476

your best bet, is probably to disassemble the extruder and housing, and replace the PTFE Tube.

please be aware that the PTFE is difficult to get out of the extruder housing when it has filament inside it... the filament reduces the flexability and 'squashiness' of the tube.

do you have any PTFE tube in your workshop?

the PTFE needs shaping as in the diagram here https://help.prusa3d.com/l/en/article/nt3gmt736i-ptfe-tubes-in-original-prusa-i-3-printers#_ga=2.121095880.1962166114.1529786588-1302184215.1523655524

and there are online instructions on the E3d site for rebuilding your E3D v6 extruder

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Broken Filament in Extruder – Please Advise

Thank you Joan (and congrats on your appointment as Moderator ... henceforth to be called "Your Moderatorship").

This is informative and vaguely depressing ... and "vaguely depressing" really means "very depressing".

I have a PTFE tube coming from Prusa - will that be pre-shaped or will it need the home-grown shaping process?

I heated the hot end to 240C for a total of 12 minutes and managed to get the filament pushed down by hand-pushing the new filament. I also "poked up" (can't really say "cleaned") through the nozzle using a long Acu needle.

However, I could only push new filament down about half way through the hot end. The tip of the new filament gets as far as the midpoint of the part-cooling fan - about mid-way down the heat sink. Then it "hits something hard" (and this is while the hot end is heated).

Would a damage PTFE tube cause this "can't feed" situation?

All this because the filament snapped when I was pulling it out. I'm gonna eat some ice cream now ...

-- Clint Goss

Re: Broken Filament in Extruder – Please Advise

[...] you could consider heating the hot end, removing the nozzle and trying to push the filament up into the Bondtech chamber, with a stiff piece of wire. but this is likely to damage the PTFE, if that's not already damaged...

I've had to do this twice. The 1.5mm hex wrench is perfect and avoids poking about with a flexy wire, hopefully reducing the odds of damaging anything. I didn't have to push far to get the stuck filament strand to poke out of the PTFE tube far enough that I could grab it with a fine pair of needle-nose pliers. So far, I have been able to carry on without any problems.

I did have to use some wire to fish out goopy material left in the hotend when removing the nozzle. If the wrench doesn't slide in cleanly, it's worth a shot.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Broken Filament in Extruder – Please Advise

[...] I heated the hot end to 240C for a total of 12 minutes and managed to get the filament pushed down by hand-pushing the new filament. I also "poked up" (can't really say "cleaned") through the nozzle using a long Acu needle.

However, I could only push new filament down about half way through the hot end. The tip of the new filament gets as far as the midpoint of the part-cooling fan - about mid-way down the heat sink. Then it "hits something hard" (and this is while the hot end is heated)I'm understanding that you can't get any filament to extrude when pushing. You can push partway down, but encounter a block, correct?

This sounds like filament stuck in the cold part blocking anything from pushing it down. Again, YMMV, but I had good luck with pre-heating to high temp, removing the nozzle, and using the 1.5mm wrench to oh-so-gently probe up until I was able to push the stuck filament out the PTFE tube to be grabbed. There is a chance of damaging the PTFE tube, but then again, it's a write-off if you don't unstick it.

I've got spare PTFE tubing, but haven't had to face that demon just yet.

All this because the filament snapped when I was pulling it out. I'm gonna eat some ice cream now ...

Ah, but you're getting so good at this now. After doing it a couple of times, it's routine. I no longer fear trying out new filament or nozzles.

Warm the extruder up above 190C when pulling out filament. I also loosen the extruder gears when doing cold pulls (though I'm not 100% certain that's necessary).

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Broken Filament in Extruder – Please Advise

Thank you Joan (and congrats on your appointment as Moderator ... henceforth to be called "Your Moderatorship").

This is informative and vaguely depressing ... and "vaguely depressing" really means "very depressing".

I have a PTFE tube coming from Prusa - will that be pre-shaped or will it need the home-grown shaping process?

I heated the hot end to 240C for a total of 12 minutes and managed to get the filament pushed down by hand-pushing the new filament. I also "poked up" (can't really say "cleaned") through the nozzle using a long Acu needle.

However, I could only push new filament down about half way through the hot end. The tip of the new filament gets as far as the midpoint of the part-cooling fan - about mid-way down the heat sink. Then it "hits something hard" (and this is while the hot end is heated).

Would a damage PTFE tube cause this "can't feed" situation?

All this because the filament snapped when I was pulling it out. I'm gonna eat some ice cream now ...

Thank you Clint,

With absolute power comes massive responsibility... but in my case, I pretty much only have my hands on the Broom... so I can sweep aside spam messages, and duplicates, ban offenders, I can edit posts if necessary (so far only one post) and I believe I can move posts, but haven't done so, so far...

Hopefully these small tasks make this a better place for all...

now that you have hopefully finished your ice cream, and cooled down a little, you can get back to the task at hand...

PTFE is a touch softer than Stainless steel or Titanium, so what has possibly happened is that you have pushed a deformed piece of filament down, displacing the PTFE until the deformity has arrived at the middle of the heat break, where the smaller hole, in the metal part is resisting further progress...

so take your courage in your hands, heat up the extruder

remove the nozzle and thrust your 1.5mm allen wrench into the lower end of the hot end, with the intent of pushing the deformed filament out of the top of the PTFE tube. the unknown is always scary... it's time to start getting intimate with your extruder...

just remember, the hot end WILL BE HOT... so it might be a good idea to use pliers to push the allen wrench in... they recover from hot parts faster than fingers 😯

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Broken Filament in Extruder – Please Advise

Ice cream set aside, wrench in hand, I assault the printer. It balks but yields to my superior will. However, the blockage defies the strongest probing I dare, and the printer, yet again, wins the day.

I found a spare Allan wrench that seemed to fit the bill - 1.54mm from face to face and 1.72mm at its widest (point to point). Tried to straighten it out, but it cracked (strong but brittle, I guess). However, I still had a length of 76 mm to work with. It seems to be about 78 mm from the bottom of the heat block to the top of the PTFE tube, and 112 mm total from the bottom of the heat block to the top of the extruder where the filament enters.

I removed the nozzle, heated to 230C and pushed up from the heat block with the Allan wrench rod. A firm and defiant blockage, 27 mm from the bottom (heat block), and I was really pushing alarmingly hard. I tried with filament from the top end and the blockage was hit 82 mm from the top of the extruder where the filament enters. The math says the blockage is about 3mm high, and appears to be 1/3 of the way up the heat sink.

I then tried an Acu needle from the bottom. It could not penetrate whatever is in there (plutonium?), One would think that, if it was filament, it would be soft enough to allow at least a very sharp Acu needle to at least stick into it. Maybe the PTFE is collapsed somehow ...

A new PTFE tube is arriving in 2 days DHL from Prusa, so I am resigned to rebuilding the extruder. (after eating ice cream).

Thanks *so much* for all the help!!!

-- Clint Goss

Re: Broken Filament in Extruder – Please Advise

[...] I removed the nozzle, heated to 230C and pushed up from the heat block with the Allan wrench rod.

Heat the block 1st, THEN remove or add the nozzle. You want the parts expanded for best fit. Shouldn't be a problem, but if it stuck, heat might help.

Sounds like you encountered a demon. Sorry it didn't work out. I thought for sure this would get you back in business. Please let us know how you get on with the PTFE, because I'm sure that's next on my list of adventures.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Broken Filament in Extruder – Please Advise

Heat the block 1st, THEN remove or add the nozzle...

Uhh ... yes, of course, that is what I did ... didn't write it, but I did it ...

I'll keep you posted!!

-- Clint Goss

Re: Broken Filament in Extruder – Please Advise

Heat the block 1st, THEN remove or add the nozzle...

Uhh ... yes, of course, that is what I did ... didn't write it, but I did it ...

I'll keep you posted!!

Once you are back up and running, always extrude 20-25mm and then immediately unload. This gets rid of the melty mess and makes unloading easy. This is a common problem if you preheat, wait, and then unload. Extrude first and immediately unload.

Re: Broken Filament in Extruder – Please Advise

... always extrude 20-25mm ... Extrude first and immediately unload.

Never seen this advice. Not sure why. Pretty basic ... like every printer should arrive with a big, bright, bold plaque announcing ...

Extrude Before Unloading ... or you'll be sorry ...

I do (now) see on Github ( https://github.com/prusa3d/Prusa-Firmware/issues/417 ) the calls for this to be added as standard practice ... Oh, this is such a young technology ...

-- Clint Goss

Re: Broken Filament in Extruder – Please Advise

Hi Clint,

If you try hard enough, you can learn something new every day! 😀

but sometimes we need a good cock-up. as the catalyst for accelerated learning! 😯

and one of the biggest time savers is a forum like this...

most issues have already been addressed. but finding the solution can be difficult with the search engine.

other users can often zoom in on the solution from a different perspective.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Broken Filament in Extruder – Please Advise

... catalyst for accelerated learning! ...

In the old model, someone with the experience, writing skills, and commercial desire would collect all this info over a decade and writes the definitive How-To book. Three years turn-around, if we're lucky.

In the new model, I think the dynamic document - a FAQ, Beginner's guide, etc. - can be incredible in so many ways for this type of content. I think that the Prusa How-To-Build on-line manual ( https://manual.prusa3d.com/c/Original_Prusa_i3_MK3_kit_assembly ) is an example of that. The quality of the presentation, the speed of improvements, the ability to drill down to everyone's thoughts without it cluttering things up (if you don't have problems) ... absolutely fantastic. However, the commercial incentive is often absent, so these things only get done on a volunteer, open-source basis.

finding the solution can be difficult with the search engine.

Search ... in its ideal form ... provides at least a workable alternative to the well-curated FAQ. However, the search engine on Prusa's forum I find lacking. Rather than use the Prusa Forum search box, I will often use Google Search with a query such as:

Clogged PFTE site: https://shop.prusa3d.com/forum/

.. I tend to get far better results ... Note that I mis-spelled "PTFE" as "PFTE", and Google Search can provide a correction ...

-- Clint Goss

Re: Broken Filament in Extruder – Please Advise

So it's a case of

a, knowing the questions to ask, and

b, asking the questions in the right place...

🙂

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Broken Filament in Extruder – Please Advise

3D printing is a lot like driving in Boston. Once you know where to go, it's pretty simple. They still throw in surprises now and then.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Broken Filament in Extruder – Please Advise

... always extrude 20-25mm ... Extrude first and immediately unload.

Never seen this advice. Not sure why. Pretty basic ... like every printer should arrive with a big, bright, bold plaque announcing ...

Extrude Before Unloading ... or you'll be sorry ...

I do (now) see on Github ( https://github.com/prusa3d/Prusa-Firmware/issues/417 ) the calls for this to be added as standard practice ... Oh, this is such a young technology ...

yeah i am cnlson over on git. so you can see me begging marek to add it so far unsuccessfully. i do it each time. Started when someone ripped the sensor off their filament sensor board and i had nearly the same experience.

Re: Broken Filament in Extruder – Please Advise

Had a replacement PTFE tube in hand, from Prague to Connecticut, less than 23 hours after Prusa Support determined that it needed to be replaced. No charge. (!!)

I also reviewed these resources, recommended by Joan and Bob and others …

https://manual.prusa3d.com/Guide/How+to+trim+PTFE+tube+-+MK2-S+MK2.5+and+MK3/500?lang=en

… found various versions of the E3D v6 Hotend Assembly instructions …

https://www.matterhackers.com/articles/how-to-assemble-an-e3d-v6-all-metal-hotend

https://e3d-online.dozuki.com/Guide/V6+Assembly/6?lang=en

… and found a video for the procedure for an earlier i3 model:

… all of which are informative, but none directly address the “Changing the i3Mk3 HotEnd PTFE Tube” procedure.

In lieu of an official procedure for changing the HotEnd PTFE tube, Prusa Support recommended this video:

... which became my primary procedure reference.

I got through Step 4 (removing the extruder fan) with no problems.

I got lost on step 5 – dismantle the thermistor cables, beginning at 2:30 in the video. The presenter (3D Gents) is apparently doing several maintenance tasks at once, and I was not sure which things I needed to disassemble in Step 5. The complexity and speed increases dramatically at this step, and the camera work prevents you from seeing what is happening.

There are lots of tiny wires begging to be broken and I’m just not sure how to proceed …

Is there some documentation or instruction procedure I’m missing??

If I purchased a replacement E3D v6 HotEnd, would I be better off??

-- Clint Goss

Re: Broken Filament in Extruder – Please Advise

Buying a new hot end would bring new issues.

If you can manag3 with what you have. You will save time and effort

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Broken Filament in Extruder – Please Advise

Hello,

Stuck. Got MK2S (kit, build it myself) that has been working flawlessly some six months but now I'm stuck. Filament got a kink/break, so I cut it before got to the extruder. Then I tried the unload the stub before unloading "new" filament.

Not sure what happened, but it just won't load the filament anymore. It feeds well, pulley is taking it in but then it stops and I get this clak-clak-clak sound, to my understanding because it cannot push the filament to the hot end for some reason. I did open the tensioner door, all seem to ok there, and it does take the filament in to the tube.

I tried also the supplied needle (luckily still found it 'cause I have not needed it) and after warming the hot end I can push it all the way in. There's nothing oozing out either like it normally does when it's warming and some PLA oozes out before the bed is ready.

So I'm puzzled... where's the problem? Is there anything I can do before taking the whole thing apart - which I don't want to do, it's a hassle and probably have to re-calibrate after that etc...

Re: Broken Filament in Extruder – Please Advise

So I'm puzzled... where's the problem? Is there anything I can do before taking the whole thing apart - which I don't want to do, it's a hassle and probably have to re-calibrate after that etc...

I would try this process, recommended by Joan and Bobstro:

so take your courage in your hands, heat up the extruder

remove the nozzle and thrust your 1.5mm allen wrench into the lower end of the hot end, with the intent of pushing the deformed filament out of the top of the PTFE tube. the unknown is always scary... it's time to start getting intimate with your extruder...

This did not work for me ... too bad a jam in the PTFE tube ... but it's a good first try ...

-- Clint Goss