After 3 or more hours my Prusa MK3S either stop extruding or begin under-extruding due to extruder filament grinding. (Example print pics included)

I’m sorry for the length of this post, but I want to make sure I’ve left no stone unturned. I have only had my MK3S for a few weeks, I’m still using the stock Prusament PLA filament that came with the printer. The printer is runs in a small apartment with a stable temperature (71 F / 21.6C).

When the filament begins under extruding or totally stops extruding, I always know immediately by the sharp clicking noise the extruder gears make on the filament. I have checked the nozzle temperature the first time I hear a sharp click, and it is always within 1 degree of 215 C.

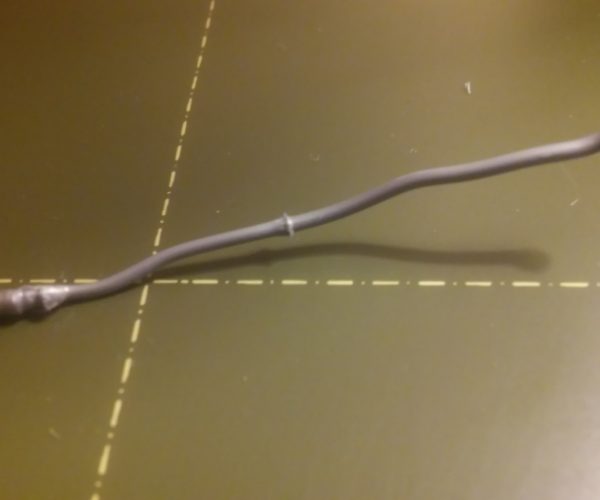

When I try to unload the filament afterwards, I hear the same clicking sound from inside the extruder as the gears try remove the filament, but cannot as it is stuck. I have to set a high temp, then advance the extrusion motors and attempt to unload a few times before the filament finally becomes pliable enough that it can be pulled out. When it finally does come out the tip is slightly bulbous and there’s very fine string running off it.

Sometimes the filament will begin extruding normally again, but my print will end up with weak layers (a couple millimeters thick) that break apart easily with little pressure. But most of the time when the clicking begins it will not stop. Then the current filament below some point in the heatsink will continue to extrude and then nothing else comes out of the nozzle for the remainder of the print time.

I have thoroughly researched the issue to no avail. Some forums indicate it could potentially be caused by the shape of the stock heatsink. I was previously using Cura, and I took this issue to Prusa support and they had me adjust my extruder tension screw and adjust my live-Z. Once they were satisfied with my hardware adjustment, they advised me to update my firmware and use the updated PrusaSlicer with stock settings. They also insisted the shape of their stock heatsink was not an issue despite the pictures I’ve send them with bulbous filament ends.

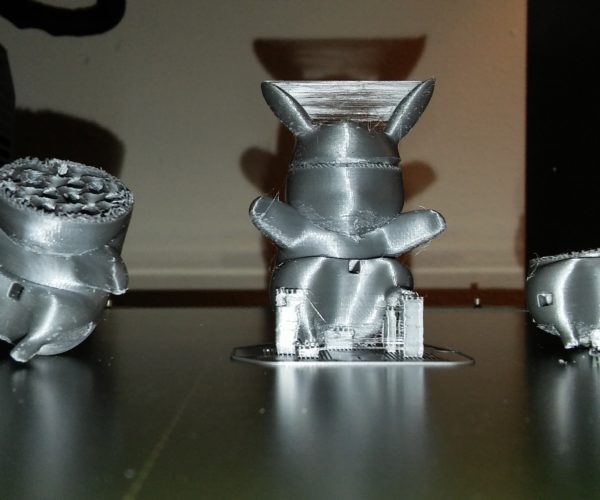

I was able to see a bit more consistency, but larger prints are still experiencing this issue. I have printed a 53 mm tall Pikachu three times, and the extruder clicking began between 3 to 4 hours or longer into the print. I’m using the PrusaSlicer .07 mm ULTRADETAIL MK3 settings and the only thing I’ve changed is to turn on the Brim and set the Filament Settings -> Extrusion Multiplier from 1.00 to .95. I only changed this after running a visual method cube test to dial in perfect smoothness for top surfaces. I’m not using adaptive layering for this print, and all my other settings are unchanged.

The below pictures show three attempts. As you can see the under-extrusion errors begin randomly at various heights, so it cannot be this particular Pikachu model causing an issue. I’ve cleaned out the inside of the nozzle several times in between prints and made sure to start a fresh strand of filament. I also ran a fresh PID calibration set at 215 C in between prints. I am hesitant to turn down the temperature because I get bad stringing as you can see in the middle (most recent) attempt. But I'm willing to change anything on the software or hardware as long as I can keep my .07 mm layer quality. I also included a picture of the end of the filament that I pulled out of the extruder after the last attempt to demonstrate extruder gear pressure.

It is extremely frustrating going several hours into a print that is perfect, then when I finally let my guard down I hear that first loud, sharp click and I immediately know my print is doomed. If anyone has had this issue and found a solution that solved it, then please share your method. I appreciate everyone who took the time to read this. I’d rather share too many details than too few, so please let me know if you need any further information to troubleshoot.

Thank you very much for any assistance.

RE: After 3 or more hours my Prusa MK3S either stop extruding or begin under-extruding due to extruder filament grinding. (Example print pics included)

Sure sounds like a heat creep issue.

If you use an enclosure, keep the doors open.

Make sure your extruder fan is set to 100%.

Worst case, buy a replacement heat sink from E3D without the Prusa recess. They are cheap.

Also - stock up on nozzle cleaning filament. Any debris in the nozzle is also bad.

RE: After 3 or more hours my Prusa MK3S either stop extruding or begin under-extruding due to extruder filament grinding. (Example print pics included)

The heat BREAK is the issue. The Prusa-fied version has a 2.2-2.0mm step not present in the standard E3D version. While you're replacing it, consider the Titanium version which is stronger and more resistant to transmitting heat up into the cold zone.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: After 3 or more hours my Prusa MK3S either stop extruding or begin under-extruding due to extruder filament grinding. (Example print pics included)

The key proof that the heat break is the issue is to measure the unload stub: If it measures only 2.0 mm, then the heat break is most likely not involved. if it measures 2.2 mm, the heat break is involved.

Also - you mention cleaning the nozzle: have you done a COLD PULL?

RE: After 3 or more hours my Prusa MK3S either stop extruding or begin under-extruding due to extruder filament grinding. (Example print pics included)

I want to thank you all for your responses. I have contacted Prusa support directly, and they directed me to the following;

https://help.prusa3d.com/article/WWVRzOY1dX-clogged-hotend

https://help.prusa3d.com/article/lnbcnhg76k-cold-pull

And as one last measure they advised to try changing the default retraction distance from .08.mm to .03.mm. The only reason I have taken this long to respond is because I have been following these instructions for days now to ensure I've tried everything several times. I have followed all these instructions to the letter with no consistent improvement. The only thing I have not done is to take the extruder totally apart because I have performed cold pulls after every attempt and they come out textbook clean every time. The guide referenced above states to take the hot end out from the extruder only if the filament is stuck in the white Teflon tube.

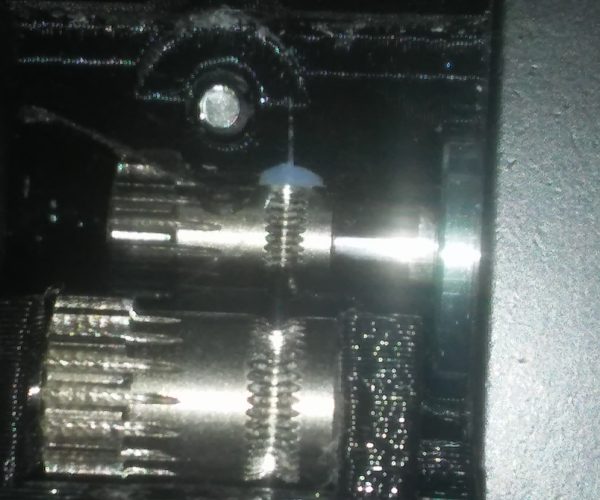

The hot end (at least as anything having to do with my actions) cannot possibly be the issue because the tube is not clogged and it is seated properly. The below pictures demonstrate both my recent cold pull, as well as the inside of my extruder to show the gears perfectly aligned and the white tube seated properly. (For some reason the picture is upside down.) I put the kit together myself, and I was extremely careful not to tamper with the hot end assembly which still came assembled from the factory.

You are all essentially telling me the same thing, and I am going to send an email to Prusa support asking them to fix their product refund my purchase. I have poured hundreds of hours into this over the last month, and this is the final straw. This is a brand new printer and I should not HAVE to buy extra parts. They directly told me "thermal paste" should not be necessary for a new printer and dismissed the idea of a flawed heat break as "lore". This is my first 3D printer, I do not own an enclosure, and I have not tampered with the fan settings. The printer passed every calibration possible.

If you see anything in my above pictures that would make you suspect an issue that's actually fixable by me (without buying a different printer part), then please let me know. Again, I really appreciate all your advice, this is a refreshing community.

Thank you.

RE: After 3 or more hours my Prusa MK3S either stop extruding or begin under-extruding due to extruder filament grinding. (Example print pics included)

It sounds like you're dead-set against taking the hotend apart, which is your best option. Replacing the (not overly expensive) heatbreak or adding thermal paste to the top of the heatbreak have helped many many people move past similar issues in the past 2 years, but you seem dead-set against that, writing them off as "shouldn't be necessary". If you're not interested in following our suggestions at this point, I can only suggest pursuing a refund from Prusa and moving on. Good luck.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: After 3 or more hours my Prusa MK3S either stop extruding or begin under-extruding due to extruder filament grinding. (Example print pics included)

Bob is right on track; an FDM printer, as near as I can tell with my somewhat limited experience, home FDM printing is an art, not a science.

There are FDM printers aimed at science. I can't afford one.

The Mk3 isn't a turn key "every print will be perfect" machine. It is an adhock collection of parts that is sold to people who want a bit better experience in FDM printing than most Chinese machines are capable of, at a price point far below the next equally capable FDM printer sold for $3,000. And keep in mind, that $3,000 printer comes with a manual that requires the user to break it down to make adjustments and fix common printing situations. Also, that $3,000 printer also isn't intended for science, it's considered an entry level device.

Contact Prusa - use CHAT not email - and request a refund. Send an email, too. But CHAT will get you into their queue faster.

Good luck.

RE: After 3 or more hours my Prusa MK3S either stop extruding or begin under-extruding due to extruder filament grinding. (Example print pics included)

By the way: here's a headline from a $5,500 FDM printer designed for industrial/educational use: only 92% success?

“In [a single year] we printed for over 7,000 hours with only one [Z18] and had a success rate of 92%.”- Thomas Schmidberger, Applications Engineer

RE: After 3 or more hours my Prusa MK3S either stop extruding or begin under-extruding due to extruder filament grinding. (Example print pics included)

Another entry level "pro" FDM printer: https://project3dprinters.com/products/fusion3-f410-3d-printer?variant=19757810974790

Only $4,874 plus shipping...

RE: After 3 or more hours my Prusa MK3S either stop extruding or begin under-extruding due to extruder filament grinding. (Example print pics included)

MakerBot Method: $4,999: https://www.makerbot.com/3d-printers/method/

RE: After 3 or more hours my Prusa MK3S either stop extruding or begin under-extruding due to extruder filament grinding. (Example print pics included)

While I appreciate the alternatives to Prusa printers you all suggested, I feel the need to elaborate on my mindset. I'm not trying to be antagonistic at all, and I truly appreciate all your help. Let me clarify that I'm not against taking my printer apart down to the last screw to fix an issue that I may have caused. I take responsibility for my actions, and I have no problem following instructions.

However, I don't think it's fair to suggest/imply that because I am against purchasing additional products to make a brand new printer function properly that I am somehow being unreasonable. This is not an "art" in my eyes, this is a piece of technology designed for a specific purpose, and the product I purchased fails to fulfill that purpose. And I sincerely hope that Prusa's company feels the same way I do and will resolve to help me make my printer function correctly without advising me to make another purchase. And if they won't, then I will take your advice and look into another printer company that will stand by their product.

I chose Prusa in the first place because I read nothing but good things about the quality of their products and customer service. I sincerely hope they wish to uphold the excellent reputation they have earned for themselves. I'm sorry if I've come across as harsh, but I have poured hundreds of hoursnow into this printer since the day I received it a month ago. I work hard for a living, and everything I have was earned with my own hands. So I am going to naturally expect a company to do what's fair and honest when I give them my hard earned money.

I have sent an email to Prusa support linking this forum post as well as referencing all my previous support chats. If I ever get a reasonable resolution I'll be sure to share the results. Thank you all for your help.

RE: After 3 or more hours my Prusa MK3S either stop extruding or begin under-extruding due to extruder filament grinding. (Example print pics included)

@lexone - I share the sentiment; and was quite upset when my new MK3 arrived with a scratched up smooth PEI print sheet. Prusa was a bit confrontational about replacing it, as if I had scratched it taking it out of the plastic bag. That single act had twisted my impression of Prusa and I try to repay their kindness whenever possible. I've kept the scratched side pristine for the cold day Joe Prusa wants to inspect the sheet.

After some time, I've learned that Prusa ships home made printers that cost a bit more than the competition. I say home made because the development from the original RepRap i3 was and remains a community effort. The current Prusa MK3s is NOT a commercial design by any sense of the term.

Yes, my MK3 was in warranty when I discovered the heat break defect. I fixed it myself because I wanted to print, and knowing that Prusa would have me jump through hoops to clinically prove the heat break was the cause. So I made the trade off of accepting the fact Prusa is a bit shady when it comes to honoring parts of their warranty. They tend to accept replacing einsy boards even when the user likely blew it up; but for things like the sheets and heat break they for whatever reason - go to the dark side.

They should be able to explain - without any real effort on your part - why your printer is failing is what is needed to make it work correctly. Asking the user -- you -- to tear apart the extruder and add thermal compound to fix a manufacturing defect is NOT honoring the warranty.

Prusa should refund your investment or replace the printer.

ps: all that said, it is an unfortunate fact that the MK3S - warts included - is the best printer available under $3,000.

RE: After 3 or more hours my Prusa MK3S either stop extruding or begin under-extruding due to extruder filament grinding. (Example print pics included)

I'm going through my ow issues with the MMU2s that is not working reliably for me. The printer itself I built from a kit and has been totally reliable when printing single material parts, and does it better and faster than the Ultimakers we also have in our shop. So I understand the frustration you are experiencing.

I'm going to make a guess that your issue is indeed related to heat creep and it that it's caused by your extruder stepper motor getting too hot and transferring that heat through the extruder gears to the filament. The clue is how long it takes before your prints start failing. When I first got my printer the extruder motor would get really hot, and I know that in a firmware update they changed the voltage going to the extruder motor and it started to run cooler. I am no software expert, but if you can change the voltage through some g-code you can get the extruder motor to run cooler (I don't know the code to do this), or there are some mods I've seen (especially for using the MMU2s as it works the extruder motor hard) that have a cooling fan and duct running over the motor to cool it off, and hence the extruder gears.

RE: After 3 or more hours my Prusa MK3S either stop extruding or begin under-extruding due to extruder filament grinding. (Example print pics included)

I'm going to make a guess that your issue is indeed related to heat creep and it that it's caused by your extruder stepper motor getting too hot and transferring that heat through the extruder gears to the filament.

The hot extruder motor doesn't match the symptoms. The OP isn't printing in an enclosure, the failure is happening down in the heat break, not above the Bondtech, etc.

RE: After 3 or more hours my Prusa MK3S either stop extruding or begin under-extruding due to extruder filament grinding. (Example print pics included)

@lexone

+1 for heat creep issue. https://www.matterhackers.com/articles/how-to-clear-and-prevent-jam

You can lower the chance by reducing the retraction settings, using thermal paste, replacing heat break, .... But you have to understand that this issue is part of PLA+FDM printing. You will have this with any printer at some point if you print PLA. You can also switch to other materials like PETG where it's less likely (actually I never had it with PETG).

So you can either try to push PR provide you with free of charge replacement parts/refunds. Or you can follow the hints experienced people in this forum giving you in order to handle this issue and move on to other exciting printing projects.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: After 3 or more hours my Prusa MK3S either stop extruding or begin under-extruding due to extruder filament grinding. (Example print pics included)

I love the term heat creep. Kinda of like calling everything you don't understand a Zombie or Monster.

The high motor temperature in an enclosure can soften filament that then deforms and piles up around the PTFE tube and/or tends to jam inside the PTFE, making unloading almost impossible. In a 40c enclosure, sure, an 80c motor may soften some PLA types and cause problems. In a normal 23c room, this does not happen: even 60c is not hot enough to soften PLA.

Look at the OP issue: where does he say filament is melting at the Bondtech gears? Look at the photos: do any of the filament images show melted filament above the actual melt zone? Is there any sign of even slight deformation above the melt zone? No. Also, and very significant: the OP does not have his printer inside an enclosure.

RE: After 3 or more hours my Prusa MK3S either stop extruding or begin under-extruding due to extruder filament grinding. (Example print pics included)

Hi,

I have exactly the same issue as you...

I also spend hours trying to solve it without success. In my case, the problem occurs when I changed for the MK3S bundle kit. It happens only with some filaments, PLA or PETG. I don't have enclosure, my room temperature is fine, I have changed the heatbreak for a stock E3D, I have checked the thermal paste issue, the PTFE tube, I use use the last firmware, I dried all my filaments, etc... Nothing solves it.

The last time it happens was yesterday with a basic object without tons of retractations (3D jake PETG):

Unfortunately, I have many other exemples.

Now I don't see how to solve it, I really think the problem comes from the Bondtech. Maybe one solution could be to change back for a classic MK3.

I can't use my printer for more than 2 hours prints, except if I use Polymax PLA which prints perfectly fine and some black PET. So some filaments are more sensitive to others.

So I agree with Lexone... even if the MK3S is full of nice features, even half the price would be too expensive for a machine you can't use. I often use 3 others fdm machines : Ender 3, Ultimaker 3, Ultimaker S5. The Ultimakers works really great, which is normal according to their prices. The Ender 3 is not as fancy as the MK3S but it works. Only the MK3S doesn't work as advertised.

RE: After 3 or more hours my Prusa MK3S either stop extruding or begin under-extruding due to extruder filament grinding. (Example print pics included)

This is a known problem with E motor. It heats a lot and increase the blondtech temperature which makes PLA filament breaks. It will only happens with PLA because at 40/50C it starts to melt.

This issue will be addresses at the 3.9.0 firmware, but, you can search the web for "prusa e motor hot" and get some mods to solve the problem, like, heatsink or a cooler.

This is an extruder design problem.

regards,

Otávio Ribeiro

RE: After 3 or more hours my Prusa MK3S either stop extruding or begin under-extruding due to extruder filament grinding. (Example print pics included)

I also have the same symptoms at times. It seems like heat creep, but I have no enclosure and the printer is in the basement with a temp of 18 C. Also happens with PLA or PETG. I have MK2.5S and MMU2S. What I have found is that the Bondtech gear on the extruder is moving and becomes misaligned a little. I put some blue Loctite on the set screw to help it and it worked great for a month including MMU prints. I seem to be having the problem again and I will check this evening and put a new set screw in.

David

RE: After 3 or more hours my Prusa MK3S either stop extruding or begin under-extruding due to extruder filament grinding. (Example print pics included)

Also check out - by the looks of your pulled filament - if your issues are not caused by the apparently very common issue of the black collet on the PTFE tube moving back and forth and thus allowing the filament to expand between hotend and PTFE tube.

See in the video in this thread, where that is explained very well: https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-hardware-firmware-and-software-help/question-what-might-cause-this-filament-stuck-in-coldend-ptfe-tube./

If so, the very simple solution is printing and installing a literally 1 cent collet ring: https://www.thingiverse.com/thing:3499966

For some reason, Prusa prefers to stay agnostic of this design flaw and my first support experiences have been sub par as well. Still, the printers are great and it's been an investment that I was instantly and still am in love with!