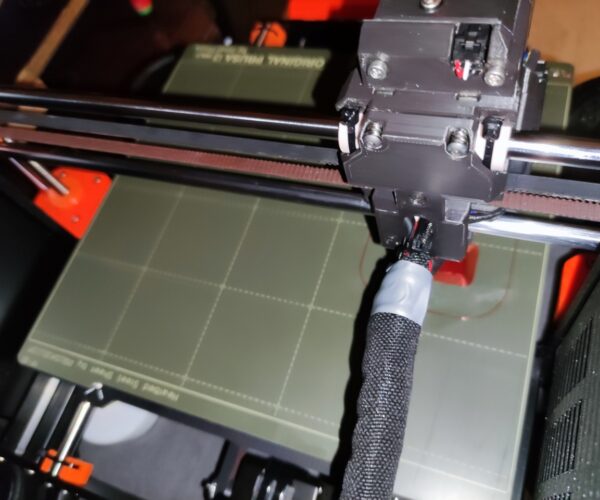

X-Axis Rod Spacing

I finally spent some time to verify a suspicion. It seems the X-Axis rods are not as precisely aligned as we'd probably like, and this is causing some of the X-Axis self test errors by increasing drag that shouldn't be there.

The crux of the problem is the two X-Axis support brackets are printed vertically, so the rod spacing side to side is relative and virtually identical, controlled by the lead screw precision and layer one - 44.934 mm on my Mk3. But, on the extruder, the bearings are held in parts printed such that the bearing spacing is controlled by X or Y axis calibration, which is not as precise as the lead screws. On my printer, the bearings are held at a spacing of 44.705 mm, which causes them to bind as the extruder moves closer to the brackets. A 0.229 mm crunch.

This issue can be amplified at Prusa's print floor when parts for X come off one printer and the extruder comes off a different printer.

A solution would be to have the extruder redesigned to allow the lower bearing to float vertically a +/-10 thousandths. The top rod and dual bearings will carry the weight or the extruder and X torque, the bottom bearing the Y torque that is applied during printing.

I suspect Y has the same generic issue, but the rod holders probably have enough slop the issue isn't as pronounced as to cause added friction.

I started looking at the extruder drawings to see if making the lower bearing cutout oblong... but there are hardware cutouts, nuts and screw ends... so not sure if a mod will work. So I am wondering if anyone else has worked through this and come up with a solution.

The alternative is to just reprint the extruder, but change the scale to better match the X-Axis supports... but this may also have problems if the materials aren't identical and thermal stability causes binding. So it looks like a reprint of everything. Lol.

RE: X-Axis Rod Spacing

this is an interesting problem - does anyone have any ideas?

RE: X-Axis Rod Spacing

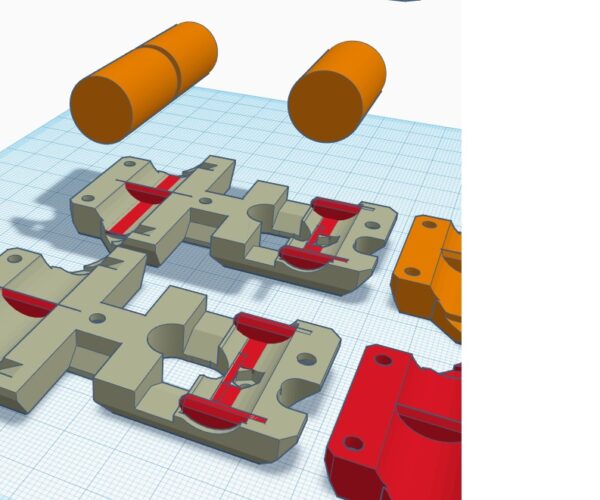

I created new x-carriage parts that allow the bearing to float vertically. I have yet to install them to see if they work as expected. But the concept is simple enough there shouldn't be any surprises. Once I get my mind into "tear down a functioning machine" mode, I'll be doing major maintenance: e.g., new rods, bearings, hotend upgrades for carbon and metal filled polycarbonate printing, and swapping in the new extruder case.

RE: X-Axis Rod Spacing

I had this idea also cause my bearings are having no play. I am using vesconite superlube bearings. The have very tight fit so i creaed a similar idea to make the bottom bearing a little bit play. I also pressed the backplate using springs so that there is more play for the bearings and can be more fine tuned when tensioning the screws.

RE: X-Axis Rod Spacing

@jimmy-3

I like the concept. I also have the Vesconite bearings but have not installed them. I would like a followup after a few weeks of use.

Have you published your bearing holder .stl file variation?