White dust on extruder area

So I am doing my usual prints when I noticed a scratching noise. Apparently the fan shroud has melted and deformed, hitting my prints to the point it dragged one of my prints off the bed. Failed print of course but definitely used to it on this new problematic printer I received from Prusa.

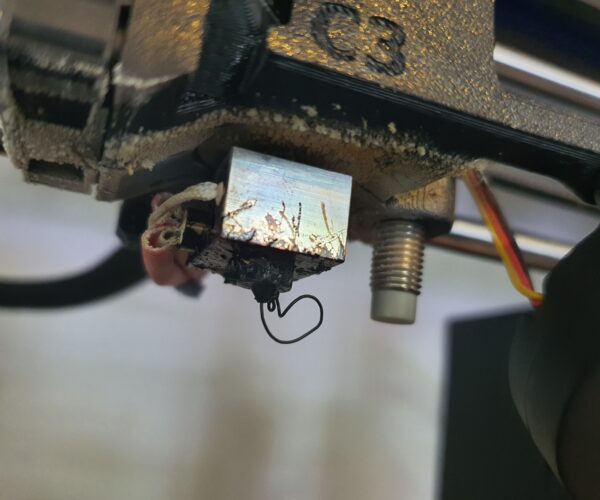

I can re-print that part, not an issue, but what makes me wonder is the white dust that is accumulating around the extruder area. Any idea what this is about and the gravity of situation I am facing at the moment? I print mostly Prusa ABS and the only time I printed PETG is to make the face shields which is roughly about 25-30hours a month back.

dust at pinda point

dust at pinda point  dust on extruder body and around it

dust on extruder body and around it  deformed fan shroud and turned almost white due to dust.

deformed fan shroud and turned almost white due to dust.

RE: White dust on extruder area

Are you printing in a slightly dusty environment? Check if you get the same dust on the outlet side of fans, or on the fan blades, elsewhere in the area, for example laptop or desktop computer fans.

Cheers,Dave Jackson"Enthralled Nooby (not so much maybe, ~58 years old)... If 3d printers had been around 40 years ago... "

RE: White dust on extruder area

Hi Dave,

I am printing in a room so I ruled out environment as the main cause. Moreover I have my older Prusa MK3s side by side without any issue. I disassembled the fans, fan shroud and extruder cover and had it cleaned up with a brush. I also had a new fan shroud and extruder cover printed out as the orignals melted. I am not sure what is wrong actually as I always play safe and use the standard settings of the slic3r.

I just find that this unit I got 2 months ago has a few issues going on ( I had a record of 150 crash detected) and I just want it to work properly, not trying to figure out who's fault is what. I am hoping I could find the help I needed here.

RE: White dust on extruder area

@jon-calma-v

Do you use any paste (copper paste or ceramics paste) on the hotend (nozzle or heatbreak)?

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: White dust on extruder area

@karl-herbert

i dont. is that necessary?

RE: White dust on extruder area

@jon-calma-v

The use of copper or ceramic paste prevents cold welding, corrosion and sticking of the nozzle and heatbreak. When the nozzle is heated, the fat in the paste evaporates and can settle in the area of the hot end and cover the surrounding parts.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: White dust on extruder area

something new that I learned. but does it have any connection to the parts "melting"?

RE: White dust on extruder area

@jon-calma-v

No, the paste is only applied thinly to the threads and has no contact with the plastic parts of the extruder or with the filament. After applying the paste, the grease contained in the paste evaporates for a few minutes and smells a little. After that you will not notice anything. If you repeat this often, a whitish layer may deposit on the surrounding parts, but this does not bother you. As long as everything works perfectly, I wouldn't bother about the coating any more. You should clean the hotend from time to time anyway.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.