Troubleshooting

hi!

Quick question, I just want to make sure my ducks are in a row. I replaced my heat break and nozzle, now I’m getting constant jamming

I have made sure the nozzle and the heatbreak are correct in terms of how much they are screwed in

I have been using artic mx4 thermal paste and I think that might be what was causing the jam, could that be right?

I don’t know if I’m not using enough or if I should even bother using it for the time being

RE: Troubleshooting

Hi Doofy,

what did you replace the heatbreak and nozzle with?

did you replace the PTFE Liner in the heatsink, up to the bondtech gears?

the thermal paste should not cause issues.

Incorrect parts and incorrect assembly can cause jams, as can distorted or loose PTFE.

can we have a picture showing your nozzle and heaterblock in a side view? please

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Troubleshooting

Did you follow the E3D-V6 assembly guide to the letter? If not, try again.

https://e3d-online.dozuki.com/Guide/V6+Assembly/6

RE: Troubleshooting

hi!

Quick question, I just want to make sure my ducks are in a row. I replaced my heat break and nozzle, now I’m getting constant jamming

I have made sure the nozzle and the heatbreak are correct in terms of how much they are screwed in

I have been using artic mx4 thermal paste and I think that might be what was causing the jam, could that be right?

I don’t know if I’m not using enough or if I should even bother using it for the time being

Did you get it to work?

--------------------

Chuck H

3D Printer Review Blog

RE: Troubleshooting

@tim-2

I did follow it, and I still had the same issue, I’m printing PLA if that helps at all

i also had a new hot end come in the mail just the regular E3D V6 and it clogged almost immediately after I ran my live level, I’m not sure how I’m able to get it to do one run and then it clogs

RE: Troubleshooting

@joantabb

Hi there! It was Heat Break E3D V6 Titanium and E3D V6 Nozzle - Nickel Plated Copper

I’m not currently at home to take the picture but once I am I’ll update!

RE: Troubleshooting

Would not having a collet clip be a factor here? I was looking around and saw people have them and I wasn’t supplied with one

just spit balling here

RE: Troubleshooting

@doofy

Hi Doofy,

If the V6 is assembled correctly, not having a circlip will not be a problem, because the PTFE is meant to be slightly compressed and therefore not able to move

Having the wrong Circlip will make the extruder difficult to get into the Prusa extruder Housing

My Dragon Hot end came with a Circlip that was on the large side... It's in a box somewhere because it would not fit inside my hotend

I have 4 prusa's, only one has a circlip, and that's only because I wanted to see if a printed one would fit...

It's not made a noticeable difference

did you replace your PTFE when you added the titanium heatbreak?

If you get a gap between your PTFE and the bottom of the recess in the heatbreak you may get issues... BUT with a titanium heatbreak you should not get enough heat up there to cause a problem.

Regards joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Troubleshooting

We need more information before we can help. Photos of the printer extruder; photos of the failed print; and a copy of the project file you are printing that is failing.

RE: Troubleshooting

@doofy

Lacking a collet clip can result in the PTFE tube being released from the heartbreak and jams.

--------------------

Chuck H

3D Printer Review Blog

RE: Troubleshooting

Push the ptfe tube -hard- while you pull up the collet, the collet won't move if the ptfe is under slight compression.

Cheerio,

RE: Troubleshooting

I was able to get a new layer z test down before it clogged

before I swapped my heatbreak the clog would look like the others usually do

this one is confusing to me, I was able to get the z layer test down just fine, and once I started to print the benchy on the SD card it got the first layer down and then clogged

but When I pulled out the filament it looked normal to me besides the gear scoring because it was jamming

RE: Troubleshooting

@doofy

You need to stand back and diagnose the issue before making more changes.

You haven't really told anyone what steps you might have done to cause the issue, nor why you did them. You also haven't told anyone what you are printing to cause 'clogs' nor how you are printing it.

Because you aren't sharing important information, you are getting swags, not pointed suggestions toward solutions. The old garbage in garbage out problem.

You need to provide solid repeatable data. It starts with a part you print for diagnostic purposes, one that prints the same way every time you print it. Post the part (a project file renamed with .zip added) - we can review settings to eliminate simple obvious issues. Then you print the part and post a photo of the result. The photo allows us to see what is actually happening (most people are lousy observers when they are engulfed in problems). You will get a suggestion to try (not five things at once). Print again, post again. Yes, it might take a few iterations.

So step back - and approach solving this methodically. You'll get an accurate meaningful answer more quickly.

Start by posting clear photos of your hot end - the best you can from underneath the extruder. And then choose a test print to stick with, save the project, rename the file project.3mf.zip, and post it along with a photo of the print.

Plus - what you describe as your problem may not even need a print - there are simple tests to run manually to check for problems.

RE: Troubleshooting

@doofy

Take a break. Post the 3mf file zipped and some images of your failed prints. Let us try to help you.

--------------------

Chuck H

3D Printer Review Blog

RE: Troubleshooting

Sorry, I've been doing everything from mobile and it isn't as easy on the computer

anywho

I've been printing the PLA that comes with the printer at 215 for the nozzle and 60 on the bed

My steps are as follows

preheat, load filament, live z level and then print

a couple of things happen, there is a jam or clog somewhere in the nozzle and the live z level does not print

or

I get lucky and I am able to start a print, but I am only able to get a few minuets into it before the printer stops extruding any filament

or

I get the first big "line" the printer puts down and then it doesn't extrude after that

I haven't been able to supply any pictures of prints because 9 out of 10 times I am unable to print anything. Just constant issues either with the z level or immediately after that.

I have been following the E3D V6 hotend reassembly guide, I just don't have the blue collet clip I don't think it was included in my box so I am waiting for that to come this week hopefully

I didn't get a picture of the benchy because I didn't remember to do so, but I should be able to take some pictures tonight

below I have included a couple of pictures.

after preheating I put the filament in the printer and it comes out just fine

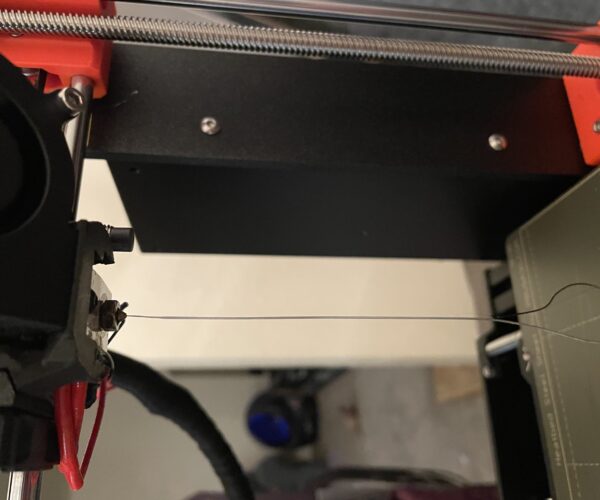

then here is the following z level after getting that squared away

last night I was trying to print a benchy, the one that comes with the SD card, and it was able to set the brim down and then it wasn't working any more after that

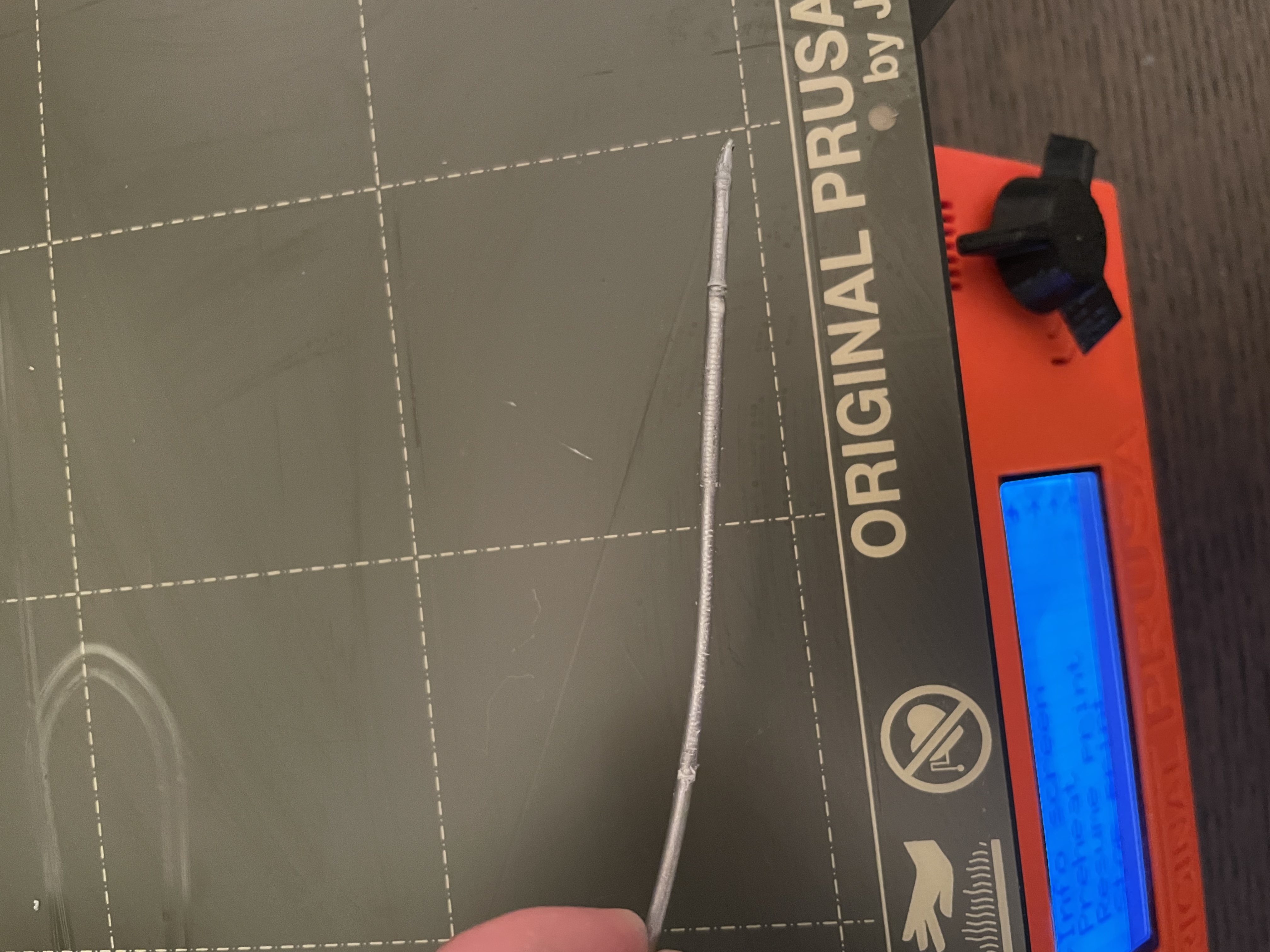

here is what I was able to pull out of the extruder

here are some pictures of the nozzle end and the heat break end

RE: Troubleshooting

Did the rectangle on the first layer calibration come off as one piece?

--------------------

Chuck H

3D Printer Review Blog

RE: Troubleshooting

The hot end is assembled incorrectly. Go back, disassemble it, and follow this guide to the letter.

https://e3d-online.dozuki.com/Guide/V6+Assembly/6

https://e3d-online.dozuki.com/Guide/Changing+Nozzles/45

ps: you might get away with simply heating it up - removing the nozzle, and turning the heat break in a turn or two... then reinstalling the nozzle. But you should also consider if you used heat sink compound on the heat break threads going into the heat sink.

RE: Troubleshooting

Any luck? Did you get it to print?

--------------------

Chuck H

3D Printer Review Blog

RE: Troubleshooting

I was able to get it to print! Thanks for the help everyone!!!!!

I thought I had enough torque on the nozzle with just a screw driver socket set but I ended up picking up a wrench to do the job!

RE: Troubleshooting

@doofy

You did have a mechanical issue during the print. It is a layer shift on the x or y-axis. Check your grub screws.

--------------------

Chuck H

3D Printer Review Blog