Re: Tired and indignant

I guess the easiest way to test would be not to replace the motor side but remove the idler side instead.

That's what I meant. The motor side alone should be fine. Personally I don't see the point in the second gear (although it must have applications otherwise Bondtech wouldn't have designed it), but I see potential trouble with it if not everything is properly aligned. The same as with the filament sensor, crash detection and octopi - I have all those disabled...

- Martin

- Martin

Re: Tired and indignant

Ok. I've mainly been programming with interpreted languages and haven't programmed in c++ in ages. I finally got the alpha firmware compiled but it output two hex files. Theres one hex file with and one without a bootloader. Which one do I use? I don't want to brick this thing lol

The file with the bootloader requires you to use a separate programmer board, while the one without it is the file to use if you are using the USB port on the control board to replace the firmware.

The board loader is what allows you to replace the firmware on the board by using the USB communication routines contained in the bootloader. So if you tried to flash the board with the bootloder file you will corrupt the bootloader firmware which will cause it to brick the USB. Then you would need the separate programmer board to reload the bootloader/firmware onto the control board.

Re: Tired and indignant

Personally I don't see the point in the second gear (although it must have applications otherwise Bondtech wouldn't have designed it), but I see potential trouble with it if not everything is properly aligned.

Same here. The longer I think about it the less I like having the second gear. It is also strange that they've designed the gear set in a way that you can have the teeth biting into the filament with any phase (displacement) between both sides, depending on how the gears have meshed when the gears were brought together (i.e. when the idler hatch was closed). In my case, the bite marks alternate between the left and the right side, which, I guess, is better than having them opposite to each other. But could also be the other way around, or it simply doesn't matter.

Re: Tired and indignant

Well it wasn’t any worse but it wasn’t any better

Re: Tired and indignant

Do you guys have the same problem?

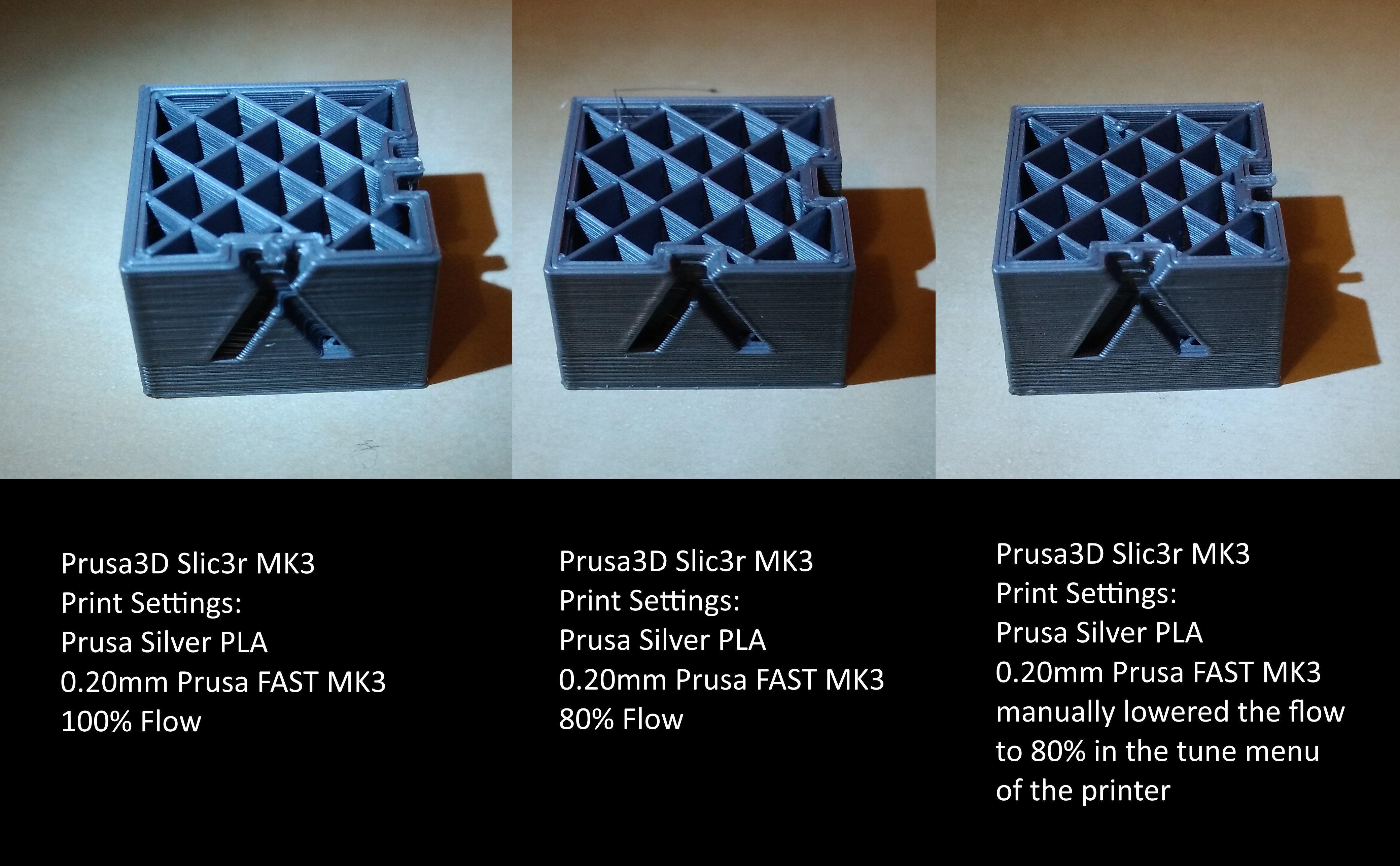

If i print the testcubes with 100% or 80% flow rate, they look absolutely the same. Even if i print them with 100% flow rate and change the flow in the tune menu of the printer to 80%.

The printer prints them all at 100%. See picture in attachment.

For this test i used the standard settings from Prusa3D Slic3r MK3 at 0.2mm layer height.

Re: Tired and indignant

Do you guys have the same problem?

If i print the testcubes with 100% or 80% flow rate, they look absolutely the same. Even if i print them with 100% flow rate and change the flow in the tune menu of the printer to 80%.

The printer prints them all at 100%. See picture in attachment.

For this test i used the standard settings from Prusa3D Slic3r MK3 at 0.2mm layer height.

different_flow.jpg

Yeah pretty much, so far I’ve drawn a blank fixing it, I’ve tried support and so far they haven’t being to helpful. It’s trying on to be a bit of a trait of a mk3.

Even people who say there machine is great have the same problem but just don’t realise or know better, support say there stacked out with chat and emails and clearly can’t cope so all you can fuss at that there’s loads of issues atm

Re: Tired and indignant

...there’s loads of issues atm

Same here. I stopped trying to debug the printer (like printing calibration cubes, trying preliminary software with K factor correction and such), there seems no point at the current state. At least there is a lot of activity on github, so I hope they'll come out with new FW versions fixing some of the problems. It's a bit annoying though not knowing what PR is up to. In the meantime, I am getting quite OK prints despite ringing, corner bulging, mesh bed leveling issues, PINDA temperature problems... MK2S was better though IIRC.

- Martin

- Martin

Re: Tired and indignant

Hi Stefan,

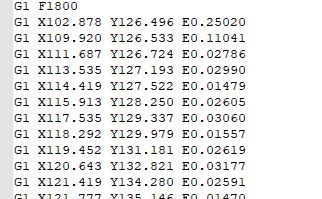

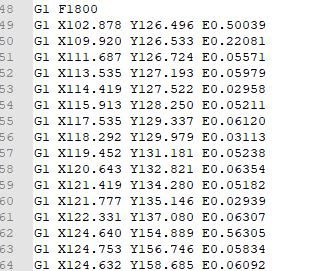

When you slice your files, check the gcode

I did a test file with the extrusion multiplier set to 50%,

and another with the extrusion multiplier set to 100%

the E commands define the extruder travel. the values in the 50% picture are as near as makes no difference, half of the values in the 100% picture... which makes sense,

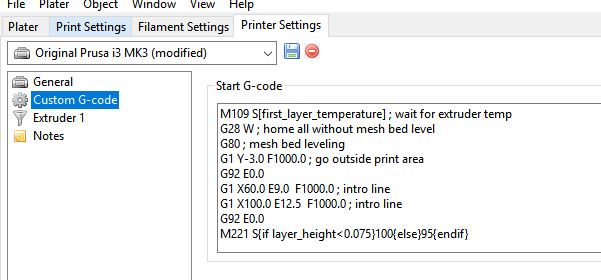

however, you will probably find M221 S95 in the beginning of the G code

there is a line in the custom gcode, start code that sets the flow rate, according to layer height, I am guessing this also plays a part in the filament delivery too...

I find that the flow rate is already set to 95% when I look at the option in the LCD menu, rather than the 100% you would expect to see,

maybe you need to make a significant change, before you see a difference in the output, regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Tired and indignant

Hi Stefan,

When you slice your files, check the gcode

I did a test file with the extrusion multiplier set to 50%, 50pc.JPG

and another with the extrusion multiplier set to 100%100pc.JPG

the E commands define the extruder travel. the values in the 50% picture are as near as makes no difference, half of the values in the 100% picture... which makes sense,

however, you will probably find M221 S95 in the beginning of the G code Custom G code.JPG

there is a line in the custom gcode, start code that sets the flow rate, according to layer height, I am guessing this also plays a part in the filament delivery too...

I find that the flow rate is already set to 95% when I look at the option in the LCD menu, rather than the 100% you would expect to see,

maybe you need to make a significant change, before you see a difference in the output, regards Joan

I find whatever the flow, extrusion or anything related makes no difference to the straight wall, no matter how well calibrated the extrusion is it’s always the same outcome, it’s rubbish. have you found your straight walls look ok?

Re: Tired and indignant

Is this Ok?

[attachment=0]20180331_004204[1].jpg[/attachment]

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Tired and indignant

Tbh it’s hard to tell with the light and the angle, different filaments show it more than others too. For example prusa Orange pet looks lovely but the inconsistency is still there just hidden, you can see it more using magnifying glass.

I’m only comparing it to my other printer which tbh is a pile of crap but it does have more consistent layers on walls

Re: Tired and indignant

Overall I am not seeing nearly as many issues, with the prints on my Mk3, as others are reporting and posting images of. However the print quality is less then I expected. Based on my experience I believe the overall design of the Mk3 has the potential to become one of the best printers, much like its predecessors.

Prior to the arrival of my Mk3 I had upgraded another one of my printers to include many of the hardware upgrades such as TMC2130 drivers in SPI mode with sensor-less homing. I also cloned the Mk3's extruder using actual bond tech gears and an authentic E3d Hot End as well as implemented linear advance. Aside from the heat bed and operating voltage the only real hardware differences between my upgraded clone and my Mk3 is the lack of the new optical filament sensor, the PINDA2 probe, the Power Fault sensor, my customized control board that began life as a RAMPS, and that my clone is running Marlin 1.1.8. Initially my clone was producing prints of a much higher quality. With all the comments and feedback from others, regarding attempts to troubleshoot their Mk3 prints, I decided to try identify the issue by duplicating the issues on my clone. I started by copying the speed settings and defaults from the Mk3 firmware over to my clone and utilizing the Mk3 default S;ic3r slicing profiles. What I ended up with was even better prints coming from my clone. While I can't completely rule out there possibly being an issue with the new Einsy board, or one of the other indicated differences between my Mk3 and my clone, I believe the issues are most likely software related. There were a lot of bugs with Marlin, when TMC2130 support was first added and several of the fixes are still official in pre-release. With the Mk3, I believe we are experiencing a situation in which the custom Prusa Firmware has been unable to keep up with all the new hardware advancements that Prusa integrated into the new design. As a further test I've been considering modifying my Marlin configuration so I can install in on my Einsy, but it will be a couple of weeks before I have the time to dedicate to the project.

Re: Tired and indignant

There were a lot of bugs with Marlin, when TMC2130 support was first added and several of the fixes are still official in pre-release. With the Mk3, I believe we are experiencing a situation in which the custom Prusa Firmware has been unable to keep up with all the new hardware advancements that Prusa integrated into the new design. As a further test I've been considering modifying my Marlin configuration so I can install in on my Einsy, but it will be a couple of weeks before I have the time to dedicate to the project.

Count me in on this as SUPER interested in your results. I think the issue is something in Firmware and the TMC2130.

If you run the same firmware as your other system, and get a different result, we know it's hardware... and if it's the SAME (as the other printer) and fixes the paterning... we know the issue lies in the SOFTWARE. Not saying it could be an easy fix, but it could become MUCH easier.

eg: just start isolating the differences.

I do have this issue everyone is fighting, however I have to hold it up to a light, and TRY to find it. (specifically looking for it)

And I have a feeling I will be making it go away // become even less visible tomorrow.

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.

Re: Tired and indignant

Overall I am not seeing nearly as many issues, with the prints on my Mk3, as others are reporting and posting images of. However the print quality is less then I expected. Based on my experience I believe the overall design of the Mk3 has the potential to become one of the best printers, much like its predecessors.

Prior to the arrival of my Mk3 I had upgraded another one of my printers to include many of the hardware upgrades such as TMC2130 drivers in SPI mode with sensor-less homing. I also cloned the Mk3's extruder using actual bond tech gears and an authentic E3d Hot End as well as implemented linear advance. Aside from the heat bed and operating voltage the only real hardware differences between my upgraded clone and my Mk3 is the lack of the new optical filament sensor, the PINDA2 probe, the Power Fault sensor, my customized control board that began life as a RAMPS, and that my clone is running Marlin 1.1.8. Initially my clone was producing prints of a much higher quality. With all the comments and feedback from others, regarding attempts to troubleshoot their Mk3 prints, I decided to try identify the issue by duplicating the issues on my clone. I started by copying the speed settings and defaults from the Mk3 firmware over to my clone and utilizing the Mk3 default S;ic3r slicing profiles. What I ended up with was even better prints coming from my clone. While I can't completely rule out there possibly being an issue with the new Einsy board, or one of the other indicated differences between my Mk3 and my clone, I believe the issues are most likely software related. There were a lot of bugs with Marlin, when TMC2130 support was first added and several of the fixes are still official in pre-release. With the Mk3, I believe we are experiencing a situation in which the custom Prusa Firmware has been unable to keep up with all the new hardware advancements that Prusa integrated into the new design. As a further test I've been considering modifying my Marlin configuration so I can install in on my Einsy, but it will be a couple of weeks before I have the time to dedicate to the project.

I could agree with what you said more, I hope prusa read that too!!! To me it’s always been the TMC/EINSY that’s causing the issues. When you read more about configuration of the TMC it’s not that sright forward and it’s clear they haven’t got it right...yet! I’m still hopeful about that but extremely pissed off that they let it ship with all these problems, at time it’s feels like I don’t want to waste filament on prints that aren’t prefect but at the same time don’t want to waste £700 or printer sitting unused! It’s very frustrating to me especially when I saved for ages to get a PRUSA.

I’ve been considering maybe repacking the board for a Rambo Just to get it back to MK2.5 its extreme I know I think it’s do able

Re: Tired and indignant

i have officially put my mk3 away until enough progress has been made with the firmware revisions and the STL parts revisions to become at least on par with the MK2S

i bought another prusa MK2S kit to use in place of my MK3.

So i felt comfortable enough to purchase yet another Prusa printer but i'm really disappointed in the MK3. the MK3 was no where near ready to ship when it did. for my current needs the MK3 is not capable enough to compete with the older MK2.

“One does not simply use a picture as signature on Prusa forumsâ€

Re: Tired and indignant

I see someone has put an issue on GITHUB, I’m not sure who on this thread done it but thanks!

Hopefully someone will start to listen or at least come out and say yes these is a problem and hold there hands up.

I know there’s loads of people with issues and loads of people who have issues and don’t realise you can see that from the pictures people post on Facebook about great prints.

I’ve emailed support, now I get no replay, I speak to chat and they say they really busy, quite frankly it feels like I’m now being ignored a little, hopefully by the end of the week I’ll hear back.

Re: Tired and indignant

I see someone has put an issue on GITHUB, I’m not sure who on this thread done it but thanks!

You're welcome.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: Tired and indignant

You're welcome.

Thank you.

But i feel that prusa will ignore it because there are enough people who have no problems. It's really sad what the company of Josef Prusa has become. The bigger the company, the smaller the interest that all customers are satisfied. 🙁

Re: Tired and indignant

Is this Ok?

20180331_004204[1].jpg

Joan

Joan, do you mind repeating that print with the silver Prusa PLA (if you have any left) and try to replicate the lighting in some of the other pictures?