Re: Tired and indignant

It's sad, but Prusa Research is riding on its reputation and our pockets. mk3 is the worst printer you can buy for $750.

Re: Tired and indignant

It's sad, but Prusa Research is riding on its reputation and our pockets. mk3 is the worst printer you can buy for $750.

Also since support no longer answer my mail ... I guess they do not know how to solve the problem

Re: Tired and indignant

It's sad, but Prusa Research is riding on its reputation and our pockets. mk3 is the worst printer you can buy for $750.

What's the best one? I have a Wanhao I want to replace.

Re: Tired and indignant

It's sad, but Prusa Research is riding on its reputation and our pockets. mk3 is the worst printer you can buy for $750.

What's the best one? I have a Wanhao I want to replace.

IMHO, there is no best one. Every cheap printer is a sacrifice in one way or another. The best printer is the one that you build yourself to serve your needs. I'm disappointed in my mk3 and I regret that I didn't spend the same money on custom VORON CoreXY.

Re: Tired and indignant

I'm definitely keeping my eye on this thread, too. I'm having fairly significant issues myself, that I can't figure out. It's like my extrusions are going from 95% to 105% in the same line, all around. It looks kinda similar to those videos posted by...er...the person I can't remember the name for in the previous page...lol.

Not sure what to do about this. I've tried flow rates from 80% to 105%, manually. I've tried using Slic3r PE and S3D, with multiple different profiles. Tonight, I was thinking of double checking the hotend assembly, and ensuring that it's stable. Oh, and I've already tried replacing the nozzle, as well.

I did notice last night that when I print the live z calibration print, when it's printing the final part, my nozzle appears to make little ripples on the line it's currently printing (not the lines next to it - it's not squished into them super hard). Almost like ringing, but on the wrong plain. So maybe I'm too low? Not sure.

Re: Tired and indignant

I have the same issue on my mk3. I spent $65 on musimu bushings like a naive kid, thought that it will fix anything... Crappy design of Y axis, crappy frame, outdated board... the whole printer is an accident.

I'm definitely keeping my eye on this thread, too. I'm having fairly significant issues myself, that I can't figure out. It's like my extrusions are going from 95% to 105% in the same line, all around. It looks kinda similar to those videos posted by...er...the person I can't remember the name for in the previous page...lol.

Re: Tired and indignant

I do not agree that your criticism of the Prusa MK3 is fair. MK3 is a really good machine for me (although there are still minor adjustments to be made).

MK3 is my first 3D printer (exept one week with the M3D Pro catastrophe machine), so I'm really an amateur in the area.

What's my punch to get good prints in PLA and PETG?

* I run the default settings in Prusa Slic3r. The default settings are good enough to get really good prints.

* I've learned from someone else's mistakes here on the forum.

* I have spent a lot of time fine-tune the X, Y and Z axes (all components run smoothly).

* I have spent a few hours working on the bed so I have as flat a bed as possible.

* I have been very careful to fine tune the z height of the first layer.

The printing problems I've had usually depend on a bad first layer or not preheated machine.

Bear MK3 with Bondtech extruder

Re: Tired and indignant

I'm definitely keeping my eye on this thread, too. I'm having fairly significant issues myself, that I can't figure out. It's like my extrusions are going from 95% to 105% in the same line, all around. It looks kinda similar to those videos posted by...er...the person I can't remember the name for in the previous page...lol.

Extrusion.jpg

Not sure what to do about this. I've tried flow rates from 80% to 105%, manually. I've tried using Slic3r PE and S3D, with multiple different profiles. Tonight, I was thinking of double checking the hotend assembly, and ensuring that it's stable. Oh, and I've already tried replacing the nozzle, as well.

I did notice last night that when I print the live z calibration print, when it's printing the final part, my nozzle appears to make little ripples on the line it's currently printing (not the lines next to it - it's not squished into them super hard). Almost like ringing, but on the wrong plain. So maybe I'm too low? Not sure.

I suspect your not low enough

I had the same problem - going lower cured it. I believe the 'ripples' are the head just catching the top of the filament bead, if you go lower it will smooth that out.

Re: Tired and indignant

I'm sorry but your prints are bad, any Anet A8 will produce the same crappy prints. No point to spend $750 when you can get the same prints for $200. Oh, and on A8 you can use LA, look at your crappy edges, right, that's because PR can't fit LA in limited MP.

I do not agree that your criticism of the Prusa MK3 is fair. MK3 is a really good machine for me (although there are still minor adjustments to be made).

MK3 is my first 3D printer (exept one week with the M3D Pro catastrophe machine), so I'm really an amateur in the area.

What's my punch to get good prints in PLA and PETG?

Re: Tired and indignant

I'm definitely keeping my eye on this thread, too. I'm having fairly significant issues myself, that I can't figure out. It's like my extrusions are going from 95% to 105% in the same line, all around. It looks kinda similar to those videos posted by...er...the person I can't remember the name for in the previous page...lol.

Extrusion.jpg

Not sure what to do about this. I've tried flow rates from 80% to 105%, manually. I've tried using Slic3r PE and S3D, with multiple different profiles. Tonight, I was thinking of double checking the hotend assembly, and ensuring that it's stable. Oh, and I've already tried replacing the nozzle, as well.

I did notice last night that when I print the live z calibration print, when it's printing the final part, my nozzle appears to make little ripples on the line it's currently printing (not the lines next to it - it's not squished into them super hard). Almost like ringing, but on the wrong plain. So maybe I'm too low? Not sure.

I suspect your not low enough

I had the same problem - going lower cured it. I believe the 'ripples' are the head just catching the top of the filament bead, if you go lower it will smooth that out.

I'll give it a try tonight. I'm already low enough that the bottoms of my prints look very good....but may as well try it too. Lol. I've never had the print head "catch" and cause those ripples before, so...that's a new one to me (and this isn't my first printer, by far...lol).

Re: Tired and indignant

It was new to me too! But the book explains it well, and boy was I surprised when my prints improved - I thought it would mess them up. I used a magnifying glass to observe the filament during the live z process so I could see the head push the top of the filament flat. My initial live z was 250 and ended up at 850.

Re: Tired and indignant

It was new to me too! But the book explains it well, and boy was I surprised when my prints improved - I thought it would mess them up. I used a magnifying glass to observe the filament during the live z process so I could see the head push the top of the filament flat. My initial live z was 250 and ended up at 850.

I'm skeptical. Like I said, the bottom layers already look near-perfect. But I'll definitely give it a try tonight. The ripples look more like the plastic expanding after the nozzle passes over it, or something (it's behind the nozzle, directly, where the ripples appear). At this point, I'll try almost anything, since I really, really don't want to dismantle the printer (ugh, I hate how poorly the printer is designed for deconstruction/reconstruction...).

Re: Tired and indignant

I also have a PRUSA i3 mk3. And I have the same problems as my partner Carlos. I am the administrator of a Telegram group in Spanish where this type of problem is being discussed. The support of PRUSA has been notified and the only thing they answer is nonsense without meaning after waiting several days. Many in my group have an mk3 either from a kit or already assembled. Here I leave some images of my impressions where you can appreciate the problems are those lines or stripes that appear in the prints. Even if the filament is changed, they keep coming out. And the only thing we ask from this forum is the support of PRUSA, to solve the problem that is serious.

Telegram group https://t.me/prusai3mk2mk3 Spanish.

Re: Tired and indignant

I'm sorry but your prints are bad, any Anet A8 will produce the same crappy prints. No point to spend $750 when you can get the same prints for $200. Oh, and on A8 you can use LA, look at your crappy edges, right, that's because PR can't fit LA in limited MP.

I do not agree that your criticism of the Prusa MK3 is fair. MK3 is a really good machine for me (although there are still minor adjustments to be made).

MK3 is my first 3D printer (exept one week with the M3D Pro catastrophe machine), so I'm really an amateur in the area.

What's my punch to get good prints in PLA and PETG?

It was sad that you thought my prints were crap. If your own prints are better than mine, I do not understand your criticism. I have really butiful surfaces (Exept my crappy edges on one part)

I am aware that my crappy edges are going to improve. I am also aware that different filaments provide different good results. Maybe that's why I put that part in my junk box.

Bear MK3 with Bondtech extruder

Re: Tired and indignant

I'm sorry but your prints are bad, any Anet A8 will produce the same crappy prints. No point to spend $750 when you can get the same prints for $200. Oh, and on A8 you can use LA, look at your crappy edges, right, that's because PR can't fit LA in limited MP.

I do not agree that your criticism of the Prusa MK3 is fair. MK3 is a really good machine for me (although there are still minor adjustments to be made).

MK3 is my first 3D printer (exept one week with the M3D Pro catastrophe machine), so I'm really an amateur in the area.

What's my punch to get good prints in PLA and PETG?

It was sad that you thought my prints were crap. If your own prints are better than mine, I do not understand your criticism. I have really butiful surfaces (Exept my crappy edges on one part)

I am aware that my crappy edges are going to improve. I am also aware that different filaments provide different good results. Maybe that's why I put that part in my junk box.

Ignore Spartacus, hopefully he will enjoy his A8's and move on...

Re: Tired and indignant

RHDreambox, don't take it personal. Spartacus is only bitching around in this forum, check all his posts.

Keep up on improving and understanding that's why many people are here.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Tired and indignant

FWIW, If I could get rid of the vertical lines I'm seeing in my prints, I'd be ecstatic with my mk3. It's pretty much the only thing I've got left to tune that's bugging me about my prints. Not sure if it's something mechanical, nozzle height related or something to do with microstepping the extruder. Hopefully I'll get to the bottom of it (or someone else will) soon.

Re: Tired and indignant

I Have probably the same (and additional) Problems. I did not have the time yet to actually try to improve.

From what i am seeing the extrusion differences are wors right after the Layer Seam.

The white Part is printed as a Pyramid (well tetrahedral because triangular base) so no "vertical" walls and moving two Axis at a time.

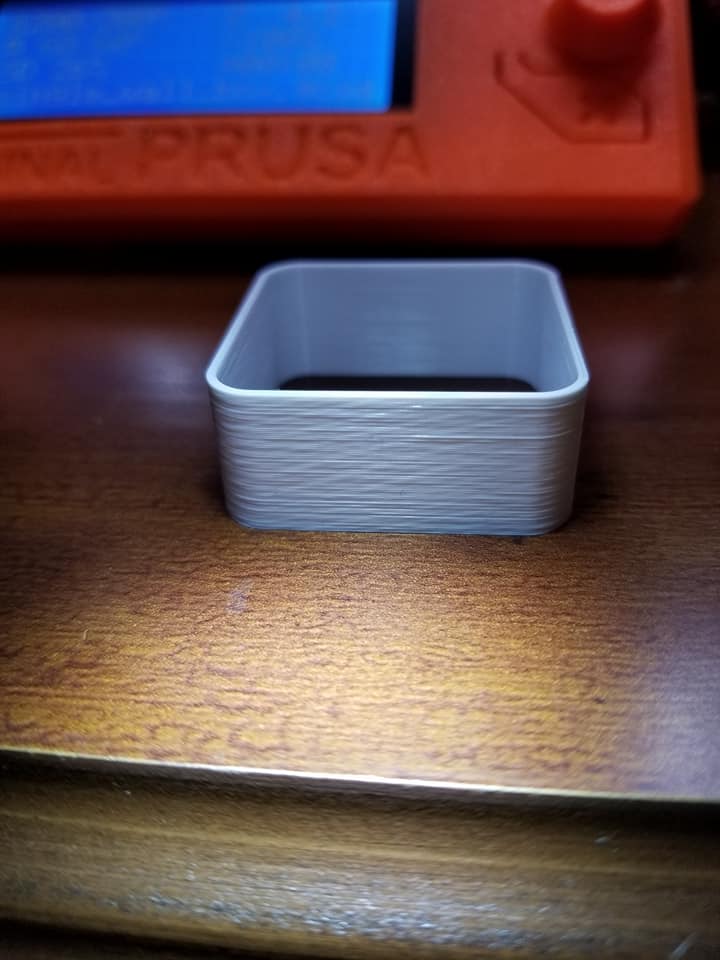

The grey Part was a quick one that i pushed speeds alot because i needed it fast. So take that as what it is: As bad as it got for me with 100mm/s perimeter without LA.

Its my first 3d Printer so i might be one of those who dont know bad if they see it and happy with the MK3 because of it. But from what i am seeing quality got worse with every Firmware update.

I checked the Mechanical Parts of the printer and i am going to update to "new Parts" in the next Week. I am not realy looking for trouble shooting right now since i dont have the time but will get back to this next Week.

Thanks to everybody here trying to get to the bottom of the Problems.

Cheers

Oliver

Re: Tired and indignant

OK. Next Step:

I disassembled the print head, changed the nozzle, put it all together, reset the printer, calibrated the printer with the wizard and printed a test cube with the s3d settings from JP. Same shit.

This thing prints worse than my tevo tarantula.

I am now printing for 4 years on 4 different machines and this one is the worst I ever had. I wish a had never sold my MK2. 🙁

Re: Tired and indignant

OK. Next Step:

I disassembled the print head, changed the nozzle, put it all together, reset the printer, calibrated the printer with the wizard and printed a test cube with the s3d settings from JP. Same shit.

This thing prints worse than my tevo tarantula.

I am now printing for 4 years on 4 different machines and this one is the worst I ever had. I wish a had never sold my MK2. 🙁

For what it's worth I personally did not like the S3D settings from JP. I had to make several changes to get excellent quality prints. It was a great starting point, but it wasn't ideal. I then did some Slicer PE and S3D comparison tests and found that I like the default Slicer profiles better in most instances.