Terrible curling on PETG - solution? Change nozzle!

Left the printer idle for a while, and after the 3.2.1 firmware I wanted to get everything tuned up again and start printing. Had a TERRIBLE time getting a good first layer, especially with PETG. Was obsessing over the Prusa Mesh Bed Leveling plugin in octoprint and trying to get things level, but I never had a variance over .3mm so was stumped on why the firmware couldn't fix it up. Every PETG print had sections of curling on the first layer, no matter what Z setting/temperature/speed. Spent way too long this weekend starting and restarting prints while changing params to try and get a good one.

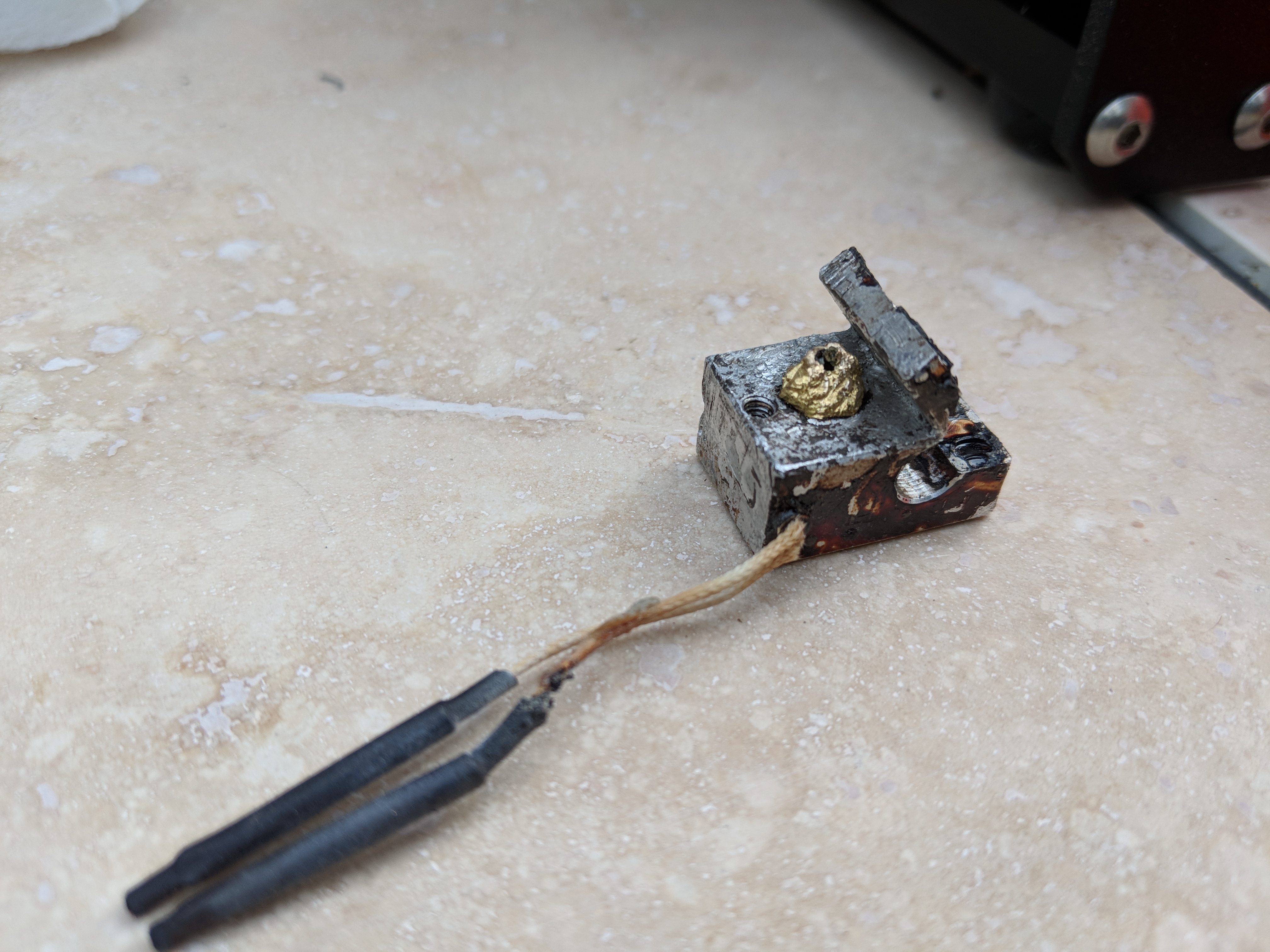

I noticed the nozzle looked kind of ground down on one side, like it wasn't flat on the the bottom anymore and when changing filaments it would immediately curly q all over the place instead of dropping down. I had a spare so figured I'd give that a try, and while I didn't intend to rebuild the whole extruder because the nozzle was seized hard in place thats what ended up happening. Result? New hotend block, new thermister, new nozzle, same heater, and now I've got a wonderful first layer in PETG again. I think the filament wasn't laying down but curling if the nozzle was moving away from the ground down direction, but worked mostly okay when the nozzle was moving towards the ground down side which is why my first layer looked great in some places and horrible in others.

I'd take a picture of it to demonstrate, but the nozzle is literally destroyed now and stuck in the old heater block. I have no lack of tools but could not get this thing loose even with the temp up to 295 degrees and ended up just grinding it down into nothing remotely gripable before just taking the E axis apart. Thankfully I had some spare E3D parts for a new build I'm doing. Not sure what ground it up, I had printed 3 spools of eSun ABS+ recently otherwise mostly just PETG.

Long story short - if you've got curling on the first layer and can't seem to get over it, checkout how flat your nozzle is. Mine was visible ground at this point. I almost wanted to try a print with it as pictured...

Re: Terrible curling on PETG - solution? Change nozzle!

Changing nozzles regularly is extremely important (as you found out), but is often overlooked by users. I think many "issues" would go away if people changed them more often.

Re: Terrible curling on PETG - solution? Change nozzle!

At what frequency to change nozzle ? in hours or kilometer of filament ?

Re: Terrible curling on PETG - solution? Change nozzle!

Depends on the type of filament being used, and if you want to get really technical many other factors too I would imagine.

But keeping it simple, you could pick an arbitrary number of hours. This would be the "proactive" method.

Or you could wait until you start to see prints not looking good, strange first layers like not sticking for example, and then change it. This is what happened to me the very first time. Had changed nothing on the printer, using same filament, bed very well cleaned, and all of a sudden the first layers would not lay down properly.

One thing is for sure, you can't always tell just by visual examination of the nozzle that you should change it.

Re: Terrible curling on PETG - solution? Change nozzle!

Would an all-steel nozzle avoid this issue? i.e. Maybe an upgrade from brass would solve the problem once and for all?

It bet it's the first layer infills which grind the nozzle down. There needs to be better software for reducing the infill height relative to the perimeter height.

Re: Terrible curling on PETG - solution? Change nozzle!

Would an all-steel nozzle avoid this issue? i.e. Maybe an upgrade from brass would solve the problem once and for all?

I guess it would lessen the need to change, although there must be some side effects to using an all steel?

But brass ones are so cheap and it only takes 10 minutes to change, so not sure if there would be much benefit. Personal choice i guess.

Re: Terrible curling on PETG - solution? Change nozzle!

Just make sure its a harde steel one and you wont have to change it for a long time! But if its just a shinny one steel one thats not harden it will still wear out faster than you think.