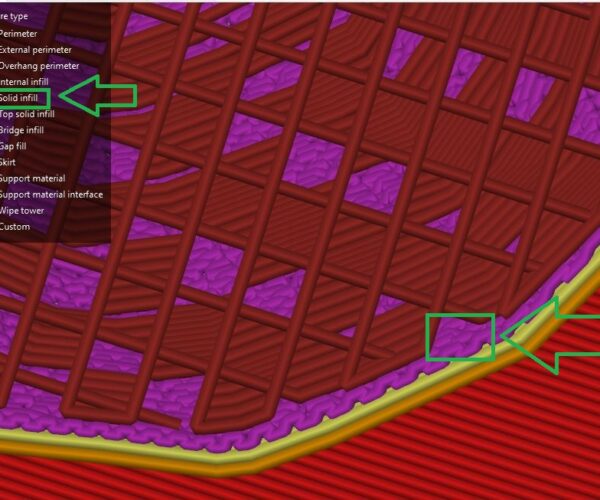

solid infill vibrations

when my printer lays down the zigzag line (the purple one marked in the green rectangle) creates big vibrations (and the higher the model the bigger they vibrations of course)

is this indeed a "solid infill" ? coz I went and decreased the speed in the slicer from 80 to 30 and still no change

RE: solid infill vibrations

That is most likely extra infill being generated when the Print Settings->Layers and perimeters->Quality->Ensure vertical shell thickness feature is enabled. If you hover your mouse over that option, it describes adding solid infill along slopes to ensure there's enough of a all for the perimeters to adhere to. So yes, it is indeed solid infill, just a special type of infill.

Speeds are probably not your issue since the lengths are so short. Acceleration and jerk settings will have more of an impact on motion.

That said, there's no way to really not have the nozzle move about rapidly on small features. I found that stabilizing my Mk3 resolved all the manic vibration problems. I coupled my printer to a 17x17 paver stone with felt pads, thus increasing the mass of the printer. I also uncoupled the printer+paver mass from the underlying table using Sorbothane pads. I now routinely print 30+ hour small, detailed prints with lots of such movement without alarming vibration or noise.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: solid infill vibrations

thank you @bobstro, that's realy helpfull

RE: solid infill vibrations

Sorry Bob but this is a known issue with Prusa Slicer, it can’t be turned off with vertical shell thickness or anything else at the moment. It is caused by sloping sides and is some internal part of the algorithms. There is an issue already on GitHub. The only ‘work around’ is to increase the number of perimeters.

RE: solid infill vibrations

@neophyl

Not so sure about that Neo. There might be some other bug being chased, but I can turn off Ensure Shell Thickness and these matriculations go away. The result can be unsupported perimeters, holes and/or gaps in the slanted walls, but it is what I tell it to do.

A copy of the model will be the only way to ferret out what is actually happening here.

RE: solid infill vibrations

ps: color me confused. With 2.3.0A2 the slicer does NOT obey the control. Funny I never noticed this - I must never actually use the OFF button in normal use.

If I turn off infill entirely, the issue goes away - so somehow it the two settings are coupled. But I see the slicer doing odd things at boundaries, too. Why the extra material being laid down here? Odd. Not expecting a reply.