Screwing With PLA

I just got my printer 3 hours ago! Yeah! So far so good.

I tried to print Benchy (the little boat) but instead I chose the dog by mistake. I let that go for a bit then aborted. It was looking good. From there I moved on to my stuff.

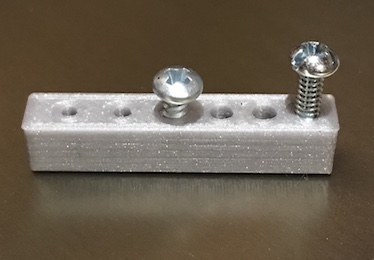

First up is a test print (with PLA) I did to determine what size hole I need to print to accommodate a #4 wood screw or sheet metal screw (screwed into the plastic) and a clearance hole for a #4 machine screw. This little block is 6mm tall in Tinkercad but printed 6.1mm tall. I don't know if that error scales with larger prints or if it's just a fixed offset. Later. The hole sizes (in Tinkercad) are, from left to right, 2.2mm (.087), 2.4mm (.094), 2.6mm (.102), 2.9mm (.114), 3.0mm (.118), and 3.1mm (.122). The 1st 3 are pilot holes for the wood screw and the last 3 are clearance holes. The 2.2mm is way too tight for a wood screw chewing into the plastic. Feels like it's about to break and is really really tight. The 2.4 is very tight, and the 2.6 feels right. Firm but not too tight. For the clearance holes and the machine screw, 2.9 won't take it, 3.0 is just barely passes the screw, and 3.1 has just a slight bit of play. That one feels right to me.

The drill tables say 2.38mm (.094) for a pilot hole and 3.66mm (.144) for a clearance hole.

I thought I'd pass this on to anyone who is in need of info like this. I looked and never found it.

Re: Screwing With PLA

Curious if you did an extrusion tuning before these tests? I imagine that if amount of plastic being extruded is not tuned for your specific spool then measurements will have a bigger margin of error. Having said this, I have no idea how much accuracy we can expect from the MK3 (or FFM in general)