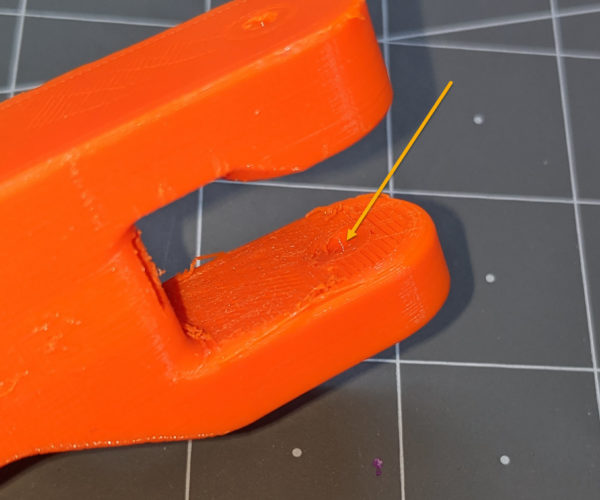

Rough support material left

I have been printing with my Prusa i3 MK3S printer for more than a year with great results. I'm printing parts for an EEZYBotArm2 robot arm from Thingiverse, some of which require supports. After I cleanup the supports, I'm left with what looks like ribs that are rough, very visible and some located where two parts need to smoothly rotate. The ribs appear on the top surface of any support.

I get the same results printing Prusa or SUN PET at 0.20 or 0.15 quality. I have tried all three patterns, Rectilinear, Rectilinear Grid and Honeycomb without changes in results.

Does anyone have recommendations to eliminate the rib effect?

Best Answer by Crawlerin:

It may be worth taking a look if there is a possibility to rotate the model to use less support material, or use it in places that are not critical to functionality. Sometimes STL files have weird and not optimal orientation. Also, with supports, some post-processing is required if you need prints looking nice or functional. Unfortunately we are not at the stage yet where you plop it off build plate and it's 100% finished.

RE: Rough support material left

This effect is normal for supported regions. The only solution is to use soluble supports with no spacing between support and part.

FDM requires the nozzle to print on something in order to squish out a nominal layer height. With supports, and gaps the generally needed, the nozzle is extruding a cylindrical 0.4 mm filament that droops until it contacts something or hardens into a bridge.

Basically, a 3D printer can't print something mid-air.

RE: Rough support material left

It may be worth taking a look if there is a possibility to rotate the model to use less support material, or use it in places that are not critical to functionality. Sometimes STL files have weird and not optimal orientation. Also, with supports, some post-processing is required if you need prints looking nice or functional. Unfortunately we are not at the stage yet where you plop it off build plate and it's 100% finished.

RE: Rough support material left

The OP is complaining about surface quality above support material. Since there is a belief an FDM printer should be able to print perfectly in any situation, like bridges and overhangs, it's probably better to educate regarding the limitations of the print process. First explain why the artifacts are there, then describe how to prevent or minimize them using part placement, position, and orientation. Once the basics are described, then move on to ways to minimize the artifacts using more complex methods that require more than a simple understanding of FDM.

For example: steps in printing overhangs, and why thinner layers help: and where the process breaks:

RE: Rough support material left

Thanks for the suggestions. I will take crawlerlin's advice and try rotating the prints to a different angle that may hide the imperfections and improve areas that have surface contact with other parts.