RE: Prusa MK3S+ vs Bambu Lab X1 carbon

You can't use TPU because of the "bowden" style of having to push it too far to get to the extruder.. I would think Prusa's MMU would have the same issue, but someone with an MMU would have to discuss. However, I believe the Bambu works fine with TPU, you just side load.. I have read reports where owners say TPU works fine by manually loading from the side.. which would be fine for me ..

Well ok, TPU does not work because it is not compatible with the AMS. At least thats what they say. I did not test it. But seems they won't add support soon, because the material is just too flexible. Don't know how you could solve that issue...

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

As a hobbyist, the Carbon has everything I’m after in the one package. I’ve literally put off some prints with my Prusa after I’ve seen the print time (I don’t like running overnight) and the Carbon would solve that. The only thing holding me back is the fact it’s a first gen product from a new company. Although with their popularity and the buzz they’ve generated so far, it’ll take some doing for them to fail IMO, but I’m still a little apprehensive because of that…….hmmmm……

RE:

It's a crowded market at the bottom, but at this price range it's mostly just BambuLab and Prusa. Most markets can support at least two primary competitors. For this reason, I wouldn't worry about BL going BK. Nothing is impossible, but from external appearances BL seems well managed, and the product appears to be selling as fast as they can make it. Anker seems to want to play at the $750 price point, but Anker's transparency hasn't been all that good because it has allegedly insisted on purely positive reviews, so due diligence is difficult. At the $1500-$2,000 price point, I might have bought a Prusa XL for the bigger build volume, but it just wasn't available. I'll be watching Prusa XL reviews with interest when it finally starts shipping. Any word yet on how long the Prusa XL build time will be once you receive the box? For many that's an important consideration.

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

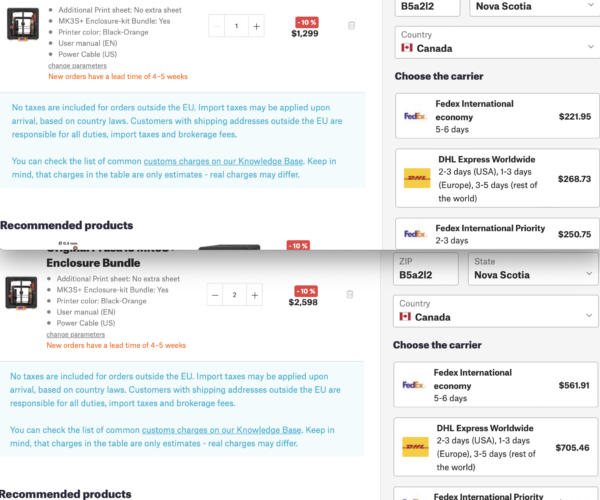

I swear Prusa doesn't want to sell printers directly to Canada.. (Canada dollars) .. thought maybe I could save a bit on our Canadian price by going direct..

One MK3+ shipping: $120

one MK3+ with enclosure: $250 (Fedex 3 day) medium cost shipping

TWO MK3+ with enclosures: $950 YUP.. count um.. almost 4x cost..

It would be nice if they'd even provide a service to actually install the printer inside the enclosure and then ship.. am wondering if they are shipping both parts separate? Surely together and shipped 2 of those should be less than $1k..

Grin.. what's worse? Yeah.. thats a US price.. so: $1330 Canadian.. a whole Bambu.. ($1500)

RE:

@crab

I was thinking that yesterday when I read your how much it cost you to get a MK3 even after I converted it to USD you were paying $200 USD more just for the printer, then I pay in the states, and the exchange rate was only a couple hours older then your post. Phew 😥 either that or your supplier is making a bunch of money.

it was the same for the enclosure.

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

So, setting TPU aside, can the AMS help combine all the other filament types together? From what I've been reading, it seems to work pretty well generally, and certainly for filaments of the same type. I've never done disolvable supports before, but even just that alone seems like a worthwhile capability to have on hand.

From what I read you can mix filament types - as PETG and PLA, for example, do not adhere to each other very well so you can print a PETG model using PLA supports, or vice versa, and hence result in a cleaner print. Dissolvable should work in the same way. It’s just TPU that can’t run through the AMS due to its flexibility.

I actually finally got around to testing this today on the AMS. I used PETG as support for a test PLA print and it worked well. It probably slowed the print down by a couple of minutes for the temperature changes but it was pretty minimal. All I did was a benchy tipped on an angle with tree supports and it popped right off after cooling down.

Interesting. When I accidentally picked an ABS spool as a color on a PLA print I was told by Bambu Studio that I couldn’t mix. For that reason I thought temps had to be the same. Thanks for the update.

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

In that case, how does one mix them if the slicer is refusing?

So, setting TPU aside, can the AMS help combine all the other filament types together? From what I've been reading, it seems to work pretty well generally, and certainly for filaments of the same type. I've never done disolvable supports before, but even just that alone seems like a worthwhile capability to have on hand.

From what I read you can mix filament types - as PETG and PLA, for example, do not adhere to each other very well so you can print a PETG model using PLA supports, or vice versa, and hence result in a cleaner print. Dissolvable should work in the same way. It’s just TPU that can’t run through the AMS due to its flexibility.

I actually finally got around to testing this today on the AMS. I used PETG as support for a test PLA print and it worked well. It probably slowed the print down by a couple of minutes for the temperature changes but it was pretty minimal. All I did was a benchy tipped on an angle with tree supports and it popped right off after cooling down.

Interesting. When I accidentally picked an ABS spool as a color on a PLA print I was told by Bambu Studio that I couldn’t mix. For that reason I thought temps had to be the same. Thanks for the update.

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

I didn’t think you could. Mixing filaments that use the same or similar extrusion temps works fine. Maybe I missed something or the software has been updated. Bambu has been aggressive about improving their software. AMS humidity indications and auto switching rolls when one runs out are recent additions. I went so far as to return a roll of PVA when I saw it had a 180 extrusion temperature. I replaced it with a more expensive roll that can handle 220.

RE:

For anyone who is interested: the build plate on an X1C is heated directly from mains. In the USA, I measure it as drawing a peak wattage of 341w using an emporia smartplug. In Europe, or any country where the mains voltage is 220-240v, it will draw approximately 4x that power and heat up 4x as fast. I think it heats fast enough that I'm not bothered by it, so I have no complaints, but apparently some impatient people have reported using a 110-to-220v step-up converter to speed things up.

RE:

Well, they (Bambu) lost me at not being able to print TPU well. I'm certainly not a race car driver, I'm a daily driver and mixed material guy. I'll continue to watch the product but it's missing the most important thing to me, the ability to mix the materials I deem important, of which TPU is very important as it brings a big player to the field, (applied flexibility). I'm sure I could apply a certain type of TPU ,NinjaTek Armadillo for example, but this is a deal killer, more and more this system seems limited to my purpose.

Once again, I'm still watching though, lets see what comes of this. It's clear at this point there is no comparison the what the XL is touted to be, but then no one of consequence has an XL at this point.

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

In that case, how does one mix them if the slicer is refusing?

So, setting TPU aside, can the AMS help combine all the other filament types together? From what I've been reading, it seems to work pretty well generally, and certainly for filaments of the same type. I've never done disolvable supports before, but even just that alone seems like a worthwhile capability to have on hand.

From what I read you can mix filament types - as PETG and PLA, for example, do not adhere to each other very well so you can print a PETG model using PLA supports, or vice versa, and hence result in a cleaner print. Dissolvable should work in the same way. It’s just TPU that can’t run through the AMS due to its flexibility.

I actually finally got around to testing this today on the AMS. I used PETG as support for a test PLA print and it worked well. It probably slowed the print down by a couple of minutes for the temperature changes but it was pretty minimal. All I did was a benchy tipped on an angle with tree supports and it popped right off after cooling down.

Interesting. When I accidentally picked an ABS spool as a color on a PLA print I was told by Bambu Studio that I couldn’t mix. For that reason I thought temps had to be the same. Thanks for the update.

Sorry I should've mentioned, the way to do this is to override the bed temperature. If for example you use the cool plate you probably dont want to do this as it might ruin it. I use the textured PEI and had to up the temperature slightly (pretty sure it was only about 5 degrees) and it then 'unlocked' the ability to use PETG for supports.

Proud owner of an original Prusa Mendel i2, original wooden frame i3 and now a mini+

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

It's interesting to look at the poll number on this thread. It is basically stating the Prusa has lost over 60% of its potential customers to Bambu Labs. That's a huge loss for any company and one that could be hard to recover from unless drastic measures are taken.

I hope Prusa can pull something out of the bag!

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

It's interesting to look at the poll number on this thread. It is basically stating the Prusa has lost over 60% of its potential customers to Bambu Labs. That's a huge loss for any company and one that could be hard to recover from unless drastic measures are taken.

I hope Prusa can pull something out of the bag!

Agreed, it's also a fair unbias one. I can't imagine many people who arent Prusa customers would be registered here.

Proud owner of an original Prusa Mendel i2, original wooden frame i3 and now a mini+

RE:

I don't agree with this, I did not participate in the pole and I'm seeing people here in this thread that can afford to buy the Bambu just to experiment with it, and can also afford to buy the XL and experiment with it, without taking a loss and having to choose one over the other. If you were on a budget and had to choose one over the other I would think the intelligent person with limited funds, would be waiting to see how things play out. Bambu has not populated to a reasonable amount by any means, and the XL has not populated at all. I think your jumping the gun big time. As well, I don't think a prusa forums poll is worth the web page its posted on. I'm not a fan boy, prove to me whats good and I'll take it into consideration.

It's interesting to look at the poll number on this thread. It is basically stating the Prusa has lost over 60% of its potential customers to Bambu Labs. That's a huge loss for any company and one that could be hard to recover from unless drastic measures are taken.

I hope Prusa can pull something out of the bag!

Agreed, it's also a fair unbias one. I can't imagine many people who arent Prusa customers would be registered here.

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

I swear Prusa doesn't want to sell printers directly to Canada.. (Canada dollars) .. thought maybe I could save a bit on our Canadian price by going direct..

Not sure that's Prusa's fault. With pretty much every hobby (cars, jeeps, boat building, aviation, shooting, etc) I have ever been involved in and engaged in an online group (be it web forum, email group, usenet news, etc) of some kind, the Canadians were always complaining about the cost and hassle involved in having stuff shipped to Canada. I am pretty well convinced at this point that it's just a feature of living in Canada and trying to buy stuff from outside of Canada. Shipping to Alaska is often a PITA but what you guys have to deal with is next level BS.

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

I’m not a Prusa customer. I found the thread doing a Google search. However, I am a Prusa fan. I like their image as a company driven by a single individual with a passion for printing. I like what Prusa has done for the community with Printables. I am also impressed with Bambu Lab. Their DJI background is showing. The P1P shows they have no intention of being a one hit wonder. Spare parts are reasonably priced. Software updates have been great. My only complaint is that right now they have supply issues. I also like that several of the makers I trust have stated that there were no conditions placed on their review. The X1C isn’t perfect. The spool holder should have been placed on the left side. There should have been a Y splitter to make shifting between the spool holder and AMS easier. The usable build volume, including Z size is slightly less than stated unless you override some things. I forget what those things are but I recall thinking “No way.” The AMS is mostly plastic. Abrasive filaments will wear the intake. I have placed some caps on the intakes to minimize the issue but I would have gladly paid a little more for a hardened filament path in the AMS. I haven’t had an issue but people printing carbon fiber day in and day out have. So far it has been restricted to intake wear which the caps prevent. For hobbyists wanting to mod it isn’t the best printer although 3rd party parts are starting to show up including high temp extruders. On the other hand, it isn’t a Stratasys which just works. All that said, it mostly just works, has incredible convenience and flexibility and is faster and way cheaper to run than the F370 at school. My hope is that we are entering an era of aggressive innovation driven by intense competition. I want to see a merging of FDM and resin with the result looking like ink jet printing with wide color pallets and easy mixing of material types. I envision resin cartridges with resin cured as it is deposited, no mess, and fine detail.

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

Well, yes and no.. I agree.. shipping is shipping.. sometimes.. but look at the pricing below. Say I want 1 item and want Fedex in 2 days. It is $250 US.. If I want 2 items, it is $966.. That makes no sense. So I'm considering, for a local College, of purchasing 2 3D printers. It is nearly 4X the cost for 2 units shipping over 1. Shipping 2 units of something should be less than 2X the cost of shipping 1. (as I should be able to make 2 separate orders and get the shipping less). This is inattention to details in how their web page is working.. I'm assuming there is some bug in their web site. We don't really have a Prusa-linked distributor here.. only some vendors that will bring stuff in from Prusa and resell. I'm thinking they are getting hit with huge shipping costs too, because one vendor is charging nearly $1k for just the enclosure. (haven't looked to see if I'd pay additional shipping on that).

Bambu is setting up a distribution point in Canada (as well as several other countries), shipping to there and then distributing.. similar to what Amazon does. We can't really think about Prusa's Prusament incentive system because the way they use Fedex, we pay duty, tax & shipping on 2-3 rolls of filament that costs about $70. (I can buy 3 rolls of filament, on sale on Amazon for about $75.. (Eryone.. which works well).

So the cost of a Bambu X1C in Canada is $1500 (all prices here are plus tax).. BUT that includes shipping!! With PRUSA the shipping would be $1k. If Bambu can do their pricing in Canada, the only assumption is that Prusa is not actively looking at the Canadian market in the same way Bambu is.

I feel Prusa has gotten so tied up in getting the XL out the door, that maybe they've stretched themselves so thin that many other things are slipping. They've got some core XY stuff in their farms that they are developing, but there's been almost no word on those.. and they seem to be expensive.. It just seems that they could be doing so much more to be competitive and have either chosen not to.. or can't.

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

Yeah that does seem like more of a glitch/oversight than anything.

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

@SR22pilot Good point. I'm not AMS enabled, and yes, I can confirm that the X1 having the print roll in the back is definitely awkward.

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

Evidently the solution is routing filament from a dry box (or a whatever kind of filament holder) to the X1C via a bowden tube. Meh.