RE: Prusa MK3S+ vs Bambu Lab X1 carbon

I would say those artifacts aren't normal, and so something is definitely wrong.

The slicer has different print quality settings ranging from "extra draft" to "optimal". Maybe re-try with the setting at "optimal"?

Also, I notice that the filaments in your comparison are different. That can have an effect as well, especially depending on how much moisture they've absorbed from the atmosphere. To rule that out, comparisons are usually only valid if using the exact same filament.

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

I've been looking at the Bambu X1 carbon, I'm not looking at it in comparison to a Prusa i3 mk3. I've worked with closed FDM systems before in the form of Stratasys machines. That closed systems had the advantage of not needing to be as knowledgeable about materials and print settings, the major disadvantage showed when things stopped working or broke. then the $$$ flowed to get things working again. There was also the, that part is on back order but we'll do what we can to expedite.

I like what Bambu is offering, and I still may buy one just to see, I mean it's only $1500 USD, but I have no real issues with my Prusa's They just keep working and I can print anything I could Print on a Bambu on it successfully. I,m not one of those speed printing people, quality prints will do just fine. I do want to mention, while I've seen multiple colors of the same material types printed on the Bambu, I haven't seen different filament types printed in a single model with the Bambu I haven't seen any examples of multiple material types being printed on one. Has anyone seen this anywhere?

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

@rd Good question. I've read it can use soluble support filament in conjunction with PLA. Were you wanting to do more than that? I imagine Prusa XL could, at least in theory, print using arbitrary combinations of filament, where each filament gets its own separate print head.

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

I keep eyeing it too and was close to ordering it, but frankly, I've been burned twice by the MMU2 and the Palette Pro 3 experience. Both sorta work — if you're willing to invest an insane amount of time tinkering. And from all the reports of the X1C I've seen so far, I'm not convinced that its approach is going to be any more reliable, plus it appears to produce an obscene amount of waste while swapping filament. The AMS is the only reason I would buy it for, and I'm afraid I'd be setting myself up for another big disappointment.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE:

I keep eyeing it too and was close to ordering it, but frankly, I've been burned twice by the MMU2 and the Palette Pro 3 experience. Both sorta work — if you're willing to invest an insane amount of time tinkering. And from all the reports of the X1C I've seen so far, I'm not convinced that its approach is going to be any more reliable, plus it appears to produce an obscene amount of waste while swapping filament. The AMS is the only reason I would buy it for, and I'm afraid I'd be setting myself up for another big disappointment.

FWIW I took the plunge and own a P1P and X1CC each with an AMS. The P1P is closing in on 1000 hours now and the AMS has been great. About half my prints are 2 colour and its handled those fine. The X1CC is newer and only has about 200 hours on it, but also working great so far. I've done no tinkering or anything on either.

My biggest concern was parts availability but they look to be slowly populating their individual region shops with all the parts now, in the last week they seem to have added loads to their UK shop for example.

Proud owner of an original Prusa Mendel i2, original wooden frame i3 and now a mini+

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

I do want to mention, while I've seen multiple colors of the same material types printed on the Bambu, I haven't seen different filament types printed in a single model with the Bambu I haven't seen any examples of multiple material types being printed on one. Has anyone seen this anywhere?

I've done PLA + the support filament sample they provided (This stuff: https://uk.store.bambulab.com/products/support-for-pa-pet). Not 100% sure what it is but it worked well. Admittedly I've only used it twice and have no plans to buy any.

Proud owner of an original Prusa Mendel i2, original wooden frame i3 and now a mini+

RE:

So how does the AMS actually work?

With the MMU, it cuts filament when one color is done, moves over to the next filament "outlet", pushes in filament from a different spool, print that one until it's done, cuts it again, moves over, etc. The failure points are mostly related to filament path issues.

With the Palette, it calculates at what point what color is needed, then splices multiple filaments together on the fly to basically create one contiguous strand of filament fed into the hotend but stitched together so that the right color reaches the hotend at the right time. The failures I've seen are mostly splice issues where the splice breaks, and some timing issues, so the filament doesn't reach the hotend when it needs to.

From what I can see on the Bambulab website, the AMS is basically a sophisticated MMU but apparently better engineered than the MMU (which is a low bar to meet). Which looks more appealing than the Palette. If the quality of engineering is high enough to guarantee a clear filament path and you can (somehow, I don't know how the AMS does it) avoid malformed filament ends (another issue with the MMU), this should work just fine. And be less sensitive to specific filament types and brands than the Palette, where every time I thought I had the splicing figured out, the next time I used a different filament I had to start tuning all over again, which gets old super quickly.

Part of me feels the tool changer approach of the XL should still be superior but then again, I can get an X1C now.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

I've been thinking for a while about expressing my opinion here... 😕

I'm amazed at how little people think about who they give their money to.

Anyone who buys such a Bambulab printer should be aware that they are - INDIRECTLY- supporting Russia's war against Ukraine.

China is still Russia's good buddy and does not impose sanctions, but on the contrary buys even larger amounts of energy from Russia and can therefore produce products cheaper than Western countries.

Got $1600 for a 3D printer? Why don't you support a manufacturer from a friendly country???

I find it shameful how these printers are hyped up in the Prusa Forum. Bambulab is also not ashamed to use the slicer further developed with the support of Prusa for its non-open-source printers...

I wish all Bambulab buyers a clear conscience and good luck with their devices

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

I've been thinking for a while about expressing my opinion here... 😕

I'm amazed at how little people think about who they give their money to.

Anyone who buys such a Bambulab printer should be aware that they are - INDIRECTLY- supporting Russia's war against Ukraine.

China is still Russia's good buddy and does not impose sanctions, but on the contrary buys even larger amounts of energy from Russia and can therefore produce products cheaper than Western countries.

Got $1600 for a 3D printer? Why don't you support a manufacturer from a friendly country???

I find it shameful how these printers are hyped up in the Prusa Forum. Bambulab is also not ashamed to use the slicer further developed with the support of Prusa for its non-open-source printers...

I wish all Bambulab buyers a clear conscience and good luck with their devices

So once its done with one filament it cuts it just above the extruder, the ams then rewinds the spool it came from. Once its clear of the AMS Hub it detects that it's gone past the point where two filaments could collide and starts feeding the next filament through the hub and into the printer. The print head sits over the bucket at the back and does a purge to clear out the old filament, it then wipes the print head clean and starts printing.

I've not used the MMU but it looks to be a fairly similar kind of idea but more refined and with better tolerances. I've had two AMS hubs running reliably on one printer and it's worked well. The biggest plus of the AMS is the filament buffer part, I'm to understand this plays a pretty big part in how it's so reliable as it keeps a 'slack' of filament - I dont know the technicalities of it but this is what makes it so reliable.

I do think a tool changer is a superior option, but in place of that it's working well for me.

Proud owner of an original Prusa Mendel i2, original wooden frame i3 and now a mini+

RE:

I've been thinking for a while about expressing my opinion here... 😕

I'm amazed at how little people think about who they give their money to.

Anyone who buys such a Bambulab printer should be aware that they are - INDIRECTLY- supporting Russia's war against Ukraine.

China is still Russia's good buddy and does not impose sanctions, but on the contrary buys even larger amounts of energy from Russia and can therefore produce products cheaper than Western countries.

Got $1600 for a 3D printer? Why don't you support a manufacturer from a friendly country???

I find it shameful how these printers are hyped up in the Prusa Forum. Bambulab is also not ashamed to use the slicer further developed with the support of Prusa for its non-open-source printers...

I wish all Bambulab buyers a clear conscience and good luck with their devices

By this logic you should stop buying Prusa printers as the logic boards, rods, all metal parts and motors come from China. You should also stop buying anything anywhere as virtually everything has something from China in it.

It's also worth noting that Bambu Lab using Prusa Slicer as a basis for theirs is perfectly acceptable - the license allows it becaus Prusa Slicer is built on top of Slic3r. Thats how opensource works.

Proud owner of an original Prusa Mendel i2, original wooden frame i3 and now a mini+

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

It's also worth noting that Bambu Lab using Prusa Slicer as a basis for theirs is perfectly acceptable - the license allows it becaus Prusa Slicer is built on top of Slic3r. Thats how opensource works.

So, using open source software to create a own variation of it, that supports only Bambulabs own closed-source Printers is OK ?

If you search this site, you will find nowhere the word "open" 😀 :

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

It's also worth noting that Bambu Lab using Prusa Slicer as a basis for theirs is perfectly acceptable - the license allows it becaus Prusa Slicer is built on top of Slic3r. Thats how opensource works.

So, using open source software to create a own variation of it, that supports only Bambulabs own closed-source Printers is OK ?

If you search this site, you will find nowhere the word "open" 😀 :

I'm not sure you understand how opensource works.

Lets take another example. Microsoft, Apple, Google, and countless other companies make use of opensource GPL licensed code within their closed source products. This isn't a revelation, the license litterally allows for it providing you follow the terms of said license. When Slic3r was developed the author intentionally chose a copy left license, much like many free/opensource packages do.

Whilst it sucks that the firmware is closed source, the printer being closed source has absolutely nothing to do with the opensource slicer, which if you desired you could fork and add support for any printer you like. Why would Bambu do that themselves? It's hardly in their interest, just as it wouldn't be in Prusas interest to add support for connecting to a Bambu printer in Prusa Slicer.

Proud owner of an original Prusa Mendel i2, original wooden frame i3 and now a mini+

RE:

Such a complicated issue that can’t be debated here. I doubt your family has zero interaction with any Apple product either at home nor at school; all that are manufactured in China. These issues can only be sorted by a conscious effort by government that puts enough incentives and restrictions in place so that fab plants and all other technology trappings are available in North America.

There are umpteen products that all started from open source roots and now are closed, proprietary products because of the huge resources put into them by their organization. This is just a natural part of the tech landscape.

Only with the competitive nature of Anker & Bambu, will companies like Prusa be pushed to provide better products.

I've been thinking for a while about expressing my opinion here... 😕

I'm amazed at how little people think about who they give their money to.

Anyone who buys such a Bambulab printer should be aware that they are - INDIRECTLY- supporting Russia's war against Ukraine.

China is still Russia's good buddy and does not impose sanctions, but on the contrary buys even larger amounts of energy from Russia and can therefore produce products cheaper than Western countries.

Got $1600 for a 3D printer? Why don't you support a manufacturer from a friendly country???

I find it shameful how these printers are hyped up in the Prusa Forum. Bambulab is also not ashamed to use the slicer further developed with the support of Prusa for its non-open-source printers...

I wish all Bambulab buyers a clear conscience and good luck with their devices

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

Such a complicated issue that can’t be debated here.

Agreed! May we please return to the topic? The multi-filament discussion was really interesting.

RE:

Pricing in Canada (VoxelFactory, which has the best customer service from my limited experience):

MK3+: Assembled: $1872

Prusa Orig. Enclosure: $ 939

NozzleX (metal) $ 62

Pi4 for OctoPi $255 (CanaKit Pi4 kit)

================================

Total: $3128 (no tax, no shipping)

Bambu X1C: $1459

Forgetting about the faster speed, better touch screen, auto-calibration first layer.. that is a tough price difference to ignore. One might even purchase the X1C and give it a life of, say, 3 years and discard.. As stated before, an organization can purchase 2 x Bambu for every one Prusa. Twice the productivity in machines.. and maybe twice more in time.. It could be a 4 fold production improvement for the same cost. Prusa has to bring that down to be competitive.

And this is ignoring that, for what I'm reading, the AMS in Bambu might be much better than the MMU2s of Prusa.. (I read some horror stories about MMU2)

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

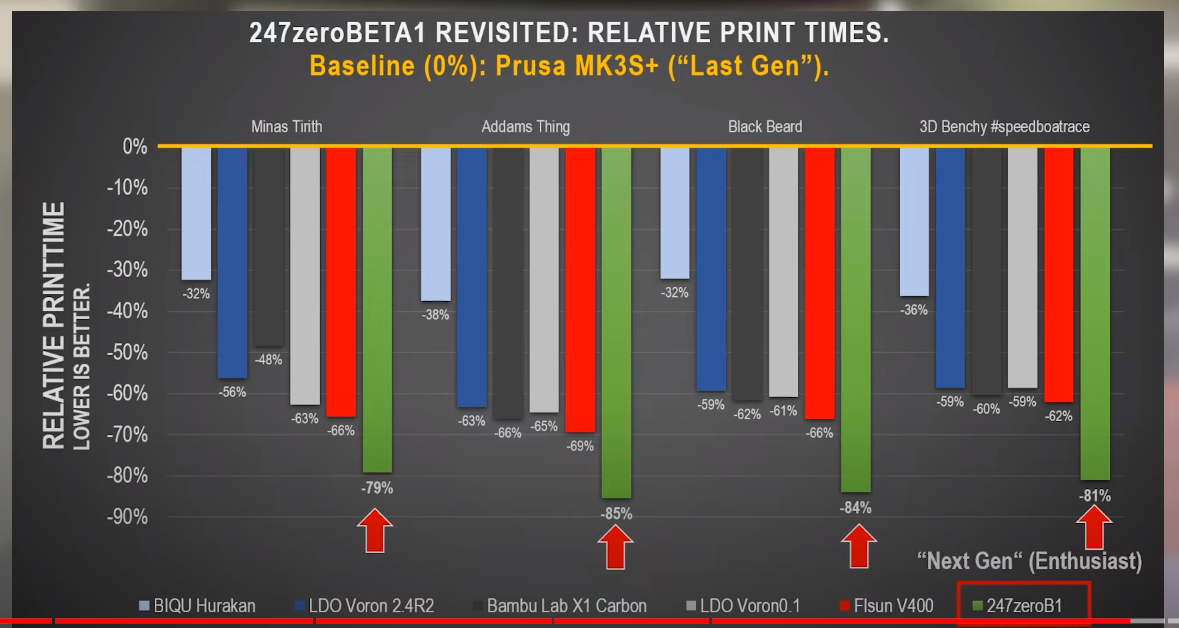

This was from the 247 youtube video right? If so the final print quality needs to be taken into consideration. While the 247 prints impresively fast the quality was still stuck at Ender levels (presumably some of that comes from the flex on the gantry that he mentioned would be something to improve). If they can solve those issues then it could be a great option but I imagine scaling it to a 25cm bed would be a bit of a stretch. Still, he seems extremely dedicated to the project so there's a good chance he'll solve it.

Proud owner of an original Prusa Mendel i2, original wooden frame i3 and now a mini+

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

This was from the 247 youtube video right? If so the final print quality needs to be taken into consideration. While the 247 prints impresively fast the quality was still stuck at Ender levels (presumably some of that comes from the flex on the gantry that he mentioned would be something to improve). If they can solve those issues then it could be a great option but I imagine scaling it to a 25cm bed would be a bit of a stretch. Still, he seems extremely dedicated to the project so there's a good chance he'll solve it.

Yes. I posted it in not to hype the 247 build (which would be hard to replicate unless you were willing to spend days if not weeks on a very involved DIY build) but because it shows MK3s+ and X1C versus others in the competitive landscape. I mean, he estimates 200 hours just to print the needed parts (well, 80 hours if you were to print them on an X1C) for a 247. I figure I'd save people the effort of watching the video, as this screenshot was one of the main takeaways.

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

@ Crab

The price difference you have is very significant. If you do this comparison in €, it is a different story. In the official prusa store, the MK3S+ is 1265€ including enclosure. I did my decision without taking price into account. In other words: compared to other printers (Ultimaker, Raise3D) both printers are cheap...

Today I printed the first 3 color print. Quality is just amazing. It is really almost perfect. No stringing, no artefacts from changing colors at all.

I did not buy the AMS because I will do mosaic prints. I think for this, the AMS is not the right technology as material waste and time loss are way too high.

I did buy the AMS because I can have 4 materials loaded. I can just choose a material without manually switching anything. Already this is very conveniant.

Additionally I intend to use a different material for the layer between print and support structures. While I have not testet that, I expect that to work perfectly fine.

I will also use the AMS for some multi color prints, which are optimized for not having too many filament changes.

I might also buy an additional AMS in the future. But I will definitely wait for the next version. For mechanically complex systems such as the AMS, you always have to expect a few iterations to find a very reliable design.

One side note here regarding spools: Officially the maximum width of the spool is 68mm. The prusa spools are 70mm. I have one which still works. But I have another one which is slightly larger (+2mm) which gets stuck in the AMS.

RE:

I agree about color.. Often for a project, I might do in PETG and want 4 spool of that loaded. I might do a raised layer lettering on a part.. so I want the color change for only the last 3 minutes of maybe a 4 hour print. The AMS is perfect for this. Now, I have to be present to do the color change... And if I'm doing a multiple part model where different models are different colors, I can do 4 sequential parts with each in a different color. Just the wastage between parts.. Perfect.. The AMS seems ideal for this and a good value as it is also a dry box. So adding a TPU spool in there works well. I would never do a multiple color print with lots of wastage.. The camera and "spaghetti detection" are two more pluses vs Prusa.. there are a lot of check boxes that get filled in.. Prusa filament is twice the cost of anything else in canada, so not fitting Prusament is not an issue..