Prusa MK3 > deception

Sorry but i use Google Traduction... I speak French

Good evening,

I would like to express not some dissatisfaction, but rather disappointment ...

I was expecting, with Prusa research to more quality, precision and after-sales service ...

I specify that I bought it pre-mounted!

After a little over 3 months and about a dozen days of operation ..., the problems encountered:

> from the beginning, the food vibrated and caused a very unpleasant noise, it took three weeks of email reminder for the change to be made (first disassembly and reassembly for me (owl, I bought it pre- climb and I already have to tinker)

> 3 weeks ago, the upper axis Y completely scratched, a bearing defective. A good week to get new parts sent! Owl, again disassembly and otherwise more complicated that one!

> and there hell comes to the fore: CALIBRATION! Well yes everything had to be disassembled ... This seems simple from the tutorial, Prusa ... At first everything is fine but the setting of the Z-OFFSET with this kind of grid zero ... good am -645, ok here seems "ok". Yeah ... I then throw a thingiverse grid of 5 squares whose center one is bigger and there ... surprise! Lower left OK> lower right really nickel> upper left null, almost hook, hangs limit much too high> upper right correct> the center bottom half right correct then it degrades line by line not enough crushed as the upper left corner .. .. Re-printing z-offset up to -700 and of course or it's too crushed bottom right or not enough top left! But what is the purpose of this probe pinda, it corrects anything at all I say ... So one between two ... -675 and it's more or less good everywhere! Conclusion, well the plateau is not right! And the probe is useless!

> and go today, I start the printer and error I do not know what calibration ... request reset, we start everything!

> when the Z axis descends from top to bottom, gossip on the bottom 20 cm of the bottom right side!

> and I do not even talk about the number of screws that I have to screw, the latest in date the two straight screws of the support lcd, !!!

> ah yes, I was going to forget, the PEI sticks less and less well, obliged to put a brimm but hey it's "consumable"

> and there, it prints and makes a sound of something that vibrates but where? Mystery, another screw screwed!

So, finally, I thought I bought the Rolls printers (in its price range) but it's only a mid-range BMW ...

I expect that in a few months, everything will be broken! For the price, we expect better quality elements (bearings, power supply), a responsive service that does not always apologize for a week to answer an email!

I have 4 printers, no worries with my Anycubic mega (modified to make it quieter), ender3 (correct printing for its price) and hell with the new Creality CR10-S pro ... also concerns of flatness of the Bed and calibration like the MK3!

Passionate for 5 months in 3D printing, I am beginning to be disappointed, not reliable enough, accurate, ... Must we remind that the accuracy is of the order of a few microns ...

In fact, we spend more time tuning these machines than print! And we are all astonished when ... it goes well!

Good for those who have (maybe) no worries with their MK3 but there was my mouth rage with mine!

PS: I specify that I interview, dry PTFE lubrication, cleaning the alcohol machine bed, soap time in time ...

Prusa Core One - Prusa MK4S -2x Prusa Mini+ - Bambulab X1 Carbon/P1P- Silhouette Cameo 4-Laser Xtool S1 40w- Imprimante Canon Sublimation...

Re: Prusa MK3 > deception

Exactly. Good point. Could not agree more.

Re: Prusa MK3 > deception

Not to make light of the OPs issues, but google translate deserves its own comedy channel.

Re: Prusa MK3 > deception

I would gues that all the coming issues are most probably related to some wrong step during the first reassembly because of the bearings and rods change. From own experience, even if you are 100% sure you did everything exactly as described, finally it will show, that you made a mistake somwhere.

There are many parts that can be damaged during operation in time, therefor I recommend to everybody to build the first printer himself from the kit. Knowing all the steps and issues you faced during assembly is the most valuable knowledge during troubleshooting in the future.

Milos

Re: Prusa MK3 > deception

Probably the largest two mistakes Prusa makes is not demanding builders lubricate the bearings with suitable grease during build; and warning owners finger prints are a disaster. This would solve several issues and reliability over time.

Re: Prusa MK3 > deception

And here is a new faulty bearing on the X axis now, the axis has a deep claw! I specify that received pre-mounted, I have never touched this part if it is not to grease the axis to dry PTFE grease, the best !!! Thank you Prusa!

Prusa Core One - Prusa MK4S -2x Prusa Mini+ - Bambulab X1 Carbon/P1P- Silhouette Cameo 4-Laser Xtool S1 40w- Imprimante Canon Sublimation...

Re: Prusa MK3 > deception

Probably the largest two mistakes Prusa makes is not demanding builders lubricate the bearings with suitable grease during build

The bearings in the kits we have received have definitely not needed lubricating during the build process. Why do you think new bearings need lube?

Re: Prusa MK3 > deception

Ok Prusa, you sent me new bearings for the Y axis, there is one that is defective, almost impossible to put on the axis! Amazing the problems I have with this printer!

Prusa Core One - Prusa MK4S -2x Prusa Mini+ - Bambulab X1 Carbon/P1P- Silhouette Cameo 4-Laser Xtool S1 40w- Imprimante Canon Sublimation...

Re: Prusa MK3 > deception

Probably the largest two mistakes Prusa makes is not demanding builders lubricate the bearings with suitable grease during build

The bearings in the kits we have received have definitely not needed lubricating during the build process. Why do you think new bearings need lube?

Many manufacturers list in their spec sheets that the bearings come only with a light "shipping oil" meant to prevent rust (and not suitable as a proper lubricant), and that it should be replaced with a proper lubricant appropriate to the service in which it is going to be placed.

Re: Prusa MK3 > deception

But does this apply for the bearings PR use, and in this environment?

A light machine oil is all we have every used, but only after hours of operation. Once we start noticing a significant build up of debris at the end stops then it's time to clean and apply some new oil.

Re: Prusa MK3 > deception

But does this apply for the bearings PR use, and in this environment?

A light machine oil is all we have every used, but only after hours of operation. Once we start noticing a significant build up of debris at the end stops then it's time to clean and apply some new oil.

From what I've read, yes. It'll work for a while, but won't be as performant as a proper replacement. Certainly it's less important in this application because we have relatively light loads, but the general consensus seems to be that it's worth doing for improved noise characteristics and longevity.

Re: Prusa MK3 > deception

My factory bearings were completely shot after 2000 hours, with nearly a millimeter of rotational play on the Y-Axis, and significant play on the X-Axis. This was less than 6 months of use. That is enough evidence for saying the bearings do in fact require grease to operate properly.

If Prusa (@Rob) believes the bearings that ship with printers do not need grease, please post the manufacturer and model of the bearings so customers can find the actual data sheets and determine this for themselves. Or better, Prusa should provide the mfg/model with care and maintenance suggestions. And warranty failed bearings sets when said instructions are followed. I'd wager Prusa would be recommending grease within a year.

As for oil on a load bearing? Short of a very few with moly additives, not many oils are really good at lubrication bearings without some form of circulation - oils tend to move with gravity away from high spots, leaving the top row in the rod bushings unlubricated.

I think we can all agree Misumi bearings are reputable high quality: the "Before usage" clause is important.

Here's IN Bearings suggestion:

Lubrication and Dust Prevention

Using IN'S linear systems without lubrication increases the abrasion of the rolling elements, shortening the life span. The IN'S linear systems therefore require appropriate lubrication. For lubrication IN'S recommends turbine oil conforming to ISO Standards G32 to G68 or lithium base soap grease No.1. Some IN'S linear systems are sealed to block dust out and seal lubricant in. If used in a harsh or corrosive environment, however, apply a protective cover to the part involving linear motion.

As always, YMMV.

Re: Prusa MK3 > deception

If Prusa (@Rob) believes the bearings that ship with printers do not need grease,

We have never used grease, period. We use "3 in 1" Multipurpose Oil. Never had a bearing issue.

You are correct, mileage on this topic does seem to vary by quite some margin.

Re: Prusa MK3 > deception

If Prusa (@Rob) believes the bearings that ship with printers do not need grease,

We have never used grease, period. We use "3 in 1" Multipurpose Oil. Never had a bearing issue.

You are correct, mileage on this topic does seem to vary by quite some margin.

Rob, do you represent Prusa in this? If so, please produce a spec sheet for the bearings shipped with Prusa printers that recommends light machine oil as the preferred lubricant.

My bearings failed in less than 6 months of service - and Prusa blamed the failure on lack of lubrication and did not replace them. I can't recall the exact words the guy on chat used, but he basically said I should have lubed the bearings with a Lithium grease, and since I didn't, they were not covered under warranty. He even said all the Prusa farm printers had Lithium grease. Yes, this is a sore point ...

Re: Prusa MK3 > deception

Rob, do you represent Prusa in this?

Why would I represent PR in this? 🙄

Sorry you have had issues, and I note what you were told by tech support (and also in the maintenance section where it mentions lithium grease). But as I stated previously, we have not had bearing issues and have not used grease, ever.

I'm not advocating people do, or do not use grease, only that we do not.

Re: Prusa MK3 > deception

Rob, do you represent Prusa in this?

Why would I represent PR in this? 🙄

Sorry you have had issues, and I note what you were told by tech support (and also in the maintenance section where it mentions lithium grease). But as I stated previously, we have not had bearing issues and have not used grease, ever.

I'm not advocating people do, or do not use grease, only that we do not.

You say you add your own oil in the post above. So both of you seem to be arguing the same side of a coin...

Re: Prusa MK3 > deception

My factory bearings were completely shot after 2000 hours, with nearly a millimeter of rotational play on the Y-Axis, and significant play on the X-Axis. This was less than 6 months of use. That is enough evidence for saying the bearings do in fact require grease to operate properly.

If Prusa (@Rob) believes the bearings that ship with printers do not need grease, please post the manufacturer and model of the bearings so customers can find the actual data sheets and determine this for themselves. Or better, Prusa should provide the mfg/model with care and maintenance suggestions. And warranty failed bearings sets when said instructions are followed. I'd wager Prusa would be recommending grease within a year.

As for oil on a load bearing? Short of a very few with moly additives, not many oils are really good at lubrication bearings without some form of circulation - oils tend to move with gravity away from high spots, leaving the top row in the rod bushings unlubricated.

I think we can all agree Misumi bearings are reputable high quality: the "Before usage" clause is important.

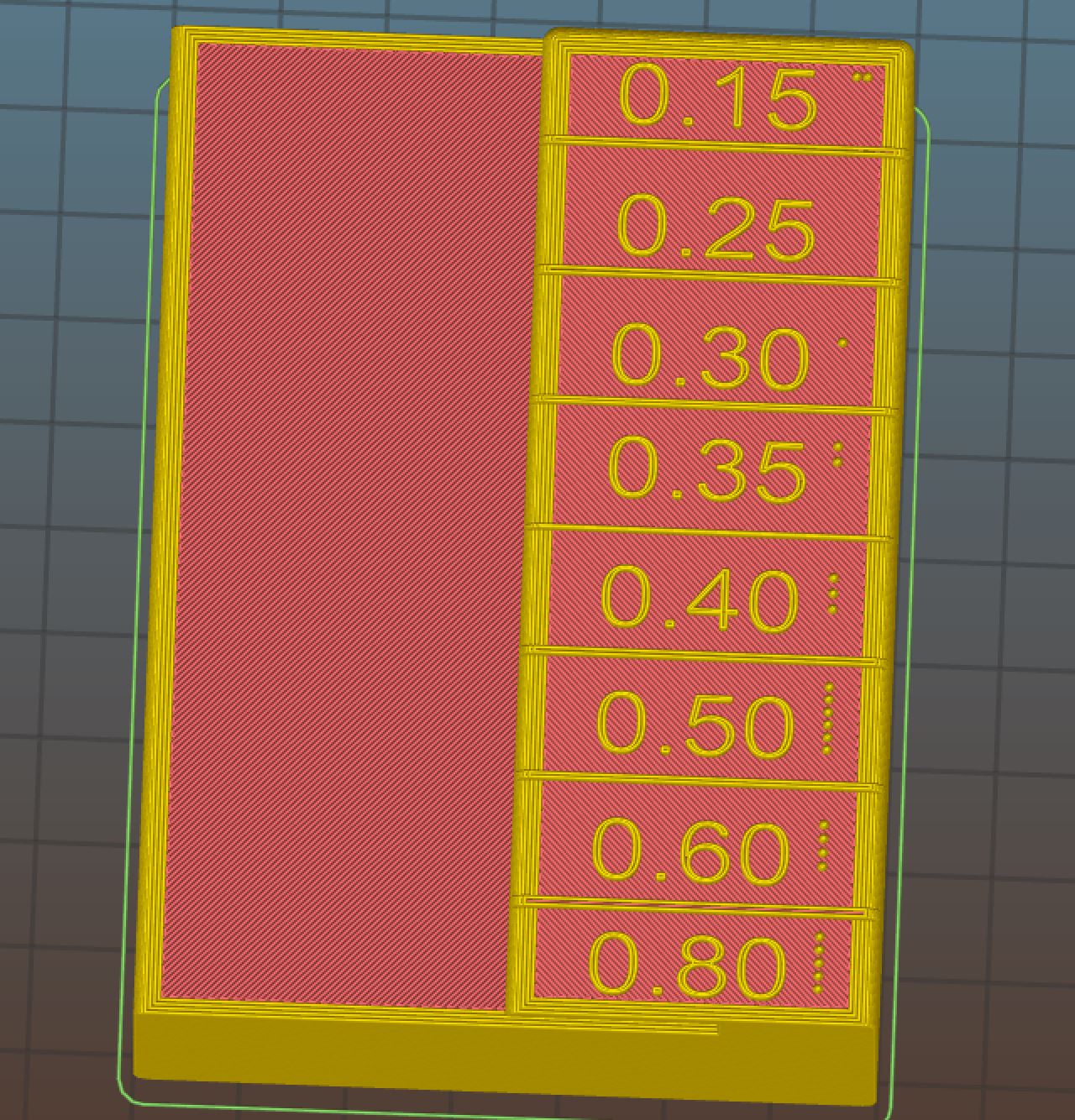

Capture.JPG

Here's IN Bearings suggestion:

Lubrication and Dust Prevention

Using IN'S linear systems without lubrication increases the abrasion of the rolling elements, shortening the life span. The IN'S linear systems therefore require appropriate lubrication. For lubrication IN'S recommends turbine oil conforming to ISO Standards G32 to G68 or lithium base soap grease No.1. Some IN'S linear systems are sealed to block dust out and seal lubricant in. If used in a harsh or corrosive environment, however, apply a protective cover to the part involving linear motion.

As always, YMMV.

Agree wholeheartedly with this, my Prusa supplied bearings were completely shot after 30 days of print time, taking the smooth rod on the x axis with them. New bearings procured from Misumi and packed with white lithium grease per the link below, so much quieter and zero wear to date.

Re: Prusa MK3 > deception

Rob, do you represent Prusa in this?

Why would I represent PR in this? 🙄

Sorry you have had issues, and I note what you were told by tech support (and also in the maintenance section where it mentions lithium grease). But as I stated previously, we have not had bearing issues and have not used grease, ever.

I'm not advocating people do, or do not use grease, only that we do not.

It's the royal "we" you keep using. So you aren't representing Prusa, rather, this is only your own personal opinion here.

Re: Prusa MK3 > deception

You say you add your own oil in the post above. So both of you seem to be arguing the same side of a coin...

Oil and grease are not the same. It is very hard for oil to stay on a top race of a bearing without some form of oil recirculation. Think oil pump in an engine, or flinging gears in a differential. The LMU type may be recirculating bearings, but unless they are filled with oil before installation, there probably won't be enough getting inside the seals to keep them properly lubed. Unless the oil has lubricant solids like moly or ptfe that adhere to the metals, it won't work as well as grease.

So yes, one side of a coin, but silver vs copper.

Re: Prusa MK3 > deception

It's the royal "we" you keep using. So you aren't representing Prusa, rather, this is only your own personal opinion here.

Is that a question or a statement? I have never claimed to be representing PR in any way.

The "we" I referred to was in reference to me having responsibility for a number of FDM printers, amongst other things.

Anyhow, you keep using your grease, and we shall keep using our oil.

Peace out.