not so intelligent mk3!!

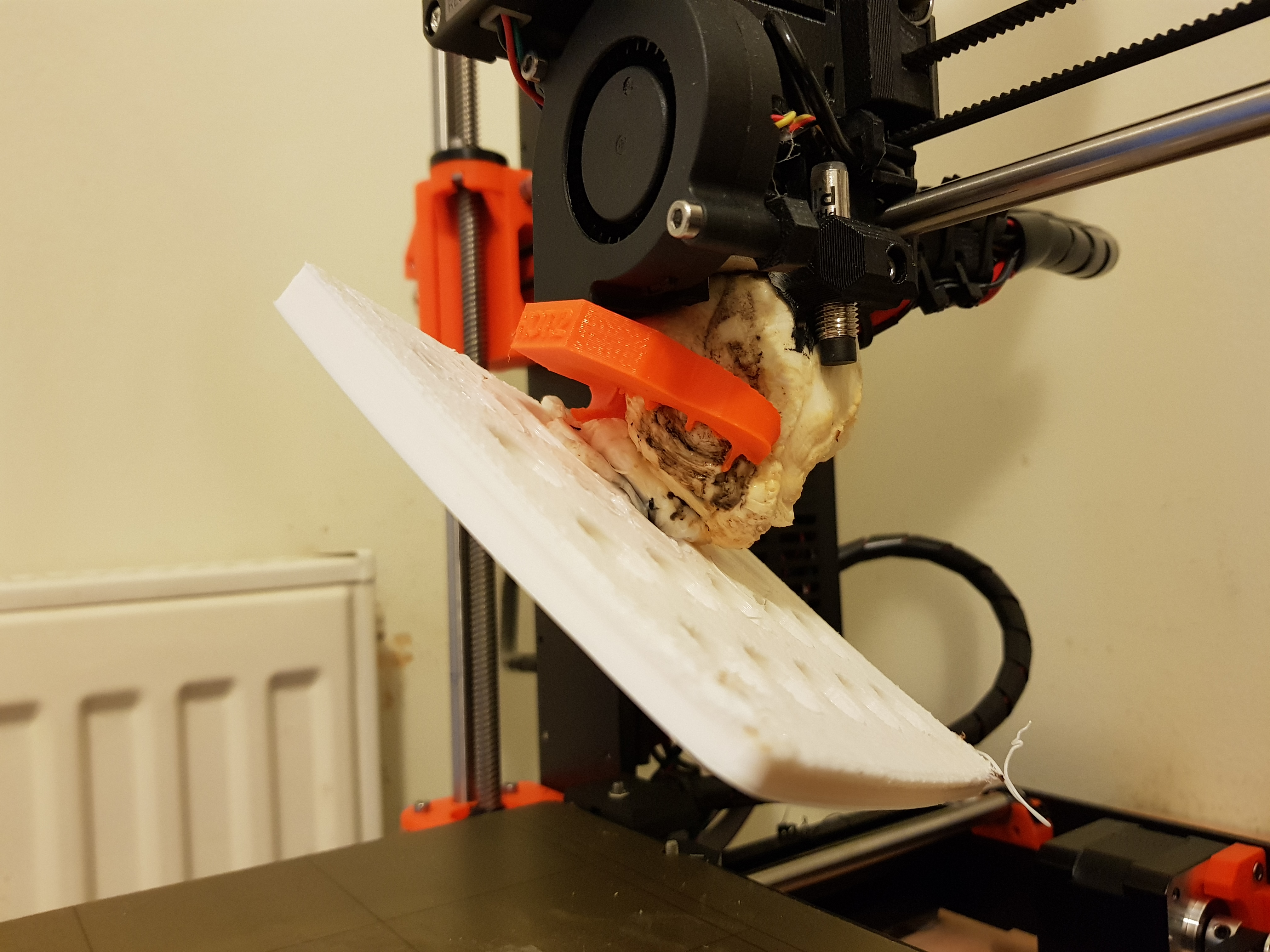

Came down to this lovely mess this morning!

had a good run with ABS and was surprised how well it was printing without an enclosure until my Mk3 decided to encase the print head in plastic.

Biggest mess ive had to deal with in the last few years of 3D printing, at least it didn't start a fire!!

Guess the option is grind it off or burn it off and see whats damaged,

Anyone have an other suggestions on the best way to salvage this??

Thanks

Re: not so intelligent mk3!!

Your title makes it seem like the printers fault but there is nothing about the printer that could detect ABS warping off the bed due to low ambient temperatures. I would attempt to use acetone to loosen the mass and if that doesn't work you'll have to heat it up and scrape it off.

Re: not so intelligent mk3!!

I agree with Steven.

The title should be "not so intelligent Me." 😉

And for you to not get me wrong: this is meant in a funny way.

You can see that it came off because of the warping.

Like Steven said, try to melt/loosen what you can before you pull the mess off.

I would suggest to first unsrcew everything around the printhead that you can safely remove.

Like the Fans or maybe the fan nozzle.

Good Luck!

Wer freundlich fragt bekommt auch eine freundliche Antwort.

nec aspera terrent

Re: not so intelligent mk3!!

yes I can see it has lifted from the bed but I would of hoped the other sensors to have picked something up here.

Layer shift, crash detection

I guess not.

printed multiple parts with quite large surface area over the past couple of weeks without issue so a bit surprised to see this.

Wont be doing any more large un-attended ABS prints without making an enclosure i think.

Was mostly using PETG as an ABS replacement until recently but PET just dosent have the rigidity that ABS seems to have.

yeah I'm thinking heat it and scrape it off will be better than grinding, less likely to cause more damage I hope,

yeah ill try to remove the head first.

I thoughe i see theres been some changes to the parts since i built this (xmas time) to make it easier to remove belts etc without having to dismantle everything so ill see how this goes. What a PITA 🙂

Re: not so intelligent mk3!!

Be careful, many people here post pictures of ripped off thermistor wires. Biggest problem is probably how to heat your blob and leve the remaining parts intact.

This also happened to me once (though not as drastic). I have to say, instead of the filament sensor (turned off due to potential of false alarms) and crash detection (also turned off) I'd like to see a "mess detection" that prevents situation like yours. BTW I mean a 100% working one.

It's easy to make a proof of concept that somehow works, but much more work to get something actually useful. I'm wondering where the MMU 2 will be.

- Martin

- Martin

Re: not so intelligent mk3!!

+1 to the ripped thermistor warning.

I had a nasty blob too. OK no where near that nasty, but still pretty nasty.

I used a heat gun to soften the outside of the blob, and the extruder heater to soften the core. Pulled ever so gently, and. Bam! MINTEMP! The heater shutdown with a ripped thermistor wire.

I ended up getting it patched, but it’s pretty fragile near the splice, especially when it’s hot.

When someone asks you if you're a god, you say, "YES!"

Re: not so intelligent mk3!!

Not so intelligent user error.

Re: not so intelligent mk3!!

Not so intelligent user error.

I’ve had a couple blobs myself, once in PETG, once in PLA. Nothing this extreme though. Both occurred after I was confident that the part was firmly stuck to the bed, and I left on other business. Both were discovered by family members walking past saying “oooh, that ain’t right”

Personally, I’d like to know precisely what the not so intelligent user error was in this case, because I’m apparently no so intelligent either, and would like to learn. I’d like to have some level of confidence that when I leave a print to go to sleep or to work, that it will continue through. Is there something constructive, or were you simply so offended by the thread title that you felt the need to kick the OP when he was already down because he chose an unfortunate title out of obvious, and understandable frustration?

Honestly, I can’t believe that print wasn’t throwing missed X steps. Maybe there should be something in the firmware to say, if there are more than X errors within some time limit, then fail the print. Granted, missed steps are not detected when Stealth mode is on, but I don’t recall coming across a warning about leaving the printer unattended with stealth on, so maybe there’s a lesson to be learned there too?

I also recall seeing somewhere (octoprint plugin maybe), someone working on using a camera to periodically inspect the top layer, and comparing that to the gcode to detect layer shifts. If it works, that should be able to seriously help with blob prevention too.

When someone asks you if you're a god, you say, "YES!"

Re: not so intelligent mk3!!

I’d like to have some level of confidence that when I leave a print to go to sleep or to work, that it will continue through.

Actually that's exactly what you can (not should). OP posting is proving it. Printer kept himself in a stable and safe condition. Printer kept printing. It doesn't mean you will get a successful print!

In case of blobs it's very hard to detect. The whole part is just moving with the head. No collisions happening. Extrusion is also successful (no clogs). The only difference is a heavier weight on the print head.

The user error was to print a big part with ABS, knowing it warps, knowing heat chamber is required and leave the whole thing unattended. I would call it "gross negligent". MK3 is pretty safe to leave it unattended.Tom tested couple printers most recently .

But you shouldn't expect MK3 to monitor your print and verify the result is still like loaded gcode. That's why everybody is suggesting to get a web cam and look at your prints from time to time.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: not so intelligent mk3!!

Not so intelligent user error.

I’ve had a couple blobs myself, once in PETG, once in PLA. Nothing this extreme though. Both occurred after I was confident that the part was firmly stuck to the bed, and I left on other business. Both were discovered by family members walking past saying “oooh, that ain’t right”

Personally, I’d like to know precisely what the not so intelligent user error was in this case, because I’m apparently no so intelligent either, and would like to learn. I’d like to have some level of confidence that when I leave a print to go to sleep or to work, that it will continue through. Is there something constructive, or were you simply so offended by the thread title that you felt the need to kick the OP when he was already down because he chose an unfortunate title out of obvious, and understandable frustration?

Honestly, I can’t believe that print wasn’t throwing missed X steps. Maybe there should be something in the firmware to say, if there are more than X errors within some time limit, then fail the print. Granted, missed steps are not detected when Stealth mode is on, but I don’t recall coming across a warning about leaving the printer unattended with stealth on, so maybe there’s a lesson to be learned there too?

I also recall seeing somewhere (octoprint plugin maybe), someone working on using a camera to periodically inspect the top layer, and comparing that to the gcode to detect layer shifts. If it works, that should be able to seriously help with blob prevention too.

It was a light hearted play on the title. I'm also fairly dry when it comes to machines. We ultimately control them. They often fail when we fail. Firmware etc of course is out of our hands. Part of this perspective is I'd like complaints to be reasonable, so that real issues don't get drowned out by user error. That way when we do bring something up, Prusa knows its worth their attention.

His mistake was printing ABS in open air. I cant speak much about yours, but I'm sure there is a logical reason if more detail is provided.

I have printed 4 spools on my MK3 and while I have problems I'm sorting out, radical failure hasn't happened once. I had one print fail due to a skip (tightened by y belt hasn't happened since) and had a print fail (unseen support-less overhang).

Re: not so intelligent mk3!!

It’s just a flesh wound!!! 😀

Re: not so intelligent mk3!!

Thanks for the constructive comments, the silly ones are easy to ignore.

I'm fully expecting to damage at least something getting this mess off but lesson learned, no more big parts in ABS, back to PETG for me.

Re: not so intelligent mk3!!

same thing happened to me, part of the learning curve for me.. only on my third print so far. Had to replace the thermistor completely cause removing my blob severed the wires for it. Now i'm back at it, i'm taking the pausing when not at the printer very seriously now 😛

Re: not so intelligent mk3!!

Personally, I’d like to know precisely what the not so intelligent user error was in this case

leaving the printer unattended is always a chancy situation. most times you will be fine, other times it will be spaghetti all over the place and if your superpower is not luck (domino) you will end up like this.

i have had 6 months of good printing so far but more than once i have returned to spaghetti and once a very small blob. luckily i had the silicon block cover on so the blob was not large and not hard to remove. on a previous wanhao I did end up having to replace the heater and thermistor and block and block wrap, so i feel for the op but if you leave it often enough you will face some regret.

one other point, my experience has been that the fan shroud, when exposed to abs temps, sags and when it does it will catch on the print. this may have been the issue initially that contributed to the curl and the blob. I reprinted mine in PC and have not regretted it.