My first volcano print

I printed Bengie after arbitrarily setting all the print speeds in slic3r to 300mm/sec. I'm using an 0.8mm nozzle on the volcano, and a 0.89mm extrusion width and 0.3mm layer height. The print is in a transparent PLA, which may be a little hard to interpret in a photo (sorry) because you're seeing not just the surface but also the layers beneath.

Print time was 50 minutes. I was hoping for something faster than that. Not sure what's limiting it. Nonetheless, at least the print quality seems satisfactory:

Comments/suggestions welcome.

Re: My first volcano print

Hi David,

it's a relatively small model, you are probably being limited by acceleration... to a degree

isn't there also a firmware limit of feed rate too, did you adjust that?

transparent filament does make viewing difficult...

you do seem to have a little reduction in quality e.g round the flag staff hole by the stern...

but that is part due to small model, big nozzle, higher speed, all of which combine to limit immediate quality.

I suspect that tuning will improve this even more

Well done for your efforts, thanks for updating us!

for interest, how does the filament change purge go... you have a longer melt zone, does it clear with one flush?

probably need to try, yellow or white, trying to flush black... sort of worst case scenario!

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: My first volcano print

Thanks to recent comments/suggestions by tiago.c, I increased the layer height to 0.6mm. That decreased the Benchy print time to 22 minutes. 😀 That's fast enough that I can really feel the difference when contrasted to my non-volcano 0.4mm print time.

So, it appears that when doing rapid iterations on a prototype, I an dial up the print speed and then later, in the end, when i need a more polished print, I can dial the speed back down--perhaps all with the same nozzle. 🙂

Re: My first volcano print

Thanks to recent comments/suggestions by tiago.c, I increased the layer height to 0.6mm.

And how was the quality after doing that?

Yeah, thanks for the info, all very interesting.

Re: My first volcano print

And how was the quality after doing that?

Yeah, thanks for the info, all very interesting.

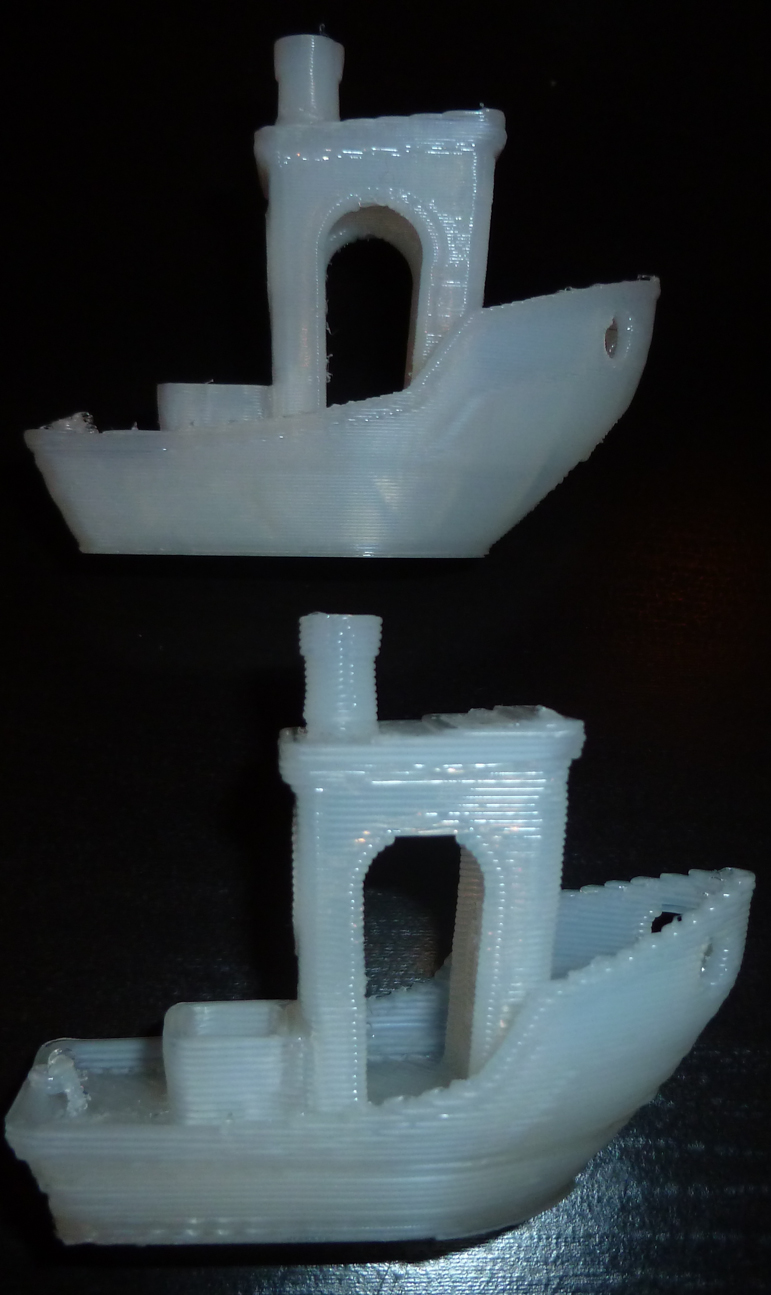

It's visibly degraded. In the photo below, the top benchy was the first print, and the 22 minute print is the bottom one.

Personally, I don't like it, so in practical terms it's beyond the limit of how fast I'd want to go. Nevertheless, it's a datapoint.

Bear in mind that I'm an absolute noob, and these are just my ham handed attempts. Probably someone else could get better results within the same print time.

Re: My first volcano print

I guess with a 0.6 layer height it's not surprising. Still not a bad job though.

Re: My first volcano print

for interest, how does the filament change purge go... you have a longer melt zone, does it clear with one flush?

I don't know, as I haven't tried it yet. I think it may flush faster though because you can push so much more filament through at once, despite the slightly longer melt zone.

Re: My first volcano print

Do a test:

- Layer Height: 0.6mm

- Use same speeds from stock 0.2mm prusa profile, but set max speed to 70mm/s on infill

- Set all extrusion width to 0.9mm and 0.8mm for top solid on the advanced tab

With that you will get much better detail even at 0.6mm layers, and print time will be fast, try it and post the result.

You want to go fast as you can, but that will destroy your part quality, instead of fast you need bigger extrusions witdh for cut print time.

Re: My first volcano print

Theoritically, with 0.9 extrusion width and 0.6 layer height, your max speed should be 27 mm/s according to the max volumetric speed of 15 mm^3/s for PLA in SLIC3R (which is a too high value).

So if this max volumetric speed is well programmed, changing your speeds settings above 30mm/s (45 mm/s, 70 mm/s, ....) won't change anything to your print time and quality.

Those big nozzles are made for big objects, because of accelerations you won't see a big difference of print time on small objects.

Just try on a big box if you wan't too see.

Moreover, you have to consider the wall thickness. With 0.8 nozzle, you should set 2 perimeters instead of 4 with 0.4 nozzle fo the same thickness. Then you will see a difference on print time.

Re: My first volcano print

Theoritically, with 0.9 extrusion width and 0.6 layer height, your max speed should be 27 mm/s according to the max volumetric speed of 15 mm^3/s for PLA in SLIC3R (which is a too high value).

You may be right. How did you arrive at the 27mm/sec number?

Re: My first volcano print

Using simplify3D and a 0.96mm width, I was able to print a benchie at 0.6mm layer height (top in photo below) in just 16 minutes:

It also turned out better than my earlier attempt.

In addition, I was able to print at a benchie with a 0.2mm layer height (bottom benchie in photo), but that took a lot longer. So, it seems I haven't lost anything by switching to a Volcano. 🙂

Re: My first volcano print

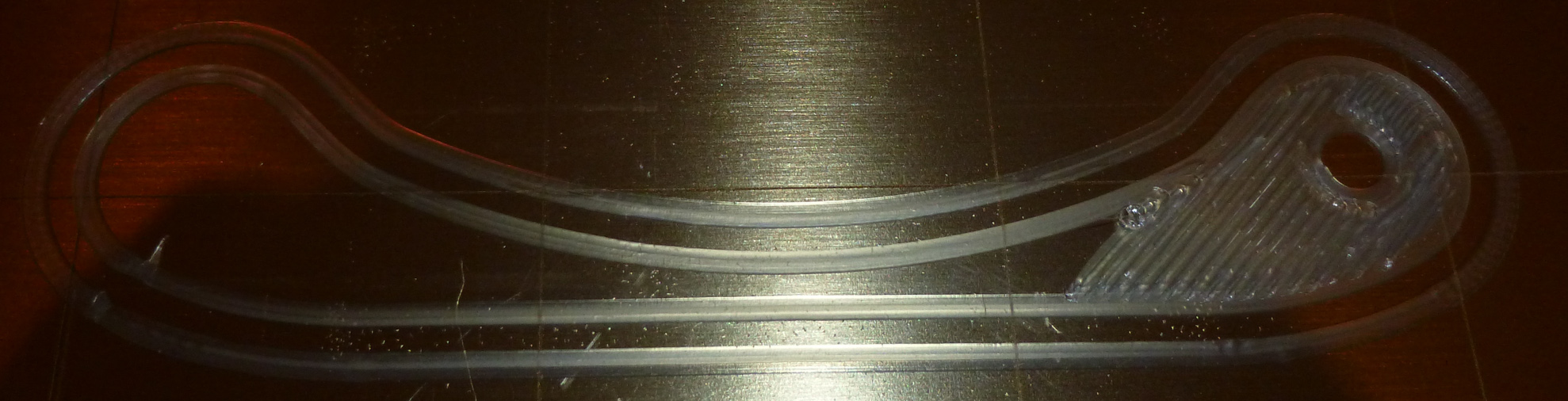

Here's the conundrum I spoke of earlier, and switching to simplify3D didn't solve it:

Basically it's this: if the z-adjust produces a good perimeter line (as in the photo), then the z-height is too close to the build plate for the infill (see photo). If the z-adjust is such that the infill is right, then the z-height for the perimeter is too high.

I may just have to live with it, but if anyone knows of a solution, I'm all ears.

Re: My first volcano print

Theoritically, with 0.9 extrusion width and 0.6 layer height, your max speed should be 27 mm/s according to the max volumetric speed of 15 mm^3/s for PLA in SLIC3R (which is a too high value).

You may be right. How did you arrive at the 27mm/sec number?

Volumetric speed = Extrusion width X Layer height X Print speed

So Print speed = Volumetric speed / (Extrusion width X Layer height)

15 / (0.9*0.6) = 27 mm/s

You can find volumetric speed for each type of filament in Filament settings / Advanced in SLIC3R.

The value for PLA is 15 mm^3/s ( but it's too high for the standard V6 which can reach 11.6 mm^3/s).

BUT I FORGOT SOMETHING ! The volcano has a bigger volumetric speed, which is 40 mm^3/s.

So you can reach 40 / (0.9*0.6) = 74 mm/s (like tiago.c said).

But If you didn't change the volumetric speed in SLIC3R, you will never reach those speeds.

That might be the reason why you don't have great improvements in print speed with SLIC3R, you have to change this value !

For what I know Simplify 3D doesn't have such a parameter, that's why it's faster, but you have to take care of not exceeding the volumetric speed limit or you will have underextrusion.

About your first layer issue, I have the same problem, I set Z to have a good permiter and my infill is a little too tight.

I guess you can play with the first layer extrusion width to solve this problem.

Re: My first volcano print

Noob question of the day: from what I've read, 0.8mm extrusion width is the minimum for an 0.8mm nozzle (i.e. don't go narrower than the nozzle diameter). Is that correct? Or, if I can print narrower, how much narrower can I print?

I'm trying to figure out what kind of dynamic range I might have for doing prints with a 0.8mm nozzle without having to change to a different nozzle.

Re: My first volcano print

One thing I am noticing though is that the support material, rather than being wispy and easily removed, is almost tough as nails and difficult to remove from the print. Not sure what to do about that.

Re: My first volcano print

I printed Benchie at a 0.1mm layer height, and the results came out almost perfectly smooth:

😀

Well, I'm done testing. I'm satisfied. I'll mostly be doing iterative design of enclosures for electronics projects, so the extra speed will be very nice to have. 😀

Re: My first volcano print

The result is impressive for a 0.8 nozzle.

What is the scale of your benchie ?

Re: My first volcano print

The result is impressive for a 0.8 nozzle.

What is the scale of your benchie ?

It's this:

https://www.thingiverse.com/thing:763622

I did not resize it.

Re: My first volcano print

About your first layer issue, I have the same problem, I set Z to have a good permiter and my infill is a little too tight.

I guess you can play with the first layer extrusion width to solve this problem.

You may need to tune your flow rate or esteps, do the test and check.

Noob question of the day: from what I've read, 0.8mm extrusion width is the minimum for an 0.8mm nozzle (i.e. don't go narrower than the nozzle diameter). Is that correct? Or, if I can print narrower, how much narrower can I print?

I'm trying to figure out what kind of dynamic range I might have for doing prints with a 0.8mm nozzle without having to change to a different nozzle.

Extrusion width must be max. +/- 120% of the nozzle size, min. is 100%

One thing I am noticing though is that the support material, rather than being wispy and easily removed, is almost tough as nails and difficult to remove from the print. Not sure what to do about that.

Obvious, the more thick the extrusion is, the more strong the suports are, you are printing 2x thicker supports which will do that. You can try to weak the supports by adjust his extrusion (0.72mm) and put less supports

Re: My first volcano print

In looking at the available settings, I think I maybe see the problem. The bottom layer has to overlap with the perimeter in order to attach to it. Otherwise, for example, the bottom would fall out of a vase. That means there are areas where the plastic is twice as high as you might otherwise expect. At 0.6mm, that means the effective height might be 1.2mm, which is high enough it could (and sometimes does with my printer) collide with the PINDA, which is about that height, or the nozzle.