RE: Multiple print failures

Uff. This should serve as a cautionary tale for anyone recommending wholesale replacement of Prusa-approved and authorized parts, no matter what "evidence" is provided. Swapping parts can cause warranty issues. Not that it would make a lot of difference in this case -- and at least @epzcaw is getting a replacement hotend -- but it would be a real shame if a pre-built warranty was voided.

Mine was a kit not pre-built so I guess that is all I can expect. They are asking me to put back the original heat break and return the hotend before sending a replacement.

I now have regrets about getting a kit rather than a pre-built one. On the one hand, it was very satisfying to put it together and get it working. On the other hand, if it had been a pre-built one, I probably would have spent so long trying to get it it work again after it started failing, but would have look for a replacement.

But this will be the last throw of the dice for me. I guess for this amount of money, you cannot expect a piece of machinery this complex and of this precision to be of excellent quality so probably not worth looking for an alternative.

A soft answer turns away wrath.

RE: Multiple print failures

@epzcaw

Usually the kits have also the hotend already pre assembled, or you had to assemble it?

Regardless the lower price, I think assembling it, we got much deeper insight how the machine works and I also enjoyed to build it. Is more exciting than LEGO and I had an opportunity to use experience a learned many many years ago. 😊

I am sorry you got one piece not working properly. But comparing the number of printers produced and number of faulty things here on the forum is not that bad quality I guess.

Still keeping my fingers crossed once you have sorted out this awfull period you will become enjoy this toy.

Nevertheless I have printed a simple small Fillament movement watcher to make easier to see the fillament flows out of the nozzle not being forced to look under the nozzle.

After you get a new hotend let us know the results.

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Multiple print failures

To my many advisers

You will be pleased to hear that my hotend arrived on Thursday. I installed it without much difficulty and have now been printing successfully for over 30 hours -7 different parts - without any problems. Fingers crossed that it is permanent.

My grandson has arrived from the US, and we have been printing parts he has designed at school. As this has been one the main reasons for getting the printer, the timing is excellent!

I hope I won't be back.

Thanks for all the help.

A soft answer turns away wrath.

RE: Multiple print failures

To my many advisers

You will be pleased to hear that my hotend arrived on Thursday. I installed it without much difficulty and have now been printing successfully for over 30 hours -7 different parts - without any problems.

Great news! I was thinking of you as I printed some goodies for Christmas. Glad you got The Toy Factory going in time for your grandson's visit. I hope you have a lot of fun together with it.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Multiple print failures

Great news,

But do not abandon us,please.

The best thanks will be to show great prints you will create with your grand childern.

Anyway a simple filament movement sensor i posted somewhere here could help you to monitor the filament movement.

Enjoy your printing

Zoltan

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Multiple print failures

Reporting back to my helpers. Several weeks of successful printing, some with grandson, some my own.

1. Stand for 500,000 year old stone axe (had been sitting in a box for several years)

2. Leg for broken chair

3. Mended chair (it is from a doll's house)

4. Egg holder for boiling eggs - made of ASA, still a bit bendy in boiling water but works

5. Cup by grandson

6. Boxes and lids by grandson

7. Filter to stop things falling down the drain in the sink

8. Boxes for efficient storage of AA and AAA batteries

Sadly, however, the old problem has recurred. Prints failing partway through the proces - extrusion stopping whiel extruder carries on as if it was extruding.

Printer now on the way back to Prusa - fingers crossed that they find something.

A soft answer turns away wrath.

RE: Multiple print failures

[...] Sadly, however, the old problem has recurred. Prints failing partway through the proces - extrusion stopping whiel extruder carries on as if it was extruding.

Printer now on the way back to Prusa - fingers crossed that they find something.

Glad you got some productive use out of it, but definitely a bummer having to ship it back. Hope they get it all sorted out for you.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Multiple print failures

Beautiful prints, but strange it ended as it did.

As far as I remember you have totally replaced the hot end. There was no thermal runaway? Filament material independent?

One of the issues I have in mind was a extruder motor shaft becoming too hot, which partially melted the filament before it reached the nozzle.

I learned on Prusa workshop, when you change filament eg. from ASA (unloading it first) to PLA, you should heat the nozzle to ASA temperature, in order to get out all ASA remains by PLA pushed out.

Curious what will the Prusa tech support find.

Keeping fingers crossed to get it finally sorted out.

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Multiple print failures

As far as I remember you have totally replaced the hot end. There was no thermal runaway? Filament material independent?

it's exactly the same fault as before. Seems like "heat creep", but I don't have any of the conditions which are supposed to lead to this. No thermal runaway. Happened with several different PLAs attempting to print the Prusa 150um tree-frog so the model could not be blamed.

Yes, Prusa supplied a new hotend which I fitted and had no problems printing for several weeks but then started up again.

I've done several cold pulls since the problems started and they appear fine.

Perhaps I've done something wrong in the assembly but no-one has suggested anything like this which could be the problem.

Hey ho!!

A soft answer turns away wrath.

RE: Multiple print failures

Hello old friends

I hope you are all getting through the corona epidemic. Strange times.

I thought I should update you on my 3d printer saga. I last reported that I had sent it back to Prusa for repair and service. After some time, I received an email from Prusa about the state of my printer – lots of minor faults, and a damaged heatbead. Final conclusion:

Technician’s note. The KIT is not well built, but on the other side, it's not as bad as it could be. There's a lot that needs to be fixed. But except the heatbed that needs to be replaced (because there's mechanical damage to it, it can't be replaced under the warranty) the rest of the parts can be used.

None of the listed problems appeared to me to explain the intermittent problems I was having with the printer but I was assured that if the fault recurred, they would take it back at no cost and repair again.

The final cost of the repair was CZK4983 (£177). I paid this with the hope that I would now have a properly assembled, fully working printer.

It arrived back on Wednesday this week. They sent some lovely models which they had printed with it.

I opened the box on Thursday and did a self check (ok) and an xyz calibration (ok). I then tried to do a first layer calibration but could not get a consistent result. At that point, I was tempted to throw it out the window.

Instead, I “chatted” to Prusa and was advised to do some cold pulls. I did this on Friday, and there were no problem with these. However, first layer calibration was unsuccessful again. There was no consistency for any specific setting.

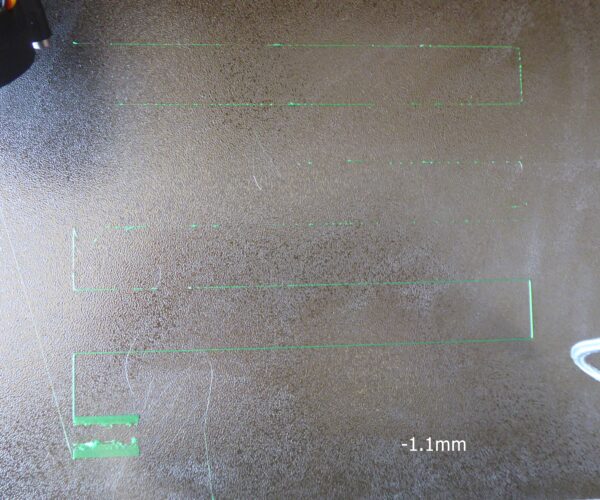

I spent several hours yesterday “chatting” with Marc who was very helpful and determined to sort out the problem. We were chatting for several hours. I tried to print a rectangle (gcode given to me by Thursday’s adviser) and you will see from the attached photo that there is a cyclic problem. I eventually gave up exhausted.

This is a different fault from before – I never had a problem getting a good first layer – the fault was an intermittent one which could occur any time during the print process. This is at least consistent – the same cycle can be seen in every rectangle I print.

If I was superstitious, or believed in ghosts, I would suspect it was cursed. I think it will have to go back again but I don’t know if I have the endurance to try any more.

So I either abandon it altogether or return to Prusa once again. 😰

In the order of things, it’s not important now.

Keep well everyone

A soft answer turns away wrath.

RE: Multiple print failures

Hello

I hope you are doing well even in this strange times. If I am correct I recognize the textured sheet and guessing it is PLA? What is your life Z height? For textured I am in range -700 till -800. If it is PLA, it sticks on textured very purely.

Is the fillament a PRUSAMENT? HWat is the print temperature?

You are not using the standard first layer callibration? On this you can better see the result of moving the nozzle when you get a corect right angles when the nozzle is turning by 90°.

It is strange you are facing those issues.

For textured versus PLA combination it helped for me to use the attached glue stick.

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Multiple print failures

[...] This is a different fault from before – I never had a problem getting a good first layer – the fault was an intermittent one which could occur any time during the print process. This is at least consistent – the same cycle can be seen in every rectangle I print.

I know you've done most of these things a hundred times, so apologies if this seems rudimentary. Just sharing what I'd do if sitting at your printer. Based on the spaces between traces and at the edges, it looks like your Live-Z is high. Some loose strands might be snagging the nozzle. If I were at your printer and observed that result doing a Live-Z calibration, I'd lower the nozzle (make Live-Z more negative) by 0.04mm and see it it improved, then continue in 0.02mm increments. All on a clean print surface, of course.

Did you by any chance pick up a smooth PEI print surface during all these adventures? I'd use that until you get things sorted out if it's an option.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Multiple print failures

This was a shortened version of what happened.

I received the printer from Prusa saying it was now all in order, with four beautifully printed parts.

I unpacked it and was all set to start printing. I did the self test and XYZ calibration which were fine. I then tried to do a first layer calibration but could not find any value which gave a consistently satisfactory result. I went from heights where the nozzle was clearly too far away from the heatbed to where it was virtually in contact with it, but I could not get a consistent result. I am attaching two photos showing what happened at different fixed z values and you will see that the result varied as it went along.

Note that I was not varying the z value while these were being done, but trying to see what happened at each height.

I went on to Prusa "Chat" and was advised to do some cold pulls (I did and these were fine), and to print the rectangle - I was sent the file.

I am using Prusa PLA and have tried both smooth and textured sheets.

The three images I posted previously were all done under the same conditions with the same fixed z-value but clearly the z-value does not remain the same but cycles up and down - I've measured the cycling time as 30 seconds.

I spent about four hours on Friday "chatting" with an agent - he was determined to sort it out but got nowhere.

I think it will have to go back to Prusa again, but something very mysterious is going on.

A soft answer turns away wrath.

RE: Multiple print failures

This must be frustrating. It's always possible it got damaged during return shipping, but the fact that Prusa certified it at least eliminates any of the build concerns.

The textured sheet is notoriously difficult to work with when printing PLA. Not to say that yours is one of the bad ones, but I'd stick exclusively with the smooth PEI for the time being simply to eliminate yet-another variable. The reason I say this is that your pics seem to show signs of both high and low Live-Z. The long strands aren't sticking, while the little square looks torn. I've seen this often if someone is trying to compensate for poor bed adhesion (due to poor cleaning or issues with the textured sheet) by lowering Live-Z (to where the nozzle starts scraping up filament).

The smooth PEI is a "known good" surface if you give it the wash under the kitchen sink with plain dish soap (Dawn or Fairy), scrub it with a plain paper towel and dry it with another. Most of all, do nothing else and avoid touching the PEI print surface.

Again, I know you've done most of these steps many times. These are the steps I follow when problems like this occur. I'm sure Prusa support walked you through these steps as well.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Multiple print failures

All my successful prints were done on the textured sheet (nearly all PLA). This was the sheet that went to Prusa on which I assume they printed the models they sent to me.

I've done a series of z calibrations at different values, and each one show a wide variation as it goes along. It may start adhering nicely along with good 90 corners, but as it moves along it starts detaching.

The problem is indeed that the z-value is varying instead of remaining at the value I set it at, and this is a periodic variation with a cycle time of 30 seconds. So something has happened to it between leaving Prusa and arriving here. What can this be? And can I fix it? Or do I need to send it back.

Or do I just throw it out and abandon 3d printing!!!

A soft answer turns away wrath.

RE: Multiple print failures

Easy variables are your filament and things like extruder tension screw and idler.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Multiple print failures

I am not willing to go down this route again. I've spent £177 to get the printer repaired and serviced. It should be in perfect working order, and not requiring me to start repairing it.

I spent hours and hours fiddling with a variety of things trying to eliminate the previous fault without success.

I'm not happy!!!!

A soft answer turns away wrath.

RE: Multiple print failures

I am not willing to go down this route again. I've spent £177 to get the printer repaired and serviced. It should be in perfect working order, and not requiring me to start repairing it.

I spent hours and hours fiddling with a variety of things trying to eliminate the previous fault without success.

I'm not happy!!!!

I don't blame you. I'm only trying to offer helpful suggestions. If you'd rather not bother, it's understandable.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Multiple print failures

Apologies - I don't mean to be ungrateful. Or rude.

But I guess a return to Prusa is the best answer. I hoped there might a simple answer that would not require more hours of taking things apart and putting them together again,, all in vain.

I spent four hours with a Prusa adviser on Friday and got nowhere even though he was convinced he could solve it.

One more Prusa chat tomorrow and that's it.

A soft answer turns away wrath.

RE: Multiple print failures

Search for the movie on the forum, some filmed the first layer and zoomed in on it, and change from to high, to to low. Than you can see what is good.

Make the extruder hot, do 10 or 15 degrees higher, then extrude filament, so you can clean out the filament.

Do z-calibration, then do a first layers test, if ok, do a z-calibration again, and print a model(stl). See if this helps.

If you switch between the 2 different steel plates, a z-calibration is needed(powdered and pei sheet are different). You can also put the sheets in de firmware, number the sheets.

Do a z-layer calibration, with more heat, what happens then.

Remember a 3d printer will never work, like start, and i have a model, you will have always problems, or adjustments you need to do, even after 20 good prints.