RE: Multiple print failures

Or pause the print until morning... Pause usually works if the filament sensor has been disabled first.

RE: Multiple print failures

I left it printing at midnight, and came down this morning to find it had almost finished but not quite - see image below Probably another 10 minutes to go. By now, the printing head had withdrawn, but there didn't seem to a problem with the filament but hard to tell.

I have started running it again. I will monitor it regularly and ensure there is no filament tension. I am also videoing the gears so might cath it. or maybe not.

The printing was excellent until shortly before failure. I was able to unload and reload without any problem.

A soft answer turns away wrath.

RE: Multiple print failures

I ran the same model but at .2mm layer thickness (to save time). I monitored it closely and videod the gear wheels throughout. I did make sure that the filament was moving freely whenever I checked it giving additional slack when I thought it was needed. And what happened? It was successful. Now of course I'm pleased because it has succeeded. But I was hoping to find out just what does happen when it stops extruding. Hey ho!

I could assume the problem is solved, though I think this is a bit optimistic.

I had a long chat session with 3 different prusa advisers today, and they came up with nothing except to print at 225 "becuase I had changed the hotend and adjustments would be required". They were also a bit sniffy about me using a non=Prusa heat break.

I think I will now print the same thing several times in a row keeping all conditions the same. I am going to do the tree frog which comes with the printer as I assume no-one will try and argue that I have a model problem. I can then assess what the variability is.

What fun!!

A soft answer turns away wrath.

RE: Multiple print failures

Great to hear, have a fun!!!

So next step to involve your grandson.

To be honest my most requesting customer is my wife 😀 - she is saying, you have a 3D printer so you have to be able to make everything.

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Multiple print failures

I don't think the problem is solved. Tim's suggestion re filament jamming seems the most logical explanation since it would occur at random times, and not very frequently. But I don't see why it should be happening with the reel and reel holder supplied by Prusa. But I did ensure that it was free running today. However, standing over the printer all the time while printing is not an ideal solution!

I will report back on my controlled trial with the tree frog and take it from there.

Thanks again.

A soft answer turns away wrath.

RE: Multiple print failures

You might watch the spool sizes ... and correlate failures to spool width.

Here's a cute spool holder idea, one that will print quickly, and uses common pipe for the harder to print sections.

https://www.thingiverse.com/thing:3224677

ps: and you might want to try Meshmixer to create a model with tree supports for the pooch.

RE: Multiple print failures

Alas, I am back. More print failures and spool jamming is not the problem.

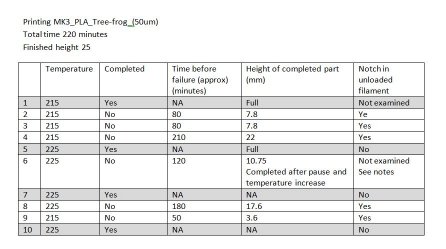

On Wednesday, I decided to conduct a series of printings of one model to see if I could get some information about the frequency of failures and also to see if I could identify anything that could be doing this.

I chose the MK3_PLA_Tree-frog_50um because it is one for the supplied g-codes, and it takes 3hr 40 minutes so within the time scale when failures normally occur. I used red Prusa PLA which I have been using for the last few weeks. I did half of the prints using the parameters built into the g-code. For the other half, I set the nozzle temperature at 225 as recommended by a Pruusa adviser in our last “chat”.

The printing was deemed to have failed when no material was being extruded - the head always continues to move around as if it was printing, and I noted that the gears were still moving in all cases where I could observe (some parts were printed at night when I was in bed)

6 out of 10 prints failed. Of these failures, 4 were at 215, and 2 at 225.

After print 1, I unloaded the filament and examined the part near the extrusion end. All the filaments had gear tooth marks, but the filaments from failed prints had notches at the point where the gear tooth marks ended. I assume that these were caused by the gears digging into stationary filament which suggests that the hotend had become clogged.

I caught print 6 shortly after it stopped extruding and paused it. I then heated the nozzle to 280 degrees, plastic started being extruded, so I started the print again. It resumed printing, and went on to completion. There is a very small step where one or two layers were missed out but adhesion is fine. This did not work with part 8 – the failure had occurred some time earlier so perhaps everything too far gone.

Only 4 out of 10 prints were successful.

When the prints failed, the average time after which failure occurred was 120 minutes (times are approximate as I did not catch the exact time when the print failures happened.)

Two of the 225 successful prints appear to have a missing layer about half-way through.

Unloading and reloading filament was done without any problems in each case, and printing always started successfully for each new part.

The extruder gear screw tensioner was set level with the outside of the motor

Here are the frogs

What do I have to do to make the printer work reliably?

A soft answer turns away wrath.

RE: Multiple print failures

The nozzle temperature was within one degree of the specified temperature anytime I looked.

The filament spool was not jammed when the head was moving with no extrusion.

A soft answer turns away wrath.

RE: Multiple print failures

@epzcaw

Looks like a heat creep to me. Especially 0.05 layer height prone to it because of slow filament movement.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: Multiple print failures

I removed my previous post - i did not recognize at the start it was 0.05 layer, which can really create a heat creep.

what was the testing fillament please?

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Multiple print failures

Hi (normally I would say welcome never mind)

Reffering to my previous analysis points 1-3 are not valid.

Could it be the fourth one?

4. Cold nozzle blocks the filament - ??? - should be checked next time

For this reason I adviced you to watch the temperature on the display at the moment the filament stopped extruding. Did you have a chance to do it?

This is no practical way to do this as the failure occurs at random times. So it could be 30 minutes after the start of the printing, or it could be 7 hours after this. I observe the temperature frequently during the printing process and it has always been within a degree of the required temperature.

I can try setting up a camera to vide0 record, but my cameras only do 20 and 30 minutes, so I would have to keep chening them. I can have a go at this, but of course, it could be many hours before a failure occurs. And this only works if the displayed temperatuer is reading correctly.

In some of the threads here people had troubles with heating block - printer were working fine at first layer ,but starting the second layer the fans started to cool the nozzle more intensively , and their nozzle temperature decreased to the level they finally got an error message "Thermal runaway" followed by print stop which is indicated when the temperature of the nozzle is for certain time (I guess 30 seconds) by -10°C below the set temperature.

This is probably not exactly your problem, but could be similar that at some starting point the temperature is not high enough to melt the fillament -> the resistance increases-> extrusion stops.

Looking at what everything you changed heatbreak, nozzle the only stuff which can be suspicious is the heat block and thermistor -> they are responsible to heat up and keep the proper temperature of the nozzle. And of course their proper installation, that the thermal resistance between the heater , heatsink and the nozzle is minimal.

During the print the nozzle temperature is not fix it fluctuates along the set temperature + and - driven by temperature measured by thermistor and controlled by electronics .

Would be great to have a look if it is in your case more in minus or more in plus and for how long time. If it inclinates more to the minus it could tell there is some issue with heating performance.

If the heating is on the edge of its capabilities even a small ambient temperature change (open door air draft) can do the damage.

And the last of my long story the electronics itself can be faulty -> I mean the drivers

To measure the nozzle temperature a simple trick can help - take a piece of appropriate fillament and at the moment the extrusion stops, stop the printing (head movement) and attach this piece of filament to the nozzle in order to see if it is going to melt.

As I said, I am unlikely to catch the moment the extrusion stops. This would mean watching the printer continuously for 2 to 8 hours. I can;t think of any way of triggering an alarm to indicate the extrusion stopping. There might be some was of fitting a motion sensor to the top of teh extrude which senses the motion of the filament on its way in, but I don't think I want to embark on that!

Advice:

1. Check the temperature fluctuation on the display during the print (edit : I see you already did) and when extrusion stops note the display temperature and try the above temperature measurement trick - if the temp on display is "correct" but the temp. measurement trick shows the fillament is not melting thermistor issue could be the reason.

2. If the display temperature is below the required - heating block issue could be the reason. - this is probably not relevant.

Or maybe I could get a non-contact temperature sensor and somehow attach it to the printing head so it detects the nozzle temperature and feeds it to a computer (rasperry pi which I have) which records it. But that is getting a bit heavy!

Will start a frog tomorrow and monitor the display with video. I can keep doing frogs until I get a failure.

Thanks again for your interest and support.

A soft answer turns away wrath.

RE: Multiple print failures

@zoltan

Re .05 layers - they may be an issue but the failure rate did nto seem significantly different from previous ones.

Red Prusa filament.

So I need to repeat the test with a different model. I chose that one because it is a Prusa supplied one and was the right duration. If it si much longer than that, it will take an awful long time to complete a sensible number of trials. If is is much shorter, I will not get many failure. But I will look through the SD card and see what there is.

A soft answer turns away wrath.

RE: Multiple print failures

@epzcaw

Suggest you following thing to try with the same gcode:

- Bump up the nozzle temp by 10C

- Blow some cool(er) air on the extruder

- Speed up to 150%

If the print will be successful, you know the root cause 🙂

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: Multiple print failures

Take a photo of the heater block and nozzle ... and post, please.

RE: Multiple print failures

Oh - and verify the extruder fan is spinning and blowing air across to the PINDA. Should not be a hurricane there, but you should be able to feel air flow.

RE: Multiple print failures

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Multiple print failures

@epzcaw

if you have built in camera in mobile, it can provide the service as well, when you plug in it to power supplier.

You can start with printing a stand for mobile. If you tell me the type or dimensions of it, I will be happy to draw simple one for you 😉.

I think the most important is to see the temperature at the moment the printer is printing in the air with no filament.

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Multiple print failures

@zoltan

Thanks for that. But at the moment, I can't print anything reliably. Sort of catch22!

A soft answer turns away wrath.

RE: Multiple print failures

Am now running the Buddy model.

But since the treefrog (50um) is one of the Prusa supplied test codes, it should surely work without any tweaking

A soft answer turns away wrath.

RE: Multiple print failures

Sorry to read that you're still having issues. Apologies if this was already mentioned but I'm on really bad wifi so can't re-read everything. If you've already got a RPi, presumably you're already experienced with it. If it's a 3B or better, it's ideal for running Octopi. This will graph temps over time and is fully configurable. This might be all you need to catch late night Gremlins. A timelapse with a camera might help as well. I ran Octopi on a 2B for months without issue before I noticed it wasn't a 3B.

I do have a Raspberry Pi, but have done only a limited amount of work with it and not for some time now. Interfacing it with the printer would be a whole new learning experience. Maybe later, I will get back to you for advice. Thanks

A soft answer turns away wrath.