RE: Multiple print failures

In each case, I left the machine printing and when I came back, the printing head was several mm above the part. It was moving as though it was still printing but nothing was coming out of the nozzle. I was able to unload the filament, and it does not now have an increased diameter at the end, so assume it is not heat break failure.

I wasn't there when the parts failed so heard no noises!

I am using red Prusa PLA. Temperature is set by Prusa slice at 210.

I went on the Prusa chat a short while ago and it was suggested that I print at 220, so I am running that on the new file now. It takes over 7 hours, and failed last time after about an hour and a half so it is a slow business....

I will attach the STL file for my new model. The Corgi is the one I previously uploaded, and several people, including you, printed it successfully. I also printed it again successfully after changing the heat break. but it failed again today.

A soft answer turns away wrath.

RE: Multiple print failures

Have you done the simple things recently: for example, increase tension on the filament idler?

And a second thing to check, is that the idler axle is not loose? Easy to test by opening the door and pushing on it: it should be firm and not flex.

RE: Multiple print failures

so no gear tooth marks on filament?

I can identify the following situations when filament does not ooze from nozzle:

1. Extruder gears do not turn - could be HW, SW or model error - we do not know - checked the sliced model, looks ok -next time please check

2. Filament jam - many reasons - eliminated for now - secondary evidence - filament with clog, gear tooth marks on filament, gears clicking - this should by also investigated next time when observing printer still "printing "

3. Spool locked - does not allow to pull filament - ??? gear tooth marks on filament, gears clicking - seldom, but happens (even to me)

4. Cold nozzle blocks the filament - ??? - should be checked next time

Something mysterious or very simple, just to find out. But any information can open our blind eyes - we do not see your printer, you have to be our eyes 😉 looking everywhere ,watching everything.

Watching the "printing" printer without filament can be observed better than discover already failed print with no nozzle movement.

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Multiple print failures

@zoltan -- All of my filament has gear tooth marks as it feeds through the gears, so that is perfectly normal. However, having a notch ground out is not normal.

That said, I think we are not being told everything that is happening. Some critical detail is being missed.

RE: Multiple print failures

so no gear tooth marks on filament?

Have discarded it - will find out at next failure...

I can identify the following situations when filament does not ooze from nozzle:

1. Extruder gears do not turn - could be HW, SW or model error - we do not know - checked the sliced model, looks ok -next time please check

The gears are certainly turning at the moment as the printer is printing successfully so far. But if it stops extruding again, but keeps on travelling around I can chekc to see if they are still turning.

I've checked the idler axle before and ti was fine. Can do it again.

Not the model, as the problem arose with a tested model. But maybe you could send me a model which you knwo to be good for me to try?

2. Filament jam - many reasons - eliminated for now - secondary evidence - filament with clog, gear tooth marks on filament, gears clicking - this should by also investigated next time when observing printer still "printing "

I don't hear any gear clicking sound. Haven't done a cold pull, but filament unloaded and loaded again after failure, and printed beautifully for a while.

3. Spool locked - does not allow to pull filament - ??? gear tooth marks on filament, gears clicking - seldom, but happens (even to me)

I did have a failure due to this but not this time! I'm not counting that as it id definitely operator error!

4. Cold nozzle blocks the filament - ??? - should be checked next time

How do I check for this?

The problem with adjusting the gear tension is that it is very difficult to test the outcome. This is an intermittent fault. So even if I do an adjustment and teh next part doesn;t fail, it is no guarantee that this was because of the gear tension adjutment. Ive; set the screw to be more or less aligned with the motor case.

Something mysterious or very simple, just to find out. But any information can open our blind eyes - we do not see your printer, you have to be our eyes 😉 looking everywhere ,watching everything.

A soft answer turns away wrath.

RE: Multiple print failures

Gear tension is easy: If the extruder gears are turning and no filament is coming out, and while the printer is still moving, simply tighten the tension screw a half turn or more. Or, pause then adjust the screw if you have problems fitting the Allen key.

ps: as zoltan said before: extruding filament is an amazingly simple process: heat the nozzle, apply downward pressure on the filament.

The only things that can prevent this from working is: no heat, or no pressure. Heat is pretty simple, the heater is on or it isn't; pressure is the motor turning, and no restrictions - like the gears spinning on the motor shaft, a nozzle obstruction, a spool not turning, or the filament packing in the heat break.

Models have never in my experience caused lack of extrusion.

RE: Multiple print failures

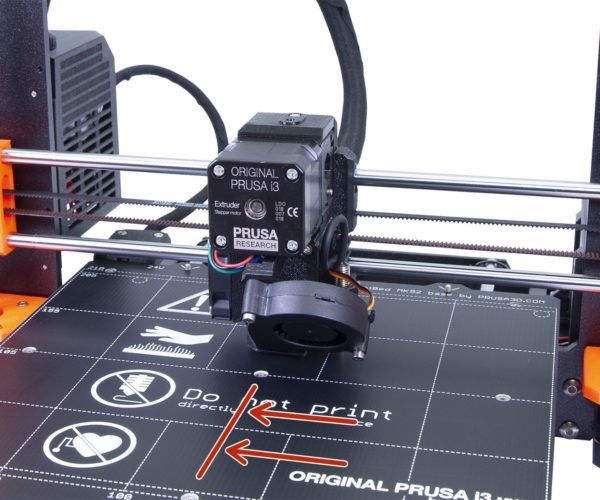

So it failed again after about 30 minutes. The gears were (obvioulsy) turning while it was printing but were not going when it had stopped extruding.

The filament does have gear marks. It also has a small bulge at the end - 2.02mm diameter. See

The gear axle screw is (and has been) fully tightened. I've done a cold pull and it is perfect.

The problem with adjusting the gear tension is that for a long (and random) period, the gears are turning. Unless I actually cathc the moment when they stop turning, I can;t adjust them as the print is going.

What am I missing?

A soft answer turns away wrath.

RE: Multiple print failures

Did you adjust the tension screw tighter?

Is there a divot on the filament about 25mm from the stub, a small spot where the filament has been abraded?

RE: Multiple print failures

No, I didn't adjust the tension screw. Have started printing again so can do so. I assume that I turn screw clockwise to tighten.

Can't see any such feature on the filament.

But I don't understand why the gears should work well for an hour, two hours or more and then fail.

Printed two small pillars (8 minutes) no bother.

A soft answer turns away wrath.

RE: Multiple print failures

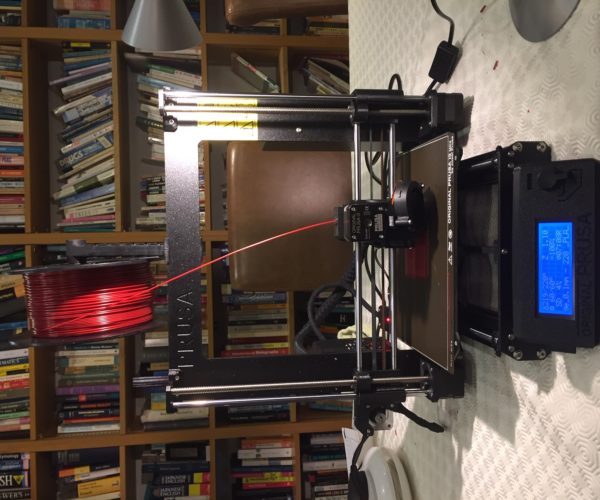

And - please post a photograph of your printer - one that includes showing the spool feed path, and area around the printer.

RE: Multiple print failures

A soft answer turns away wrath.

RE: Multiple print failures

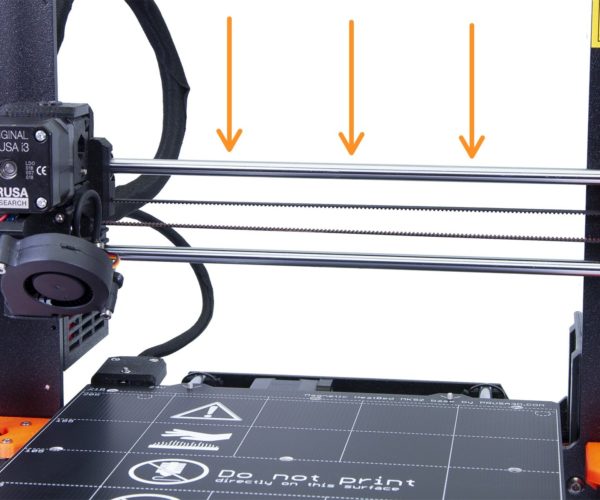

Is that spool actually hanging off over the end of the spool holder? If it is, that might be the problem all along.

Also, the cables in back are not right. The bed cable should be routed flat to the left, not upwards. And the extruder harness appears to not have the 3mm nylon embedded in it and is drooping. The two harness should never touch in normal operation. Dout it's causing the print problems, but should be fixed.

RE: Multiple print failures

Here's the relationship:

RE: Multiple print failures

Will sort cables when this print is over.

6% done. Gears still turning and printing looks good. But 6hrs 50min to go, and I will probably be in bed when it fails.

Something must surely be changing during the printing process to cause the gears to seize up (if this is the problem). Overheating? Something needing lubrication?

(Thanks for help yet again!!)

A soft answer turns away wrath.

RE: Multiple print failures

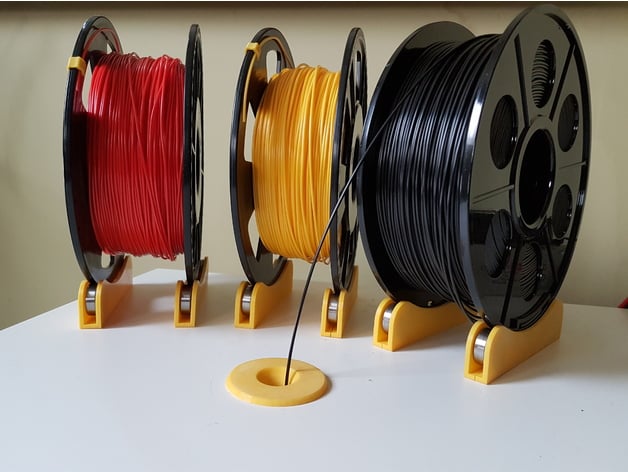

The filament spool and holder are suspicious. Looks like you fixed it before taking that last photo. The first showed the spool off the rod. And, the spool also looks like it is too large for the holder, and isn't free to spin. There is a reason folk build roller bearing spool holders.

https://www.thingiverse.com/thing:2047554

RE: Multiple print failures

Trouble is, I can't build anything until I have a working printer!!!

I don't think it was actually off the rod - I didn't do any adjustment between photos.

A soft answer turns away wrath.

RE: Multiple print failures

I will see tomorrow if I can set up a video to record the filament for the whole printing time. Could be problems with the duration (fitting onto an SD card) or camera battery.

Sounds plausible but not sure how I'd fix it. I haven't noticed it being stuck after failure. The rell has now rotated by about 40 degrees since I took the photo.

It is still printing. I am going to leave it now but will report back in the morning.

A soft answer turns away wrath.

RE: Multiple print failures

The spool should be free to spin. Any drag is a potential problem. A spool wedging in place will cause what you are experiencing 100% of the time. And if you discover it printing in mid air again, tug on the filament - if there is resistance, you've found the issue. Now nudge the spool forward and see if it starts extruding again. If it does you have confirmation that was the problem.

Do a time lapse at 1 second intervals... saves space, and I plug my camera in to power for these longer time videos.

RE: Multiple print failures

It would explain the random timing of the print failures as well as the fact that they seem to occur only in longer printings. I've been monitoring this one, and its still going 46% of the way through. I've made sure that the filament is loose each time I've checked it. Unfortunately, it is now past midnight, and I don't propose to stay up another 4 hours nursing it!!

If it fails tonight, I can start again tomorrow and try and nurse it through.

I will be both extremely annoyed and extremely pleased if this turns out to be the problem. Will keep you posted.

Thanks again for your input and advice

A soft answer turns away wrath.