RE: Multiple print failures

When you do the install, just be patient, and follow the E3D assembly instructions to the letter: including the notes on how to ensure proper contact between the nozzle and heat break where the seal is actually made, and that loosening and final tightening of the nozzle must be done at temperature (280-285c).

https://wiki.e3d-online.com/E3D-v6_Assembly

https://e3d-online.dozuki.com/Guide/Changing+Nozzles/45

Thank you, I will endeavour to do so properly!!

A soft answer turns away wrath.

RE: Mehrere Druckfehler

@epzcaw

Windows 3D Builder has found bugs in the corgi2.stl file.

RE: Multiple print failures

Next test: Export the fixed STL file from 3D Builder and see if it prints!

3D Builder has become my go-to model problem fixer. Invaluable for random Thingiverse files.

I just wish it was better at telling me what it fixed.

Note: it has found problems PrusaSlicer missed. Those usually result in a failed print.

RE: Multiple print failures

started to print the dog, twice with almost getting a filament ball on nozzle 😋 without brim and support on legs there is no way to stick it on the bed.

Are you using brim and supports printing the DOG?

Strange thing happened, after the first level the nozzle fan started to run and the temperature dropped from required 215 °C to 200°C,then slowly back to 215. Seems there is something in FW with temperature regulation after the first layer. Late response.

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Multiple print failures

@

hatschy 3D bugs or SW bugs 😮 ?

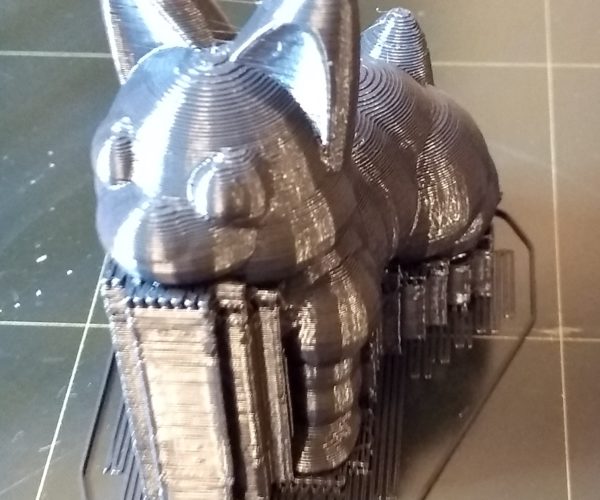

A little dogy is not an issue, successfully printed at 0.15mm height PLA Prusament Galaxy Black. it took about 2 hours and 27 minutes.

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Multiple print failures

Looking good.

That is from the uncorrected model?

If so, the OP is back to looking for hardware issues...

RE: Multiple print failures

YES - stl imported into PrusaSlicer-> sliced for 0.15 mm quality print->G-code generated-> and luckily printed

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Mehrere Druckfehler

@zoltan

3D Bugs

RE: Multiple print failures

I found the same thing: two of the legs are not sitting on the bed; but after a fresh clean of the bed supports stayed put and now dog is printing using the OP gcode (it's been weeks since I last cleaned it, so not the model's fault).

I would never ever slice it that way ... but so far it is printing. Will post results when available.

But there is no doubt in my mind the problem is the heat break. The unloaded filament stub measuring 2.17 mm virtually proves it.

RE: Multiple print failures

Perhaps the STL file has errors, but those errors are NOT affecting the print.

My print using the gcode from @epzcaw:

RE: Multiple print failures

@tim-m30

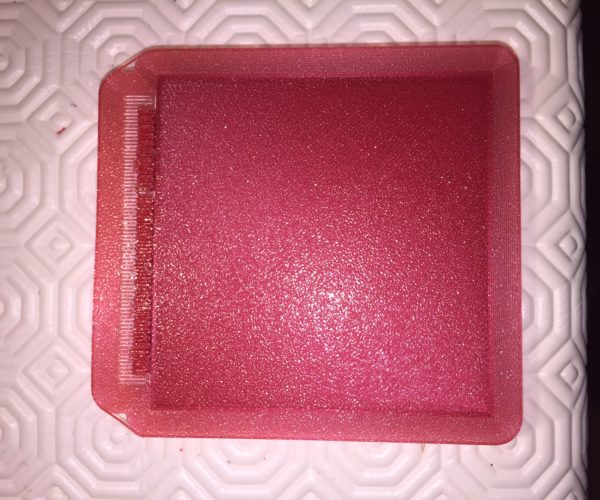

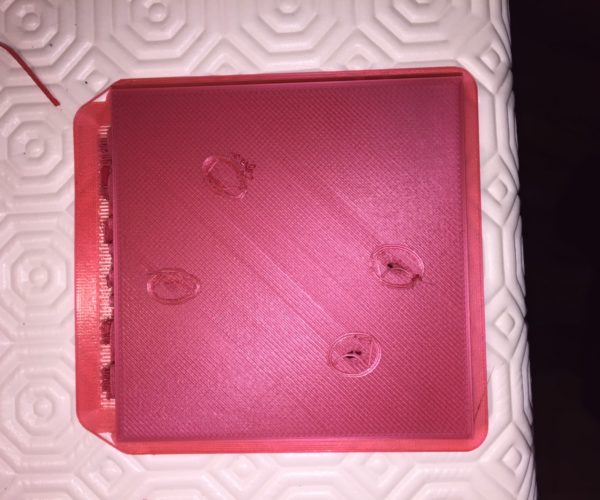

Most of my failed prints were not the dog but a 120x7-x45mm box with some slots. I then tried to print other things including the dog in case it was the file that was the problem, and sometimes in the hope that it might work. See images for some of my failures! I’d printed the dog several times before so it seemed like a good test.

It is that most annoying of problems – an intermittent fault. I did actually manage to complete the box the other day even though it is a 1hr 50 mins print.

I’m hoping, as you have said, that the heat-break is the solution, and am awaiting its arrival. Not looking forward to trying to install it, but will follow the guidance documents you sent me.

Thanks again.

A soft answer turns away wrath.

RE: Multiple print failures

Boxes are my favourites - box for protractor, box for arduino uno controlling the WS2812 led strips, box for mini toothbrashes for my wife, tablet holder for my DJI Mavic air drone controller, mobile phone holder for DJI OSMO Pocket camera… holders and boxes.

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Multiple print failures

@zoltan

This box is the solution to a problem which I have been trying to solve for a long time before I got the 3d printer. The issue is the difficulty of taking photographs with a digital camera in bright sunshine especially when the sun is behind you – you can’t see anything on the display screen.

So I’ve made a box with an opening for the controls, an opening for the lens and an opening for a slot through which I insert a screw to fix the camera. I’ve made a cover from black felt which can be attached to the case using Velcro. The felt covers the controls but with a bit of practice, it is easy to press the “take photo” button through the velcro, which is all you need.

Unfortunately, I haven’t had a sunny day since I completed it but it looks as if it will work.

A soft answer turns away wrath.

RE: Multiple print failures

Great, I di s holder for my tiny DJI Camera allowing to extend it by larger display (mobile phone) and join it to the tripod via standard tripod thread.

and tablet holder for the Mavic Air drone

by those two little recording tools we have a marvelous memories of our vacations

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Multiple print failures

To avoid looking like I am using my great granddad's 1897 view camera, I simply use a camera that has a viewfinder. Sun no longer a problem.

That said, printing a box as shown in the photos should be a walk in the park. Mostly looks like adhesion failures, but a especially bad heat break problem might present itself.

As an example: here its the part that pushed me over the edge to replace my heat break: so many retractions exacerbates the jam:

RE: Multiple print failures

I’m back with a successful print – see image.

I replaced the heat break with the titanium one suggested by Tim, and also replaced the nozzle. It was an expensive job, as I had to buy a torque wrench which came with lots of sockets but not a 7mm one, so I ended up buying a socket set which included a 7mm one. I also bought a 17mm spanner only to find that the hotend is less than 17mm – maybe 16mm. I could have bought a whole new hotend for less, but I guess I have learnt a lot more doing this, which may help to stave of the Alzheimers! And I will be able to repeat the process!

This is a model made up of a fox model I downloaded from somewhere or other and put on a platform with a name in. It failed early on last time I tried to make it recently. It is about 50mm high and takes 1hr 50min.

Of course, this could just be good luck, but I hope not. Fingers crossed.

I need to get on now making some new things.

So thanks to you all for advice and help. If I have more problems, I’ll be back.

A soft answer turns away wrath.

RE: Multiple print failures

Congratulations on your fox!

RE: Multiple print failures

Alas, I spoke too soon. After after 30 hours of successful printing, it has started to fail again.

A new model I’d put together failed after about an hour and a half. Again, the head continued to move as if it was printing, but no plastic was coming out. I’m attaching a photo of the top and the bottom which look fine to me. I decide to try and print the Corgi again and was able to do since replacing the heat-break and nozzle. This time, it also failed after about 30 minute

I’ve unloaded the filament after failure, an

I’ve unloaded the filament after failure, and it no longer shows signs of heat-break failure

What now? Thanks again

A soft answer turns away wrath.

RE: Multiple print failures

Can you please let us know more details about the failed print? Did you encounter a jam again?

What sort of filament it is?

How the sliced model looked like?

etc.

.stl or .3MF file attached would be great

edit: did you hear any gear teeth clicking? did the gears of extruder turn or tried to turn?

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect