Re: Many new printed parts on GitHub

Just for your info. I received my MK3 kit yesterday (ordered 22.11.2017) and still the "old parts", but who cares..........I have bigger problem. My Einsy was f...n death. Now I have to wait for replacement. 😳 Prusa support are just amazing. I spent over 2 hours on chat trying to fix the problems unfortunately no success.

Bad news, I order mine the 24.11 they told me I will have the last revision... Maybe because it's a black one. But I'm not confident now...

Re: Many new printed parts on GitHub

I really like the orange 😡

Has anyone got to any conclusion on what brand the Orange filament is??

I have some Blue Prusa PETG (transparent).... i might give that a try except for the Extruder body which will be the default black :p

EDIT: In other post talking to some users someone said it's from ColorFABB....

And you can see this on their video:

That Label is from one of the PETG spools on the farm.... any detectives out there?

I will try to find out because I have ordered thier orange PETG and UPS shoul deliver it tomorrow. Before I made my order I've ask support if orange PETG from e-shop is in the same colour as orange printed parts in MK3. They said no and if I want the same colour I should leave a note in my order to get the correct one.

Well... if all we need to do is leave a note saying we want the same color as the MK3 than its not that bad... =)

Re: Many new printed parts on GitHub

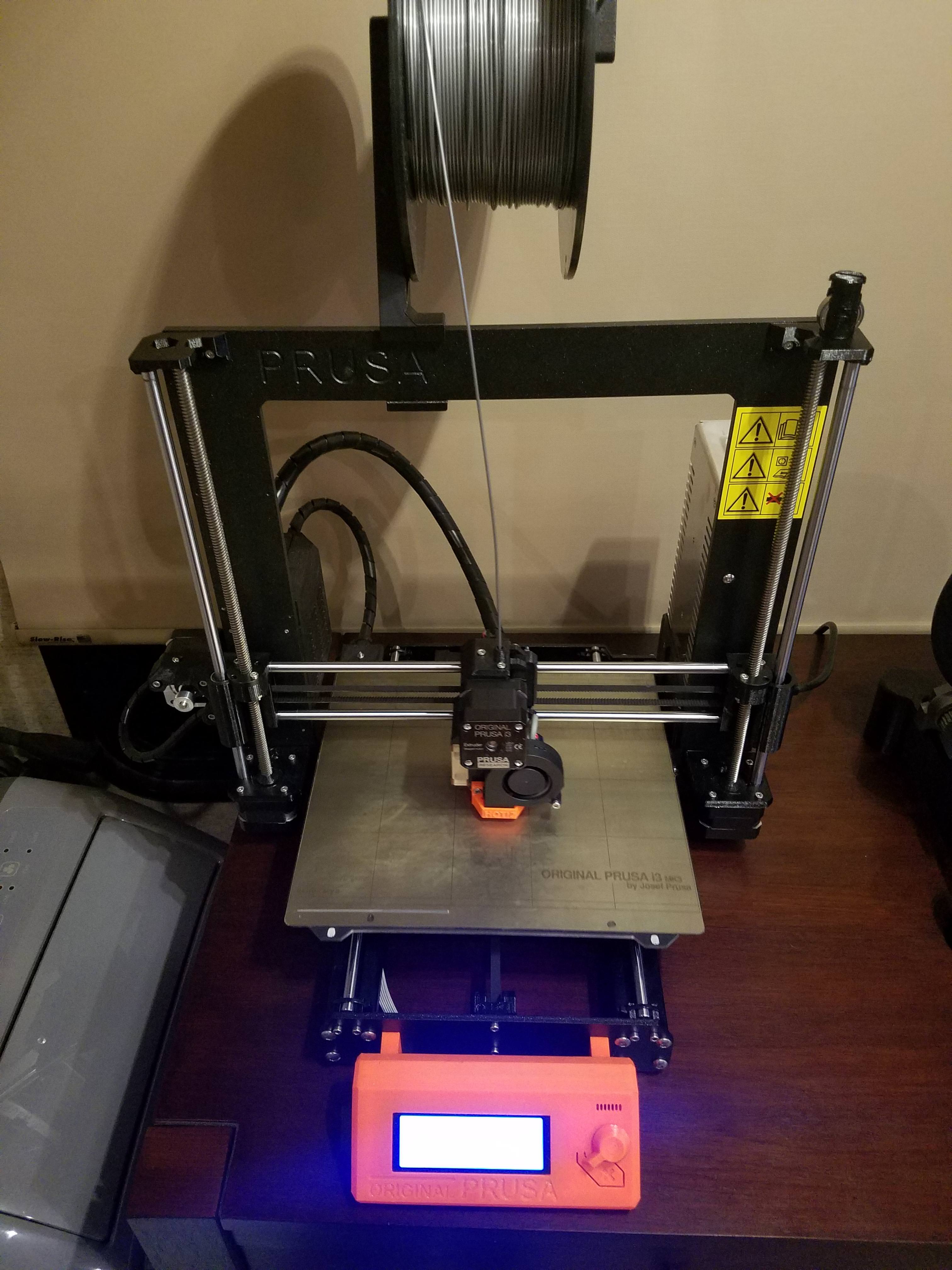

Behold, this used to be an orange Prusa, only orange left is front panel and ABS fan nozzle:

This MK3 now has the following:

Got the PLA up top momentarily to do the first layer calibration and currently spitting out an XYZ calibration cube. Will post it up as soon as I have it, then I will do my usual glossy black PETG version that shows artifacts worse than anything.

Let me know if you have any R2 X-Axis / Extruder assembly questions. I can tell you immediately you need to have your bridging on point with the PETG before doing these, else your captive square nuts won't go in very easily. 🙂

EDIT: On and SWEET filament guide top right by jltx. One of my best upgrades yet. 😛

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: Many new printed parts on GitHub

Looks like this was just added to the store.

Prusa Orange PETG

https://shop.prusa3d.com/en/filament/218-prusa-orange-petg-filament-1kg.html

Re: Many new printed parts on GitHub

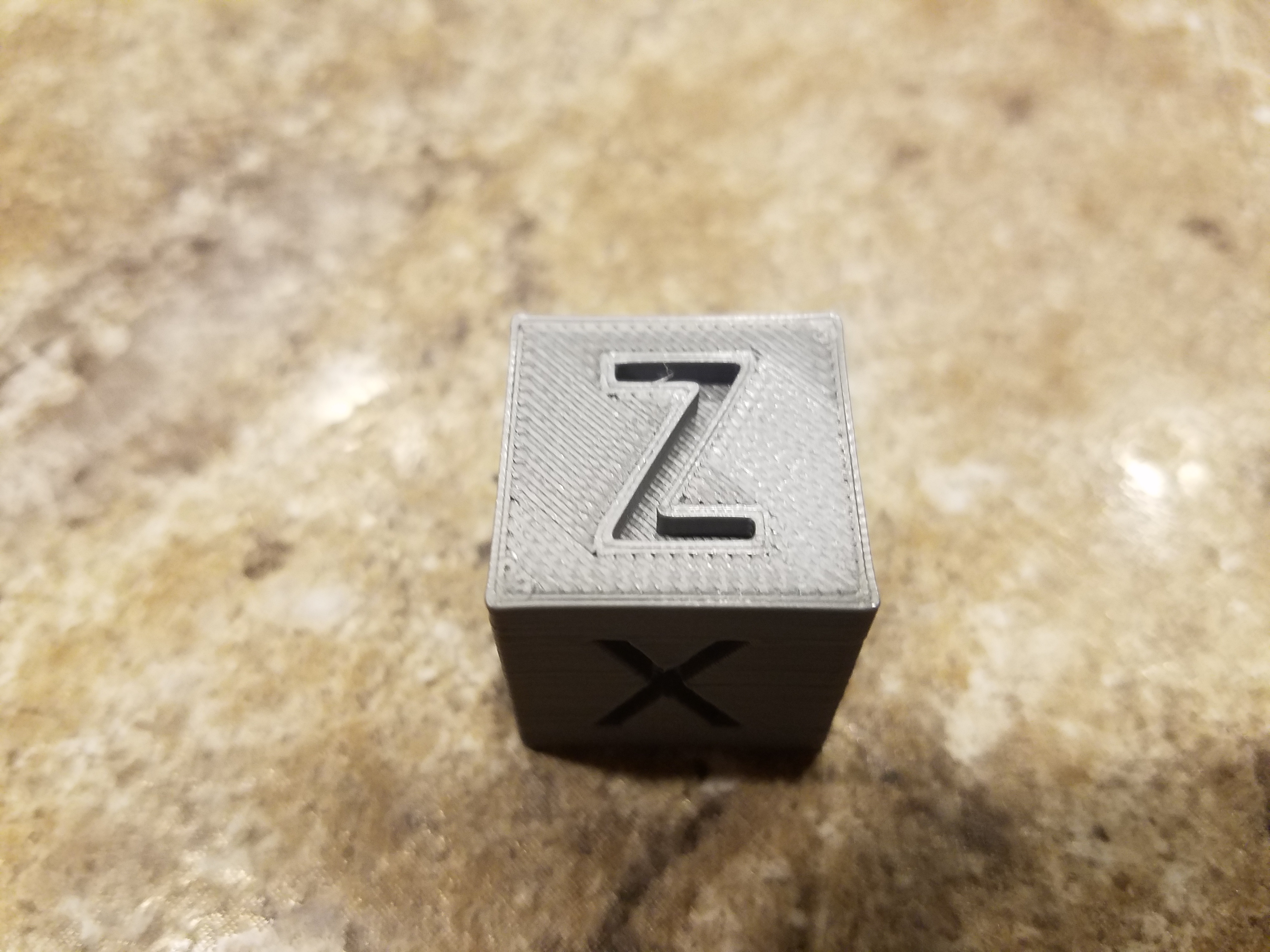

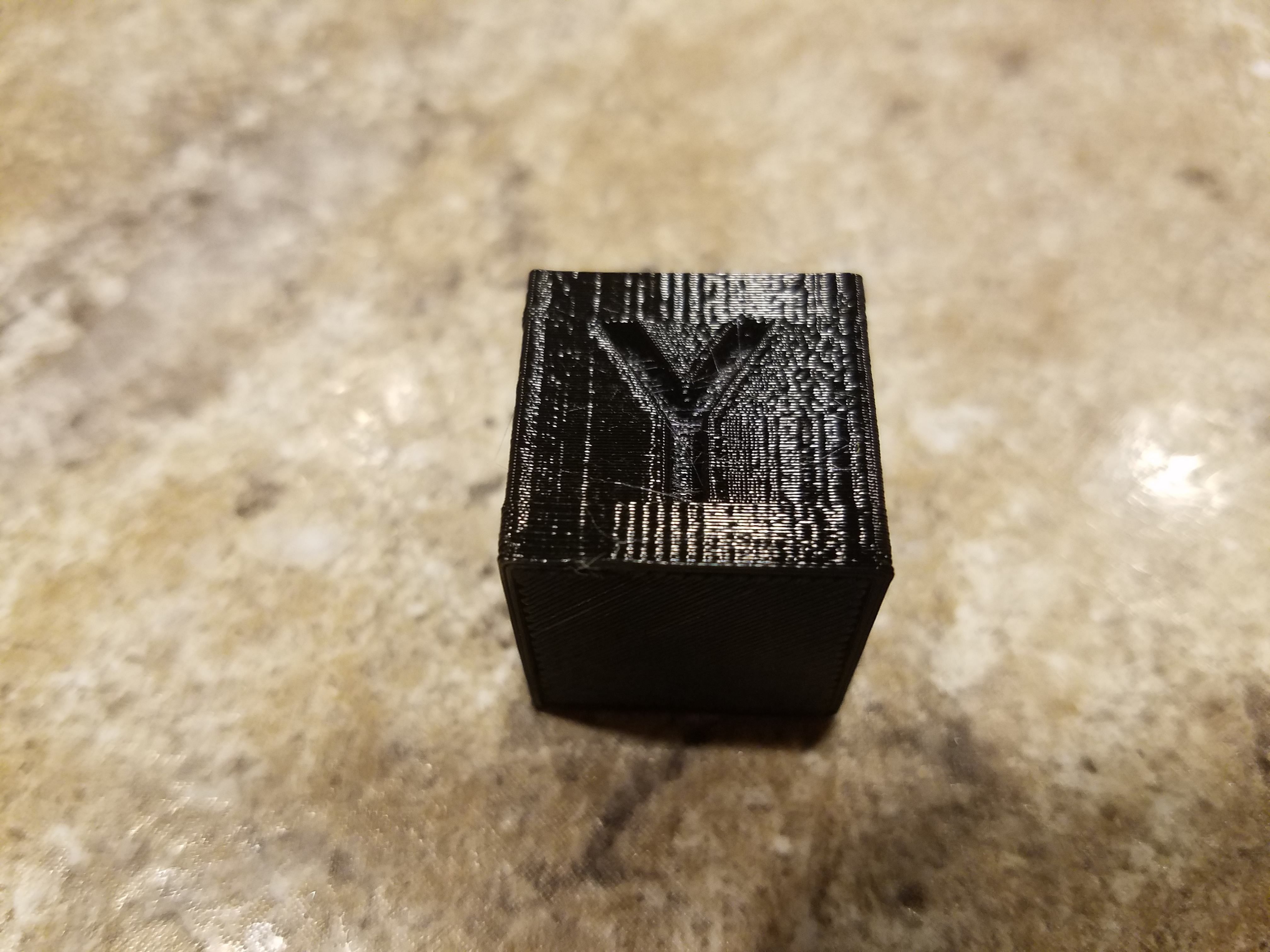

Please ignore the sloppy first layer, forgot to alcohol the bed. Working up a PETG version now.

Also keep in mind I am running illegally modded firmware (Linear Advance on, collision detection off)

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: Many new printed parts on GitHub

About the usual for PETG as well. Going to start doing vibration tests per the Z Axis Brace thread to see if I come up with anything there.

I can say my X Axis belt is now riding on the idler perfectly centered.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: Many new printed parts on GitHub

Got half way through changing the new parts in, and the linear rods were very tight to get into my prints of the x-axis, ended up cracking/layer separating the stepper side and can't even fully seat the rod in the idler side, so back to the stock parts to reprint I guess.

Did everything in maker geeks petg on the Simplify3d fast setting (.3 layer height) so think this time I'll try medium (.2) and maybe add extra shells and see if the fit is better.

One thing I did notice is my printed parts were much "crunchier" when tightening down than the stock parts, more crackles and pops at moderate tightness.

Re: Many new printed parts on GitHub

Would printing these in PLA be good enough for things like the X-idler and so on? I need to do something about this because the not perpendicular angle of the idler cause the MK3 to eat the X belt... there's a pretty serious amount of damage already.

Unfortunately I don't have any PETG in house.

XL (5T) / CORE One / MK3S+-MMU3 / MK3S / Mini / SL1S

Re: Many new printed parts on GitHub

No do not use PLA. I learned on Toms video about PLA that it deforms under pressure!

Re: Many new printed parts on GitHub

Got half way through changing the new parts in, and the linear rods were very tight to get into my prints of the x-axis, ended up cracking/layer separating the stepper side and can't even fully seat the rod in the idler side, so back to the stock parts to reprint I guess.

Did everything in maker geeks petg on the Simplify3d fast setting (.3 layer height) so think this time I'll try medium (.2) and maybe add extra shells and see if the fit is better.

One thing I did notice is my printed parts were much "crunchier" when tightening down than the stock parts, more crackles and pops at moderate tightness.

Did you use a drill on the holes for the rods? At Prusa Research they drill out the holes for a perfect fit.

Maybe increase temperature a little too?

Re: Many new printed parts on GitHub

Makes sense, didn't even consider that. I'll order a spool of PETG. Thanks!

XL (5T) / CORE One / MK3S+-MMU3 / MK3S / Mini / SL1S

Re: Many new printed parts on GitHub

Got half way through changing the new parts in, and the linear rods were very tight to get into my prints of the x-axis, ended up cracking/layer separating the stepper side and can't even fully seat the rod in the idler side...

Did you use a drill on the holes for the rods? At Prusa Research they drill out the holes for a perfect fit.

Maybe increase temperature a little too?

Great advice, I had no idea they drilled/reamed them like that to clean them up. Overnight I re-printed with a different roll of the same petg and used Slic3r PE's Optimal/Prusa PETG settings and increased the shells and infill.

Re: Many new printed parts on GitHub

Great! Let us know how the new prints went!

Re: Many new printed parts on GitHub

Got half way through changing the new parts in, and the linear rods were very tight to get into my prints of the x-axis, ended up cracking/layer separating the stepper side and can't even fully seat the rod in the idler side...

Did you use a drill on the holes for the rods? At Prusa Research they drill out the holes for a perfect fit.

Maybe increase temperature a little too?

Great advice, I had no idea they drilled/reamed them like that to clean them up. Overnight I re-printed with a different roll of the same petg and used Slic3r PE's Optimal/Prusa PETG settings and increased the shells and infill.

Interesting. Me neither. I’d use a 5/16 (7.94 mm) bit first for tight fit. 8mm could end up too loose.

Re: Many new printed parts on GitHub

There's a photo of a guy drilling them out. I'm not surprised.

I'd personally attempt to teardrop those holes. You'd think that would save time and make things more consistent than a hand-reaming job.

Re: Many new printed parts on GitHub

Anyone re-printing the extruder parts? I'm not really having any issues there and while better tolerances are great, I didn't see anything startling in the github PRs about the E axis. Already did the Y axis from git but didn't notice much difference there, thinking of just finishing the X axis now and maybe doing beefed up Z holders and calling it good.

Re: Many new printed parts on GitHub

Anyone re-printing the extruder parts? I'm not really having any issues there and while better tolerances are great, I didn't see anything startling in the github PRs about the E axis. Already did the Y axis from git but didn't notice much difference there, thinking of just finishing the X axis now and maybe doing beefed up Z holders and calling it good.

I have reprinted and installed them. Wasn't it something about a filament path not being straight that was fixed? I know after I put the stepper back on to the new part, I had to adjust the pulley back about 1mm to be centered with the filament path again. I don't know if this was needed because of the new part, or if my professional assembly also screwed that up.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: Many new printed parts on GitHub

I have reprinted and installed them. Wasn't it something about a filament path not being straight that was fixed?

No, that's not fixed. The path of the filament is still 0.5 mm off side.

Bear MK3 with Bondtech extruder

Re: Many new printed parts on GitHub

There's a photo of a guy drilling them out. I'm not surprised.

I'd personally attempt to teardrop those holes. You'd think that would save time and make things more consistent than a hand-reaming job.

They are teardrop. I went to ream mine just to see but they are already round and true as printed so it had no effect. I will install soon and find out.

I wonder how old that photo is. Maybe they were suffering the early over-extrusion.

Re: Many new printed parts on GitHub

I have reprinted and installed them. Wasn't it something about a filament path not being straight that was fixed?

No, that's not fixed. The path of the filament is still 0.5 mm off side.

So that makes it easier to leave the extruder reprint for another time.

My upgrade is going to look like this then:

X-end in red makergeeks petg using Slic3r PE optimal (.15) with 30% infill and 5 tops/bottoms/perimeters - these came out great at the default temps of 230/85 first and 240/90 rest.

X-carriage in blue mg petg using S3D high (.1) with 30% infill and 5 tops/bottoms/perimeters and fan turned down from 50% to 30% after 1st layer. I couldn't get the Slic3er toolpaths to stick the hole perimeters on the first layer even though the X-ends had just printed perfectly, filament curled back onto the nozzle immediately. Spent a long while adjusting Z, doing calibration squares, cleaning the plate, changing temps and speeds, changing out the red to blue filament fresh from the bag, and finally gave up. Did a full re-calibrate and adjusted the pinda probe lower, and Ive got a not-flawless but reliably sticking 1st layer again with the S3D toolpath but Slic3r still unsticks the screw hole perimeters each time. I must of done a crappy job putting it back together after the 1st round of prints cracked or something... I'm not really happy with this print yet so will probably retry it after some more tests with settings/more parts are done.

Reinforced Z-mounts from gregsaun https://www.thingiverse.com/thing:2775169 and the updated Z-tops from github. These are printing now on S3D medium (.2) with 30% infill and 5 top/bottoms/perimeters and the 30% fan setting.

X-backplate with cutout from jitx https://www.thingiverse.com/thing:2727523 is next, based on which S3D setting looks better once the Z's print.

RHDreambox's 16T Y axis if my 16T idlers come today, I've got my previous reprints in there now and they fit but are super brittle. They looked great...