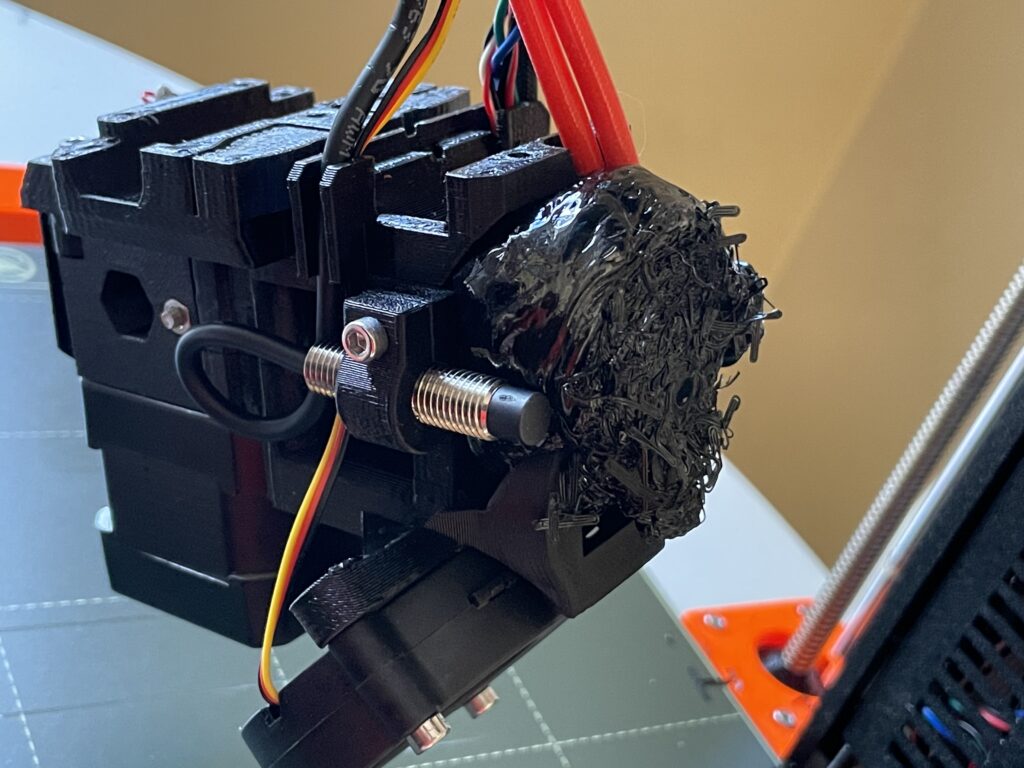

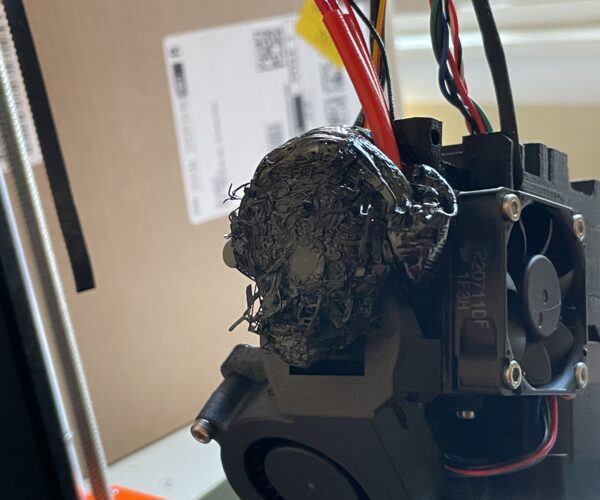

how did this happen?

Best Answer by jsw:

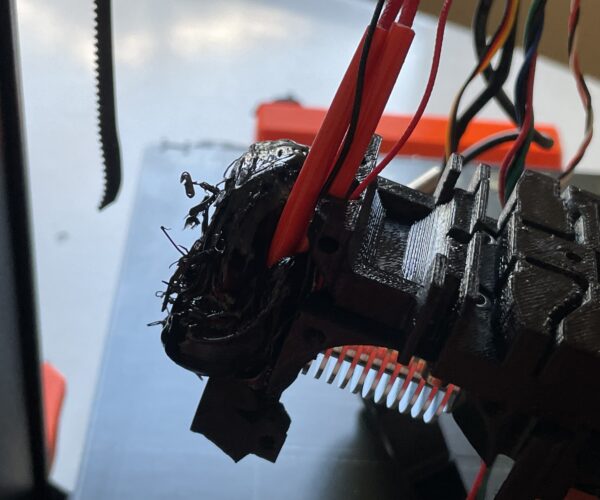

These often times look far worse than they are.

In your case, the Pinda mount looks unaffected. You may even still have a good fan shroud.

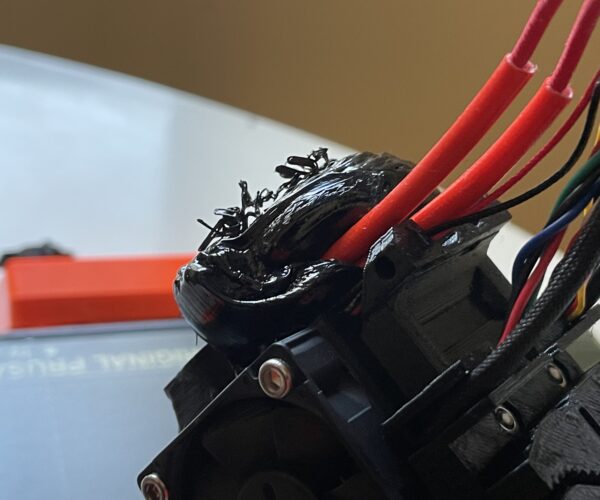

The blob is, however, partly surrounding the heatblock wiring.

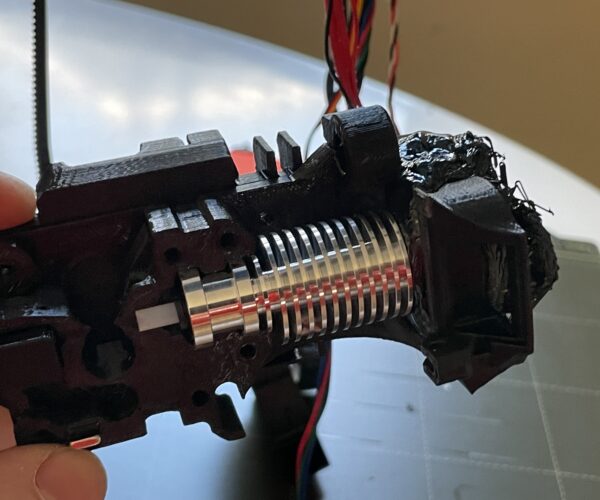

If I were you, the first thing I would do is heat up the hot end to a high operating temperature above the printing temperature of the filament that caused the issue.

Then let the machine sit, and sit, and sit, and get the blob very warm.

Sometimes they will simply fall off.

The only thing about yours is to carefully watch the heatblock wiring and don't pull on the blob in a way that might pull the wires as well. As stated, you can carefully use a soldering iron or a hot knife to work around these parts. Diagonal cutting pliers may help as well, but be careful not to cut any wiring.

If you want to see many examples of such blobs, visit this URL: https://www.flickr.com/groups/14741465@N23/

(And if you don't mind, I am going to add one of your photos to that group.)

RE: how did this happen?

Excellent example of the ‘blob of doom.’

Assumption is you left a print running which failed while you weren’t looking. Typically the part comes loose from the bed and sticks to the nozzle which continues to extrude molten plastic because that’s what the GCode tells it to do.

You should be able to remove that by using a soldering iron to remove chunks of material from the blob. When you’ve reduced the size of it, heat the nozzle to print temp for your filament and try gently prying off the rest. This will be time consuming so have patience.

Try to avoid contact with or putting strain on the wires attached to the heater block. They are fragile and easily broken.

Search the forums for ‘blob of doom’ for more details.

Good luck.

Cheers

RE: how did this happen?

These often times look far worse than they are.

In your case, the Pinda mount looks unaffected. You may even still have a good fan shroud.

The blob is, however, partly surrounding the heatblock wiring.

If I were you, the first thing I would do is heat up the hot end to a high operating temperature above the printing temperature of the filament that caused the issue.

Then let the machine sit, and sit, and sit, and get the blob very warm.

Sometimes they will simply fall off.

The only thing about yours is to carefully watch the heatblock wiring and don't pull on the blob in a way that might pull the wires as well. As stated, you can carefully use a soldering iron or a hot knife to work around these parts. Diagonal cutting pliers may help as well, but be careful not to cut any wiring.

If you want to see many examples of such blobs, visit this URL: https://www.flickr.com/groups/14741465@N23/

(And if you don't mind, I am going to add one of your photos to that group.)

RE:

thank you for your help — it came off pretty easily!