Re: getting a 3d printer...

You are already on the Slippery slope Jorg... you still believe things like.... " the filament can be hidden away" I have two multidrawer cabinets with a total of 10 drawers. and I still have more rolls of filament than the drawers will hide...

I live in an average size apartment, I have to believe such things :).

But it means I have to plan it well to optimize the use of space (hence a few of those weird questions). I have some idea for a table/cabinet that would look nice in the living room, but if it is too complicated then it just goes to the other room (easier to hide stuff, less of an issue if it is not hidden).

I have been doing multicolour printing on both machines, the Mk2 MMUv1 can easily do four colours in one layer so I have been using it to make badges, and the Mk3 has been making layer separation colour items... where I have to change the colour periodically.

But it sounds like you use it professionally. For me it is purely non-professional (and unlikely to become professional, unless they suddenly let my play with the 3D printers at one of the institutes where I work). But given that their printers print titanium and other metals, I doubt there is much similarity. 🙂 It is really for specific purposes we have in mind, but of course the more fun it gets, the more purposes you find... or invent...

It may go the way of our boardgames: we started with a few boardgames and considered to have a nice collection, it grew, so then we said that all our boardgames have to fit in one shelf-space. They still fit (those hours of playing tetris were not wasted!), but for ease we tend to put a few of them already on a different shelf. I wonder when they will stop fitting..... 😀

I bet you're itching to get designing!

My last experiences were with 3D Studio Max 2.5 and AutoCad 13 (if I remember correctly) - it was a huge step up from manually typing objects to render them in Povray :). Afterwards I did a few basic things in Blender, just to keep up a bit with the interface but now it has been a while. A few years ago I programmed a module to import dxf files, but no own design was required for that (just processing files). Now I'm a bit stuck abroad till New Year in a less optimal situation with a low powered laptop, and I have to finish a few other projects first, but I should manage to start in a couple of weeks. The 3D design was a long time ago, and I'd have to move to new software, but the basic concepts of 3D design will be similar. 🙂

Re: getting a 3d printer...

it's a funny old world... I don't do this commercially...

I am currently printing items for fundraising for one of my voluntary groups...

and sliding in some proof of concept prints to answer queries like can it print 2mm discs... or my glider keeps falling over... how can I stop it! 🙂

Povray... there's a name from the past, from what I remember it used to sap the power from the CPU... and still take hours to render anything

and we used to compress discs because the cost of large discs was so high

My first ram was £22+ per kilobyte...

Aaaaahhhhh! Nostalgia, aint wot it used to be!

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: getting a 3d printer...

You are already on the Slippery slope Jorg... you still believe things like.... " the filament can be hidden away"

BINGO!

Jorg, in EVERY YT vid I've seen about 3D printing (not just the full-time PRO guys, but the hobbyists as well), the background is FULL of filament spools.

I don't think either of us (spouse & myself) have ever had a hobby that didn't eventually take over every available horizontal surface in the house... and then some. Our game closet also began as a shelf, then a closet. Now it's 2 closets, several boxes and two bookcases in a spare room, space on my computer (board games--not video), and more space in my office. And that doesn't include tabletop RPGs, miniatures, etc...

If you know any quilters (or woodworkers, crafters, etc.), they collect material they intend to use for projects for years, and have/save scraps & leftovers from past projects. Filament is much like that--immediate needs, deals you pick up on sale for future use, partial spools from past projects, samples... And that doesn't include all the filament you'll process into both useful and useless hunks of not-so-cheap plastic...

Show me a hobbyist, and I'll show you a hoarder. 😉 😀

Just keeping it real.

That's "MISTER Old Fart" to you!

Re: getting a 3d printer...

🙂

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: getting a 3d printer...

it's a funny old world... I don't do this commercially...

I am currently printing items for fundraising for one of my voluntary groups...

Nice! I like the things you mentioned (e.g. the name tag things). I never thought something like that could be an option, and now come to think of it, the 3D printing may be something that can help in one of my jobs, when we organize conferences or so. 💡

and sliding in some proof of concept prints to answer queries like can it print 2mm discs... or my glider keeps falling over... how can I stop it! 🙂

What kind of people ask such questions... 😯

But I can see from your replies that you really are into the 3D printing for the challenge of the 3D printing, not just seeing 3D printing as tool to make something. Very cool! I will have to see if we will be similar, but for now the appeal is more making some things we want and the 3D printer seems the best option; we've looked at alternatives with a lower-price entry level, but it just does not go so well; especially as we are limited to stuff you can do on an apartment (noise wise, ...).

Povray... there's a name from the past, from what I remember it used to sap the power from the CPU... and still take hours to render anything

and we used to compress discs because the cost of large discs was so high

My first ram was £22+ per kilobyte...

🙂 It is weird to look back: my first computer had 112KB of ram and used exotic 92KB 3" disks, my first internet connection was 9600 bps dial-up. And now you carry a usb disk of 2 TB, have a 100 Mbit internet connection (which is the cheapest offer!) and even a high speed mobile connection... Still, I like having experienced those old days. 🙂

Fun fact: a few years ago we reached the point where the average website is bigger than the game Doom.

Jorg, in EVERY YT vid I've seen about 3D printing (not just the full-time PRO guys, but the hobbyists as well), the background is FULL of filament spools.

Hey, I still want to buy a printer! Don't scare me! 🙂

(But thanks for the reality check)

We are still a bit worried that the printer will not get used that much, but somehow we want to try it. We are both computer scientists, boardgamers and tinkerers, so... why not? Either we like it (and then we go from there), or we don't... no big issues... but there is only one way to know which of the two it is, and that is to try it. We see enough things we would like to make with it (but are not considering it as a "now we can 3D print every single item we ever need" solution).

Our game closet also began as a shelf, then a closet. Now it's 2 closets, several boxes and two bookcases in a spare room, space on my computer (board games--not video), and more space in my office.

We keep saying we have a nice collection of different style games, and no new games are really necessary... and then something new gets added anyway. 🙂

Filament is much like that--immediate needs, deals you pick up on sale for future use, partial spools from past projects, samples... And that doesn't include all the filament you'll process into both useful and useless hunks of not-so-cheap plastic...

Show me a hobbyist, and I'll show you a hoarder. 😉 😀

Maybe yes.... but you are not changing my mind!

🙂

Re: getting a 3d printer...

My intention has NEVER been to change anyone's mind or scare anyone off. I'm really sorry if you got that impression. I do believe in sharing experiences and opinions--both good and not-so-good--as I've said, to keep things real(istic). I've made enough mistakes to know firsthand how disillusion/disappointment feels! 😳

A lot of time and research went into our decision to get & build this MK3 kit. Several articles & videos convinced us a kit was the way to go for us, to get a better understanding of the technology and the machine (as we also knew a lot of tinkering would be involved). It's also a good experience/foundation if we ever decide to scratch-build a 3D printer in the future (should things go that way... 🙄 ).

I've been tinkering with board game designs for.... 40mumble years, too much of which was spent trying to find "parts" to hobble together to make playable prototypes. Hours/days spent scouring the internet, haunting game & toy stores, teachers' supplies,, tile stores, etc., etc., etc. for parts that would "do", but never quite exactly what I envisioned. Computers (we started with a VIC-20) and--eventually--2D printers were a HUGE advance over typewriters and little square cardboard chits. THIS (3D) technology is... I can't find the words... You've seen my Proof of Concept prints; I'm just getting started. 😀 😀 😀

Joan has opened my eyes to ways other than the MMU to utilize dual colors (Thank you, Joan!)--now I just have to find some tutorials...

Jorg--check your private messages... 😉

That's "MISTER Old Fart" to you!

Re: getting a 3d printer...

My intention has NEVER been to change anyone's mind or scare anyone off. I'm really sorry if you got that impression. I do believe in sharing experiences and opinions--both good and not-so-good--as I've said, to keep things real(istic).

Don't worry, it was really a light-hearted comment! 🙂 I appreciate all the comments: the good help to teach me what is possilbe, the not-so-good help to curb my enthousiasm and keep my feet on the ground.

Personally, I think that other people's not-so-good comments are sometimes more valuable: the person raises an issue that you may not have considered, and then you can decide for yourself if it is an issue for you as well or not. The good comments tend to be in line with what you already think or hope and therefor sometimes risk putting you in an information bubble. So: very good that you point all those things!

I'm actually less scared and more excited about it then before. I still feel I won't be using the printer that extensively, but at the same that does not seem to prevent me from trying and learning.

A lot of time and research went into our decision to get & build this MK3 kit. Several articles & videos convinced us a kit was the way to go for us, to get a better understanding of the technology and the machine (as we also knew a lot of tinkering would be involved). It's also a good experience/foundation if we ever decide to scratch-build a 3D printer in the future (should things go that way... 🙄 ).

"Should things go that way" or "When things go that way"? 😀

I have been playing with the 3D printer idea for 2 years now, but now feel it may be the time for me. I think putting a kit together would be great fun, but a different type of fun than 3D printing. Now I just want the print-fun.

I've been tinkering with board game designs for.... 40mumble years, too much of which was spent trying to find "parts" to hobble together to make playable prototypes. Hours/days spent scouring the internet, haunting game & toy stores, teachers' supplies,, tile stores, etc., etc., etc. for parts that would "do", but never quite exactly what I envisioned. Computers (we started with a VIC-20) and--eventually--2D printers were a HUGE advance over typewriters and little square cardboard chits. THIS (3D) technology is... I can't find the words... You've seen my Proof of Concept prints; I'm just getting started. 😀 😀 😀

Well, it is quite a difference from making something manually and making it on computer. Those design programs are powerful but take some getting used to.

When I see boardgames I think it is a shame that many games still provide quite low quality cardboard tokens (that you usually carefully have to push out of the stamped sheet and hope that none of the pieces tears slightly). Regarding artwork and tokens, Black Fleet is I think one of the nicest: the drawings on the cards, the real metal coins. The cargo are simple cubes, but I can understand that that was the only way to make them fit easily in the ships (which are also nicely detailed).

Joan has opened my eyes to ways other than the MMU to utilize dual colors (Thank you, Joan!)--now I just have to find some tutorials...

Yes, mine too... The name tag things are interesting and made me think of whole other set of things that could be interesting (both privately and for work) .

Basically, the MMU is just an automation of that process, so if there are not too many changes, it could suffice to do it that way as a start.

Jorg--check your private messages... 😉

Edit: received on 29/07, around 20.50. 🙂

Re: getting a 3d printer...

Small additional questions.... regarding printer placement... and particularly vertical space. I will refer to the lack-table enclosure on the blog as example.

1. I found a video-tutorial where filament is places in the head. And it made me wonder: do you need much headroom to put the filament (I assume that it may be at max. Z position, but how much above the head to you need at least to comfortably put the filament (or solve issues)? (the lack-table enclosure makes it relatively easy to remove the top table, providing near full access. I suppose something like that is desirable?

2. I watched the MMU2 in action on this video, and noticed that the filament comes from below: . From the comments on the lack-table on the blog, I know that the MMU2 does not have to be positioned exactly on that spot (they write that you could put it on the upper lack table). But: can it only come from below (if the roll is in close proximity)?

3. Again MMU2: there also seem to be three buttons ( ), and most likely there will be moments when you need to open up the MMU. So if it is mounted on the printer, I assume more vertical space is needed to access it. If it is mounted elsewhere (e.g. on the upper lack table, to stick with that example), easy vertical access there seems necessary for both access to the buttons as well as to the device. Does that make sense?

I'm beginning to have some ideas for a cabinet/table construction (I will have to make something, so might as well get it flexible enough).

Thanks!

Re: getting a 3d printer...

The Prusa printers ship with a spool holder that clips to the frame. Although this works, it's not ideal as it adds weight to the top of the structure and can vibrate, adding to possible print quality issues... or at least not helping with them. Many people building lack enclosures are stacking 2, with the filament spool on top of the upper table to relieve this stress. Another alternative is to relocate the spool behind or beside the printer, and creating a low-friction path for the filament feed. This can do a lot to reduce the height profile of the printer.

[...] but how much above the head to you need at least to comfortably put the filament (or solve issues)? (the lack-table enclosure makes it relatively easy to remove the top table, providing near full access. I suppose something like that is desirable?

No idea on MMU2. I'm still waiting for mine. There's no room on top of the printer frame for the MMU and multiple spools of filament, so I assume they just set them on rollers behind the printer. You can clearly see the spool on a roller base at the 2:00 & 3:20 marks in that video.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: getting a 3d printer...

The Prusa printers ship with a spool holder that clips to the frame. Although this works, it's not ideal as it adds weight to the top of the structure and can vibrate, adding to possible print quality issues... or at least not helping with them. Many people building lack enclosures are stacking 2, with the filament spool on top of the upper table to relieve this stress. Another alternative is to relocate the spool behind or beside the printer, and creating a low-friction path for the filament feed. This can do a lot to reduce the height profile of the printer.

Thanks! Yes, I've read this... But how easy is it to put filament?

I noticed on this video: that for example a covering shelf a few cm above the top of the frame may make it unnecessary difficult. Judging by the image where I paused on the video, I would guess 10cm above the frame at least, but if the shelf covers the entire printer, then a bit more should be added.... yes?

But it also seems the head is not near the max Z position, so some headroom for the filament would be necessary, as well as for inserting filament (e.g. for a colour change near the top layers)... So that even adds more necessary space above the printer... 🙂

No idea on MMU2. I'm still waiting for mine. There's no room on top of the printer frame for the MMU and multiple spools of filament, so I assume they just set them on rollers behind the printer. You can clearly see the spool on a roller base at the 2:00 & 3:20 marks in that video.

Yes, so quite a different position from the situation without MMU. Hence my question... 🙂 It is a shame there are not that many images of the MMU yet.

Re: getting a 3d printer...

I was originally excited about building an enclosure, but having read about the issues people are having with temps, coupled with the fact that I have no interest in printing stinky materials in my home, I've decided not to bother.

[...] But it also seems the head is not near the max Z position, so some headroom for the filament would be necessary, as well as for inserting filament (e.g. for a colour change near the top layers)... So that even adds more necessary space above the printer... 🙂

As you note, you don't have to put the head at max Z to change filament, but if you do wind up doing color changes at the top of a tall print, that could be a consideration. I also like to have some lighting from above, so don't want to crowd the top of the printer. There's nothing particularly great about the Lack table, other than price. You could do a simple frame instead. Build something more robust with ample top clearance.

[...] Yes, so quite a different position from the situation without MMU. Hence my question... 🙂

I've got mine configured very much like JP shows in the MMU video. I have my filament positioned behind the printer. I tried a number of stands:

I finally have settled on this stand:

It's working very well for my basic Mk3 setup combined with this roller guide to feed the filament up over the printer frame. I'm planning on printing off more stands and just leaving them positioned behind the printer on the happy day that my MMU arrives.

Of course, I'll probably change my mind on all this in a week.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: getting a 3d printer...

I was originally excited about building an enclosure, but having read about the issues people are having with temps, coupled with the fact that I have no interest in printing stinky materials in my home, I've decided not to bother.

I'm still mulling... I'd like to play around with printing nylon at some point; undecided about PC.

I'm working on a couple of different designs, but if I need something temporary in the meantime, I think a corrugated box is going to have to do. It won't be strong enough to support spools or the MMU, but it should be enough to keep things toasty and drafts out.

I liked the one-piece aspect of the Filament DUCK and similar stands, but they don't fit all spools.

What about putting a telescoping base (for variable width) on that?

I finally have settled on this stand

I think I'd be worried about full spools being top-heavy, and near empty spools just falling/being pulled off. (But we have a four-legged tornado with non-stop tail action that tends to contribute to things like that... 🙂 )

Of course, I'll probably change my mind on all this in a week.

😀 😆

That's "MISTER Old Fart" to you!

Re: getting a 3d printer...

I was originally excited about building an enclosure, but having read about the issues people are having with temps, coupled with the fact that I have no interest in printing stinky materials in my home, I've decided not to bother.

As you note, you don't have to put the head at max Z to change filament, but if you do wind up doing color changes at the top of a tall print, that could be a consideration. I also like to have some lighting from above, so don't want to crowd the top of the printer. There's nothing particularly great about the Lack table, other than price. You could do a simple frame instead. Build something more robust with ample top clearance.

Yes, I'm just using the Lack as an example, I cannot imagine it being very stable, but it is an easy concept as a frame of reference for the discussion. I'm more thinking along the lines of some frame construction but then there still is the clearance on the top-issue. I don't know what I will print, but am quite sure I won't I need any stinky materials. It now makes me think that the easiest would be if the printer is on the top, unless the construction above it opens somehow or is easily removed.

I've got mine configured very much like JP shows in the MMU video. I have my filament positioned behind the printer. [...]

I finally have settled on this stand:

I noticed the TUSH, but wondered by there were not linked together for stability... or at least have wider feet to prevent them from falling over. The one you settled on looks great! I like the detail that there is an edge on the cylinders that prevents the spool form shifting.

If you have the spools behind the printer, the whole setup gets quite deep. I like that positioning, but I'll have to see if I can fit it ... Depth is an issue for me, it would be easier to go in height or even width.

One option could be that the shelf above the printer is more of a bracket that covers only the back half (or from the back just to the Z-frame): there would be space for spools on top while still providing access to the printer.

It's working very well for my basic Mk3 setup combined with this roller guide to feed the filament up over the printer frame. I'm planning on printing off more stands and just leaving them positioned behind the printer on the happy day that my MMU arrives.

Of course, I'll probably change my mind on all this in a week.

Yes, I know what you mean... 🙂

I finally have settled on this stand

I think I'd be worried about full spools being top-heavy, and near empty spools just falling/being pulled off. (But we have a four-legged tornado with non-stop tail action that tends to contribute to things like that... 🙂 )

The TUSH has the same issue (even worse I think). You could always put some extra weight on the one bobstro indicated (or attach it to a board or so). But I don't have four-legged tornado's running around...

Re: getting a 3d printer...

Ah well, my choices are easy on that count: No stinky stuff in the house. I'll move the printer into the garage, or inside a box outside if I get the urge to try the exotics. Meanwhile, I'm having a good time discovering non-stinky materials that have some of the same characteristics, particularly Colorfabb NGET, XT and HT.

[...] I'm still mulling... I'd like to play around with printing nylon at some point; undecided about PC.

[...] I'm working on a couple of different designs, but if I need something temporary in the meantime, I think a corrugated box is going to have to do. It won't be strong enough to support spools or the MMU, but it should be enough to keep things toasty and drafts out.

Drafts and temp seem to be the main concern. I've seen some reasonable-looking collapsible nylon "tents" that might work in a pinch.

[...] What about putting a telescoping base (for variable width) on that?

That would probably work, but I don't think it'd be any less complex than what I've gone with. There is something to be said for holding the spool from both sides. You could probably work out a hinge on the side arms to allow it to adapt to varying widths as well, though that seems a bit over-engineered.

[...] I think I'd be worried about full spools being top-heavy, and near empty spools just falling/being pulled off. (But we have a four-legged tornado with non-stop tail action that tends to contribute to things like that... 🙂 )

Heavy spools (up to 1Kg from several manufacturers) haven't been an issue. The 200g GizmoDorks spools worked fine, although near-empty light spools can fall off. One of the TUSH designs include a pair of little brackets that could slide on to hold things down, which I think is sufficient. Ease of reloading is my main concern.

One of my concerns in setting up is a 60 lb bulldozer with no tail to speak of, but a tendency to go after his ball regardless of where it lands. I like having the spools lower to the floor and off the printer when he dives in. I made the mistake of setting his ball up on my TV stand, and he nearly took down the entire thing when he noticed it.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: getting a 3d printer...

I first became aware of the Lack tables when I saw a post noting that it was perfect for 19 inch rack-mounted equipment. It's a great idea, but I think there's a bit of a "lack craze" going on now, and a lot of people seem to be building enclosures that don't really need it, then running into problems. If I ever build one, I'm going to make sure it's easy to remove the sides and top for ventilation.

[...] Yes, I'm just using the Lack as an example, I cannot imagine it being very stable, but it is an easy concept as a frame of reference for the discussion.

I'm more thinking along the lines of some frame construction but then there still is the clearance on the top-issue. I don't know what I will print, but am quite sure I won't I need any stinky materials. It now makes me think that the easiest would be if the printer is on the top, unless the construction above it opens somehow or is easily removed.

I'm mostly worried about a stable platform. I've got a solid side table that is the perfect size, and I've got the bottom shelf loaded with heavy magazines, so it's very stable. You don't want the printer too high so you can easily access it and inspect things.

I noticed the TUSH, but wondered by there were not linked together for stability... or at least have wider feet to prevent them from falling over. The one you settled on looks great! I like the detail that there is an edge on the cylinders that prevents the spool form shifting.

The TUSH were are bit of a disappointment. Great idea, but really fussy to set up each filament change. There are variations of brackets, but you're stuck with having to adjust for different spool width. I like the "one size fits all" and "one-handed" aspects of the one I'm currently using.

If you have the spools behind the printer, the whole setup gets quite deep. I like that positioning, but I'll have to see if I can fit it ... Depth is an issue for me, it would be easier to go in height or even width.

It's deeper certainly, but not particularly huge. My entire print station is a 28inx24in/71cmx61cm side table. That leaves room for the printer to be set back a bit from the front (to avoid dog-dozer), and the Y axis to be backed up completely with room for spools behind without being cramped.

One option could be that the shelf above the printer is more of a bracket that covers only the back half (or from the back just to the Z-frame): there would be space for spools on top while still providing access to the printer.

If I were building a rack, I'd consider something like the Prusa spool holder suspended inverted from the top. You could put it on a rail to slide it around and accommodate multiple spools.

The TUSH has the same issue (even worse I think). You could always put some extra weight on the one bobstro indicated (or attach it to a board or so). But I don't have four-legged tornado's running around...

The stand I'm using doesn't move about too badly, but the other designs definitely get pulled around when the extruder pulls the filament. I put rubber feet on those, and will do so with the new version if it's an issue, but so far, it's worked quite well. The bigger issue is light (e.g. cardboard) near-empty spools, but those aren't a major problem. They stay put until the last few rolls of filament, so a simple block in front would probably fix the problem.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: getting a 3d printer...

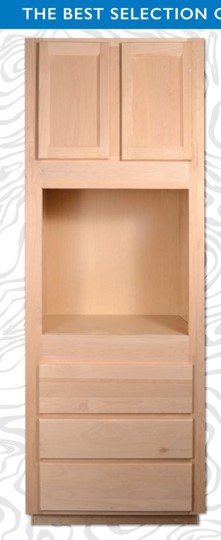

Another possibility for an enclosure/cabinet... If you have any home improvement bargain outlets where they sell distressed (seconds, returns, overstocks, discontinued, etc.) kitchen cabinets CHEAP. 😉

Something like this (if the dimensions are workable) could be the cat's pajamas...

That's "MISTER Old Fart" to you!

Re: getting a 3d printer...

Do be sure to measure the inside dimensions. I'd allow at least 24"/61cm depth to allow full bed travel. My 19" stereo rack looked perfect, but the cables mashed up against the back when the Y axis was fully retracted.

Another possibility for an enclosure/cabinet... If you have any home improvement bargain outlets where they sell distressed (seconds, returns, overstocks, discontinued, etc.) kitchen cabinets CHEAP. 😉

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: getting a 3d printer...

Do be sure to measure the inside dimensions. I'd allow at least 24"/61cm depth to allow full bed travel. My 19" stereo rack looked perfect, but the cables mashed up against the back when the Y axis was fully retracted.

No Problemo. These things are standard 24" deep (minus ~1/8" back material) A very few mfrs. make some 30" deep. I've measured our MK3 several times. I get 22" including clearance for the heat bed cable, so on a standard US kitchen cabinet there's even room for doors on the front. 🙂

The trick comes in finding one suitable. 😉 Of course, something like that won't fit in my office closet either (though a base cabinet might). When I originally mentioned it, I was thinking of Jorg trying to build something. I thought this might be an alternative if available where he is.

That's "MISTER Old Fart" to you!

Re: getting a 3d printer...

I'll move the printer into the garage, or inside a box outside if I get the urge to try the exotics. Meanwhile, I'm having a good time discovering non-stinky materials that have some of the same characteristics, particularly Colorfabb NGET, XT and HT.

No such option for me... but I have plenty of time to do non-stinky stuff anyway. And interesting to learn that there are some alternatives now. I did not know, thanks!

I first became aware of the Lack tables when I saw a post noting that it was perfect for 19 inch rack-mounted equipment. It's a great idea, but I think there's a bit of a "lack craze" going on now, and a lot of people seem to be building enclosures that don't really need it, then running into problems. If I ever build one, I'm going to make sure it's easy to remove the sides and top for ventilation.

Hey, I also saw that use for 19 inch rack-mounted equipment. Well, just used a short piece of wood to mount my 19 inch ethernet switch and patchpanel together. Suffices for that. But I agree; I think the issue is that on photo, the Lack approach looks nice, and seems to make sense. Maybe it suffices for most, but I too am not conviced. Does not prevent me from taking some of the concepts and learning from it. 🙂

I'm mostly worried about a stable platform. I've got a solid side table that is the perfect size, and I've got the bottom shelf loaded with heavy magazines, so it's very stable. You don't want the printer too high so you can easily access it and inspect things.

I have this very heavy metal table leg (intended as a single central leg for a 150cm diameter round marble table), which is really stable (RufusClupea: I may end up being glad I hoarded that one ;-)). I'm thinking of using it as a base: add a piece of kitchen countertop and then take it from there. It might not be the most functional as it lacks more storage, but it would put the printer very stable at table height.

It's deeper certainly, but not particularly huge. My entire print station is a 28inx24in/71cmx61cm side table. That leaves room for the printer to be set back a bit from the front (to avoid dog-dozer), and the Y axis to be backed up completely with room for spools behind without being cramped.

Which one is the depth?

One issue is that in either location I'm considering, it would be in a corner. Having to reach over it to reach behind it may not be easy (depending on how high the printer sits).

If I were building a rack, I'd consider something like the Prusa spool holder suspended inverted from the top. You could put it on a rail to slide it around and accommodate multiple spools.

Oh! I could put a metal horizontal bar (or even two) at the back of the rack, similar to the bar on the top of the Prusa: all the things that you could clip on top of a Prusa, you could clip on to that one. Some things may need a slight redesign if you want to hang them upside down, but other than that it would be very compatible.

Question: does the MMU for the MK2 contain spool holders? The guide for installing it ( https://manual.prusa3d.com/c/Original_Prusa_i3_MK2_to_Multi_Material_upgrade ) has sections 5A and 5B which seem to mention that.

Something like this (if the dimensions are workable) could be the cat's pajamas...

Not sure where I could find such outlets around my place, but there are plenty of DIY places that have quite cheap stuff and even furniture to work with. And then also not sure it would fit me. Given the prevalence of DIY places, it would just be easier to get new materials and take it from there.

Re: getting a 3d printer...

Oh man... I finally came to terms with a Lack cabinet not being suitable for my needs, and now you drop the idea of a kitchen cabinet base. Drawers. That would be awesome!

[...] Of course, something like that won't fit in my office closet either (though a base cabinet might). When I originally mentioned it, I was thinking of Jorg trying to build something. I thought this might be an alternative if available where he is.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…