Firmware Needs to Know Nozzle Size?

Does the firmware need to know what size nozzle is installed? Have I missed this somewhere??

For things like Calibration => First Layer Cal. ... isn't this important?

I just changed the MK3 nozzle 0.40 => 0.50

Experienced folks will chuckle ... but changing nozzles for the first time is a moderately cheek-clenching experience for a newbie who got the printer assembled. The instructions and images are outdated, the tool-size suggestions were way off, and there's an all-around lack of details (compared with the extensively detail Kit Construction manual).

Some issues:

It would be *great* to have a mini-manual on this with commenting and live editing - along the lines of the Kit Construction manual.

-- Clint Goss

Re: Firmware Needs to Know Nozzle Size?

There are many guides, and this is a bit universal, you can watch youtube videos which is a good point for confirming steps, watch before do can save your life. eg:

You don't need to remove the cover, just the fan shroud.

Steps are:

1) Pre heat at the temperature they say

2) Unload filament

3) Securing the hotend with a proper tool to avoid move for break anything when unscrew and screw nozzles

4) While 3) unscrew the nozzle with a proper tool

5) Screw in the new nozzle while 3) and don't forget to give it the proper torque, less will not cause permanent damage but prints will fail but can be ajusted, but much more can damage the nozzle or the block. There are tools you can print to give the exact needed torque. Or follow the e3d indications, apply gentle force with one finger until wrench not move (People with strong hands need to be more gentle 😀 )

6) Follow the rest of steps (pre heat again, load, calibrate, test print)

3) is very important and should not be skip!

Manual are not updated for a mk3 but is very identical

e3d guide: https://e3d-online.dozuki.com/Guide/Changing+Nozzles/45

Re: Firmware Needs to Know Nozzle Size?

The firmware doesn't need to know very much; it's just does what the G-code tells it to.

Likewise, the slicer doesn't need to know the nozzle size, only the width of the extrusion you require. The slicer then generates G-code based on you line width, layer height and speed.

Example G-code:

G1 X0 Y0 F1000 (G1 = move; X, Y = co-ordindates; F = speed mm/min)

G! X100 Y100 E3 (move to 100, 100 while extruding 3mm of filament)

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Firmware Needs to Know Nozzle Size?

Hi Peter, Clint,

the slicing software does need to kn ow how much plastic to push into the hot zone of the extruder in order to give the correct Gcode values for the task in hand,

Peter useses Kisslicer which relates the calculation to the extrusion width

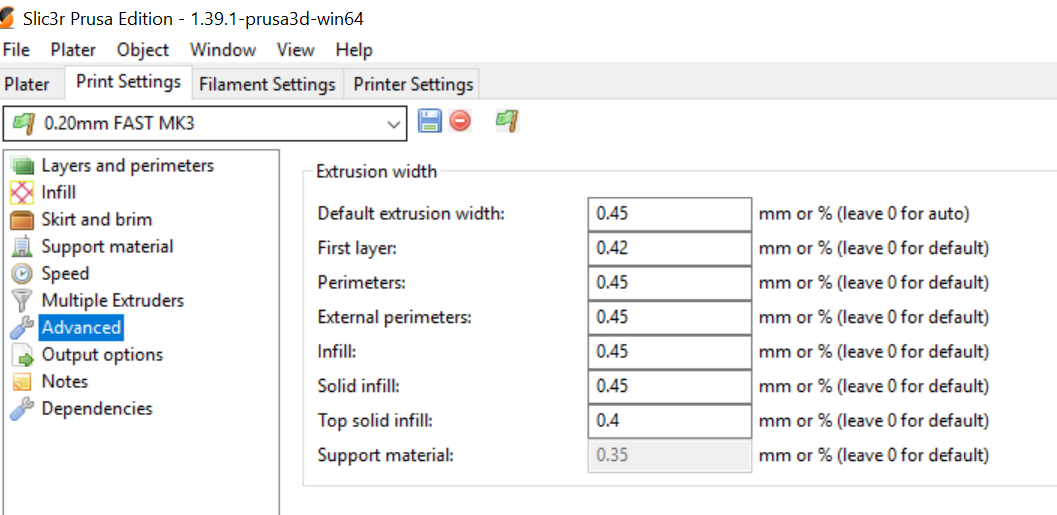

I expect Clint is using Slic3r, which has two areas

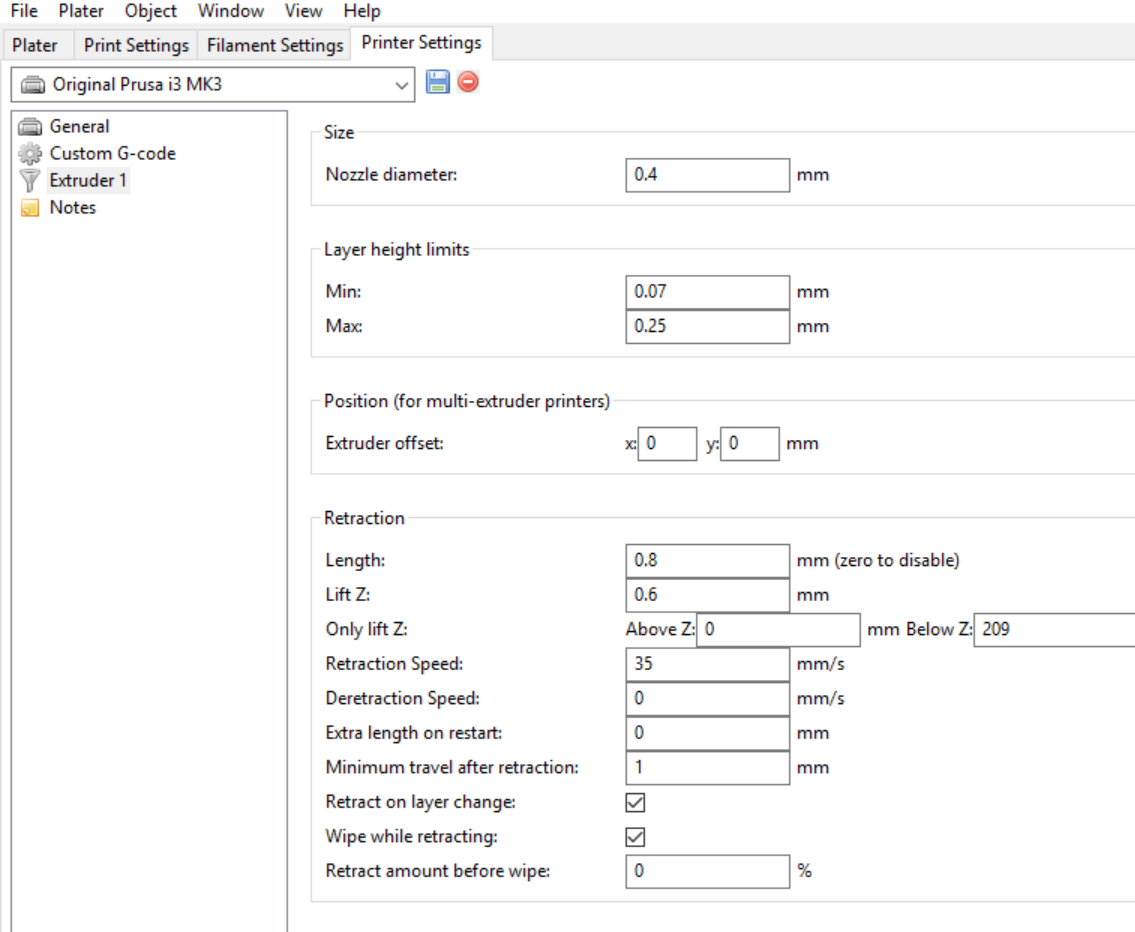

in the extruder there is a Nozzle size dialogue box,

and in the print settings tab there are extrusion width settings

similar ways of achieving the same result

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Firmware Needs to Know Nozzle Size?

Thanks All!

I'm using S3D, and have set the corresponding parameters - and things are working nicely at 0.50 (I'm printing Corkfill, hence the bigger fire hose ...)

However ... The Firmware is not doing a change similar to Joan's suggestion when you execute Calibrate => First Layer Cal. ... it has no way of knowing the nozzle size ... it's just using the same (internal?) G-Code ... how is this handled?

-- Clint Goss

Re: Firmware Needs to Know Nozzle Size?

Clint

The firmware will always print the calibration at the same width, irrespective of nozzle diameter.

Joan

Slic3r only needs nozzle size in case the parameters are set to "Auto" - which is not really a good thing to do. I believe that it also uses nozzle size for the purge tower, but in this case it's not relevant.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Firmware Needs to Know Nozzle Size?

Thanks All!

I'm using S3D, and have set the corresponding parameters - and things are working nicely at 0.50 (I'm printing Corkfill, hence the bigger fire hose ...)

However ... The Firmware is not doing a change similar to Joan's suggestion when you execute Calibrate => First Layer Cal. ... it has no way of knowing the nozzle size ... it's just using the same (internal?) G-Code ... how is this handled?

You will be unable to do the "built in" first layer calibartion. Simply start the print of a object, and pull up the menu and there's a "Live Z adjust" thing to click on. Click that, and you can do your live Z adjust on ANY print, running ANY gcode. 🙂

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.