Firmware 3.7.0-RC1 for Original Prusa i3 MK3S & MK3

UPDATE: Final version is out https://shop.prusa3d.com/forum/general-discussion-announcements-and-releases-f61/firmware-3-7-0-final-for-original-prusa-i3-mk3s-mk-t28802.html

WARNING: Note that MK3S, MK3, MK2.5S and MK2.5 are different printers! Each has its own firmware file!!!

Hi guys,

this is an upgrade of the firmware for the Original Prusa i3 printer. Keep in mind this a release candidate (testing version) for experienced users 😎

What is new?

–> 7x7 mesh bed levelling

–> MMU2S fast mode (MK3S + MMU2 only)

–> Improved T-code load (printers with MMU2)

–> Change filament fix (printers with MMU2)

–> Eject filament contains ramming (MMU2 printers)

–> The informative message during switching between normal and stealth modes

–> Improved behaviour when removing SD card

–> Autoload disabled in extruder info (MK3) and sensor info (MK3S) menu

7x7 mesh bed levelling

It is now possible to increase mesh bed levelling XY resolution by activating measuring 49 points in 7x7 mesh. This can be done in the menu "Settings -> Mesh bed levelling". There is also a possibility to change the number of measurements for each point from 1 (fast, but less accurate) to 5 (most accurate) and also turn on/off magnet compensation. PINDA probe Z-coordinate measurement can be influenced by heatbed magnet proximity (by approximately 80 um) and thus distort mesh bed levelling calibration. If magnet compensation is off, all 49 points are measured and used for mesh bed levelling correction. If magnet compensation is on, for chosen points (which may be affected by magnets) are counted from surrounding points. Also, the mesh bed levelling Z-measurement algorithm was slightly modified to make the whole process faster. No G-code modification is needed. Standard G80 G-code will behave according to settings which were set in "Settings -> Mesh bed levelling" menu. It is also possible to use G80 Nx Ry G-code, where x is a number of mesh bed levelling points in one axis (3 or 7 are valid values) and y is number of Z-measurements for each point (which are then averaged). Settings done directly in G-code has higher priority then settings which are set in the menu.

I would like to thank all who were working on this feature and helped to implement it to our Prusa FW, especially @stahlfabrik, @mionut and @3d-gussner.

MMU2S fast mode

On MK3S printers with MMU2 connected it is possible to switch MMU between fast and stealth mode. This can be done in the menu "Settings -> MMU mode". With MK2.5S MMU runs always in stealth mode.

Improved T-code load

Load sequence was slightly modified to reduce missing layer error count.

Change filament fix

When changing filament (M600 G-code, menu "Tune-> Change filament" or filament runout) on printers with MMU2 connected, there is a possibility to re-do filament unload and load by choosing "Filament not loaded". This, however, didn't work properly in some scenarios and filament could remain stuck between extruder Bondtech pulley and nozzle. This has been fixed.

Improved behaviour when removing the SD card

When SD card is inserted SD card menu is automatically shown. When SD card is removed menu which was active when the SD card was inserted is restored.

Autoload disabled in extruder info (MK3) and sensor info (MK3S) menu

These menus serve for checking if the filament sensor works properly. The filament can be now inserted (without triggering load function) to check if sensor state changes.

---

Supported printers:

Original Prusa i3 MK3S MMU2S

Original Prusa i3 MK3S

Original Prusa i3 MK3 MMU2

Original Prusa i3 MK3

Original Prusa i3 MK2.5S MMU2S

Original Prusa i3 MK2.5S

Original Prusa i3 MK2.5 MMU2

Original Prusa i3 MK2.5

Download link:

https://github.com/prusa3d/Prusa-Firmware/releases/tag/v3.7.0-RC1

Firmware flashing guide:

https://manual.prusa3d.com/Guide/Upgrading+the+firmware+v1.5/66

Please report any bug here:

https://github.com/prusa3d/Prusa-Firmware/issues

As always, we wish you happy printing and look forward to your feedback!

/ Knowledge Base

The guy behind Prusa assembly manuals...

Re: Firmware 3.7.0-RC1 for Original Prusa i3 MK3S & MK3

Figures. I just finished calibrating after applying my MK3S mod (and performing misc. PM) and there is a new firmware available... Ok. Tomorrow night. Upgrade firmware and re-calibrate. Looking forward to seeing how the 7x7 mesh leveling options work out.

See my (limited) designs on:

Printables - https://www.printables.com/@Sembazuru

Thingiverse - https://www.thingiverse.com/Sembazuru/designs

Re: Firmware 3.7.0-RC1 for Original Prusa i3 MK3S & MK3

shocker yet, I just installed 3.6. might just upgrade it again.. I do have the cables out. im almost always a lv behind.

I have a Prusa,therefore I research.

Re: Firmware 3.7.0-RC1 for Original Prusa i3 MK3S & MK3

Is 7x7 compatible with Prusa Mesh Leveling octopi plugin?

Re: Firmware 3.7.0-RC1 for Original Prusa i3 MK3S & MK3

Is 7x7 compatible with Prusa Mesh Leveling octopi plugin?

Good question. I don't know how the the octopi plugin works, but the 7x7 works either by explicitly calling it with G80 N7, or configuring the 7x7 in the printer's settings and just simply calling G80.

Even with the 5x sampling, it runs really quickly. Kudos to the Prusa development team (and any assistance from community members).

See my (limited) designs on:

Printables - https://www.printables.com/@Sembazuru

Thingiverse - https://www.thingiverse.com/Sembazuru/designs

Re: Firmware 3.7.0-RC1 for Original Prusa i3 MK3S & MK3

Is 7x7 compatible with Prusa Mesh Leveling octopi plugin?

Good question. I don't know how the the octopi plugin works, but the 7x7 works either by explicitly calling it with G80 N7, or configuring the 7x7 in the printer's settings and just simply calling G80.

Even with the 5x sampling, it runs really quickly. Kudos to the Prusa development team (and any assistance from community members).

I test it, it appear to work just fine, and map show variance according.

Re: Firmware 3.7.0-RC1 for Original Prusa i3 MK3S & MK3

Yes, the octopi plugin works the same way. But how is the setting on the heating bed done at 7x7 measuring points? There are only 9 fixing screws and no 49? What brings me 7x7 then. Replace the spring steel plate or the heating bed? Or just for personal information? 😉

2x Personal MK3IR-BMG09 (Full) BEAR + MMU3 mod., ...

Re: Firmware 3.7.0-RC1 for Original Prusa i3 MK3S & MK3

Hi is there anyway to slow down the mesh bed leveling procedure back to what it use to be? i get muchhh better results with the unofficial 7x7, I wonder if it’s the speed? I have no idea

Re: Firmware 3.7.0-RC1 for Original Prusa i3 MK3S & MK3

Hi,

what are the pro's and con's of turning on/off magnet compensation ??????

Texy

Re: Firmware 3.7.0-RC1 for Original Prusa i3 MK3S & MK3

Should compensate the magnetic influence from the heating bed to the PINDA probe, if activated, I think.

2x Personal MK3IR-BMG09 (Full) BEAR + MMU3 mod., ...

Re: Firmware 3.7.0-RC1 for Original Prusa i3 MK3S & MK3

Yes, the octopi plugin works the same way. But how is the setting on the heating bed done at 7x7 measuring points? There are only 9 fixing screws and no 49? What brings me 7x7 then. Replace the spring steel plate or the heating bed? Or just for personal information? 😉

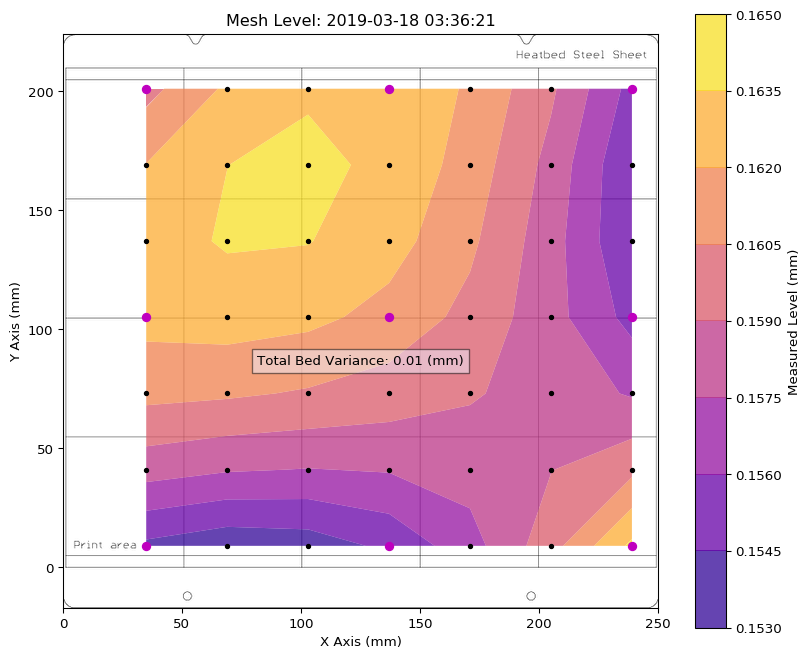

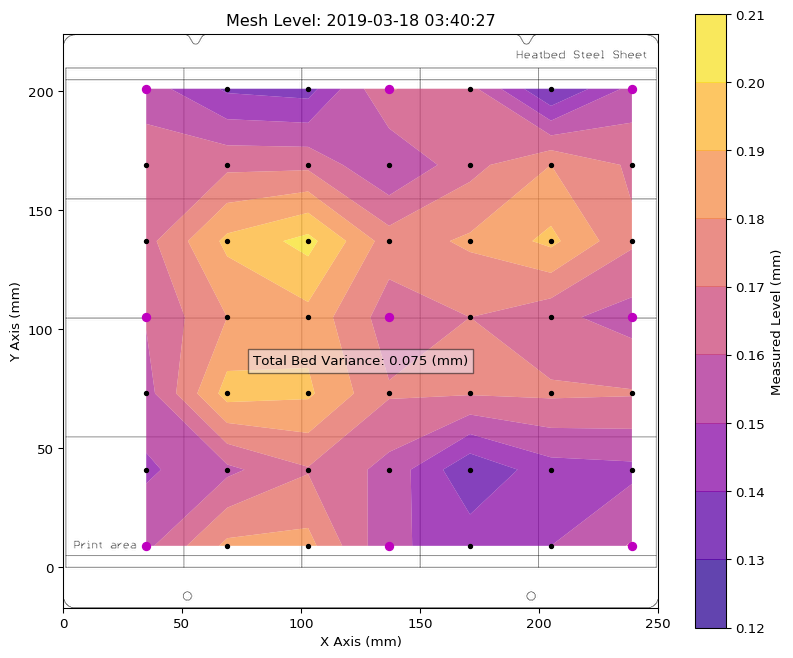

heatmap3x3_3_MC1.png

heatmap7x7_3_MC1.png

The Printer should correct the height of the extruder automatically according to the measured values,

the heatbed is not meant to be adjusted with the screws.

Re: Firmware 3.7.0-RC1 for Original Prusa i3 MK3S & MK3

A common misconception! Unfortunately, only an average of the deviation is calculated, a complete mechanical compensation does not take place automatically. Or could anyone ever observe that the z-axis is moving within a layer to be printed? 😉

2x Personal MK3IR-BMG09 (Full) BEAR + MMU3 mod., ...

Re: Firmware 3.7.0-RC1 for Original Prusa i3 MK3S & MK3

That sounds a little disappointing, i thought the correction was ideed made live while printing.

Usually these deviations should be quite small so it would be very hard so see the Z-Axis moving even if it worked that way 😉

I'm tempted to force one point of calibration to be higher and see for myself if the z-Axis is lifted.

Where can i learn about the way the meshbed-leveling actually works in detail?

Re: Firmware 3.7.0-RC1 for Original Prusa i3 MK3S & MK3

I've noticed that when my printer does a mesh bed level it will home X/Y and then crash by doing a quick move left. It will then continue on like nothing happened. Anyone else have this?

Re: Firmware 3.7.0-RC1 for Original Prusa i3 MK3S & MK3

Where can i learn about the way the meshbed-leveling actually works in detail?

You can look at the source code of the firmware on Github.

I have observed the Z movement during printing, only the Z-hopping (0.6mm) can be seen.

2x Personal MK3IR-BMG09 (Full) BEAR + MMU3 mod., ...

Re: Firmware 3.7.0-RC1 for Original Prusa i3 MK3S & MK3

A common misconception! Unfortunately, only an average of the deviation is calculated, a complete mechanical compensation does not take place automatically. Or could anyone ever observe that the z-axis is moving within a layer to be printed? 😉

I can assure you that this is not true. I can clearly see the Z plastic cap moving on mine while it prints in different areas of the plate, (E.g. printing from from left side of the plate to the right side one straight long line I see it rotating slowly).

Re: Firmware 3.7.0-RC1 for Original Prusa i3 MK3S & MK3

Certainly it does not happen automatically, but is due to a manual adjustment of the printer.

2x Personal MK3IR-BMG09 (Full) BEAR + MMU3 mod., ...

Re: Firmware 3.7.0-RC1 for Original Prusa i3 MK3S & MK3

That sounds a little disappointing, i thought the correction was ideed made live while printing.

Usually these deviations should be quite small so it would be very hard so see the Z-Axis moving even if it worked that way 😉

I'm tempted to force one point of calibration to be higher and see for myself if the z-Axis is lifted.

Where can i learn about the way the meshbed-leveling actually works in detail?

While printing a 75mm square for life z calibration (after a PM tear-down and rebuild with MK3S upgrade, lots of mechanical things changed), I can't see the z threads moving, but if I look very carefully at the black dust caps over the motor hub I can see a little bit of movement. The small facets on the top cone surface help by watching the reflection from a static light source on the opposite side of the printer from me. (In my case, a window.) The printer is compensating to it's measured values by micro adjustments of the z-height. I haven't checked this on the second (or higher) layers, but I would expect the mesh leveling compensation z movement to stop happening at layer 2 or higher.

See my (limited) designs on:

Printables - https://www.printables.com/@Sembazuru

Thingiverse - https://www.thingiverse.com/Sembazuru/designs

Re: Firmware 3.7.0-RC1 for Original Prusa i3 MK3S & MK3

Certainly it does not happen automatically, but is due to a manual adjustment of the printer.

As far as I understand/know, It is automatic, based on values obtained in mesh bed leveling.

That's the whole purpose of the thing, and now with more points it should do these adjustments more precise on different regions.

I have a total bed variance on .2 mm, however I like christoper wrote, you can see these minute movements on the motor plastic cover grooves.

Re: Firmware 3.7.0-RC1 for Original Prusa i3 MK3S & MK3

for the most part the 7x7 mesh bed leveling appears to work.

i had one unexpected problem at beginning of a print yesterday.

just before the print i did homing of all 3 axis so extruder was already placed at regular starting point.

when i started a print directly after it looked like the homing may have been skipped and then went straight to mesh bed leveling.

mesh leveling completed all points but at the end of it i got an error about the offset being too large (a number with i think 27 something) and then aborted the print.

it also sounded like a head crash when it was homing just after mesh leveling and it did one extra homing sequence of each axis just before it stopped with error.

this has never happened before, once i restarted print again everything worked just fine.

so this must have been a minor glitch and i only saw this once.