Re: Firmware 3.5.1-FINAL for Original Prusa i3 MK3

+1

Fix it.

A real pita.

Hasn't worked properly for me in 4 attempts.

If you watch Prusa when he is doing demos at maker fairs this year you can see him automatically plucking the dangling bit of plastic from the nozzle as each print starts... I bet he does not even think that he is doing it.

I addition to that plucking of the dangles that Prusa does, I hit pause as soon as the wipe and outer circle line is printed and give the bottom of the extruder a good scrub with a soft brass brush.

Re: Firmware 3.5.1-FINAL for Original Prusa i3 MK3

I found an issue that happened in 3.5.0 also, not sure about before then though.

When the filament is changed during a print, it shoots out a small amount to make sure the color has changed (even if you are not changing color). After you say yes and remove the filament it put out, it puts out a little more and then instantly moves. This strand of filament is then pulled onto the print and lays across it unceremoniously, causing future havoc.

It would be great if it did not push out more filament on purpose after asking you if the color changed and you said yes.

Agree.

This might work with PLA, but with PETG, it often sticks to the nozzle and makes a mess...

Would be better not extruding extra filament.

Have a look at my models on Printables.com 😉

Re: Firmware 3.5.1-FINAL for Original Prusa i3 MK3

I found an issue that happened in 3.5.0 also, not sure about before then though.

When the filament is changed during a print, it shoots out a small amount to make sure the color has changed (even if you are not changing color). After you say yes and remove the filament it put out, it puts out a little more and then instantly moves. This strand of filament is then pulled onto the print and lays across it unceremoniously, causing future havoc.

It would be great if it did not push out more filament on purpose after asking you if the color changed and you said yes.

they explained this some time ago. what is supposed to happen is that the pile of filament stays put and the small extra amount it extrudes is supposed to allow that pile to stay put and not get dragged into the print. it is supposed to stretch and pull off the nozzle, not pull the pile of filament change into the print. in my experience, it works about 50/50 so i grab the whole thing as it extrudes that last extra bit and pull it off the plate so none of it ends up in the print. but i will confess that i have had it work perfectly also.

I would rather not have it, unless they can figure out how to make it work all the time.

well that kinda depends on you. the place it unloads at is a corner. which is the same place you put your fingers when popping parts off the plate. if you keep it clean with alcohol, pet-g, pla, abs all stick when extruded there. if on the other hand you don't keep it wiped then when it switches it will not stick (just as filament will not stick elsewhere you have fingerprints) and it will drag all over the print. I have found that the textured plates work better since you have a better surface that doesn't get all finger printy.

Re: Firmware 3.5.1-FINAL for Original Prusa i3 MK3

I have a new MK3 printer and in my oppinion there is a bug in 3.5.1 firmware - I have "bed preheat error" in the same point of print - from my experience it depends on bed temperature change from 100 to 110 deg C in ABS default, and strongly depends on fan speed.

I use Slic3er PE and with some fan settings print is OK and with some there is very repeative "bed preheat error"

In my opinion there is fan noise average (filter) problem.

More important problem is that after error printer stops and nozle burn holes in prined parts. Is it possible to raise head after error ??

Best regards

Kamil

Re: Firmware 3.5.1-FINAL for Original Prusa i3 MK3

It's not a firmware error, but rather a physical limitation.

Higher bed temperatures like 110 and 115 are at the limits of the heat bed capability. Once you get past the first few layers and the print cooling fan turns on, the heat bed temperature drops and sometimes the bed heater simply can't attain or maintain 110-115C.

A few things help from simplest (least effective) to most effective

1. Print with the object away from the center of the heat bed. That keeps the print cooling fan away from the bed temp sensor at the middle of the bed. This doesn't help keep the actual bed temperature elevated, but you can avoid the error because the temp sensor doesn't see the fan cooling effect.

2. Insulate the bottom of the heat bed. I've test this with vinyl foam insulating tape. It works and gives you about 2C more headroom. Eventually, I removed the insulation because solution #3 is the most reliable.

3. Enclose the printer and PREHEAT the enclosure to at least 25C. You can preheat by turning on the heat bed and letting it heat up the enclosure. Once the enclosure is up to temperature, you can proceed with printing ABS or Polycarb. Preheating my enclosure lets me reliably set 115C heat bed for polycarb. Without preheating the enclosure, aiming for 115C will routinely trigger a bed preheat error.

TLDR: Higher temp materials require placing the printer in a preheated enclosure.

Re: Firmware 3.5.1-FINAL for Original Prusa i3 MK3

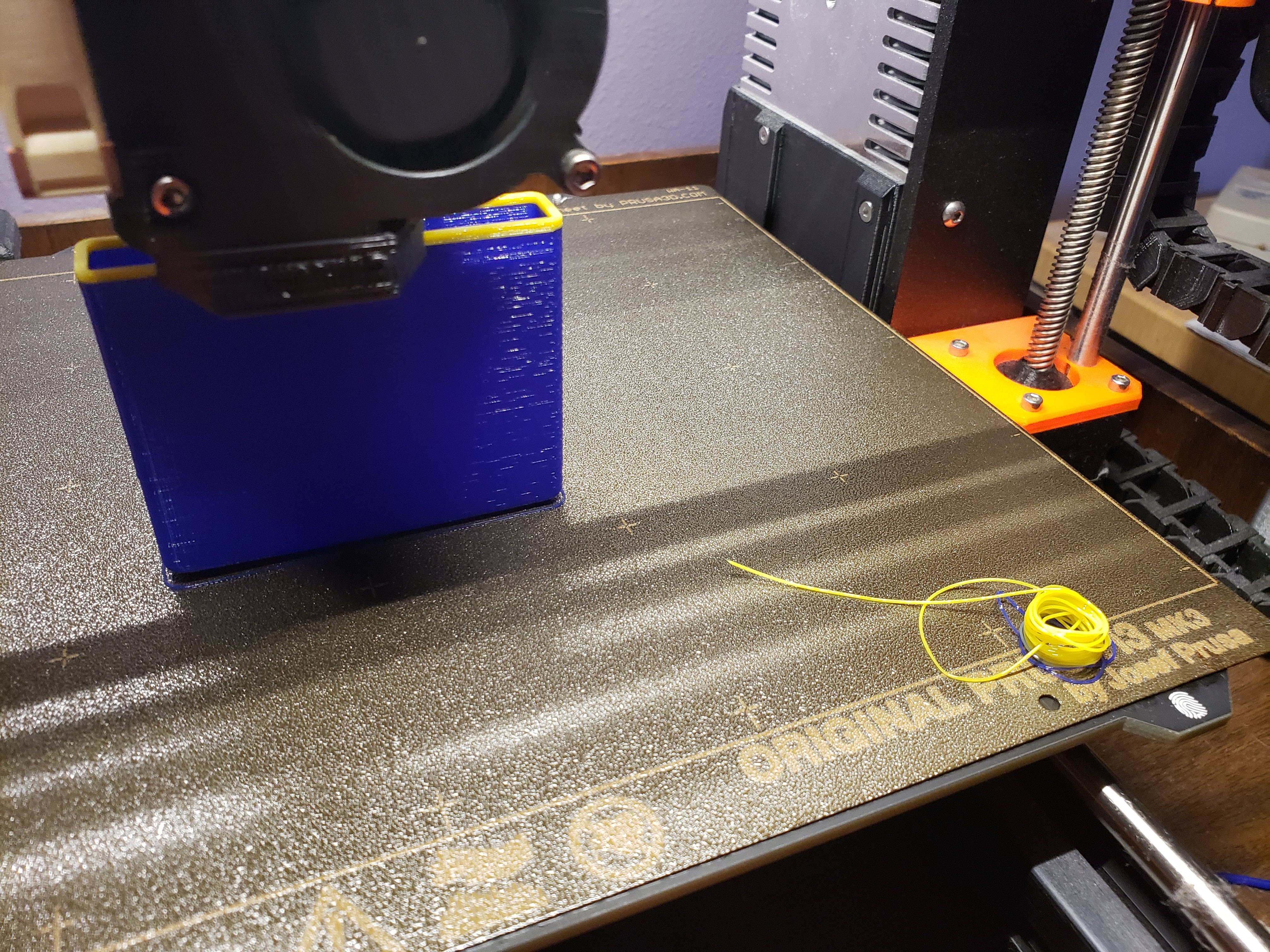

they explained this some time ago. what is supposed to happen is that the pile of filament stays put and the small extra amount it extrudes is supposed to allow that pile to stay put and not get dragged into the print. it is supposed to stretch and pull off the nozzle, not pull the pile of filament change into the print. in my experience, it works about 50/50 so i grab the whole thing as it extrudes that last extra bit and pull it off the plate so none of it ends up in the print. but i will confess that i have had it work perfectly also.

I would rather not have it, unless they can figure out how to make it work all the time.

well that kinda depends on you. the place it unloads at is a corner. which is the same place you put your fingers when popping parts off the plate. if you keep it clean with alcohol, pet-g, pla, abs all stick when extruded there. if on the other hand you don't keep it wiped then when it switches it will not stick (just as filament will not stick elsewhere you have fingerprints) and it will drag all over the print. I have found that the textured plates work better since you have a better surface that doesn't get all finger printy.

20181228_155932.jpg

I hear what you are saying, but I would rather not have to worry about my surface being nicely clean and usable just so they can push filament while they are moving the head back onto my print. On a large print, the string will still fall onto the print and mess it up.

Make it an option. Those who want to risk damaging their print can have it squirt out filament while moving and those who want to play it ultra safe can have it not do that.

Re: Firmware 3.5.1-FINAL for Original Prusa i3 MK3

Make it an option. Those who want to risk damaging their print can have it squirt out filament while moving and those who want to play it ultra safe can have it not do that.

Agree - On Github it was suggested to have a parameter on M600 to specify if extra extrude was needed.

Could be something like: M600 just change color and M600 P2 change color and feed extra 2 mm to build up pressure before print.

Have a look at my models on Printables.com 😉

Re: Firmware 3.5.1-FINAL for Original Prusa i3 MK3

I hope that Prusa sees the 7x7 leveling and includes this as an option or as std in the next Fw uppdate.

Re: Firmware 3.5.1-FINAL for Original Prusa i3 MK3

I hope that Prusa sees the 7x7 leveling and includes this as an option or as std in the next Fw uppdate.

this would be awesome!

Re: Firmware 3.5.1-FINAL for Original Prusa i3 MK3

I also see the temp drops in the same ranges as in previous posts.

I noted also that the bed mesh is incorrectly mapped. Behavior not present in 3.4.1

Nozzle is lifted when moving towards back end of the plater. Hence , the filament gets

overly squished at the front end of the plater.

Re: Firmware 3.5.1-FINAL for Original Prusa i3 MK3

copying this from my github post with pics

This is also happening to me on 3.5.1 with new machine and flash/reflash.

I even spent several days on the chat with 2 different people before I started looking elsewhere.

I have even had one CSR send me another thermistor with no change.

I am VERY surprised the CSR's don't know of this issue that it seems many have had. I added a post on that thread with my temp dips.

Can we please get this sorted out so I can print on this amazing machine as it was intended to print with the latest firmware 🙂

Re: Firmware 3.5.1-FINAL for Original Prusa i3 MK3

Just tried a test by putting my print on Pause from the SDCARD, and then waiting for the I3 MK3 to cool down, and then turning the printer off at the PSU, just to see if the print would go back to the pause status, when turned on again, well it did not so 15 minutes of print lost, this is not a rant, just a heads up to see if in future firmware versions there is a way to resume the print from the SDCARD when PSU is turned off by accident by somebody........... 💡 💡 💡 💡 💡 💡 💡

Re: Firmware 3.5.1-FINAL for Original Prusa i3 MK3

copying this from my github post with pics

This is also happening to me on 3.5.1 with new machine and flash/reflash.

I even spent several days on the chat with 2 different people before I started looking elsewhere.

I have even had one CSR send me another thermistor with no change.

I am VERY surprised the CSR's don't know of this issue that it seems many have had. I added a post on that thread with my temp dips.

Can we please get this sorted out so I can print on this amazing machine as it was intended to print with the latest firmware 🙂

Have you tried the 3,5.2 firmware to see if your problem is still there, I got around to connecting up octoprint last night and didn't noticce anything worng on an ABS print as far as temperature control goes, but I didnt't have the fan running obviously. Give it a go and see if your problem is still there.

Re: Firmware 3.5.1-FINAL for Original Prusa i3 MK3

Hi guys,

UPDATE: Final version of 3.5.2. is out: https://shop.prusa3d.com/forum/general-discussion-announcements-and-releases-f61/firmware-3-5-2-final-for-original-prusa-i3-mk3-t27856.html

/ Knowledge Base

The guy behind Prusa assembly manuals...

Re: Firmware 3.5.1-FINAL for Original Prusa i3 MK3

copying this from my github post with pics

This is also happening to me on 3.5.1 with new machine and flash/reflash.

I even spent several days on the chat with 2 different people before I started looking elsewhere.

I have even had one CSR send me another thermistor with no change.

I am VERY surprised the CSR's don't know of this issue that it seems many have had. I added a post on that thread with my temp dips.

Can we please get this sorted out so I can print on this amazing machine as it was intended to print with the latest firmware 🙂

Have you tried the 3,5.2 firmware to see if your problem is still there, I got around to connecting up octoprint last night and didn't noticce anything worng on an ABS print as far as temperature control goes, but I didnt't have the fan running obviously. Give it a go and see if your problem is still there.

I am seeing temperature dips also, but I'm still on 3.3.1. I was not seeing it previously, it started for me without changing the firmware. From when my printer was new, the hot end temp would only vary up or down a degree or two at most. Then I started seeing it vary 35 degrees plus. Along with that, I started seeing extruder skips. I made two changes in a print that I'm running right now and my temp is holding steady so far. I turned the model on the print bed from this-

I don't want to jinx myself, but the print is halfway finished, the temp is holding solid, and I don't see any skips in the outer perimeters or looking down inside yet. Fingers crossed! Other change I made was to alter the filament diameter in Slic3r from the default 1.75mm that I had been using since new to 1.70mm after measuring the filament (3D Solutech) and seeing it varied from 1.68-1.75mm. I never measured it before. I'm 2/3rds of the way through this roll and it had been printing fine at 1.75 but I measured it after I started having trouble with skipping.

Question is, why would turning the model affect the temps? Do I have a break in a wire going to the hot end heater that only happens when the extruder is across the X axis?

Re: Firmware 3.5.1-FINAL for Original Prusa i3 MK3

Just a quick update- my print finished complete, with no skipping and the temp never dropped more than a degree that I saw. I think I need to check my extruder heater cables?

Re: Firmware 3.5.1-FINAL for Original Prusa i3 MK3

Just a quick update- my print finished complete, with no skipping and the temp never dropped more than a degree that I saw. I think I need to check my extruder heater cables?

Looks like you may have a break, try setting your X asix to 250 and see if your nozzle heats up, If it does move your y axis up to about 20 or 30 and see fi it still does.

Re: Firmware 3.5.1-FINAL for Original Prusa i3 MK3

Just a quick update- my print finished complete, with no skipping and the temp never dropped more than a degree that I saw. I think I need to check my extruder heater cables?

Looks like you may have a break, try setting your X asix to 250 and see if your nozzle heats up, If it does move your y axis up to about 20 or 30 and see fi it still does.

Yep, going to try that after work tonight.

Curious why you suggested to move the Y axis? They’re different cable bundles, aren’t they? Noob here, just trying to learn.

I did get a spare heater from Prusa with my last order, wish I had the MK3S upgrade kit here if I have to unwrap the extruder bundle anyway! Lol

Re: Firmware 3.5.1-FINAL for Original Prusa i3 MK3

Just a quick update- my print finished complete, with no skipping and the temp never dropped more than a degree that I saw. I think I need to check my extruder heater cables?

Looks like you may have a break, try setting your X asix to 250 and see if your nozzle heats up, If it does move your y axis up to about 20 or 30 and see fi it still does.

Yep, going to try that after work tonight.

Curious why you suggested to move the Y axis? They’re different cable bundles, aren’t they? Noob here, just trying to learn.

I did get a spare heater from Prusa with my last order, wish I had the MK3S upgrade kit here if I have to unwrap the extruder bundle anyway! Lol

I think he might have meant z axis because he also said "up".

See my (limited) designs on:

Printables - https://www.printables.com/@Sembazuru

Thingiverse - https://www.thingiverse.com/Sembazuru/designs

Re: Firmware 3.5.1-FINAL for Original Prusa i3 MK3

Update-I ran the temp up to 215C ( I had PLA still loaded) and it heated fine so I started gently flexing the cable bundle from the extruder to the Einsy case. Underneath the post that sticks out the back of the extruder, the temp started to change rapidly then it threw a MINTEMP error message. I removed the hot end thermistor and checked it with an ohmmeter. There’s an intermittent open in the wire on mine. I have a spare so I’ll put it in tomorrow and see how it does.