Filament stuck

Hello,

I have problem with filament stuck.

This happened to me for the second time today. I disassembled the extruder and cleaned everything, made a Wizard setup and first layer. In the meantime, the electricity went out while he was working for the second time. What could be the cause?

On the next print, "plastic tears" fall all the time from hottend, which harden and make me have trouble printing. In 12 hours print, it wass fall about 20-30 "tears".

does anyone know why this problem occurs?

RE: Filament stuck

Can you give a bit more detail please.

What filament, what temperature, cooling fans on/off....etc. This will help trying to work out what's going on.

I've had blockages and filament "chewed" through by extruder gears. I've had poor extrusion from gears "choked" and not being as sharp as they should be. But I've never (yet) had it wrap filament round them so others may know the cause....with a bit more info.

Andrew

RE: Filament stuck

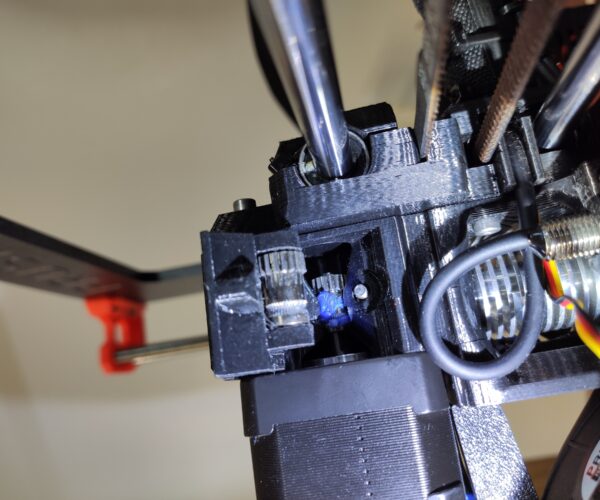

I found a problem why plastic tears were dripping ... but I don't understand why jw wrapped the filament. The filament is PLA marwiol.pl

RE: Filament stuck

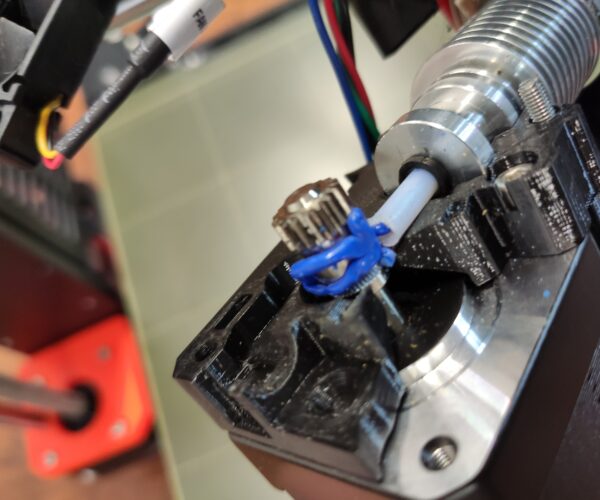

Well its obvious you dont have a correct seal between the nozzle and heatbreak so plastic is leaking up through the threads, onto the top of the heatblock and then down onto your print.

That slight gap between the 2 also causes uneven extrusion as its a little reservoir of molten plastic that can absorb pressure changes from retraction/extrusion. Looking at your pla filament around the gears then it looks squished. I think the extruder motor is getting hot, the heat is transferred to the bond tech gear and it softens the pla. With it not extruding due to the extra pressure the pla has got to softening temperature and the gears are trying to force it through somewhere it doesnt want to go and so its wrapped around. In effect the pla is acting more like tpu as its now more flexible due to the heat.

The mk3 extruder runs hot normally. This is probably exacerbated bu the heatbreak/nozzle issue as its probably been having to work harder. That combined with temperature getting warmer anyway. I can see that you have what looks like a lack enclosure. I do hope you are printing with your doors open at least ? With the extruder being air cooled it really doesnt like printing pla inside an enclosure as theres not enough air circulating to properly cool it once the weather gets warmer.

Once you have cleaned up the hot end and properly sealed the nozzle/heatbreak you may want to look into cooling your extruder stepper. Fastening heat sinks to it is a simple way to drop approx 10 degrees or you could go the powered approach and add an extra fan to it, check thingiverse, there are several extruder motor fan shrouds on there that will work.

RE: Filament stuck

Thank you very much to help! 🙂

Now, it is all ok!