Re: Extruder Motor getting too hot

If the extruder motor can chew a notch into the filament during a jam or plugged nozzle, which mine does without any problem, motor torque isn't playing a roll in the jamming. As for operating temps, my extruder motor hits 55c - a very comfortable temp for normal operation. Sure, warmer than room temp, but perfectly normal for motors. The operational spec for the motor is up to 55c ambient, which means the motor can be much hotter than 55c; a motor temp of 80c if you figure a 25c temp rise.

With all of the possible reliability issues using a different motor spec - things like current limits, back-emf compensation, even inductive kickback - I'd hesitate to change a motor without engineering advice.

Re: Extruder Motor getting too hot

I found helping the air to stay in the heat sink a bit longer helped

And as others have mentioned, a heat sink on the extruder motor helps.

I maintain an informal list of San Diego, CA 3D printing enthusiasts. PM me for details. If you include a contact email and I can add you to the informal mailing list.

Re: Extruder Motor getting too hot

As for operating temps, my extruder motor hits 55c - a very comfortable temp for normal operation. Sure, warmer than room temp, but perfectly normal for motors. The operational spec for the motor is up to 55c ambient, which means the motor can be much hotter than 55c; a motor temp of 80c if you figure a 25c temp rise.

The motors handling the heat aren't the problem. It's the heat from the motor that gets transferred down the shaft to the bondtech gears which then softens the filament enough to cause issues.

Re: Extruder Motor getting too hot

The motors handling the heat aren't the problem. It's the heat from the motor that gets transferred down the shaft to the bondtech gears which then softens the filament enough to cause issues.

I could see this if someone is using an enclosure and the enclosure ambient is well over 40C ... otherwise, it's difficult to see how a 55c extruder gear is an issue. But hey, I'm a novice and my printer operates in an air conditioned 23c +/- 0.4c room.

Perhaps adding a duct from the part cooling fan that redirects incoming air across a suitable motor heatsink. Something that replaces the angle bracket. A cool project for someone.

Re: Extruder Motor getting too hot

I was wondering; are the Bond Tech gears Stainless Steel? if they are that would have less thermal conductivity THan mild steel or even tool steel. but there are metals with e even less conductivity than SS such as Titanium we have folks fabricating expensive heat breaks out of it out there has anyone tried it? or other low thermal conductivity metal or composite?

Re: Extruder Motor getting too hot

The motors handling the heat aren't the problem. It's the heat from the motor that gets transferred down the shaft to the bondtech gears which then softens the filament enough to cause issues.

I just measured the gears on my printer. 55c motor and 38c gears. Though my IR thermometer may be reading the exposed metal low as much as 10%, so let's call it 40c at the gear.

Re: Extruder Motor getting too hot

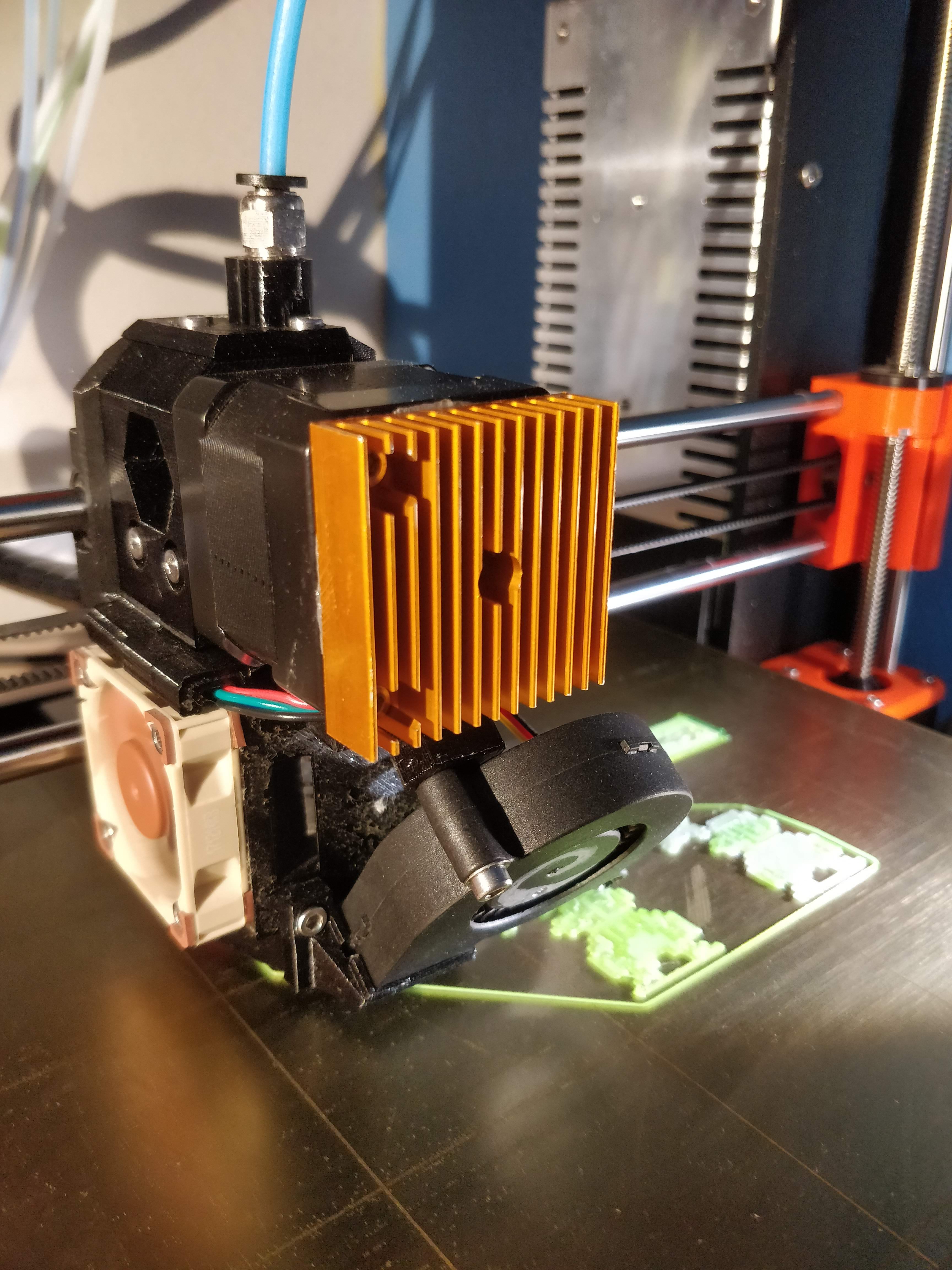

And as others have mentioned, a heat sink on the extruder motor helps.

IMG_20181017_143013.jpg

What heatsink did you use and what did you use to glue it on? I am going to do the same thing. It might not be needed, but it cannot hurt, so why not do it?

Re: Extruder Motor getting too hot

Running mk3 from last week, i had lot of clicking from extruder area in the begining and after i added coolers attached with zip tie clicking is gone.

Still fighting with terrible over extrusion with S3D and layer inconsistency using PETG. I must say i am little disapointed because i am getting much better prints from my 5 year old heavily modified K8200 than new MK3 🙁 .

Re: Extruder Motor getting too hot

And as others have mentioned, a heat sink on the extruder motor helps.

IMG_20181017_143013.jpg

What heatsink did you use and what did you use to glue it on? I am going to do the same thing. It might not be needed, but it cannot hurt, so why not do it?

I used some Arctic Silver I had laying around because it's a great conductor. I held the heatsink on with bolts, my zip ties worked but this is a better bond.

You probably want the fins oriented vertically to encourage convective cooling - although with all the zipping side to side one could argue horizontal will get better airflow.

A small fan, or getting the layer fan to draw off the heatsink, would help.

I maintain an informal list of San Diego, CA 3D printing enthusiasts. PM me for details. If you include a contact email and I can add you to the informal mailing list.

Re: Extruder Motor getting too hot

I used some Arctic Silver I had laying around because it's a great conductor. I held the heatsink on with bolts, my zip ties worked but this is a better bond.

You probably want the fins oriented vertically to encourage convective cooling - although with all the zipping side to side one could argue horizontal will get better airflow.

A small fan, or getting the layer fan to draw off the heatsink, would help.

[/quote]

That golden heatsink, did you have it lying around as well (an old GPU or CPU sink) or did you buy it? If you bought it, what did you buy? That looks like a perfect fit. I have Arctic Silver lying about as well. 🙂

Re: Extruder Motor getting too hot

It came with a cheaper 3D printer which was more concerned with performance instead of image.

Search "Nema17 Heatsink" and there's plenty online.

I maintain an informal list of San Diego, CA 3D printing enthusiasts. PM me for details. If you include a contact email and I can add you to the informal mailing list.

RE: Extruder Motor getting too hot

I'm giving this topic a quick update on what I have learned in the past time.

The real problem :

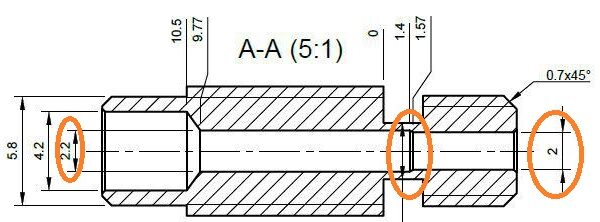

It seems Prusa is using a special "prusa" version of the E3D heatbreak. This special heatbreak is prone to cause jams when filament starts to deform earlier in the heatbreak then intended. Normally heatbreaks have a ~2mm hole all the way through, but Prusa seems to use a heatbreak with a portion of the hole being 2.2mm and then narrowing to 2mm just before the heatblock, see picture below :

Orange areas show the 2.2mm to 2mm narrowing in the special prusa E3D heatbreak.

This explanation of the problem matches with the symptoms that I have and read from others :

- Only with PLA filament or other low melting point filaments;

- Occurs only between 30 to 90 minutes in the print after a cold start, and after that repeats faster (10-20min) because it is already warm/hot;

- Occurs more often with a 0,25 nozzle because the flow of cold filament is slower, so filament has more time to warm up higher up in the heatbreak;

- Occurs often only when ambient temperatures are higher (Closed enclosure or summer, I can't even print PLA in summer times >32C ambient)

- The pulled out jammed filament has a nice cylindrical shaped plug with a diameter of exactly 2.2mm.

The whole "Extruder temperature" thing is just adding to this problem by also warming up the filament (through the shaft/gears) and before it even goes in the heatbreak.

Solution and work arounds :

I see people are changing out the heatbreak for the original E3D one with only the 2mm bore hole in it, and they claim it solves the problem. I also see on internet and also heard from prusa that this 2.2mm modification was needed for MMU support. But I'm a bit confused / uncertain about this all. Why did prusa added this special heatbreak to all the MK3's as only a small portion might get MMU in the futur

Temperature Work Around : Lowering or heightening the extrude temperature seems to help either keeping the deforming location below or well above the narrowing point, at expense of the negative print characteristics paired with these lower or higher temperatures.

Oil Work Work Around : Some report Oiling the filament stopped there problems, but the gives reduced layer fusion and thus less strength in prints.

Cooling Work Around : Somehow lower your ambient temperature. Open up your enclosure (if you did not do this already XD) or maybe set your air-co in "Arctic Blizzard" mode

If people have some more updates or information about this, please let me know. As I still don't have a solution for printing PLA with an MK3+MMU (and thus also the special prusa heatbreak) in summer day's or at ~25C ambient with a 0,25 nozzle.

Creative Engineer and 3D printing @ AcEcraft.eu

RE: Extruder Motor getting too hot

1 Extra cooling fan on top of extruder motor, this is a very lite part with a little fan. On thingiverse you can find the model for a mk3/s if for a mmu is the same i do not know. I have a mk3(no s) and installed this with a extra power adapter, this helps a lot to cool down the motor. Also a original e3d heatbreak i installed.

2 Second open your enclosure of course.

3 Third you could try a extra fan to blow through your enclosure, but only in the higher part of the printer.

or suck the warm air away from the printer(high in the printer enclosure).

Max temperature of the e3d is 35 degrees.