RE: Drying Times and Temps in Dehydrator

I did keep some weight measurement when printing some test spanners using ePA-CF when printed (dry) and over 18 days left in the atmosphere they have both gained 3% in weight.

So I'm now preparing a test. I've taken 6 approx 1 metre samples of eSun's ePA-CF, PETG, TPU, PLA, ABS+, ePC that all come from old spools that have been in my dry cabinet for months. I've measured the samples in Grains (down to 1/10th of a grain = approx 0.0065 of a gram). The plan is to:

- Soak them in water overnight and re-weigh

- Let them air dry / stabilise and re-weigh

- Vacuum Dry them and re-weigh them every 30 mins???

RE: Drying Times and Temps in Dehydrator

I'm thinking that entire dialog with the vacuum pump / dryer system is a bit bogus. There is absolutely no need to "vent" then pull another vacuum. That really sounds like the design shows a lack of understanding of how outgassing via vapor pressure differential works.

Add in the fact they heat the air - and that's probably what they are doing when they say venting, adding hot air to heat the filament (otherwise heat would need to be be radiated rather than conducted, and it's going to be difficult to regulate radiant heat absorption).

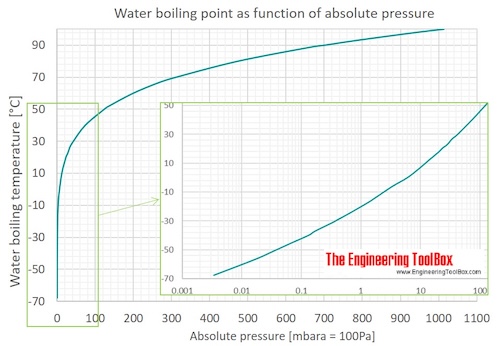

The simple fact is that if you achieve a vacuum pressure that promotes evaporation of water, and that pressure stays constant, you do not need to keep the pump running until the chamber pressure rises above the vapor pressure of water. Since water at 23c evaporates at 21 Torr (21mmHg), as long as you are below that pressure moisture in the filament will outgass. So pulling a vacuum down so that chamber pressure is 0.1 Torr or less will continue to cause absorb moisture to evaporate, "if it can."

The "if it can" part comes down to the water having an affinity for the plastic. Sort of like water and desiccants - water sticks to desiccants until the chemical relationship fails - and that can be at fairly high temperatures depending on the material.

Of course, I am approaching this as an armchair chemist/physicist.

But my experiments prove to me that vacuum doesn't work well at drying filament.

RE: Drying Times and Temps in Dehydrator

@jmone -- I'd watch for actual water drops affecting weights. I used vapor to avoid that risk. And 24 hours isn't long enough to represent real world use we see.

RE: Drying Times and Temps in Dehydrator

@tim-m30

Thanks for your posts (and I too am just an armchair scientist!!). Anyway, here is where I'm at. At after 8hr in water this is what each filament gained in weight (after drying them with a paper towel so they are "dry to the touch"

ePA-CF: 4.1%

PETG: 0.7%

TPU: 2.4%

PLA: 1.1%

ABS+: 0.8%

ePC: 1.0%

No great surprises of which gained the most, though I did think ePC was classed as relatively hygroscopic.

I'll now let sit in the air for a bit in the open. Here in Sydney we are currently at 25c/60% RH.

As I have no way of measuring the actual moisture content of the filament at any stage, all I'll be doing is seeing how long (if at all) the vacuum can bring the filament back to what it was originally.

RE: Drying Times and Temps in Dehydrator

@tim-m30 - I've been having a look at various presentations for industrial machines used to dry thermoplastic pellets in preparation for injection moulding. They use a variety of machines, including Vacuum. Here is one such presentation comparing dryers https://www.wolvcoll.ac.uk/wp-content/uploads/2018/04/4.1-Mike-Jordan-Summit-Drying-solutions-2018.pdf

When discussing Vacuum batch dryers, they suggest, heating the material for 20-25 minuets then applying the vacuum. The following is their tables on the reduction in drying time between a desiccant dryer and vacuum (drying time in Mins)

ABS: 180 vs 20mins

PC: 200 vs 25mins

PA: 240 vs 40mins

PET: 360 vs 60mins

...and the benefits are 50-70% less energy with a drying time that is 6 times faster. Now how this translates to home use is another thing.

RE: Drying Times and Temps in Dehydrator

@jmone - If you heat a mass up to some high temp, like 100c, vacuum will remove the moist air between the pellets that convection can't remove easily. That is the only advantage I see. The vacuum is NOT removing moisture from the product, rather, the heat boils the moisture out of the pellets into the stagnant hot air around them, then the vacuum sucks out all the hot moisture laden air from between the pellets.

Think of the moisture laden air inside the billions of hot pellets as bubbles in a fluid. Sure, over time gravity/convection will cause the air to move around, but it will be slow. Vacuum speeds this movement up a great deal.

RE: Drying Times and Temps in Dehydrator

Just read the Power Point: and it confirms what I just wrote. It's the heat doing the drying, not the vacuum. The vacuum simply pulls out the vapor laden air - and to a lesser degree allows the hot plastic to outgass more readily. Without the heat, vacuum alone drying is ineffective. I love this bit from the presentation:

STEP 1: Heating Hopper: Insulated stainless steel hopper for drying temperatures up to 350°F (175°C).

I wish they'd have included the temps for vacuum-drying materials, that would have informative.

For your tests, make sure you have equal mass samples taken at the same time, and wet them equally for each type of drying you plan to test. I'd also recommend a single wetting container to keep the water quality equal for all samples.

sample 1: ABS for heat dry

sample 2: ABS for vacuum dry

sample 3: ABS for heat+vacuum dry

sample 4: ABS for freeze dry

etcetera ...

RE: Drying Times and Temps in Dehydrator

Another article to read on vacuum drying, also explains the need for direct heat application while drying:

https://www.researchgate.net/publication/283088611_Vacuum_Drying_Basics_and_Application

Vacuum drying is a process in which materials are dried in a reduced pressure environment, which lowers the heat needed for rapid drying. Vacuum dryers offer low-temperature drying of thermolabile materials and are suitable for solvent recovery from solid products containing solvents. Heat is usually supplied by passing steam or hot water through hollow shelves (Figure 2).Drying temperatures can be carefully controlled and, for the major part of the drying cycle, the material remains at the boiling point of the wetting agent. Drying times are long, usually about 12 to 48 h.

RE: Drying Times and Temps in Dehydrator

@guy-k2 There is also IR Drying! but lazzzzerssss 🙂

@tim-m30 - I read it a bit differently, in that all the vacuum does is lower the boiling point of water. You then need to have the filament to be above this point. The bigger the temp difference between the boiling point and the material the quicker it should dry (and the industrial models don't have a particularly strong vacuum). We already know the stronger the vacuum the better and if it is strong enough the water should require nothing more than ambient temp, the weaker the vacuum the more you need to apply heat.

What we don't have is a graph (by material) showing a drying curve over time by the temp difference between the boiling point and material temp.

RE: Drying Times and Temps in Dehydrator

...and the other thing that apply heat will help with during the process is that as you boil water in a vacuum, the remain water will cool and it can even freeze - found this explanation:

Under vacuum, all things being equal (namely, temperature), water doesn't freeze in a vacuum, it boils.

If you are in a situation where heat is not being added to the system (i.e., violating the assumption that all things are equal), however, then the water will eventually freeze. If you keep pulling vacuum from a chamber with water in it, the water will keep evaporating, and each molecule of water evaporating will take its heat of vaporization (http://www.w3.org/1998/Math/MathML"><mi mathvariant="normal">Δ</mi><msub><mi>H</mi><mrow class="MJX-TeXAtom-ORD"><mi>v</mi><mi>a</mi><mi>p</mi></mrow></msub></math>">ΔHvapΔHvap) from the water with it, decreasing the temperature.

A secondary effect is that the overall temperature in the chamber is going down because whatever residual gas is left is expanding to fill the space once occupied by the gas pumped out, lowering ambient temperature (the Joule effect). The magnitude of this secondary effect is very low because the transfer of heat from the surroundings depends heavily on convective heat transfer, which in turn depends on ambient pressure, so it is usually negligible in comparison to the vaporization effect.

Eventually, the temperature of the water will get low enough that it will freeze. That being said, under vacuum the water is still subliming like crazy, still decreasing in temperature, and will eventually disappear as invisible vapor out of the vacuum pump outlet. It just doesn't look as spectacular as boiling and most demonstrations don't go that far, because as the ice continues to cool the rate of sublimation goes way down.

Heaps videos on Youtube - like this one

RE: Drying Times and Temps in Dehydrator

@jmone - All I can do is suggest you try to dry filament in a vacuum and come back with method and results. I think you might be surprised at what you learn. I have no accurate tools for high vacuum measurements, though my pump specs ultimate vacuum at 0.3Pa, and it didn't dry very well at all. Also, once you reach a high enough vacuum, even continuous pumping has negligible effect because molecules have to find the pumping port before they leave the chamber, but then we are nowhere close to this level (lol -- sorry, I worked around true high vacuum for a while, and we worried about this - I was designing a machine to count ions (as electrons) so we could measure the vacuum).

What is unknown to me is the migration rate (aka mobility) of water molecules inside PLA, ABS, Nylon, etc. I.e., I doubt very much a water molecule at the center of a filament will really care too much about the pressure on the surface.

RE: Drying Times and Temps in Dehydrator

@tim-m30. I sure will. The plan is to leave the filament samples out in the air today, re-weigh them and then see how it goes tomorrow.

RE: Drying Times and Temps in Dehydrator

With only a 24 hour wetting, seems like leaving the samples out in free air for 24 hours is - well - ruining the entire experiment. Ideally you want samples to be 100% saturated, and how far in can water make it in only 24 hours? Then place that not very wet sample in free air for 24 hours may well suck out the water you just put in.

But, this other technique looks very interesting: Magnetic Resonance Drying of materials: https://link.springer.com/article/10.1007/s10973-018-7312-x

RE: Drying Times and Temps in Dehydrator

Yesterday, I did a test run on some test spanners that I had printed a few weeks ago in ePA-CF. I guess they were bone dry straight after printing and I took measurements at the time. For the last 18 days they have been sitting in my shed and both gained about 3.0% in weight. I put one of the spanners in the vacuum chamber and tested it at the following intervals (5 mins for the first half hour then at the end of an hour). I did not leave the pump running during this period:

Spanner 1: Weight gain over the 18 days was 3.0%, and the cumulative loss was as follows:

5min: 0.28%

10min: 0.37%

15min: 0.37%

20min: 0.46%

25min: 0.56%

30min: 0.56%

60min: 1.02%

So it lost 1% in an hour. I then tried to see if adding heat helps (as this is what I had done with my spool, eg let it heat soak / dry in the oven at 80c then put in the vacuum chamber again).

Drying in the Oven for 30min: 1.48%

Vacuum for 30min: 1.58%

Drying in the Oven for 30min: 1.67%

Vacuum for 5min: 1.76%

I then left it in the vacuum chamber overnight and the final weight was

- 2.04%

Spanner 2: Weight gain over the 18 days was 2.88%, and on this one I tried a different cycle with the cumulative loss as follows:

Heat (30min): 1.02%

Vac (30min): 1.48%

Heat (30min): 1.76%

Vac (30min): 1.95%

Heat (30min): 2.13%

Vac (5min): 2.22%

Vac (overnight): 2.5%

RE: Drying Times and Temps in Dehydrator

Mmmm I'm going to have to rethink the approach as the weight of the samples are too light (all are only between 2.5 and 3.0 grams) and differences are now getting hard to repeatable measure accurately with my manual scale. My error over 3 Measurements on each of the 6 samples ranged from 0.23 to 0.89%, which is way too high. The spanners were easier as they were one lump and almost triple the weight.

Anyway, How does the following design sound?

- Get a better digital scale and calibrate it

- Print Three Sets of 5m of each filament (approx 15g) in a 1.75mm spiral pattern. This should both ensure that the sample is truly dry to start with as it has passed thought he extruder boiling off any water, it will be in once peice making it easier to handle, and the print will replicate the cross sectional profile of 1.75mm filament.

- Soak the filament in water for XX Days ???

- Dry the surface moisture for XX Days ???

- Dry one Set in my 0%RH Dry Cabinet

- Dry one Set in an oven

- Dry one Set in a Vacuum Chamber

- Compare the change in weights over time

Filaments for the test. I have most types. Stick with ePA-CF, PETG, PETG, TPU, PLA, ABS+, ePC? Add others?

This will all take awhile to put together, but how to the approach sound?

Thanks

Nathan

RE: Drying Times and Temps in Dehydrator

The best method - my opinion - is to use a 100% RH humidor to wet the samples. That best fits who we use filament and get it wet by leaving it out in ambient conditions. It also approaches the steam method without destroying the sample integrity. And it is easy to do.

Loose coils of filament are a fair sample. I welded a base on my coils using a filament pen using a flat of the same printed filament. That way the entire weight was 100% the same material and made measurements much easier.

My scale has milligram resolution, but only a 20 gram range,: so my 18 gram test was borderline, but I could measure small changes in weight. My scale claims 5 count accuracy, measuring samples each five times and averaging was required. I saw random +/-3 count changes reading to reading. Even moving the sample a few millimeters this way or that had an effect. My scale has a cover to eliminate drafts, but my samples wouldn't fit under it.

As for the test:

Take a sealed container, a marinade container or even the vacuum pot: add all of your samples so they are suspended in free air, then add a jar of near boiling hot water and seal it up. The hot water will evaporate to saturate the air. I added a hygrometer to monitor humidity.

Then let it stand for 30 days. After that you then have moisture laden samples with no water on them that mimic leaving a spool out in the open weeks.

Remove the lid and immediately weigh the samples. This is crucial. Be careful handling, a finger print has a weight, so handle each sample the same number of times and in the same manner.

Transfer one sample to the dryer, one sample to your vacuum. Let the race begin.

Measurements every hour will provide a detailed drying curve for each method. You can probably stop the test after 24 hours (for PLA).

And if you want to evaluate the professional vacuum dryer technique, use three samples, and add two to the dehydrator, one to the vacuum. At the 30 minute or hour mark, remove one dehydrator sample and weigh it, and place it into the vacuum. It is important to weigh it so you know how much water was remove by simple heating.

RE: Drying Times and Temps in Dehydrator

ps: if you print something, try a small cube or tower with no perimeters, no top or bottom layers, gyroid infill. That should maximize surface area. It won't represent 1.75 mm filament, but should be interesting. I used raw filament because it has the real world characteristic of diameter and the related "how deep does moisture get into the material," aka moisture migration so my tests evaluated how I use filament, not printed parts.

RE: Drying Times and Temps in Dehydrator

So after too much research on Balance Scales, I have an Ohaus SPX-223 (Weighing Capacity: 220g x 0.001g) on it's way. I've designed a 50g test model with 1.75mm walls (printed one) and will see if it fits on the scale. I'm going to be short of time over the Summer Holiday period, so may try a week of immersion to fully hydrate to start with and then see how the various methods dry out.

RE: Drying Times and Temps in Dehydrator

commercial bulk resin vacuum drying systems - 1 pass ( warm / vacuum / eject)

http://www.maguire.com/product.php/325.htm

http://www.maguire.com/ps_image/pdf/1608021-Materials-Drying-(LPD-VBD)-v16-LR.pdf