Re: Any response from Prusa on the inconsistent extrusion?

Any chance you could post before and after comparison pics with 2 cubes printed with it? Stack the cubes to guarantee the same lighting, and angle until the inconsistencies pop.

For those of you who want to try Martin.w15's fix, it is listed as the "BEST ANSWER" to the posted question on this thread: https://shop.prusa3d.com/forum/hardware-firmware-and-software-help-f64/extrusion-gears-grinding-black-petg-idler-part-int-t19247.html

i get the impression most people aren't aware of it, and it is top notch design that, in my opinion, should be a part of the official MK3 build. Like I said, I'm using it, and I'm very happy with it.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any response from Prusa on the inconsistent extrusion?

Any chance you could post before and after comparison pics with 2 cubes printed with it? Stack the cubes to guarantee the same lighting, and angle until the inconsistencies pop.

For those of you who want to try Martin.w15's fix, it is listed as the "BEST ANSWER" to the posted question on this thread: https://shop.prusa3d.com/forum/hardware-firmware-and-software-help-f64/extrusion-gears-grinding-black-petg-idler-part-int-t19247.html

i get the impression most people aren't aware of it, and it is top notch design that, in my opinion, should be a part of the official MK3 build. Like I said, I'm using it, and I'm very happy with it.

It's a fair question, but it's too late for me to do it. On the other hand, if someone hasn't yet done the upgrade, it would be trivial.

Re: Any response from Prusa on the inconsistent extrusion?

For those of you who want to try Martin.w15's fix, it is listed as the "BEST ANSWER" to the posted question on this thread: https://shop.prusa3d.com/forum/hardware-firmware-and-software-help-f64/extrusion-gears-grinding-black-petg-idler-part-int-t19247.html

i get the impression most people aren't aware of it, and it is top notch design that, in my opinion, should be a part of the official MK3 build. Like I said, I'm using it, and I'm very happy with it.

Did this have any impact on the inconsistent extrusion issues?

Re: Any response from Prusa on the inconsistent extrusion?

For those of you who want to try Martin.w15's fix, it is listed as the "BEST ANSWER" to the posted question on this thread: https://shop.prusa3d.com/forum/hardware-firmware-and-software-help-f64/extrusion-gears-grinding-black-petg-idler-part-int-t19247.html

i get the impression most people aren't aware of it, and it is top notch design that, in my opinion, should be a part of the official MK3 build. Like I said, I'm using it, and I'm very happy with it.

Did this have any impact on the inconsistent extrusion issues?

Sorry, I don't know: I wasn't really paying attention to the inconsistent extrusion issue before the upgrade. Maybe if someone who is aware of (and having) the inconsistent extrusion issue does the upgrade, they can comment. In Martin's case (see his comment above), he thinks it may have helped a little.

I happen to think it's an upgrade worth doing regardless, but maybe that's just me.

Re: Any response from Prusa on the inconsistent extrusion?

For those of you who want to try Martin.w15's fix, it is listed as the "BEST ANSWER" to the posted question on this thread: https://shop.prusa3d.com/forum/hardware-firmware-and-software-help-f64/extrusion-gears-grinding-black-petg-idler-part-int-t19247.html

i get the impression most people aren't aware of it, and it is top notch design that, in my opinion, should be a part of the official MK3 build. Like I said, I'm using it, and I'm very happy with it.

Did this have any impact on the inconsistent extrusion issues?

I'm somewhat new to all of this but IMHO, this could make some sense as a cause. It'd be hard to spot given the black on black nature of the debris and a bit of variation in tolerances or assembly could account for why some see issues and others don't. Also, this could possibly explain why some people report a change over time in quality, couldn't it? (Or am I trying to account for too much here?)

Re: Any response from Prusa on the inconsistent extrusion?

The funny thing is: this issue has been considered CLOSED since... I'm not sure when:

https://github.com/prusa3d/Prusa-Firmware/issues/602

I guess the official response was simply "If you are needing guidance, please refer to http://prusaowners.com/wiki/index.php?title=How_to_make_prints_better_on_the_mk3 and Prusa Support"?

Well, no wonder this has been like Waiting for Godot. It's case closed. End of story. Nothing is going happen.

Re: Any response from Prusa on the inconsistent extrusion?

The funny thing is: this issue has been considered CLOSED since... I'm not sure when:

https://github.com/prusa3d/Prusa-Firmware/issues/602

I guess the official response was simply "If you are needing guidance, please refer to http://prusaowners.com/wiki/index.php?title=How_to_make_prints_better_on_the_mk3 and Prusa Support"?

Well, no wonder this has been like Waiting for Godot. It's case closed. End of story. Nothing is going happen.

It was not closed by Prusa. It was closed by Briganandier because the thread had become an unruly mess. People were no longer reading previous posts and were simply reposting ideas and pictures that had already been discussed to death. It ran it's course and was no longer providing useful feedback.

They had long since moved onto other places to discuss the issue. I don't believe the issue is closed, just that no longer useful github issue.

Re: Any response from Prusa on the inconsistent extrusion?

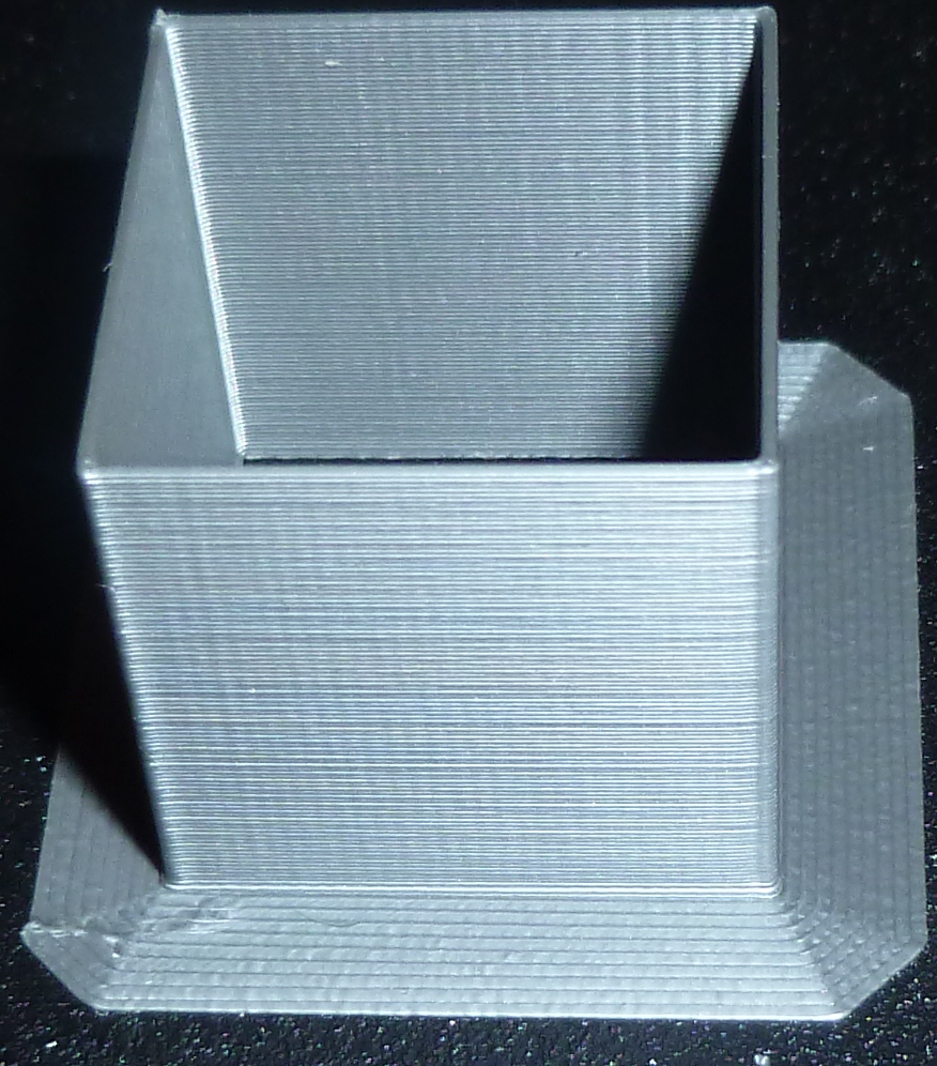

I finally did try the test cube using Prusa PLA, and this was the closest I could get to reproducing the problem:

So, with the right lighting and view angle, there's something visible, but in my case it's quite difficult to even photograph it. Different angles and it disappears.

Honestly, I find the vertical striping to be a much more visible artifact which is visible under many more angles and lighting conditions.

Re: Any response from Prusa on the inconsistent extrusion?

That is not the right angle. Not saying that your print has the issue though. 🙂 Your light is not coming from the top but from the top left. Your pic seems to show some slightly wider rows in the front but not sure how they will look with the light from above (center).

Re: Any response from Prusa on the inconsistent extrusion?

I can see the issue just fine in that pic. You just need the light at an angle to get shadows. Having read up on it, it's a common photography trick to make things more dramatic, as well as one to avoid if doing portraits. It's a bear to get the right angle, but this pic shows it. If you pick a horizontal line and follow it from side-to-side, you can see the inconsistency. Of course, it looks a lot more dramatic at 400% magnification, but even on 20mm cubes, it pops out at the right angle. Prints are still good by any standard used until very recently, but it is a bummer.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any response from Prusa on the inconsistent extrusion?

Some progress with a mk3 bowden: https://github.com/prusa3d/Prusa-Firmware/issues/602#issuecomment-403262487

This is the same experience I have had with my Geeetech Mecreator2. After designing and implementing a bowden upgrade, the surfaces became stunning!

Re: Any response from Prusa on the inconsistent extrusion?

Do all direct drive extruders, including the Titan, have this problem?

Re: Any response from Prusa on the inconsistent extrusion?

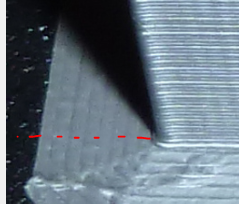

Should the shadow not be on the red line for best effect?

redline.png

So that each lines makes a slight shadow on the next. That way you can see how THICC they are. Or am I missing something?

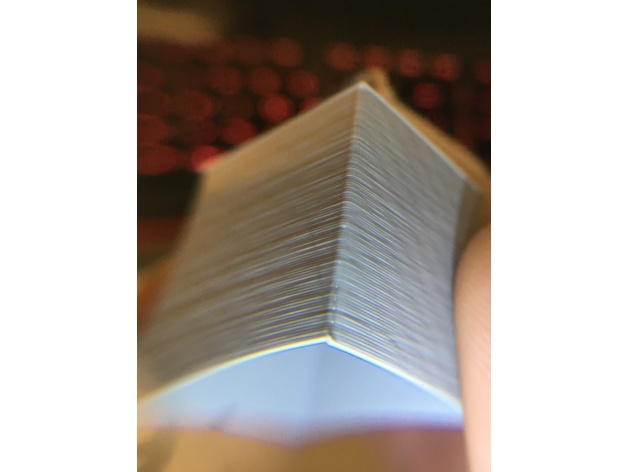

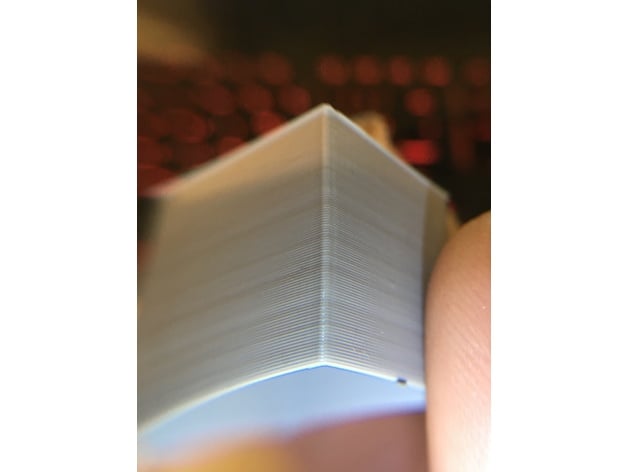

It's hard to spot "the issue" without seeing what the target is. Most of the comparison photos do a poor job of showing the Mk3 and other examples in near-identical lighting, angles etc. The best I've seen were posted by rawlogic/Marcus Adams on Thingiverse.

Here's his Mk3 pic:

Notice how any individual layer line varies as you move across horizontally.

And here's his CR-10 pic:

Notice the layer lines, while still clearly visible, are more consistent as you move across horizontally. It's a long way from "smooth", but it is visibly different.

Of course, these are shots of a 20mm cube blown up 400% or so, but there is clearly a difference. One owner of both the Mk3 and CR-10 described it something like "The Mk3 is crisper, but less consistent. The CR-10 is not as crisp, but more consistent". I'd really like to see the same care taken preparing Mk2, Mk2/s examples.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any response from Prusa on the inconsistent extrusion?

I just printed a little cylinder vase-like part and I sliced it with the special mode for single-wall parts.

This is Hatchbox PLA and a printer fairly close to stock with fairily stock settings. I cannot find the basket-weave surface on this cylindrical part though I have seen this on other parts.

What variable should I change to try to _cause_ the problem. That test may narrow something like root cause. One thing I noticed is that since this was only a single wall it becomes the one and only 'outside' so the entire print runs at low speed.

this print had no corners, no infill, all low speed. I was thinking I should add a corner or two to this part and see if this causes linear advance to kick in and for more interesting things to happen.

Re: Any response from Prusa on the inconsistent extrusion?

I just printed a little cylinder vase-like part and I sliced it with the special mode for single-wall parts.

This is Hatchbox PLA and a printer fairly close to stock with fairily stock settings. I cannot find the basket-weave surface on this cylindrical part though I have seen this on other parts.

What variable should I change to try to _cause_ the problem. That test may narrow something like root cause. One thing I noticed is that since this was only a single wall it becomes the one and only 'outside' so the entire print runs at low speed.

this print had no corners, no infill, all low speed. I was thinking I should add a corner or two to this part and see if this causes linear advance to kick in and for more interesting things to happen.

That's an interesting result. Perhaps it has something to do with either jerk or acceleration or maybe even just speed? On a cube the speeds can get higher than on a similar sized cylinder, since the straight lines allow for continued acceleration in just one direction, whereas on the cylinder it's constantly varying.

Or maybe there's enough noise on a cylinder's surface anyway that it effectively hides the effect.

As to linear advance, I don't believe it's automatic. Rather, it's a number you have to explicitly set using gcode.

Re: Any response from Prusa on the inconsistent extrusion?

[...] This is Hatchbox PLA and a printer fairly close to stock with fairily stock settings. I cannot find the basket-weave surface on this cylindrical part though I have seen this on other parts.

What variable should I change to try to _cause_ the problem. You don't have to do anything. Print in a high-gloss black or silver for best contrast, although you'll see it in any glossy surface. Hold the part horizontally under direct light from above so no light is shining on the vertical surface that printed as the side of the object. Make sure it's oriented so the sides are aligned as printed. Now slowly rotate the object back until the light starts to pick out lines. On a cylinder, it's going to be hard to see the side-to-side inconsistencies, but you will see some layers popping out more than others and you may see some of the un-evenness from side-to-side. It's a lot easier to see on flat surfaces printed with the same parameters.

That test may narrow something like root cause. One thing I noticed is that since this was only a single wall it becomes the one and only 'outside' so the entire print runs at low speed.

Look at the cubes I posted pics of previously. Those were all single outer perimeter prints with no infill. You do get less of an effect with vase mode, but it's still there.

this print had no corners, no infill, all low speed. I was thinking I should add a corner or two to this part and see if this causes linear advance to kick in and for more interesting things to happen.

You can, but keep in mind that Prusa is already running with the issue. We're just having fun here. I see it on every part I print, regardless of size.

Here's a recent print I did for testing. If someone had told me 4 months ago I'd be able to print with this quality with no experience, I'd have been thrilled:

Not perfect by any means, but a pretty decent print. Ah, but now we're looking for the issue. Change the lighting and you get:

Same print is now crap, and some guys $200 printer does better, lulz. It is very subjective. Like I said, it's like Megan Fox's thumb. If you want to find imperfections, you can. Taken from a distance, they're pretty minor.

I did finally find examples of print quality on some of the other printers that the Prusa Mk3 is being compared against. Check out this video. Ignore the thumbnail of the scrawny shirtless guy (why the hell did he think THAT was a good idea?) and watch the Alphawise U20 and CR-10 examples carefully. Throughout, he is praising the print quality on both. Now if you pause at a good point, you'll see something like:

Better? The lighting is difficult and the images blurry, but what I'm seeing confirms what I've read. The crispness of the Mk3 makes these defects pop. On these others -- at least in this example -- the overall print isn't as sharp, so naturally, surfaces don't catch light the same way. I'm not saying there's not an issue that can't be improved. I'm just remaining very skeptical of the claims of "smooth as a baby's backside" praise for some of the others in comparison.

I've yet to see an objective comparison photo of the Mk3 against others with both samples held in identical lighting at identical focus. No funny shadows over one or the other, so slightly different angle. Same print, same light, same angle.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any response from Prusa on the inconsistent extrusion?

I really wish we could get some communication. 85,000 printers sold and they can't even just drop a line about what's going on. Even things like a modified einsy housing are 6+ months and waiting. The x idlers are supposed to be redesigned .... sometime. 3dp moves too fast for things to move this slow.

Re: Any response from Prusa on the inconsistent extrusion?

Prusa has responded in the GitHub thread that they are looking at it, and Jo confirmed as much in Tom's video last week. I think they've learned the hard way that they need to manage expectations. If they say "we're working on it and expect a fix this week", then can't deliver, they'll get beaten up. They're keeping it low key, and when there's an answer, there's an answer. Considering how subjective this one is, I'd be curious to see where it ranks in their priorities. It may be in the "urgent but not important" category compared to other issues.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any response from Prusa on the inconsistent extrusion?

Considering how subjective this one is, I'd be curious to see where it ranks in their priorities. It may be in the "urgent but not important" category compared to other issues.

probably LOW - Compared to say, making an SLA machine instead, filament and MMu.... seems like they're adding more products to their lineup while still keeping insane lead times.....