Re: Any response from Prusa on the inconsistent extrusion?

What I'd most like to see is a fixed target, a print done using (ideally) a Mk2 that is "correct" that we can use to judge whether/how the Mk3 results are different. I see plenty of Mk3 prints with specific filament under specific lighting at specific angles to show an effect, but nothing showing what it "should" look like. To be fair: We'd need a lighting and stand jig to ensure consistency, but at this point, any target would help judge the severity of the issue.

I think if you guys want to make progress on this you need to post a photo of each test cube individually together with the filament and all settings you used to produce that. Then see if others can reproduce it exactly the same, or whether theirs is different. [...]

A tip for anybody wanting to compare two prints: Stack them vertically. The effect really varies as you turn shapes horizontally, so it's hard to get 2 in frame showing the same lighting. Vertically, it's easier to ensure the same lighting from above.

Unfortunately, the only old print I have was the little 20mm cube I did when I first received my Mk3. I see a marked improvement in recent months, but whether that's due to firmware updates (2 applied recently), software updates (moved between Simplify 3D, Cura & Slic3rPE betas) or me simply getting smarter, I can't say.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any response from Prusa on the inconsistent extrusion?

I forgot to mention: people should post to thingiverse the model that they're using too, and a link to it here. There needs to be a common anchor in order to try reproducing people's results.

Anyhow, that's all I have to say. If people just want to showcase their bad prints, well, I have made plenty of those too! However, the trick is figuring out how to get past that and then on to a good print. As it stands, people just aren't providing enough info to either (1) reproduce their problem, or (2) provide them with good feedback on how to make it right.

We're lucky in that we all have more or less the same hardware, so exactly reproducing a problem should be easy. One things is for sure: if the Prusa people can't figure out how to exactly reproduce your problem, to establish that it really is a problem, you can bet they're not going to be doing anything about it. On the other hand, if three independent people on this thread can all reproduce it, then that carries some clout worthy of attention.

Re: Any response from Prusa on the inconsistent extrusion?

[...]I printed it using a clear PETG at 230C with a 0.4mm nozzle, extrusion width of 0.75mm, and a print speed of 1000mm/minute (which is, admittedly, pretty slow). No linear advance.

In vase mode?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any response from Prusa on the inconsistent extrusion?

[...]I printed it using a clear PETG at 230C with a 0.4mm nozzle, extrusion width of 0.75mm, and a print speed of 1000mm/minute (which is, admittedly, pretty slow). No linear advance.

In vase mode?

Actually, no. I didn't use vase mode. I suppose maybe I could have.

Re: Any response from Prusa on the inconsistent extrusion?

What I'd most like to see is a fixed target, a print done using (ideally) a Mk2 that is "correct" that we can use to judge whether/how the Mk3 results are different. I see plenty of Mk3 prints with specific filament under specific lighting at specific angles to show an effect, but nothing showing what it "should" look like. To be fair: We'd need a lighting and stand jig to ensure consistency, but at this point, any target would help judge the severity of the issue.

A tip for anybody wanting to compare two prints: Stack them vertically. The effect really varies as you turn shapes horizontally, so it's hard to get 2 in frame showing the same lighting. Vertically, it's easier to ensure the same lighting from above.

Good suggestions! I second that.

[Edit: In this video:

Prusa says the inconsistent extrusion issue is caused by the teeth on the extruder digging into the filament, I guess resulting in a jerky feed (?) of the filament into the extruder. In the same video, Tom Sanlanderer says that he's seen it on the MK3, but also on just about every other 3D printer also. I guess some of you may beg to differ with him on that.... Prusa said he would be posting an article about it in a couple of days, but that was about a week or so ago. ]

Re: Any response from Prusa on the inconsistent extrusion?

I forgot to mention: people should post to thingiverse the model that they're using too, and a link to it here. There needs to be a common anchor in order to try reproducing people's results.

What really should've happened from the outset is one (and only one) model be used by everyone, along with some method to using and modifying slicer settings. Otherwise the whole exercise is rather futile. But this has now dragged on for months with people still arguing about what is or isn't considered "inconsistent".

As you say, it's easy to print a crappy print, it doesn't take many settings changes to make that happen 😉

Re: Any response from Prusa on the inconsistent extrusion?

[...] Tom Sanlanderer says that he's seen it on the MK3, but also on just about every other 3D printer also.

It's worth emphasizing that Tom said that, not JP. JP pretty plainly stated his understanding of an issue and that they're working on it.[/quote]

We're well into the land of the subjective at this point. There no objective target that we're all working towards. A lot of the criticism seems to be made of Mk3 printed models in isolation. In the very few side-by-side snaps I've seen, some sort of layer lines are visible on all the models, and I've seen none that are 100% even from side-to-side. Nobody's going to confuse an FDM-printed surface with glass, at least not at this price point.

I do see the issue and it is definitely more pronounced on the Mk3 than others. Mind you, I suspect we're still talking < 10 microns. It's also clear that the lighting being selected is set up to emphasize these defects. (I've read up more on photographic lighting than I care to.) For me, and some percentage of the user base, this is a non-issue. For some other percentage, it's a problem. Fair enough. Prusa's working on it, so hopefully we'll all -- as well as the others who clone Prusa's work -- will benefit. A net win for all.

If somebody cares to nominate a model and perhaps the community identify a ranges of lighting and angles to try to objectively spot the difference, I'm all for it. Truth be told, though, at this point, JP & his team are on it, so I'm not sure we'll be contributing much. If we can be of assistance, I hope they put together some guidelines so we can crowdsource some of the tedious work.

In the meantime, if somebody can spot the difference at 4 feet in a side-by-side shootout under normal lighting conditions, I'll be impressed.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any response from Prusa on the inconsistent extrusion?

If somebody cares to nominate a model and perhaps the community identify a ranges of lighting and angles to try to objectively spot the difference, I'm all for it. Truth be told, though, at this point, JP & his team are on it, so I'm not sure we'll be contributing much. If we can be of assistance, I hope they put together some guidelines so we can crowdsource some of the tedious work.

The horse (or horses) have well and truly left the stable, been in and out of the barrier and done 3 laps of the course. 😆

PR was meant to have released an update about this just after the TS video. That should provide some info about where to take it from here.

Re: Any response from Prusa on the inconsistent extrusion?

I forgot to mention: people should post to thingiverse the model that they're using too, and a link to it here. There needs to be a common anchor in order to try reproducing people's results.

We already established there is an issue. See all the 602 posts on github.

But if you want a specific model here is one: https://www.thingiverse.com/thing:2892579

Combine that with harsh top down light.

This thread is about the lackluster response from Prusa.

Re: Any response from Prusa on the inconsistent extrusion?

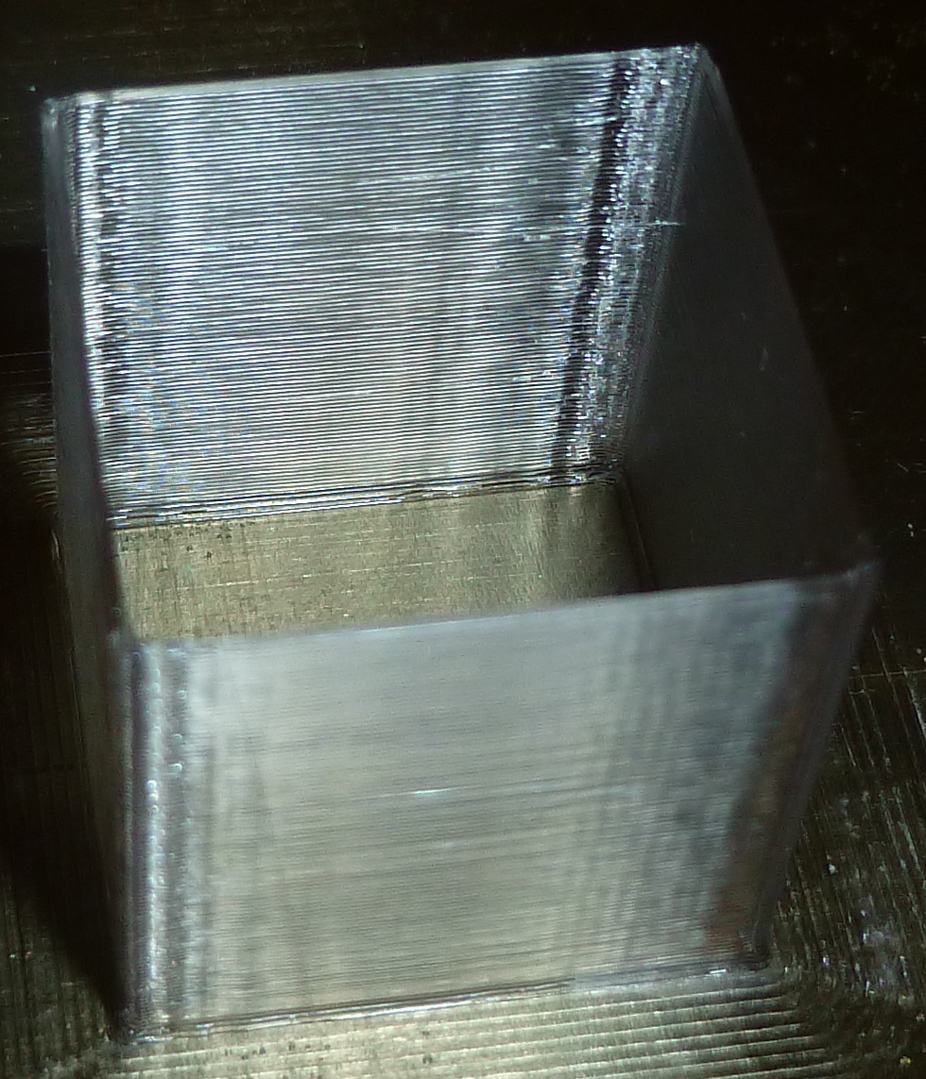

Here is a photo of a 1" test cube with 0.040" walls that I printed just as I finished building my Mk3. I had made no adjustments to the settings, had not even set the filament thickness, It printed this 1 inch cube with this accuracy. I was amazed.

I dont see a horrible basket weave effect here, though there may be a little of it. It is a nice print to my eye and perfect for what I will do with this printer.

That said, if something is going on that can be fixed, I am all for fixing it! Especially if the mk2 did (does) not exhibit the same behavior.

Re: Any response from Prusa on the inconsistent extrusion?

It printed this 1 inch cube with this accuracy. I was amazed.

I dont see a horrible basket weave effect here, though there may be a little of it. It is a nice print to my eye and perfect for what I will do with this printer.

If you want to see it, use a harsh light perpendicular to the lines until you get some slight shadows.

This has nothing to do with the size of the object printed.

Re: Any response from Prusa on the inconsistent extrusion?

If you want to see it, use a harsh light perpendicular to the lines until you get some slight shadows.

Yep. Light from above to the front is the key. This is actually a well-known aspect of lighting in portrait photography. Light from angles creates shadows, which makes defects more visible. To make something (or someone) look "good" (even), light from the front. Light from the side or (in this case for horizontal banding) top to emphasize textures (or wrinkles). I hold the object with the X axis (layer lines) horizontal from left-to-right, then stand under direct light and start rotating it around the Y axis, tilting it back and forward. At a specific angle, layer lines and any imperfections really pop out.

This has nothing to do with the size of the object printed.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any response from Prusa on the inconsistent extrusion?

I forgot to mention: people should post to thingiverse the model that they're using too, and a link to it here. There needs to be a common anchor in order to try reproducing people's results.

We already established there is an issue. See all the 602 posts on github.

But if you want a specific model here is one: https://www.thingiverse.com/thing:2892579

Combine that with harsh top down light.

This thread is about the lackluster response from Prusa.

OK, I printed the model you linked in a clear PETG at 230C using my copper Volcano at 200mm/sec print speed, no linear advance, using a 0.4mm copper nozzle, at 0.48mm extrusion width, and at 0.2mm layer height. In addition, I'm using a Micro Swiss heat break. This was the harshest light I could work out with my camera:

Bear in mind that this is a magnified image. I don't see much problem here. I do see artifacts, but not really a consistent pattern of the type described. I would say that the other types of print artifacts are more dominant.

Unfortunately, I don't have an MK2 to compare a print in the same material against, so I guess I can't help any further.

I hope you find the satisfaction you're looking for.

P.S. FWIW, the smoothest prints I've ever gotten have come from printing at a 0.1mm layer height using a 1.2mm nozzle. Those came out very, very smooth indeed. So, if smoothness is what you're after, then if worse comes to worst, you might try that.

Re: Any response from Prusa on the inconsistent extrusion?

david.f42, I don't see the problem much at all when I print PETG, but I see it when printing PLA. Some users are working under the theory that the tight grip of the Bondtech gears on the filament and the short path from the gears to the nozzle are causing the bulk of the inconsistencies. This isn't conclusively proven but if this is correct then it makes sense that PETG may be not affected as much.

One, the gear teeth deform the filament as they bite into it, creating a repeating pattern of slightly wider and narrower segments, so the nozzle pressure goes up and down in a pattern matching the teeth of the gear. Since PETG is more resilient than PLA, it doesn't suffer this effect as much. You can see this by running some PETG and PLA through the gears and pulling it back out. The PETG is noticably less deformed and doesn't show the teeth marks as much as the PLA.

Two, the tight grip on the filament followed by the short filament path work to amplify any inconsistencies in stepper movement. PETG, being more flexible and springy than PLA, acts like a spring which dampens small jerky movements, while PLA being more rigid transfers those movements directly into the nozzle. This also explains why Bowden printers tend to have smoother extrusion: the long length of filament between the gear and the nozzle works like a giant spring that absorbs sudden changes.

Re: Any response from Prusa on the inconsistent extrusion?

Thanks! That's the best explanation of what's going on that I've heard so far.

Re: Any response from Prusa on the inconsistent extrusion?

so..that´s it...?

Re: Any response from Prusa on the inconsistent extrusion?

Yep, that's it. Again, I liken it to a mild case of tinitus. You could have it and never know. It's entirely subjective. It's a definite issue, it's observable and Prusa is looking at it. If they can improve it, that would be awesome. Of course, Cura added a "fuzzy skin" feature to provide more texture on external surfaces, so perhaps Prusa can master it and turn this into a "perimeter skin texture" feature.

so..that´s it...?

I don't want to downplay it. If someone owns a Mk2 and is getting noticeably different results on a Mk3, that's a concern, and Prusa continues to lead the way for affordable print quality. I'm all for developing a comprehensive understanding of the problem, especially now that we're at the point where the average hobby printer is dealing with things like 0.25mm nozzles and 0.05mm layer heights. It's an amazing problem to have compared to where things were when I started looking seriously at a 3D printer several years ago.

In reality though, if you thought you were getting great prints before, you're still getting great prints. In the future, whenever I read about this sort of thing, I'm going to ask for some objective means of measurement. A consistent model, print settings and lighting. A bunch of worst-angle shots at intentionally bad angles with poor lighting for even an expert photographer isn't going to send me into a panic. Show me examples of "good" and "bad" -- an actual comparison under comparable conditions -- with consistent parameters so I can judge for myself.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any response from Prusa on the inconsistent extrusion?

Your layer seam seems to be at the back-right perimeter, and unfortunately, that's the clearest surface. The inconsistency is in the individual layer lines from side-to-side. You'll see a bit of reflection on one layer at one side, diminishing as you move to the other. This has been described as "basektweave". To really judge, we'd have to see a comparable shot, and none seem to be forthcoming. I've yet to see a glass-smooth FDM-printed surface, and all seem to have some inter-layer distortion. It's all very subjective, and anybody with a point to make can find supporting things to point out.

[...] Bear in mind that this is a magnified image. I don't see much problem here. I do see artifacts, but not really a consistent pattern of the type described. I would say that the other types of print artifacts are more dominant.

I wouldn't really care, but looking back, I'm a bit pissed off at all the snide "cancel your order" advice I got back when I ordered my Mk3. Even now, there are people dropping into discussions making this out to be a major problem even for people just looking for advice on their 1st printer. It's a bit like when fans of the unknown indie music group see the band make it big and get resentful that they don't play the cafe circuit anymore.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any response from Prusa on the inconsistent extrusion?

To test the theory, you could tighten the hell out of your extruder idler, so that it gives really deep bite marks to the filament. Do a print that way, then loosen the idler as much as possible and do a print in the loosened state. If the observed effect diminishes, then you will have confirmed the root cause is indeed the idler teeth gnashing into the filament.

I hope that's what it is. There are probably good solutions for such a problem, like maybe using toothless rollers that are simply clamped a little tighter around the filament.

Re: Any response from Prusa on the inconsistent extrusion?

I posted it a few comments back as well, but did not see a comment from anyone. Is built up twist tension in the filament a possible source of the variability? uilding, relieving, building, relieving, etc, as the filament moves through the gears?

I proposed a simple experiment to test: remove a long enough length of filamet off the spool so it wont twist while being sucked into the extruder, and see if the print quality changes. Maybe I will try now....

edit: I just tried a print with loose filament supply, and no change, same basketweave pattern. The print still looks good to my eye, and I dont consider it a problem. If it can be improved I would improve it, if it cant, no big deal either.