Re: Any response from Prusa on the inconsistent extrusion?

Bobstro. Fan boy or employee?

Re: Any response from Prusa on the inconsistent extrusion?

Making suggestions to try to help people with issues rather than jumping on a dozen threads with unhelpful comments. Troll?

Bobstro. Fan boy or employee?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any response from Prusa on the inconsistent extrusion?

Correct me if I'm wrong, but the latest seems to be that models prior to the Mk3 also have the issue. The same models that has been praised for print quality for some time. If people are going back and re-examining older prints and realizing that, under certain lighting, they can see the issue, were they not good prints to start with?

What bugs me is if that's the case Prusa didn't do his research. Also, this seems to be an issue with this extruder. Other official Bondtech extruders work fine.

A lot of people spent a lot of time (and still are spending a lot of time) trying to narrow this down. JP acknowledges as much in the recent video interview. To fix a problem, you first have to define it, and a lot of unrelated issues have been thrown into the mix. They're working on it, and they have a strong track record of open sharing information so the entire community, not just Prusa owners or people with current Prusa maintenance contracts, can benefit. Not sure what more you can reasonably ask.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any response from Prusa on the inconsistent extrusion?

At 13:08 in this video, he states: "... we are now experimenting with how to reduce that, different shapes of teeth and when we have that ready, we will upgrade it." (Or words to that effect.)

[...] Do you know something I don't?

All I know is they are preparing a blog post about the issue.

Of course, talk it cheap, and it hasn't been fixed until they do this, but Prusa seems to have a pretty good history of shipping parts necessary to resolve issues. If it turns out to be a 3rd party part -- which seems to be the culprit according what I've read -- it will be interesting to see what their response is, as well as that of every other printer manufacturer using the same parts. Prusa's the whipping boy on this one, but seem to be willing to take it and contribute fixes back to the community. As a Mk3 owner, I'd like to see it fixed. As somebody new to the community, it's refreshing to see a small company go to such lengths to maintain the open source philosophy. I hope it works out.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any response from Prusa on the inconsistent extrusion?

....

I don't mind the problems. What got me heated was that they minimized the problem first and made me feel silly that my $750 MK3 shouldn't have the same print quality of a stock CR-10 (which prints great from what I've seen)

Others who've had the issues also are MK2S owners and said that their MK3 prints are inferior, side by side.

Once again, I don't mind the issues if Prusa treats every customer with an issue seriously and works towards a solution. Tom and Jo's response made me feel like I was silly.

The launch of the MK3 has been less than stellar. From shipping units out with soft rods, defective PSUs, no powder coated sheets (I'm fine with but the communication sucked big time for early buyers like myself).

Re: Any response from Prusa on the inconsistent extrusion?

I've read through the github thread. I haven't spent time on the discord server. I have not seen any case where Prusa minimizes the issue, other than saying that many issues cited prove to be something else. A lot is open to interpretation on the written web, so if somebody takes it differently, fair enough.

I don't mind the problems. What got me heated was that they minimized the problem first and made me feel silly that my $750 MK3 shouldn't have the same print quality of a stock CR-10 (which prints great from what I've seen)

Others who've had the issues also are MK2S owners and said that their MK3 prints are inferior, side by side.

This is where I'm no longer so certain. It sounds like, now that the issue is being narrowed down, other printers besides the Mk3 do seem to have the same issue. If they use the same parts, that would be expected. Unfortunately, I don't have different printers to compare, but I'm very curious to see how this turns out. It will be great if Prusa working on the Mk3 produces a fix for a problem that users of other models didn't even realize they had.

Once again, I don't mind the issues if Prusa treats every customer with an issue seriously and works towards a solution. Tom and Jo's response made me feel like I was silly.

Tom is a YouTuber. I like the guy and have learned a lot from watching his videos. He and JP don't see to have the best chemistry in that video, so it did sound like Tom was trying to be lighthearted. JP said nothing more than "yeah" throughout the intro bit. It sounded (to me) more more like JP was anxious for Tom to finish talking so he could make his point. He seemed to want to get past it and say his piece without over-committing or being too cheerful lest there be another onslaught of criticism. [Edit: Kudos to Tom for putting the outtakes in for all to enjoy.]

The launch of the MK3 has been less than stellar. From shipping units out with soft rods, defective PSUs, no powder coated sheets (I'm fine with but the communication sucked big time for early buyers like myself).

I ordered a Mk3 with MMU the 1st week of January, so I am familiar with these frustrations. That said, I've never felt kept in the dark, although Prusa's missing dates was aggravating. I am glad for others to see the Mk3 queue shrinking, and was relieved to be able to finally order a sticker PEI plate. Things do seem to be getting better day-by-day. Being an early adopter usually sucks to some degree, and this has't been any different than any other rollout I've experienced.

I'm not trying to say JP is the only one working on things that benefit our community, but damn I'm glad they're working on the issues I have with my printer. From what I've read, support is spotty at best with a lot of the inexpensive printers.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any response from Prusa on the inconsistent extrusion?

I would like to know why in Slic3r PE (1.39.1).... the starting Gcode is set at 95% FR..

I actually read the explanation somewhere since forgotten -- perhaps in the release notes. It was thrown in to compensate for (obviously) extrusion issues. It was driving me crazy, and I hunted it down and removed it from my profiles. I believe it is still present in 1.40.1-beta+ as shipped. I'm not sure those sorts of tweaks that are hidden from the main settings pages are really a good idea. The damned dependencies drove me crazy until I figured them out. Definitely the sort of thing that could be cleaned up in the user interface.

M221 S{if layer_height==0.05}100{else}95{endif}

Perhaps better to start another thread on this. I think your question was lost in this one.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any response from Prusa on the inconsistent extrusion?

I ordered a Mk3 with MMU the 1st week of January, so I am familiar with these frustrations. That said, I've never felt kept in the dark, although Prusa's missing dates was aggravating.

I ordered in October when the website still said they were expecting to ship in November. We were kept in the dark and then first units started to ship around December 1st and we found out that they wouldn't ship with the powder coated sheets. The communication was very late and a lot of people were anxious to get their printer.

I invested in the MMU V2 and I'm confident that they're working hard and will figure out the extrusion issue, even if it will be resolved in the MK3s update.

Overall, I think Prusa has room for improvement when it comes to communicating with their customers. Tom has a large fan base but he shouldn't be your communication delivery vehicle. I think Prusa would greatly benefit for hiring a PR person, even if it's just a college kid dedicated to delivering excellent articulate customer service and news articles. It would only strengthen their brand.

Re: Any response from Prusa on the inconsistent extrusion?

[...] I ordered in October when the website still said they were expecting to ship in November. We were kept in the dark and then first units started to ship around December 1st and we found out that they wouldn't ship with the powder coated sheets. The communication was very late and a lot of people were anxious to get their printer.

Ah, I was reading up on the Mk3 at the time and the Make: shootout convinced me. I sat on the fence through Christmas, and only ordered in early January. I imagine running into the cold stark reality of production at volume was a learning experience for Prusa. I'm glad to see a small tech company making some adjustments in 6-8 months. Elon Musk's crew doesn't seem to be having much more luck, and their customers have paid thousands to get on the Tesla 3 waiting list. I can say that, by January, I had a pretty good idea of what to expect, although it was a bummer every time I read of another delay. I think it was around 90 days for the Mk3 to arrive, during which I received the updates on the powder-coated beds and MMU re-design. Still want those!

I invested in the MMU V2 and I'm confident that they're working hard and will figure out the extrusion issue, even if it will be resolved in the MK3s update.

I was really surprised to get a $50 credit back on the MMU1 order. I hope they don't wind up asking for it back! It will be a bummer if the fix for the extrusion issue is a discount on a Mk3s kit.

Overall, I think Prusa has room for improvement when it comes to communicating with their customers. Tom has a large fan base but he shouldn't be your communication delivery vehicle. I think Prusa would greatly benefit for hiring a PR person, even if it's just a college kid dedicated to delivering excellent articulate customer service and news articles. It would only strengthen their brand.

On that, I agree. Still, I'd rather have the competent techie fixing problems with poor communications skills than the slick shill calming me down while never delivering. It sucks and it's frustrating. It's also really great to be using a product with these capabilities for this price, and knowing there's still more to come.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any response from Prusa on the inconsistent extrusion?

I have since switched to a titanium heat-break and copper heater block. Removed the 95% flow in all start codes, and it prints fine for me. I do not see the same inconsistencies nearly as much

I would like to know why in Slic3r PE (1.39.1).... the starting Gcode is set at 95% FR..

I actually read the explanation somewhere since forgotten -- perhaps in the release notes. It was thrown in to compensate for (obviously) extrusion issues. It was driving me crazy, and I hunted it down and removed it from my profiles. I believe it is still present in 1.40.1-beta+ as shipped. I'm not sure those sorts of tweaks that are hidden from the main settings pages are really a good idea. The damned dependencies drove me crazy until I figured them out. Definitely the sort of thing that could be cleaned up in the user interface.

M221 S{if layer_height==0.05}100{else}95{endif}

Perhaps better to start another thread on this. I think your question was lost in this one.

Anything can be made better

https://www.myminifactory.com/users/Joe%20Prints

Re: Any response from Prusa on the inconsistent extrusion?

I have had mostly good experiences with my MK3 that I purchased as a kit (quite early). Recently I started moving from PLA to PETG so that I could print some backup plastics of the MK3 and start experimenting.

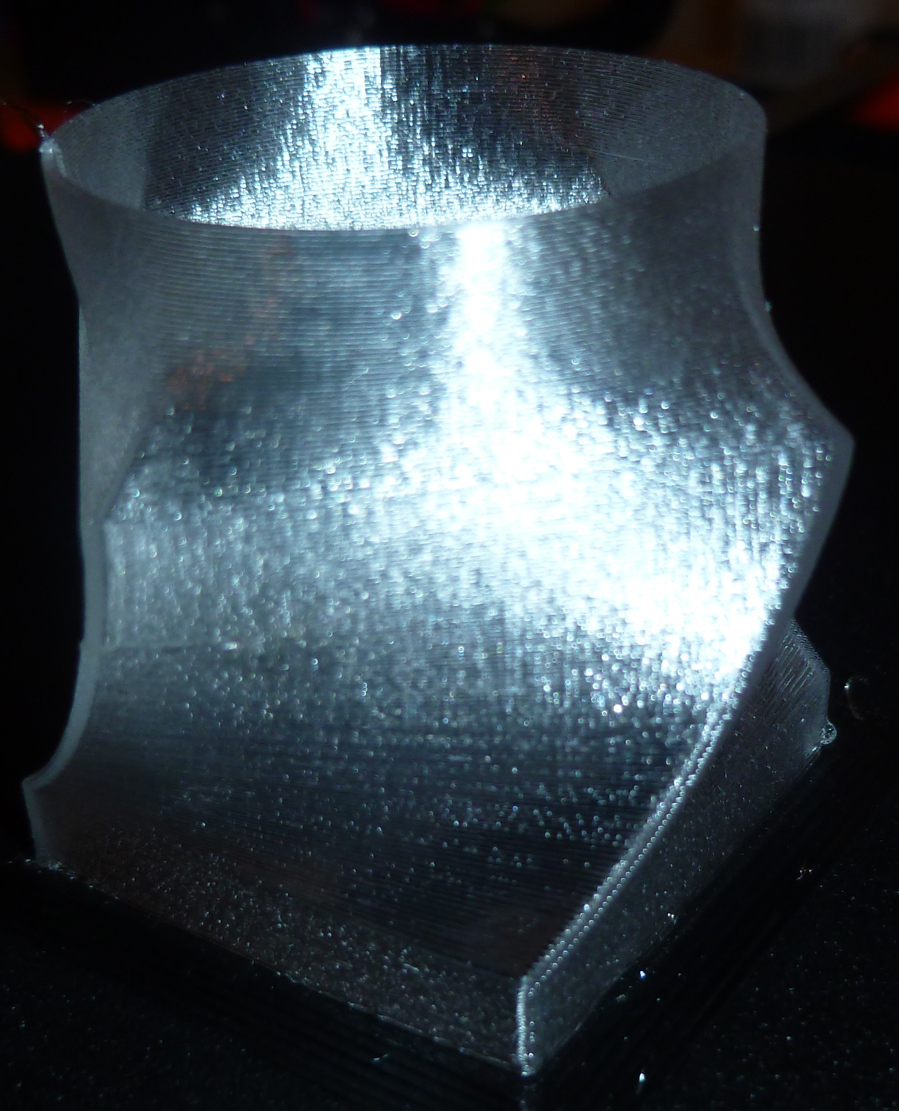

I have noticed the complaints about inconsistent extrusion so I went about looking at my parts to find it. I can see this if I shine a LED flashlight at a very shallow angle across the surface.

I found the name "basket weave" in a post by member david.f42 and I found this to be a very good description of the look. To my eye it almost appeared as if the plastic is a different color (more white) in these areas but that does not seem right. Is there a particular color that would show the issue more or one that would show it less?

Other than this look the parts printed in Hatchbox PETG at 0.2mm layer height are very high quality.

Re: Any response from Prusa on the inconsistent extrusion?

Dark glossy finishes and silver really highlight it. With other filaments, I have to work a bit to spot it. Lighter non-sparkly or matte finishes hide it nearly completely. I've got 20mm cubes printed with identical settings in silver and orange. Holding both together, I can spot it on the silver with a bit of twisting and turning. With the semi-matte orange, I can't see it at all.

[...] I found the name "basket weave" in a post by member david.f42 and I found this to be a very good description of the look. To my eye it almost appeared as if the plastic is a different color (more white) in these areas but that does not seem right. Is there a particular color that would show the issue more or one that would show it less?

Here are pics of some single-perimeter 20mm cubes in bright sunlight. The separated cube at the right is one I printed in Prusa silver PLA the 1st week after my printer arrived. The others are recent (3 months later) with a variety of filament, layer height and nozzle settings. (Unfortunately, I'm out of Prusa silver and can't afford another with shipping.) The difficulty trying to get the effect to show up at all illustrates how "big" of an issue this is. These are crap test prints, and I have no illusions that I'm a 3D printing stud. Keep in mind, these are 20mm in real life. This view is likely magnified on your screen.:

Obviously, something is there. It's a question of how big a deal it really is, and that varies by individual. I'll print some glossy PETG cubes for comparison later. I'd be very interested in comparable displays printed with other printers showing the glass-like finish that's being attributed to them.

Other than this look the parts printed in Hatchbox PETG at 0.2mm layer height are very high quality.

I have to be quite close to spot it even on silver. From a distance of more than 1-2 feet, the finish looks very nice. It's very smooth to the touch at low layer heights. Anybody not looking for the issue would probably remark at how smooth the surface is at 0.10mm layer height. The parts are sound and strong (assuming I print them correctly). If I were doing artwork or jewelry, it might bug me more.

I did have to chuckle when I saw Cura has a new(ish) "fuzzy finish" feature for those that want to introduce more textures to their prints for things like grips.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any response from Prusa on the inconsistent extrusion?

Prusa talks about it near the end of this video:

Basically, it is caused by how FDM printers work. They are working on how to make it go away, though. Listen to the video and not just take my way too simplified explanation, please.

Re: Any response from Prusa on the inconsistent extrusion?

For what its worth, i finished my build on sunday, i have printed only 3 things so far, 2 small sub 2 hour prints and one very large 14.5 hour print. And they all show signs of this inconsistent extrusion. I wouldnt call it bad and i am happy with the quality of the prints more so because im printing useable parts not models that need to be perfect, but it is there and it is not there as badly on many other prints i have seen before from other printers. So for sure an issue thats worse on the mk3 than other brands.

Re: Any response from Prusa on the inconsistent extrusion?

I'm printing a hollow 1" test cube right now on mine to see if I have this extrusion issue going on. I will duplicate it with PET-G and maybe even try ABS for the first time, to see what I can see. I will try to post photos for the first time when I have some results.

Maybe others would do the same with their printers? It is curious to me that some (or at least one) have claimed that the problem was not noticed when their printer was new, but developed over time. Is something wearing out, etc?

Re: Any response from Prusa on the inconsistent extrusion?

I'm printing a hollow 1" test cube right now on mine to see if I have this extrusion issue going on. I will duplicate it with PET-G and maybe even try ABS for the first time, to see what I can see. I will try to post photos for the first time when I have some results.

Spoiler alert: You have it. Every Mk3 has it. Do me a favor though. Before you go specifically looking for it, hold your print at arm's length and judge whether it's a good print. How's the surface feel? How's it look in normal conditions? Would you say it's a good print?

Now hold it up close under direct light from above until you spot it. With a glossy surface, you will. Just keep turning and twisting it slowly until the surface pops. Is it now a worse print? Does it feel any different?

It's an undeniable issue. It would be great if Prusa can figure out a tweak. I think the big question is whether it's something we see because everything else is so crisp, or a critical flaw. I've heard from a CR10 owner that says that's the issue. I've heard from others who have a Mk2 and Mk3 and say it's horrible, and others who say it's not an issue. I can understand why someone dependent on surface quality might be upset, but I don't think it's an issue that would cause 90% of users to declare their printer unusable... unless they specifically went looking for it.

Here are a couple of additional snaps with some glossy PETG and funky translucent PLA added. Original cube offset at right as printed 1st week it arrived, others printed 3 months later.:

This is the best shot I could get with 4 glossy materials under the same light. Again, orignal print offset to right, newer prints to left:

Maybe others would do the same with their printers? It is curious to me that some (or at least one) have claimed that the problem was not noticed when their printer was new, but developed over time. Is something wearing out, etc?

I've got dozens more if anybody is really bored. What I'd really like to see is a similar series in harsh light done with other printers. I've seen various samples, but they're very specific in showing the Mk3 sample, not so much the others.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any response from Prusa on the inconsistent extrusion?

I actually noticed it by feel before I saw it.

looking straight on the print looks ok, but the surface felt very rough compared to the same print with the same filament done on the mk2.

using the infamous angle shot, it became very, very clear there was a problem

I have printed hundreds of these on the mk2 & the surface finish felt & looked perfect by comparison

Re: Any response from Prusa on the inconsistent extrusion?

[...] I have printed hundreds of these on the mk2 & the surface finish felt & looked perfect by comparison

Would you mind posting a few pics of the Mk2 finish at the same angle (ideally, stacked with the Mk3 print) for comparison? I've got a good feel for what the Mk3 results are, but I'm trying to get a sense for what the target is.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any response from Prusa on the inconsistent extrusion?

FWIW, I notice this artifact when printing at low speeds without linear advance. Trying printing at faster speeds with linear advance. I don't recall noticing it then. Of course, don't forget to re-calibrate your extrusion multiplier when you do.

Re: Any response from Prusa on the inconsistent extrusion?

I think if you guys want to make progress on this you need to post a photo of each test cube individually together with the filament and all settings you used to produce that. Then see if others can reproduce it exactly the same, or whether theirs is different. Also, it seems as though some of these cube examples are illustrating different errors/effects that are somehow getting lumped into the same category. It may be that their root causes are different.

Anyhow, I thought it was on this thread that I saw a link to a thingiverse surface thest. I tried printing it, and it seemed to come out fine:

https://www.thingiverse.com/thing:2884669

I printed it using a clear PETG at 230C with a 0.4mm nozzle, extrusion width of 0.75mm, and a print speed of 1000mm/minute (which is, admittedly, pretty slow). No linear advance.