X-axis length

I have just assembled my i3 mk3, but it fails on the x-axis length self test.

I'm pretty sure that I have assembled it correctly (the x-gantry touches the z-gantries on both sides).

When I run the self test with serial port, I see that the printer thinks the length is ~227mm but the test expects it to be 255+-5 mm (from source code).

I just can't see how the x-axis can be ~20mm too short, the extruder reaches outside the build plate on both sides, and the build plate measured to be 250 mm.

I also don't think the belt is too lose, since missing a step would only make the axis appear longer.

Perhaps the conversion of steps->mm is wrong? I tried to do a factory reset in case there were a wrong factor in the e2, but still same result.

It is the correct motor running the x-axis as well.

Edited

Hmm, I just measured the diameter over belt in the x-axis pulley and compared it with the y-axis pulley, the x-axis had a larger diameter than the y-axis despite having the same step->mm conversion factor in the code. This is also consistent with the printer thinking the axis is too short.

Can I change the conversion factor in the E2, or do you have to send me a new one?

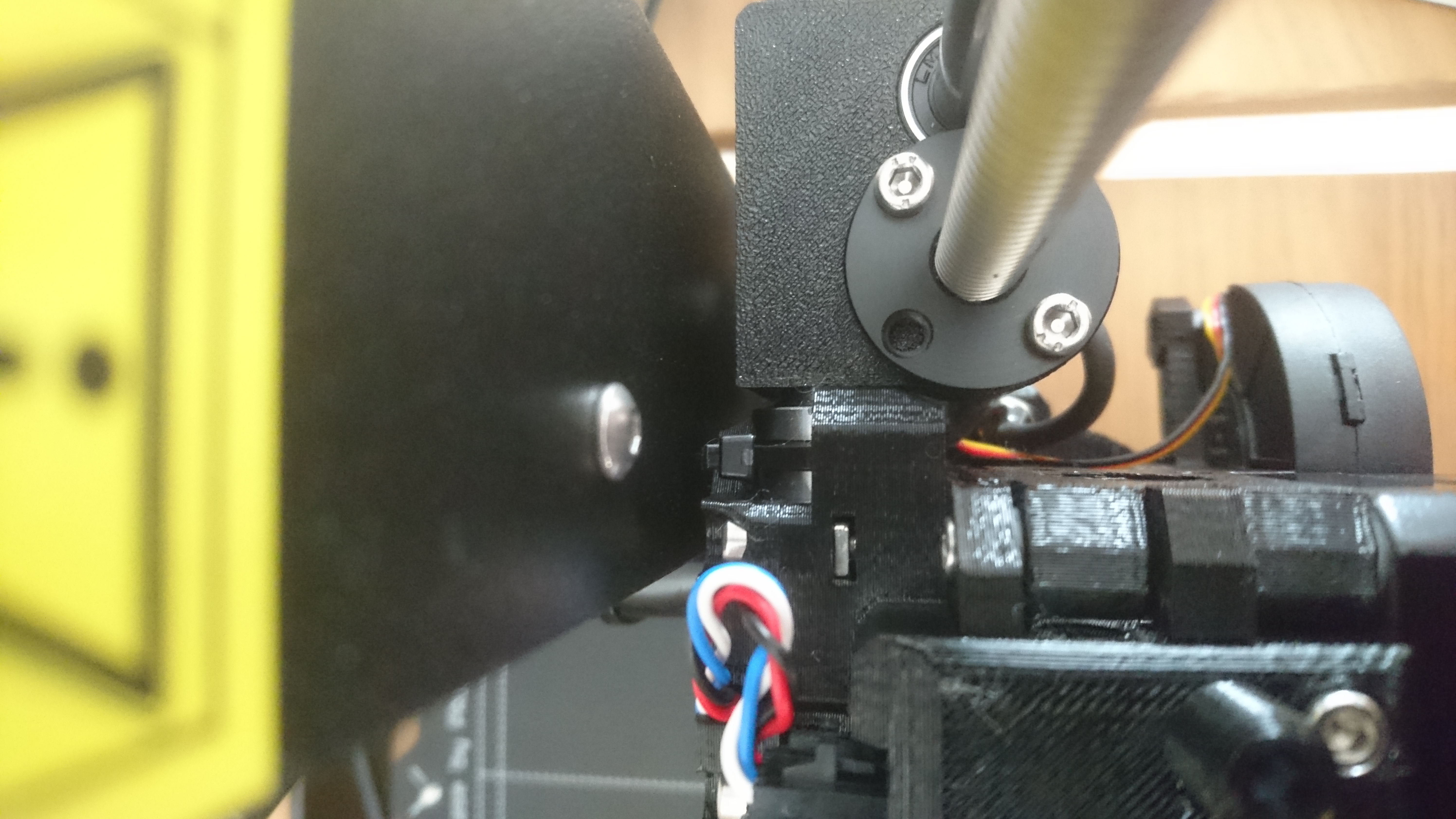

Right side:

Left side:

Re: X-axis length

You need to observe the extruder when it is performing the self test for x-axis. When it starts, extruder will go up on z-axis. If does not, you need to fix z-axis first. Next, it will touch the left side. it should be no sound. If it "bumps" with sound and it goes immediately on the other side, it is ok. On the other side with similar behavior, probably it will be ok. It means that your belt tension is on the limit (not tense enough).

If your extruder is stalling when it touches sides and straggling to go in oppostie direction i.e that your definitly need to thigthen your belt or check pulley motor . The extruder "thinks" that moves and goes in opposite direction and when it reaches realizes that distance is shorter then expecting. I think that this your case.

For other or similar case, I would suggest not to assamble printer completly. it is much better to have test plateform first. See attached image :

Re: X-axis length

Thank you for your interest my problem!

Yes, the extruder will go up 17 mm before the test. As I said, the x-gentry will touch the z-gentries on both side without a sound.

Here is a video when it does the test:

Re: X-axis length

Hi,

Well, when I watch I video, I can hear the sound when extruder touches the left side, on the right side no sound and when it comes back double click. The goal is to have no sound at all. Can you check the belt tension on your printer : Support -> Belt tension ?

Re: X-axis length

Thanks for the tip. I removed the pulley from both x and y axis and took a photo side by side, and they are not identical as you can see below.

The pulley to the left is from the x-axis and it has wider teeth than the other from the y-axis.

Edit: corrected left/right mixup

Re: X-axis length

I never had that problem. IMHO, they need to exactly the same ,otherwise instructions need to mention the difference. The best solution here is to contact support.

To check by yourself, mount the printer. Push the extruder completely on the left side. Power on. printer assumes this as 0 point. Use Move axis x from the printer menu to move completely to the right. It need to show 255. Repeat with the other pulley.

If you have another printer, I will suggest to print another back plate which will allow to change/tense belt without disconnecting your cables.

Re: X-axis length

I switched pulleys between x and y axis, and the x-axis length test passed (and the y axis test failed).

I contacted support and they will send me new pulley.

Thanks for your assistance and the backplane link, it looks great!