Wobbly sides

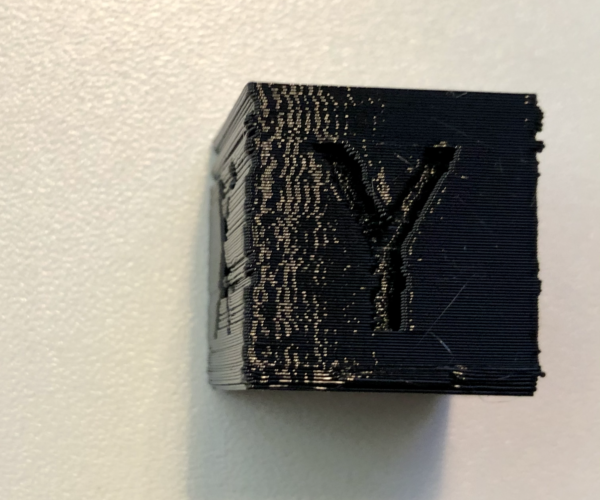

After assembling my new printer over the weekend, I'm trying to get it dialed in for printing PETG. I've printed the XYZ cube, and the corners are wobbly in a single direction. The X faces forward on the bed, and the wobbliness is visible when looking at it from the Y side (or the opposite side; just around the corner from the X side). Looking at the corners from the front (X side), they look quite sharp.

The belt tension, according to the support menu, is 250 for X and 267 for Y, which is within the 240 to 300 limit the manual advises. I'm therefore assuming that's not it, but who knows.

What could be causing this?

Best Answer by Neophyl:

Small layer shifts like that are often caused by the pully on the stepper not being tightened properly.

Each pully has 2 set screws. One should be tightened perfectly perpendicular to the flat on the motor shaft and only then the second grub screw (often called a lock or set screw is tightened to lock the first in place). If this is not done then over time it can loosen slightly and rock back and forth on the shaft slightly. As it gets looser the shifts get bigger until finally it just spins all the way around.

Given the shifts are on the Y axis you should check the pully on the bed stepper (its one reason those test cubes are marked for XYZ).

RE: Wobbly sides

Small layer shifts like that are often caused by the pully on the stepper not being tightened properly.

Each pully has 2 set screws. One should be tightened perfectly perpendicular to the flat on the motor shaft and only then the second grub screw (often called a lock or set screw is tightened to lock the first in place). If this is not done then over time it can loosen slightly and rock back and forth on the shaft slightly. As it gets looser the shifts get bigger until finally it just spins all the way around.

Given the shifts are on the Y axis you should check the pully on the bed stepper (its one reason those test cubes are marked for XYZ).

RE: Wobbly sides

Thanks, giving that a try!

RE: Wobbly sides

Also don't use the belt status numbers. I just learnt this myself and was getting 'slop' even though the numbers and belt looked good.

With the printer off put a pair of pilars on the motor spindle and hold the motor still... then try and move the extruder and see if there is any slop in the belt. If there is tighten it.

RE: Wobbly sides

Thanks for the heads up @cynan.

@neophyl, you were spot on! It indeed was the Y pulley.

RE: Wobbly sides

@roy_t

Good to know you got it sorted. As I said it’s a very common thing.

one thing you can do once you have the pulleys set up is take a thin sharpie and draw a line that goes from the motor shaft onto the pulley. That way you can see at a glance if it’s still aligned. More useful on the x axis than the y as it’s easier to see but still handy for both.