Whistle bridging problem

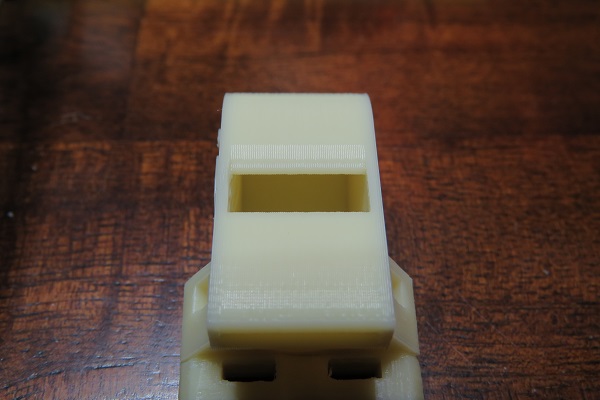

Finished assembling my Mk3 kit and I'm pretty impressed so far. One problem I've encountered is the bridging in the included whistle model. I've printed a couple copies now, and both show collapsed filament inside the whistle (see image). Does this indicate something needs to be tweaked? Is it expected that this model will print successfully on an MK3 with default parameters? I'm using the included filament ad the default 215c.

Thanks.

Re: Whistle bridging problem

a belt too tight? im guessing that is one direction. just an idea

I have a Prusa,therefore I research.

Re: Whistle bridging problem

Thanks. I guess that would be the X-axis belt; I can try adjusting. Why would a tight belt cause the bridging issue?

Re: Whistle bridging problem

Are you slic3r this yourself or printing from the provided gCode file on the SD card?

Re: Whistle bridging problem

I printed the whistle from the gcode without any issues. If slicing, you need to ensure the bridge detect is on and you adequately slow the printer when printing the bridges.

I do not see how belt tension would cause the drooping extrusions.

Re: Whistle bridging problem

That amount of sagging is not normal. Mine come out as expected using the pre-sliced model on the SD card. Did you try different filament? Another option is to slow down the printer as it gets near the top layer.

Steve

Re: Whistle bridging problem

Thanks for the replies. I'm just using the model included on the SD card and haven't sliced my own. I'm using the included gray filament; it's the only filament I have so far. Could it be the result of bad first layer calibration? I'd guess no since it's not the first layer...

Re: Whistle bridging problem

It's highly unlikely first layer issues cause drooping upper layers.

Since you mentioned a kit build: Do you see the centrifugal fan running after layer 1 is printed?

After layer 1 is down, both fans should be spinning at 100%. If the front fan is not spinning, you have something wrong there.

Re: Whistle bridging problem

Yep, the fan spins after the first layer. Pretty sure it's spinning at 100% based on the sound in comparison to spinning it up manually through settings. I also verified when spinning it up manually that it is blowing air across the nozzle, so it's definitely spinning in the correct direction.

Nozzle temp is set to 215. Is it possible I need to reduce this? 215 is the default I think, but the PLA spool gives a range of 200-220.

Re: Whistle bridging problem

Nozzle temp should be controlled by the gcode, 215/60 first layer, then 210/60 subsequent layers. Same goes for extrusion rates and print speeds. It really is pretty simple printing samples from the SD card. And all of them I've tried work very well.

This is a long shot, Try manually extruding some filament - look carefully at the flow. Does it stay the same 0.4mm diameter -- or -- is the filament expanding after it leaves the nozzle? Expanding is not good - usually caused by fingerprints or hand lotion on the filament. Handle everything by the edges, including the filament, the PEI sheet ... avoiding finger and palm prints is a hard lesson to learn.

The only other thing that comes to mind is the hot end is somehow tweaked/damaged and getting too hot. You can try reducing the temps using the TUNE menu as the print progresses. Drop it down to 190 and see if the bridging gets better.

Re: Whistle bridging problem

I manually extruded some filament (by changing the extruder "axis" in settings). The string came out to ~0.55mm measured with calipers. Although I measured the print outline of the planetary gear model that I printed last night at ~0.44mm, so the machine must be capable.

I tried the the nozzle temp at 200 and 190, both gave the same results. But when watching the bridging during the print I realized that the filament does actually seem to bridge fine from one direction to another, but when the print head changes direction to bridge another row it seems to pull the previous row along with it, resulting in the collapse.

Maybe the end of the bridge isn't adequately adhering to its anchor point? Or maybe this filament expansion is happening and the nozzle is grabbing onto the end of the bridge when changing direction? I'm not nearly experienced enough to know what the discrepancy could be.

We have a few Mk3s at work. I printed a whistle on one of them today and it was fine.

Re: Whistle bridging problem

Interesting. The material bridges, but doesn't stick at the far end.

My bet is still on bad filament. Maybe the temperature is too low for that roll. Or else it is under-extruding because the filament is a small diameter.

Borrow a spool from work and see if it changes anything.

Steve

Re: Whistle bridging problem

Well I had pretty good success printing a 100mm bridging stress test. So it can print bridges, just not whistles. I guess I'll just try again next time I get a new batch of material. Other prints are turning out good.

I found in the support section that the skew on my build is only 0.01, which seems pretty good.

Re: Whistle bridging problem

I still haven't thought of anything else but at least your bridges are nice

I have a Prusa,therefore I research.

Re: Whistle bridging problem

Hi jeremy.v7

Could you share your settings please,I would like test it by myself

You bridge is very long and nice

Bye

Re: Whistle bridging problem

Hi jeremy.v7

Could you share your settings please,I would like test it by myself

You bridge is very long and nice

Bye

I used the 100mm STL from here: https://www.thingiverse.com/thing:2754688

Sliced with slic3r using the optimal mk3 profile. I didn't change any other settings in slic3r or on the printer, as far as I'm aware.

Re: Whistle bridging problem

Thanks 😉

Re: Whistle bridging problem

Remember that bridges needs to work in all directions to avoid surprises.

Extruded filament should measure 0.400 mm or less. Gravity will usually stretch it before it hardens. If an extrusion is larger than the nozzle, moisture or some other contamination is having fun at your expense.

Re: Whistle bridging problem

So I brought my machine to work today to test with some of the filament here, and I think I've ruled out a problem with the material. I successfully printed a whistle on a work mk3 using some of the work filament, and then moved the filament over to my machine and witnessed the same failure as before. So debugging continues.

Is there a proper way to test extrusion diameter other than preheating and moving the E axis manually?

Re: Whistle bridging problem

have you tried the Prusa live 24-7-365 chat support.? if not I would provide chat support with a link to this thread and the pictures you have. we are just other users here some are quite expert.. others like myself muddle along learning and when we see something we have encountered before we provide what guidance we can but I think in your case I would take it to the the live chat support as a next step... the info in this thread should help them help you