whats the next option if support doesnt know whats wrong ?

i still cannot get a first layer down good no matter what i do, i tried texture bed, smooth bed, prusa filament, generic filament, petg filament, flexi filament, 0.4 nozzle,0.6 nozzle, live z adjust hundreds of times, new tube in hot end twice, new heater cartridge, temp sensor, re calibrated from scratch dozens of times, support has no more clues except try new heat paste which is another strip down 🙁 and they are only guessing at that, i really have no idea what else to do and have had nothing but trouble since i got this a few weeks ago, i was expecting it to be printing fine by now without any issues.

anyone got any last ideas to try before i have no choice but to send it back 🙁

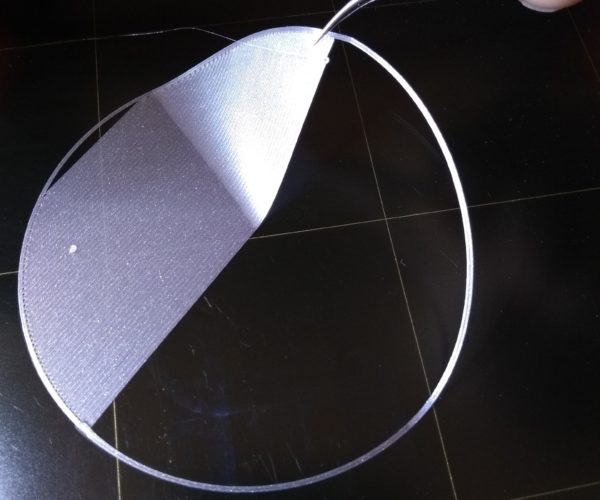

pic attached of results pretty much all the time, the odd time it prints good

im back home in 3 days so need to decide to keep at it or just send it back and forget about 3d printing

RE: whats the next option if support doesnt know whats wrong ?

Find a Prusa user near you and let him take a look.

RE: whats the next option if support doesnt know whats wrong ?

@lichtjaeger

thank you good idea, only one near me but have sent a message

RE: whats the next option if support doesnt know whats wrong ?

What is your printer sitting on? Is it on a solid floor like wood or concrete, or is it sitting on a desk/table on carpet? Does the desk have a wobbly leg? Without knowing what you've tried, maybe it is best to start at the absolute beginning. Make sure you have an absolutely solid surface sitting on a solid surface. Once that is done, run the initial setup tests then check the belt tensions under the support menu. Please post the results 😀

Is your printer grinding? Bearings squeaking? Motors smoking?

Step 1) Wash your Steel Sheet

Step 2) Return to Step 1

RE: whats the next option if support doesnt know whats wrong ?

@itcarsales

It’s on a solid wood base no movement at all , support went through the belt tensions and said they were fine, I have tried every thing possible I think lol , I’m starting to suspect something faulty on the printer

RE: whats the next option if support doesnt know whats wrong ?

But what is the wood base sitting on? As an example, I planned to put my printer in my upstairs office. I had a huge oak dresser along a wall just waiting for a pretty install and wall mounted-accessories. My carpet and pad underneath added too much vibration/movement and made patterns similar to yours. My solution was to move the printer to my kitchen counter which is mounted on a hardwood floor. My wife isn't thrilled....the kitchen has now become a mess.....but I have amazing prints finally. At least now I get to install hard flooring in the spring in the office.

So start with your surfaces......and once you're 100% of a solid base rerun the initial config. You'll need to start there and then re-re-re-check the belts. Number Values are way better than "fine" 😀

Is your printer grinding? Bearings squeaking? Motors smoking?

Step 1) Wash your Steel Sheet

Step 2) Return to Step 1

RE: whats the next option if support doesnt know whats wrong ?

By "similar patterns" I mean it looks like your Z is moving around while its printing - so unless you're adjusting it using live Z in that picture, I would guess vibrations from something may be a place to start.....just like I dealt with

Is your printer grinding? Bearings squeaking? Motors smoking?

Step 1) Wash your Steel Sheet

Step 2) Return to Step 1

RE: whats the next option if support doesnt know whats wrong ?

TBH I have a tough time believing something like this is a mechanical failure or hardware fault in the printer. I don't doubt you've tried everything you can think of so at that point it must be something that takes an experienced eye in person to see the issue.

If the message on PP falls through, next best is see if there is a local makerspace you can take it to for help - that's also a good place to connect with folks experienced with the hobby.

RE: whats the next option if support doesnt know whats wrong ?

@vintagepc

I am in a very remote area and there is nothing anywhere near me sadly , when I first got the printer it wasn’t working at all and support diagnosed the extruder motor after 10 hours of doing this and that Over chat , so that was faulty but now with the new motor on this is what’s happening so I still think maybe something else is faulty , they weren’t sure if it was the board at first but eventually diagnosed the motor , so there is hardware problems sometimes , but this time has me beat

RE: whats the next option if support doesnt know whats wrong ?

Your picture looks light the head speed is higher than normal? Are you printing from a standard programmed Slicer object.?I have been tring to print a part specifying a .25 nozzle but using a .4 nozzle and got lines like what you show. Have you tried (I am sure you have) printing a stock Prusa sliced object? Bed temp?

I just broke the head thermistor wires so I am shut down.

Harley

RE: whats the next option if support doesnt know whats wrong ?

@kelsey-harley

Bed temp I’ve tried 50 to 70 makes no difference , I’ve tried standard prusaslicer prints and even the first calibration is direct from the printer , I’ve tried speeds of 30 to 100 makes no difference

RE: whats the next option if support doesnt know whats wrong ?

I really wanted to help, but you seem like you have already decided "something" is beyond repair and you don't seem to want to recheck or work with anyone to diagnose the issue. Nobody here can get back any time or money you spent already, only move forward and try to help. In hindsight, I assume you should have ordered a pre-build model.....but moving forward all you can do is fix your kit or abandon it. Based on your posts, it sounds like Prusa Customer Service has already made their decisions. If you are looking for people to agree with and feed your anger, a previous user had a great suggestion of posting to reddit instead.

If you would still like help in diagnosing and fixing the issue, it is sometimes ok to be frustrated and angry.....I get it......but not providing diagnostic info isn't going to get you very far.

You are welcome to PM me anytime

Is your printer grinding? Bearings squeaking? Motors smoking?

Step 1) Wash your Steel Sheet

Step 2) Return to Step 1

RE: whats the next option if support doesnt know whats wrong ?

@nilok

I’m not quite sure what your meaning ? I’ve told everything on here what’s happened and what I’ve tried and that I would of liked suggestions for something that maybe I have missed or support has missed ? I personally think there is something wrong with the printer like there was the first time with a faulty extruder motor diagnosed by customer support , but everyone got on my case blaming me etc when I was actually right all along , I’m fine if people don’t want to help they can make their own decisions but I am also very grateful for any help from people they may just find the solution for me , I can send the printer back for a refund yes but I posted in the hope that someone could offer a solution to the problem , I really do not know where your post has come from or what it’s meaning is ?

RE: whats the next option if support doesnt know whats wrong ?

Diagnostics is a very methodical process and it only wastes time to skip steps or make assumptions. If you really want to fix a problem on here, start at the very beginning. In your case that would be where/how the printer is mounted. Next would be running the initial calibration the kit version has - and posting the results. The third step would be to post the belt tension numbers from the support tab. This gives ANYONE helping you a good starting point to start finding real problems. That tells people what direction to go.....but assuming something hasn't changed with printing problems like yours is asking for more issues. It seems you've changed nozzles, filament brands, and a number of settings.......getting back to the beginning would be best. Start at the very beginning with stock parts.

Pics of any of these things help, and my advice applies to troubleshooting anything in life.....not just a printer.

Is your printer grinding? Bearings squeaking? Motors smoking?

Step 1) Wash your Steel Sheet

Step 2) Return to Step 1

RE: whats the next option if support doesnt know whats wrong ?

To be clear - putting the stock nozzle back on, then running the initial calibration isn't just a test for some info - there is a self-test you should run for that, but the initial calibration is critical as it saves settings and creates its own starting point. This should put your system back to newly-build and allow people to help you narrow down actual mechanical problems you have. Don't get hung up on Z - get it as close as you can and move on. You can adjust this later and save various settings for multiple sheets.

Is your printer grinding? Bearings squeaking? Motors smoking?

Step 1) Wash your Steel Sheet

Step 2) Return to Step 1

RE: whats the next option if support doesnt know whats wrong ?

@keithcowell I'm sure you feel like you've tried everything. Here's what I would do given the result shown in the picture in your first post in this thread.

- First of all, this is a minor issue and one of the most common problems new users encounter. Relax, and don't take it personally. You need to both get your PEI sheet clean and Live-Z set correctly. Over-correct one or the other and you'll get that sort of result.

- Take your smooth PEI sheet to the kitchen sink. Give it a good scrub with plain, unscented Dawn dish soap or your local equivalent (e.g. Fairy in UK). Use hot water. Use a plain paper towel to scrub it and another to dry it. Avoid touching the PEI print surface.

- Place the smooth sheet on the printer and try using Jeff Jordan's "Life Adjust" procedure for calibrating your Live-Z setting. It is much easier to use and understand than the on-board Live-Z routine. It's much easier to make mid-print adjustments accurately with. In general, start high (less negative) and work lower (more negative) in large increments (e.g. 0.1mm) until the filament starts to stick on its own. When you've got your Live-Z setting adjusted properly, you should be able to gently rub the extruded lines on the PEI surface without dislodging them. Then start lowering (more negative) the level until there are no gaps between layers.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: whats the next option if support doesnt know whats wrong ?

Ok I will start again although I have done the first setup calibration dozens of times and I mean dozens and all things pass ok and bed is perpendicular, I have scrubbed the steel plate with fairy over and over again, I have also done the live z loads of times with different filament and different speeds starting from 30 up to 100 , but I will do it all again

RE: whats the next option if support doesnt know whats wrong ?

Step one is a clean print sheet. Alcohol is almost useless, soap and water is best. But, alcohol and acetone do play in the mix after you've been using the printer a while. It is a hard learned lesson that a single finger print will ruin a print at the worst moment.

That built-in layer 1 cal is almost useless. Gets you close, but not close enough. You need to print something large enough to allow time to adjust and see results, and repeat.

Reading the "Life Adjust" article is good info, but a shortcut is here: slice and print the 100 mm circle, adjust so the strings are firmly welding together, with no gaps (too high) and not forcing ridges along them (too low).

RE: whats the next option if support doesnt know whats wrong ?

@keithcowell

Just pretend it is a brand new printer. Once you get all the way thru the initial config and everything saves, navigate to the support menu and get your belt tensions. Post those here along with anything weird it may have done at any point from the begining of THIS time. We can just consider this the first time.......and everyone on the forum can see the results and chime in. nobody has to nake any assumptions.

If you do something....post it

If it does something....post it

Once you get that done, like others have said....clean your sheet and print one of the larger z prints.....and we can see how your progress is going if you post pics of prints!

Is your printer grinding? Bearings squeaking? Motors smoking?

Step 1) Wash your Steel Sheet

Step 2) Return to Step 1

RE: whats the next option if support doesnt know whats wrong ?

First layer speed is 20 mm, and often i use 10 mm speed if it does not stick.

Cleaning is very important.

Hotter extruder can also help, 10 higher for only the first layer.

Make good pictures off first layer and the forum will help.