Weird extrusion

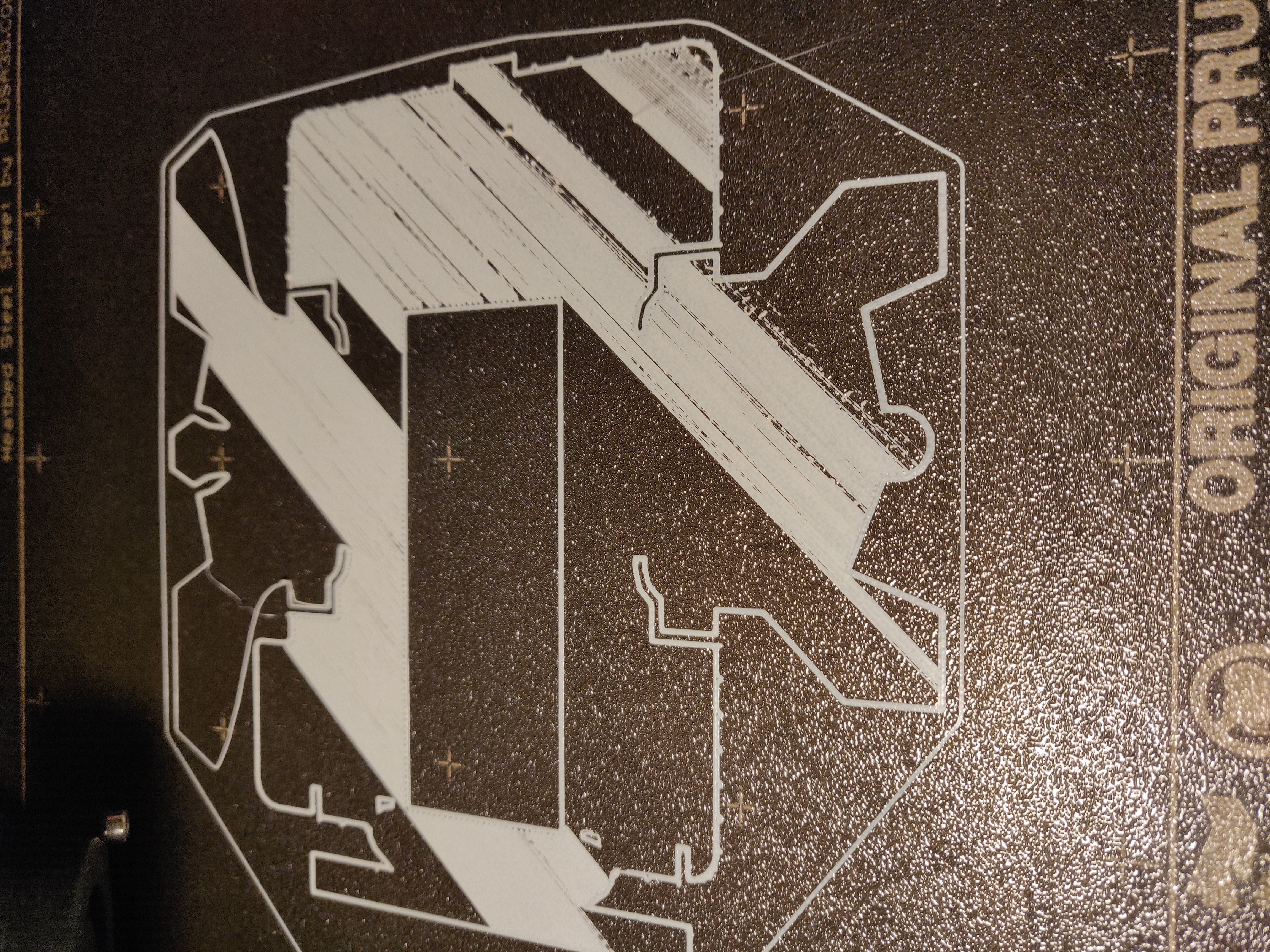

I upgraded my mk3 to mk3s. Everything went fine and prints looked good. But now all of a sudden, I get strange extrusion behavior. See the photo:

It just skips some lines, but others are excellent. I thought about a clogged nozzle, but it feeds through allright. Tried with different filaments, but all do this. On the photo you see Prusa beige filament.

Hope someone can tell me what's wrong here.

Re: Weird extrusion

It almost looks like the nozzle is too close to the bed, and you need to raise your first layer cal a bit. Or it could be something plugging the nozzle and a cold pull is needed. Hard to say for sure.

Re: Weird extrusion

Sorry for the late reply. I just got around to testing your suggestions. Unfortunately, two cold pulls later and quite some fidgetting with the live Z later, I still get the same results. On closer inspection of the printer while printing this first layer, it seems like a retraction issue: a lot of times, when it retracts, moves and begins printing again, it skips one or more lines. So I've upped the temperate and decreased retraction amount to 0.6 instead of the default 0.8. But no time to print again yet. So will update when I've time to test these new settings.

Re: Weird extrusion

I don't understand why folk think retraction causes a clogged nozzle. Why would the printer retract filament 0.6 mm in the middle of a track? It would only do that if a motor or the electronics were bad. But you are probably thinking of lift, not retraction.

Oh well - good luck finding an issue.

Re: Weird extrusion

If you are printing with (at least decent quality) PLA or PETG and you are using the Slic3r PE settings made by Prusa the quality of your parts should be at least at 95% of the maximum capability of your printer.

If this is not the case (like with your prints) it is usually a hardware issue.

Retraction issues usually go along with clicking noises (use forum search clicking noise)

If you print a very small part like 10x10mm and optimize life z for that area does it work fine than? Is your first layer always bad in the same area? If so, try raising live z when your printer gets to that area. If it gets better, it seems to be a pinda problem.

Re: Weird extrusion

Thanks. Just tried printing again, but no luck. I've tried cleaning the nozzle again, this time with the acupuncture pin. And I've tried switching out the filaments. The first filament was Prusa's own filament; the second one from a local supplier. The same thing happens. The extruder doesn't extrude enough at random places during printing. I thought with the previous post, it only did this when moving to a new area to start filling that area (that's why I thought about changing retraction settings), but it also doesn't extrude enough when just continuing a fill. I've tried with different models, I tried reslicing the object (default Slic3r PE settings), I updated software and firmware to latest versions, but all no luck So it seems like a hardware issue and not so much a software issue. But looking at my build, I don't know where to start looking: selftests are ok, first layer calibration is ok, I've rechecked whether my fans are on correctly, sensors are ok, Live Z is at -0.650, so P.I.N.D.A is ok. I don't know where to look next. Any other tips?

Re: Weird extrusion

I think you pointed yourself in the direction to check - the extruder / filament spool holder.

• Filament moves freely within extruder with idler open

• Bondtech drive aligned with filament and PTFE tube

• Bondtech set screw tight on motor shaft

• Bondtech idler axle equally in BOTH mounting pillars

• Idler tension set to 1-2 turns tighter than initial spring engagment

• Spool holder turns freely

Re: Weird extrusion

A needle won't clear the nozzle. If a cold pull didn't help, there are times you must remove the nozzle and blast air up the filament path to clear any debris that gets caught in the heat break. The debris rattles around and eventually jams the filament. This is usually because the PTFE isn't where it belongs, but can happen with any setup.

Re: Weird extrusion

If there is a clicking noise that accompanies your extrusion issues, I have modified the axle supports in the Idler Door part to fix the issue. It eliminates any possibility of the axle shifting during printing. It also ensures the axle is always in the optimal "non-clicking" position. This way you always get proper extrusion from the gears.

This is the remixed part: https://www.thingiverse.com/thing:3504682

Re: Weird extrusion

Also, it looks like one of the reasons that slowing a print down and turning up the temperature can also reduce or eliminate clicking/under-extrusion issues is that the “custom” PRUSA e3D heatbreak changes bore size from 2.2 to 2 close to the heat zone. Proto-Pasta did a bunch of testing that showed that this was probably the major cause of the click (stepper slips) and under-extrusion sometimes leading to jams. If this is your problem, the solution is to by the non PRUSA custom e3D heatbreak https://shop.prusa3d.com/en/mk2-spare-parts/121-e3d-heatbreak.html

Re: Weird extrusion

While the Proto-Plasta theory sounds great, a cold pull can prove it is - or isn't - the cause. On a printer exhibiting this issue, the pulled filament will show a cone, a 2.0mm section (inside the nozzle) and then a 2.2mm section (inside the heat-break). If you don't see two distinct steps on your cold pull, then your heat-break isn't causing this.